Pre-tensioning method hollow board core extraction type square steel inner mold construction method

A technology of hollow-core slab and pre-tensioning method, which is applied to floors, building components, buildings, etc. It can solve the problems of poor internal appearance of hollow-core slab products, difficulty in removing formwork, and deformation of formwork, so as to ensure the thickness of the top slab and the thickness of the protective layer. The appearance is smooth and straight, and the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

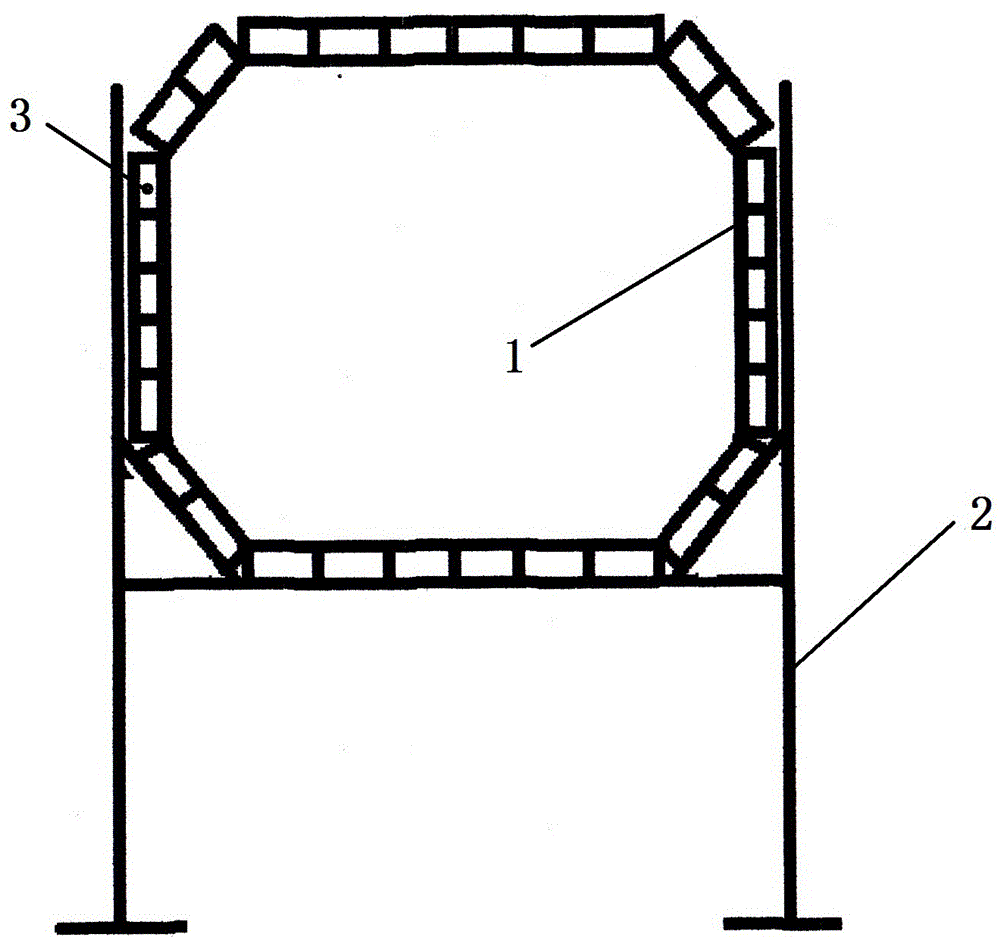

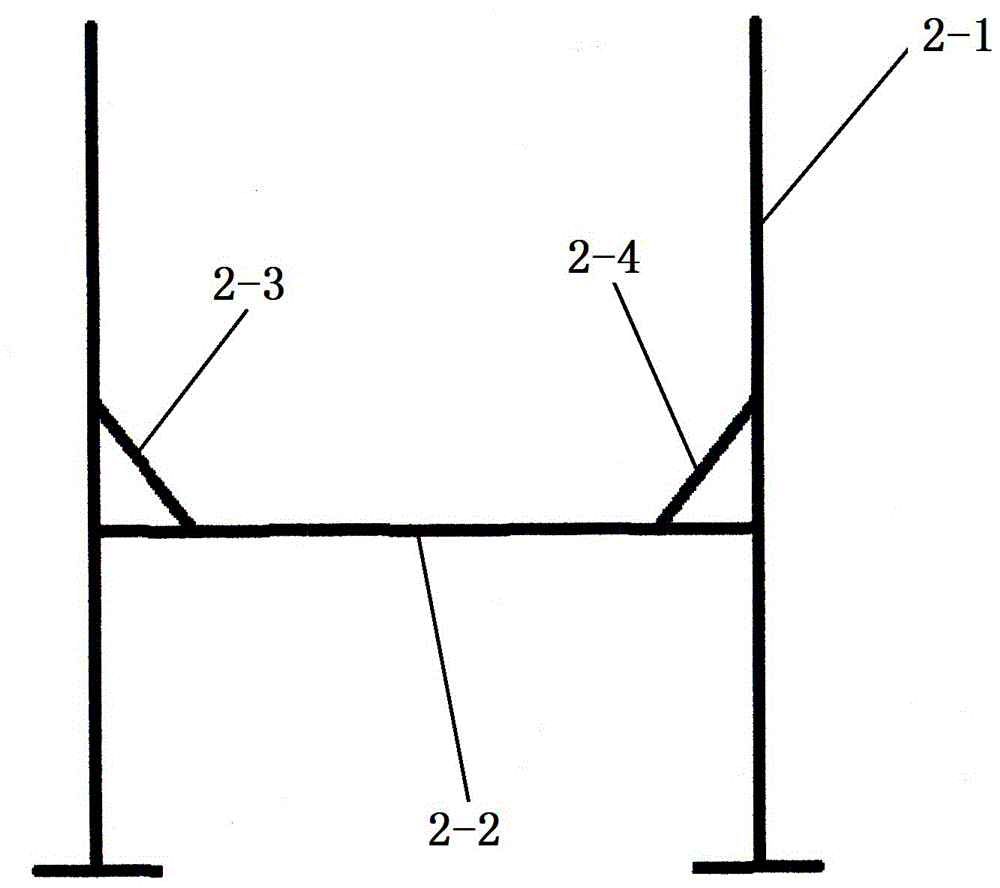

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] The materials used in this method include: several square steel pipes, several steel bar supports, plastic films, steel strips, and several positioning moulds;

