Construction method adopting aluminum formworks

A construction method and technology of aluminum membrane panels, applied in the field of construction, can solve problems such as unfavorable cleaning, formwork removal, increased weight of aluminum membrane panels, unfavorable installation and use, etc., so as to improve production efficiency and production effect, optimize construction technology, and facilitate cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

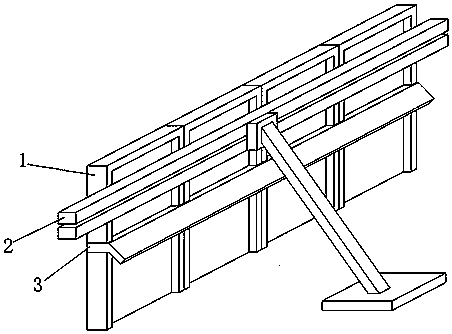

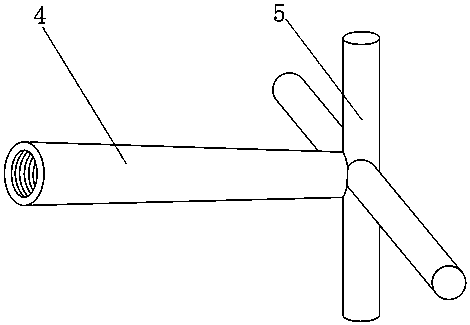

[0026] Such as figure 1 and figure 2 As shown, a construction method using aluminum membrane panels includes the following steps: Step 1, install aluminum membrane panels 1; Step 2, erect back corrugated 2 to support the aluminum membrane panels; Step 3, upper and lower layers of aluminum membranes Set K board 3 between the boards, the outside of the K board is provided with a first flanging, the first flange is inclined from top to bottom; Step 4, set up the back flute to support the K board; Step 5, install and fix the K board of nuts. Through the construction method, the present invention optimizes the construction process when the aluminum film plate is used, and improves the production efficiency and production effect. The first flange is set on one side of the K plate, which prevents the fallen concrete from sticking to the aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com