Installation method capable of reinforcing pipe through structural protection ring and reinforced pipe assembly

An installation method and pipe technology, applied in the direction of pipes/pipe joints/fittings, pipes, mechanical equipment, etc., can solve the problems of difficult assembly of pipes and structural retainers, and achieve the effects of easy reinforcement, optimized construction process, and avoiding rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

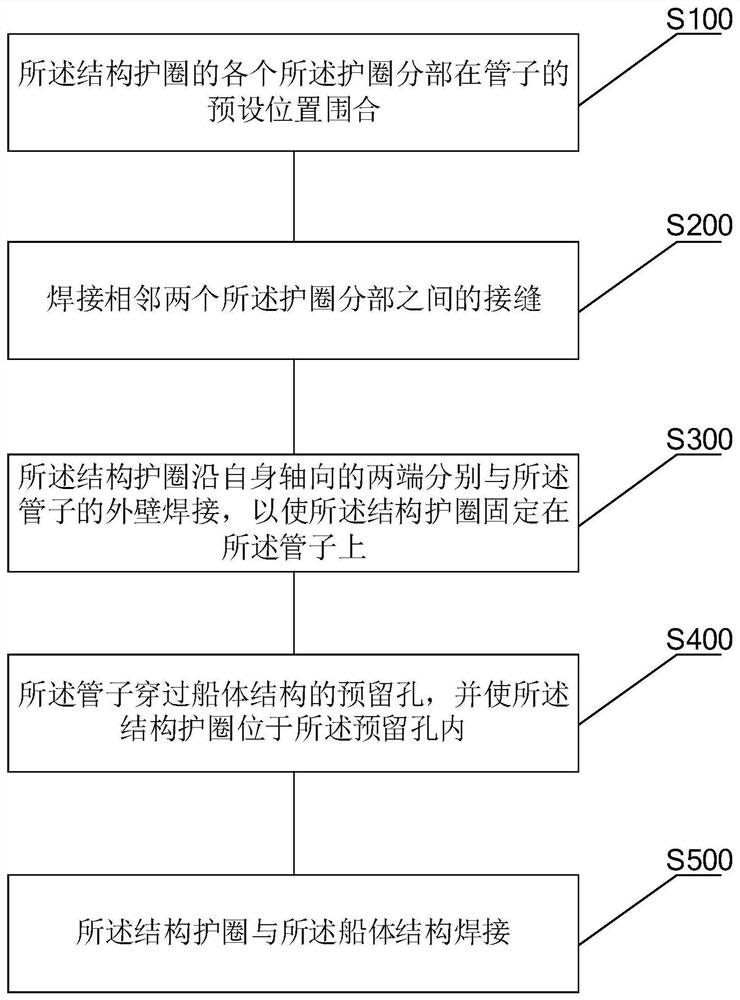

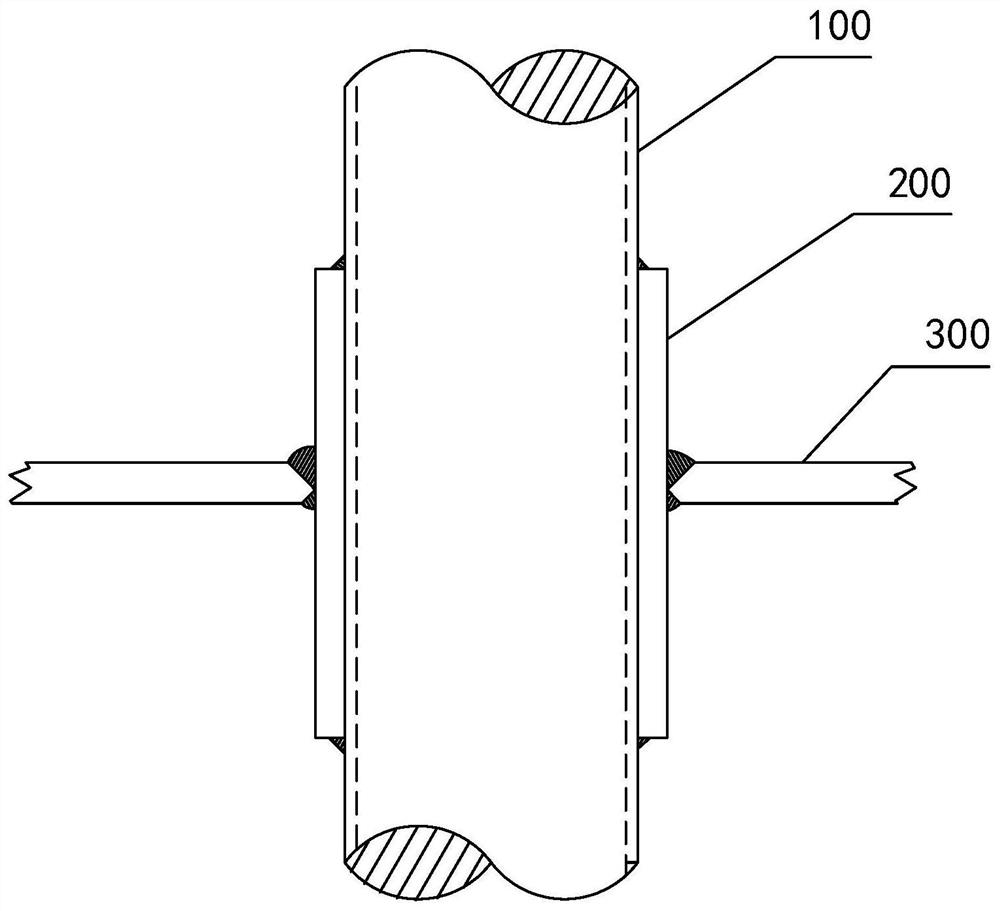

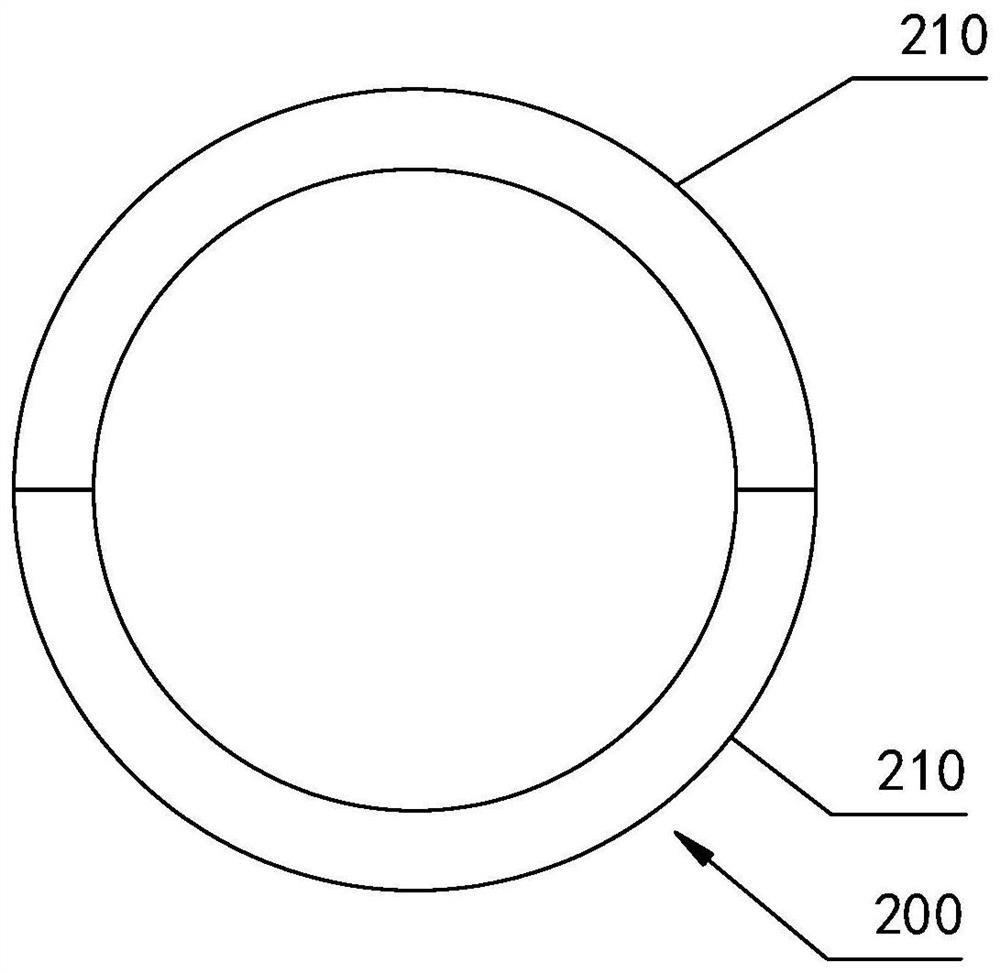

[0042] This embodiment provides an installation method and a reinforced pipe assembly using a structural retainer to strengthen the pipe; please refer to Figure 1-Figure 3 , figure 1 The flow chart of the installation method of adopting structural retainer to strengthen the pipe provided by this embodiment; figure 2 The schematic diagram of the structure of the reinforced pipe assembly provided for this embodiment shows the schematic diagram of the installation state of the reinforced pipe assembly in the hull structure; image 3 Schematic diagram of the structure of the structural retainer provided in this embodiment.

[0043] The installation method provided in this embodiment to strengthen pipes with structural retainers is used for strengthening pipelines and pipelines, especially for strengthening pipes passing through structural bulkheads or decks of ships.

[0044] see image 3 As shown, in this embodiment, the structural retainer 200 includes a plurality of retain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com