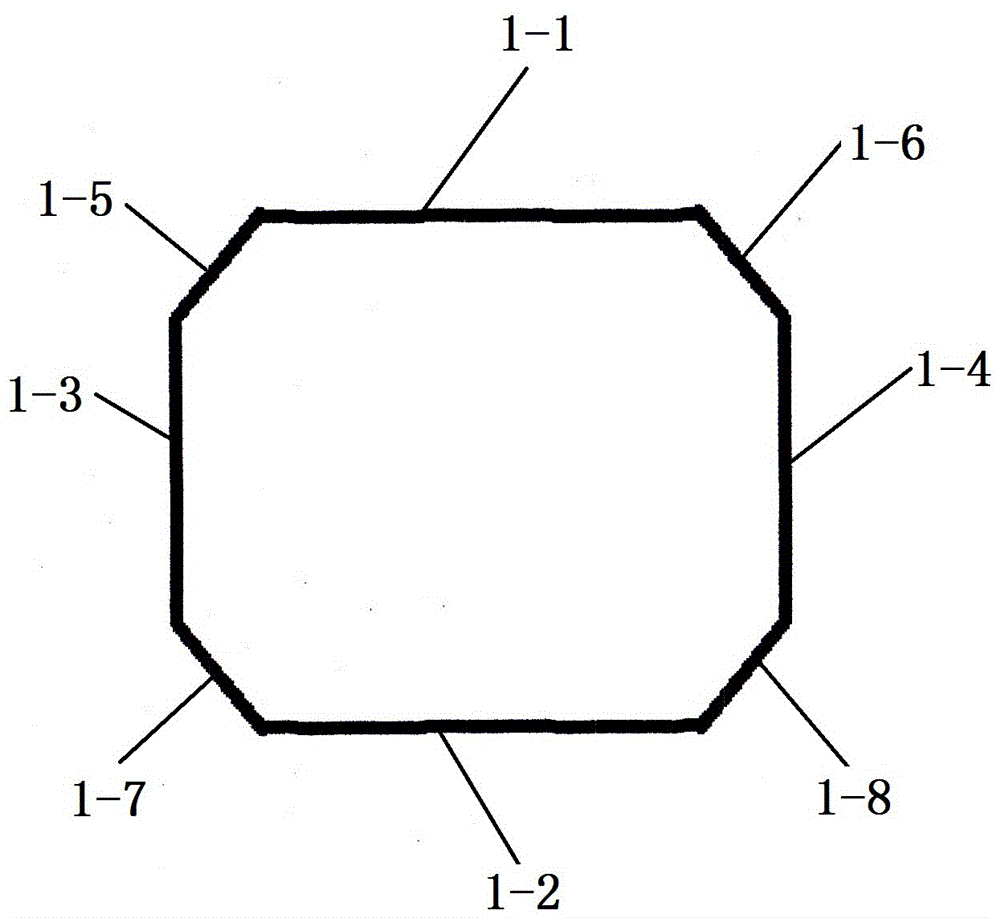

[0014] The steel bar support is octagonal, including upper steel bar, lower steel bar, left steel bar, right steel bar, left upper inclined steel bar, left lower inclined steel bar, right upper inclined steel bar, right lower inclined steel bar, the left end of the upper steel bar and the upper end of the left steel bar Connected by the left upward inclined steel bar, the right end of the upper steel bar is connected with the upper end of the right steel bar by the right upward inclined steel bar, the left end of the lower steel bar is connected with the lower end of the left steel bar by the left downward inclined steel bar, and the right end of the lower steel bar is connected by the lower end of the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com