Method for manufacturing rapidly-detachable rebuilt and reassembled composite building unit

A technology of building units and manufacturing methods, which is applied to the preparation of building components on site, construction, building construction, etc., which can solve the problems of difficulty in lifting prefabricated building units, large amount and weight of molds, and high cost of mold manufacturing, and achieve the goal of dismantling in the later stage. The mold is convenient and fast, the product quality is easy, and the assembly is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0040] The prefabricated building units produced by the method for making fast detachable and rebuilt composite building units of the present invention can have various specifications and models, the most common of which are as figure 1 The shown hexahedron comprises a top plate, a base plate and four wall panels, wherein two wall panels are arranged along the length direction of the building unit, and the other two wall panels are arranged along the width direction of the building unit, and the wall panels can also be There are door openings or window openings. Below just take this hexahedral prefabricated building unit as an example to illustrate the manufacturing method of the present invention.

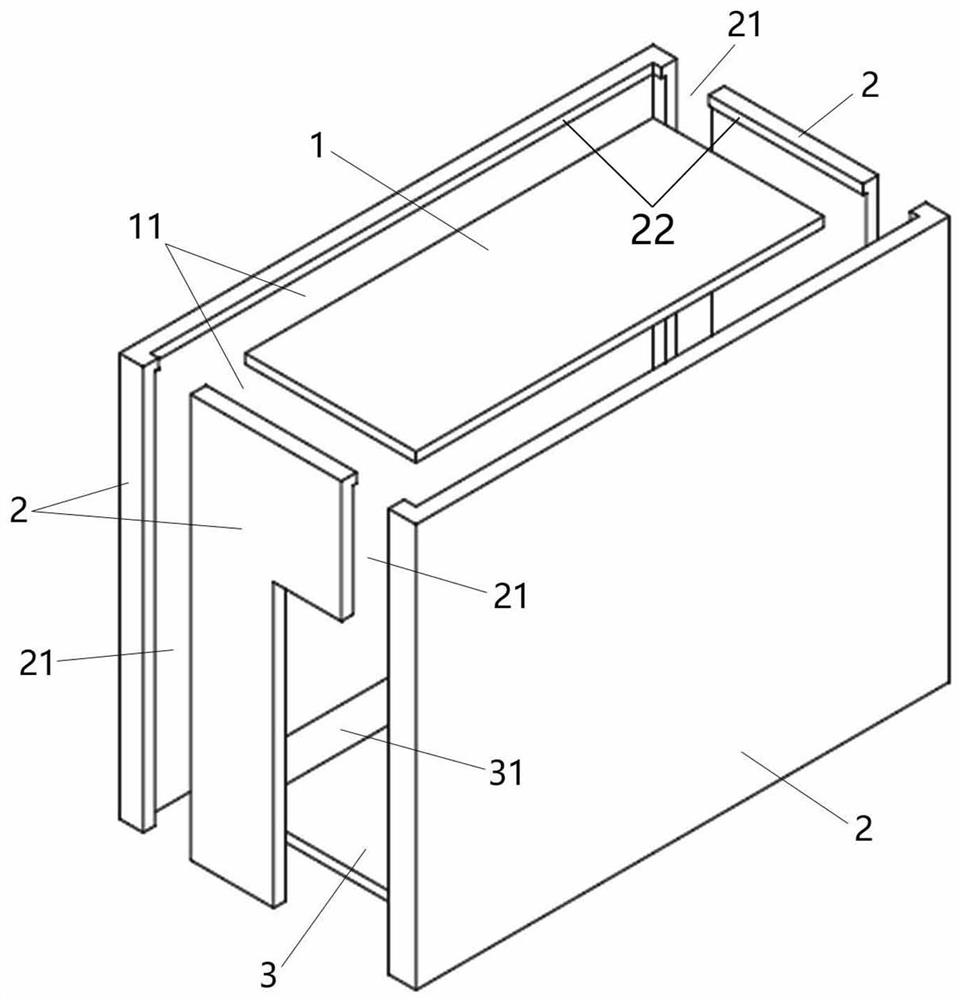

[0041] In one embodiment, the fabrication method of the present invention is to split the building unit design into figure 2 As shown in the mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com