Circular foundation pit reverse sliding formwork and construction method thereof

A sliding form and foundation pit technology, applied in the field of geotechnical engineering, can solve problems such as difficult construction, achieve high construction efficiency, ensure safety, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

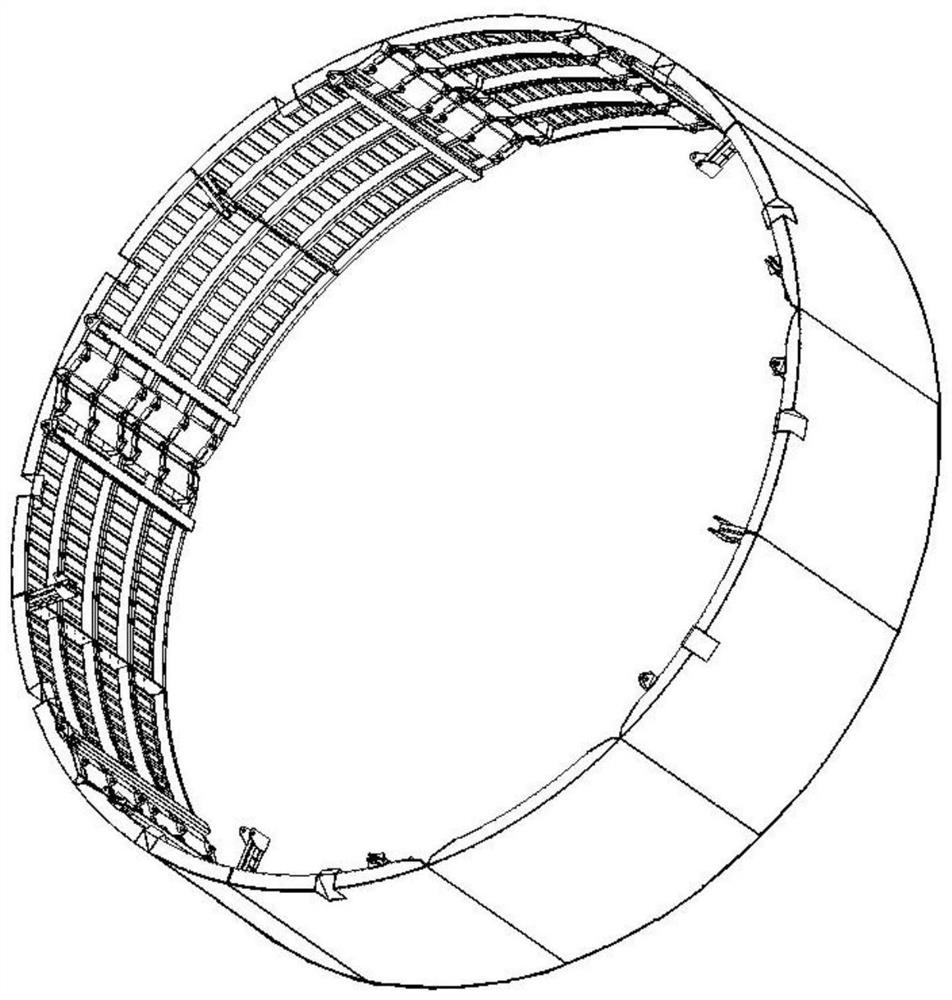

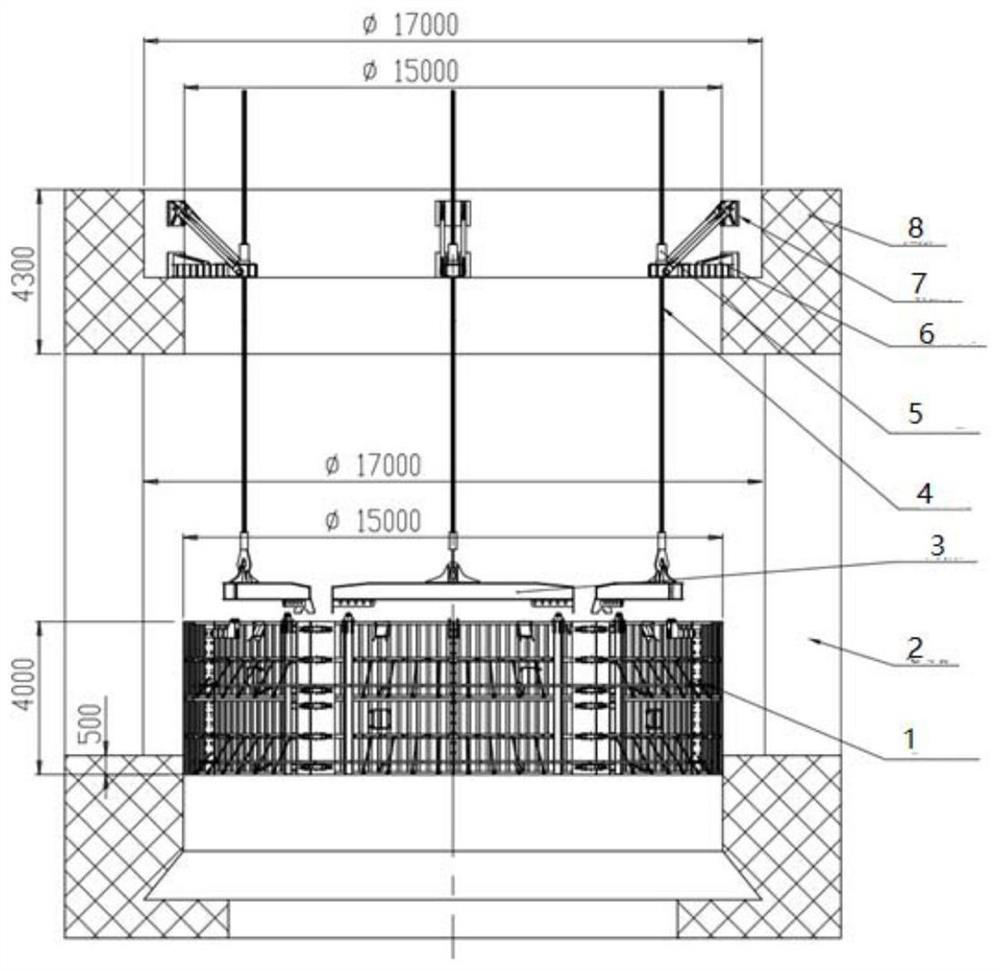

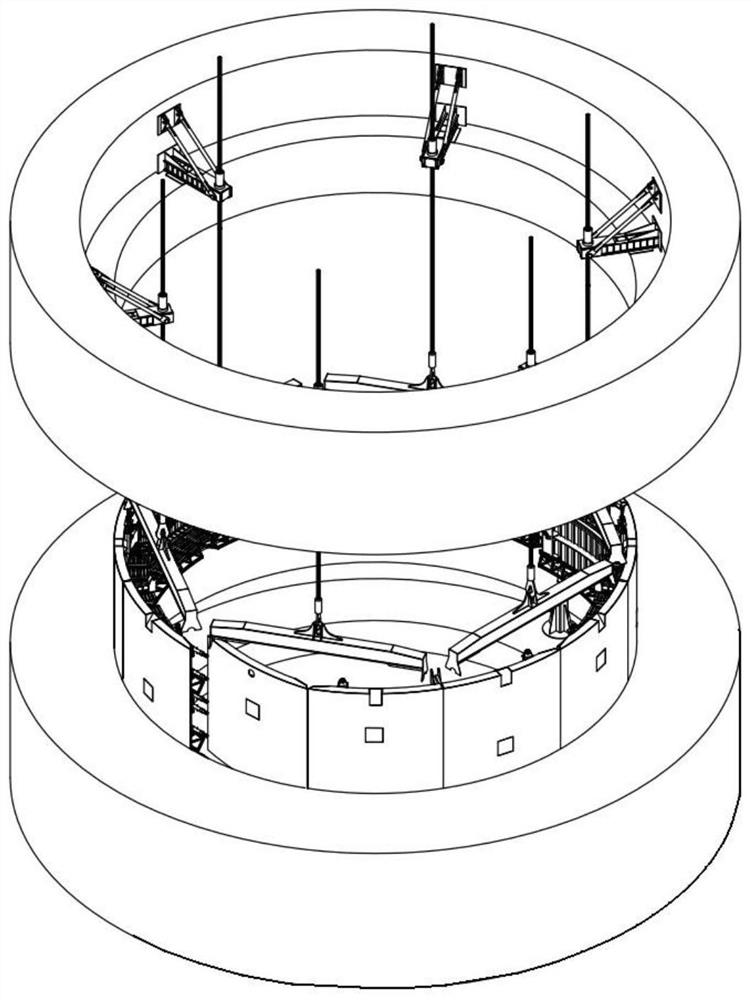

[0049] The reverse sliding form structure of the circular foundation pit in this embodiment is as follows: figure 1 , Figure 4 , Image 6 and Figure 8 As shown, the combined formwork structure is adopted, and the whole circle formwork structure is composed of 12 pieces of sliding formwork 1, and two pieces of formwork are symmetrically set at the demoulding position as the demoulding pieces, and the other formworks are divided into two groups, which are connected by bolts to form 5 The large fan combined formwork, the hinged parts of each fan are adjusted into a fixed ring structure through the tension screw; the lifting system is evenly arranged along the circumference of the crown beam of the foundation pit, and the lifting system is controlled by the hydraulic system, such as figure 2 and image 3 As shown, the lifting and lowering of the sliding mode are controlled.

[0050] Firstly, the wellhead crown beam lifting support and pre-buried installation are completed b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com