Concrete magnetic side form with form removal device

A technology for concrete and side formwork, which is applied in the treatment of formwork, formwork/formwork components, and on-site preparation of building components. Efficiency, shortening the demoulding time, and reducing the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

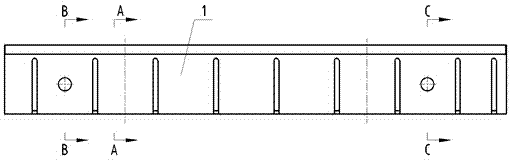

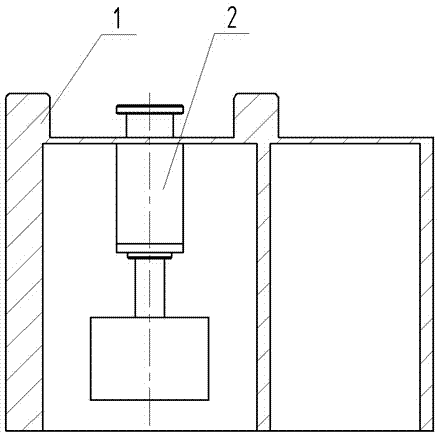

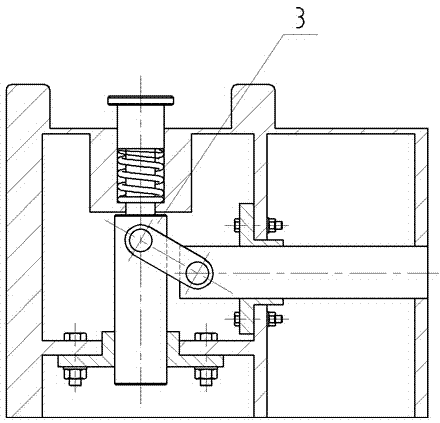

[0016] Referring to the drawings, a concrete magnetic side mold with a mold removal device is composed of a side mold body 1, a magnetic unit 2, and a mold removal device 3. The magnetic unit 2 and the mold removal device 3 are fixed in the side mold body 1. The side mold can be fixed on the template tray, and the mold removing device 3 is composed of a top rod cap 3-1, a spring 3-2, a vertical top rod 3-3, a middle connecting rod 3-4, and a horizontal push rod 3-5. , Push rod guide sleeve 3-6, push rod pin 3-7, ejector pin 3-8, ejector guide sleeve 3-9, where ejector guide sleeve 3-9 is fixed on the side mold body 1, The top rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com