Stair formwork structure and stair construction method adopting same

A construction method and stair technology, applied in the direction of ladder-like structure, formwork/formwork/work frame, connection parts of formwork/formwork/work frame, etc., can solve the need for special equipment for erection, low service life, inconvenient erection, etc. problems, to achieve the effect of light weight, improved service life, and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0044] The embodiment discloses a staircase formwork structure and a staircase construction method using the formwork structure.

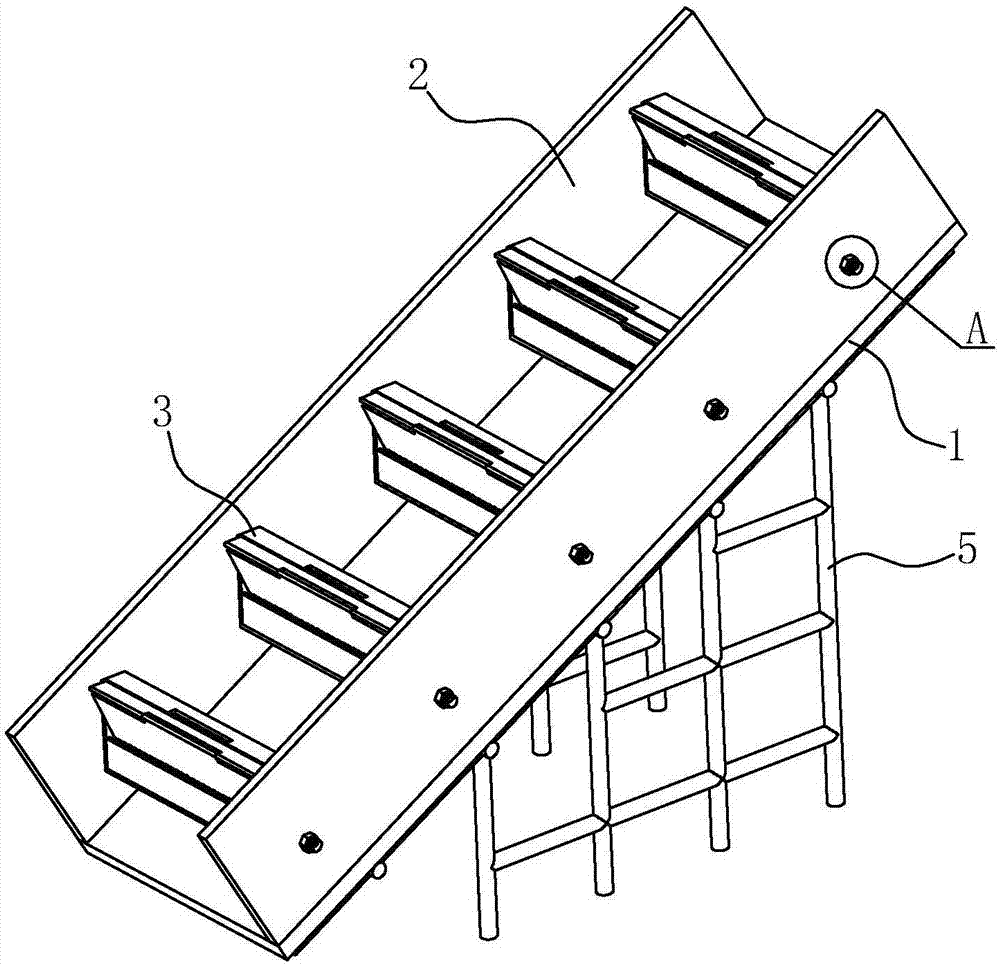

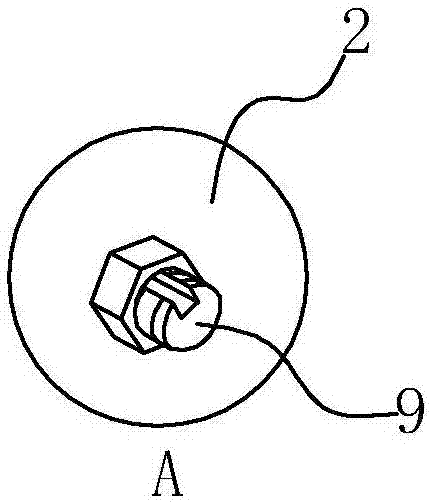

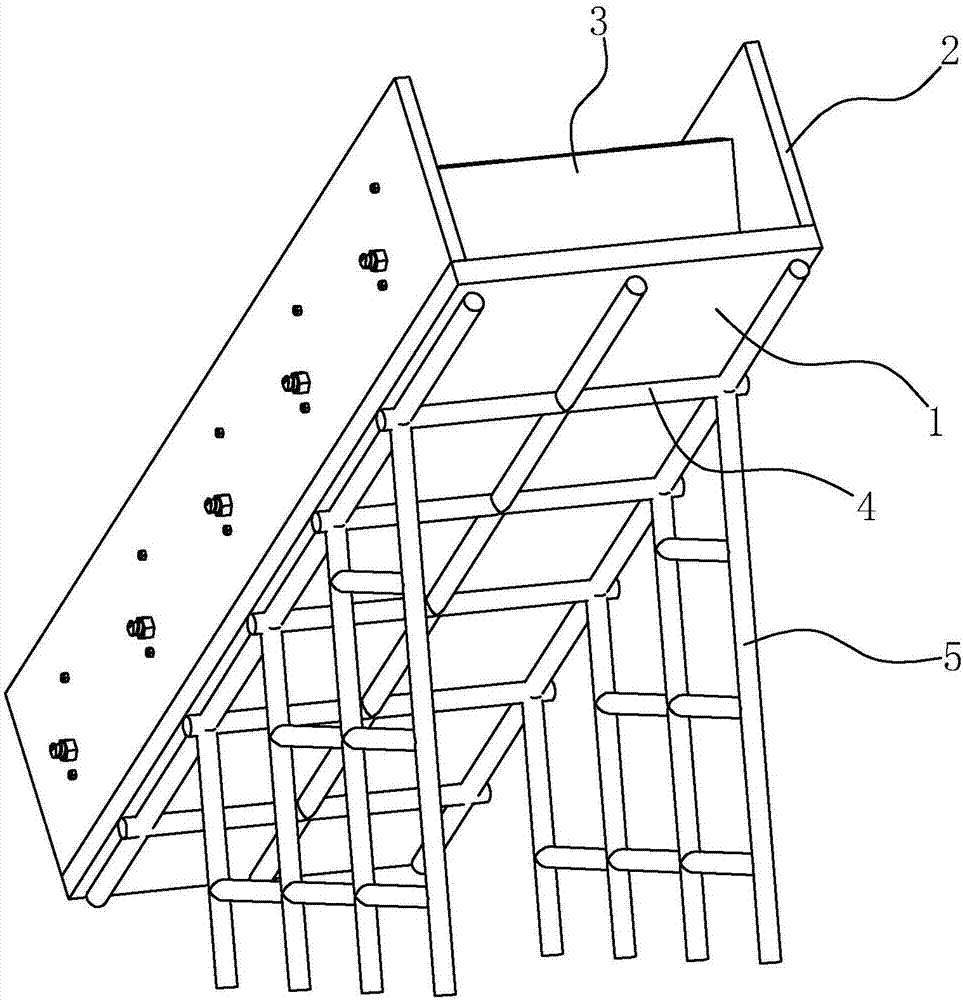

[0045] like figure 1 , 2 As shown, the formwork structure mainly includes stair bottom formwork 1, bottom formwork support, stair side formwork 2 composed of wooden squares, and stair spacer formwork 3 of steel structure; The frame 4 and the vertical support 5 supported under the grid-shaped bracket 4.

[0046] like image 3 As shown; the stair partition 3 is made of metal plates by cutting, bending, and welding; one side of the stair partition 3 is a plane structure, and the side of the plane structure is used to block concrete; the other side is a groove structure, and It includes two upper and lower long side walls 6 and two left and right short side walls 7; the joints of the long side walls 6 and the short side walls 7 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com