Combined cofferdam suitable for offshore large-size bearing platform construction

A combined cofferdam and large-volume technology, which is applied in infrastructure engineering, construction, etc., can solve the problems of easy deviation measurement and positioning, large material usage, and difficult cofferdam sinking, etc., so as to save the use of pipe pile steel , small safety risks, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

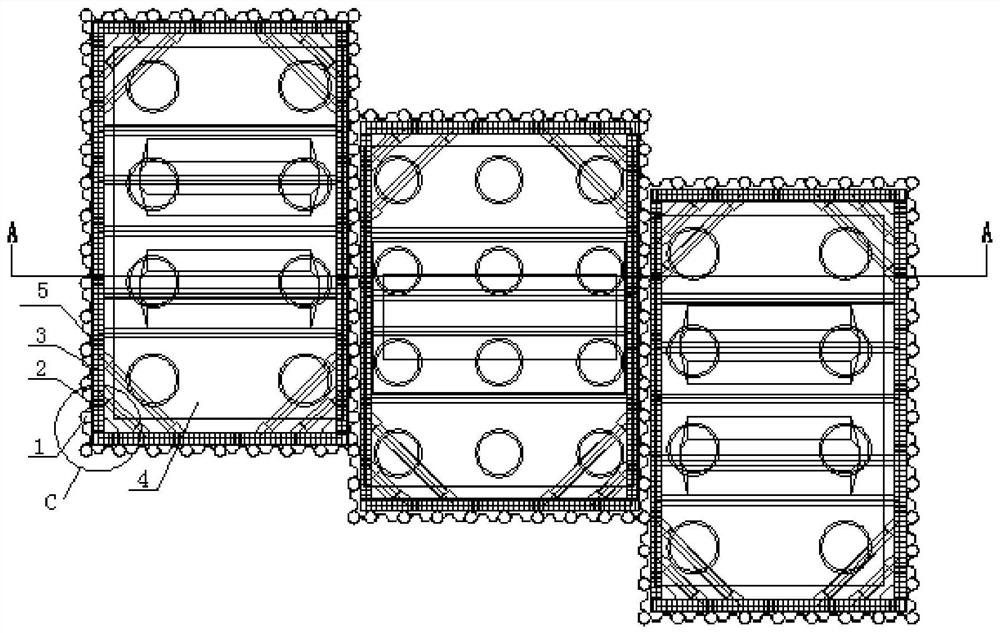

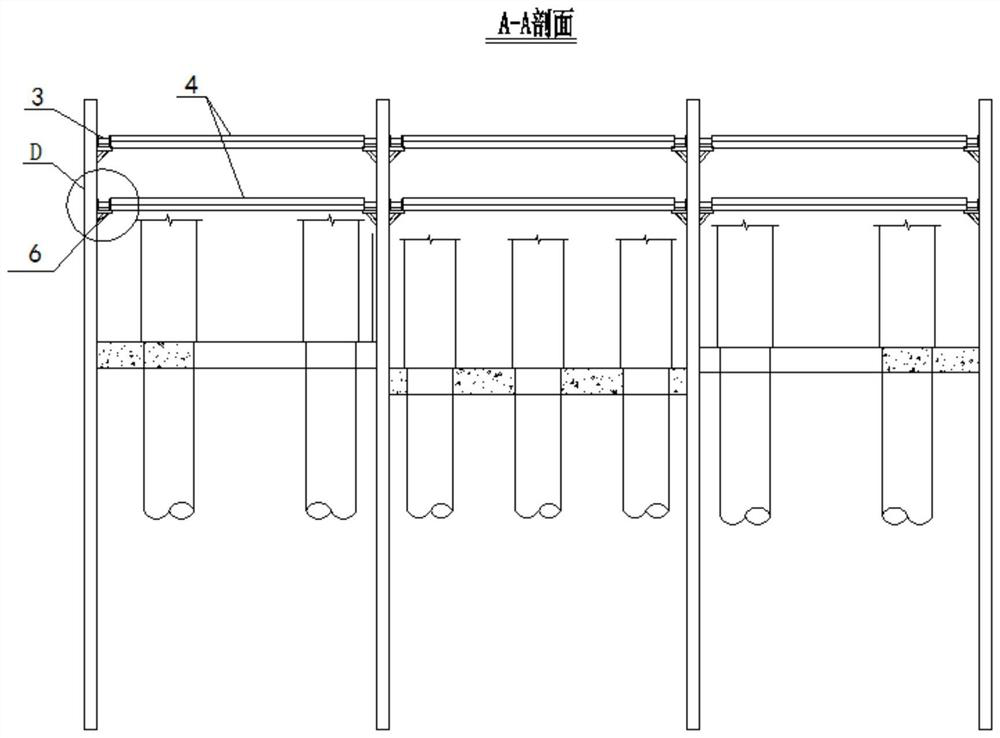

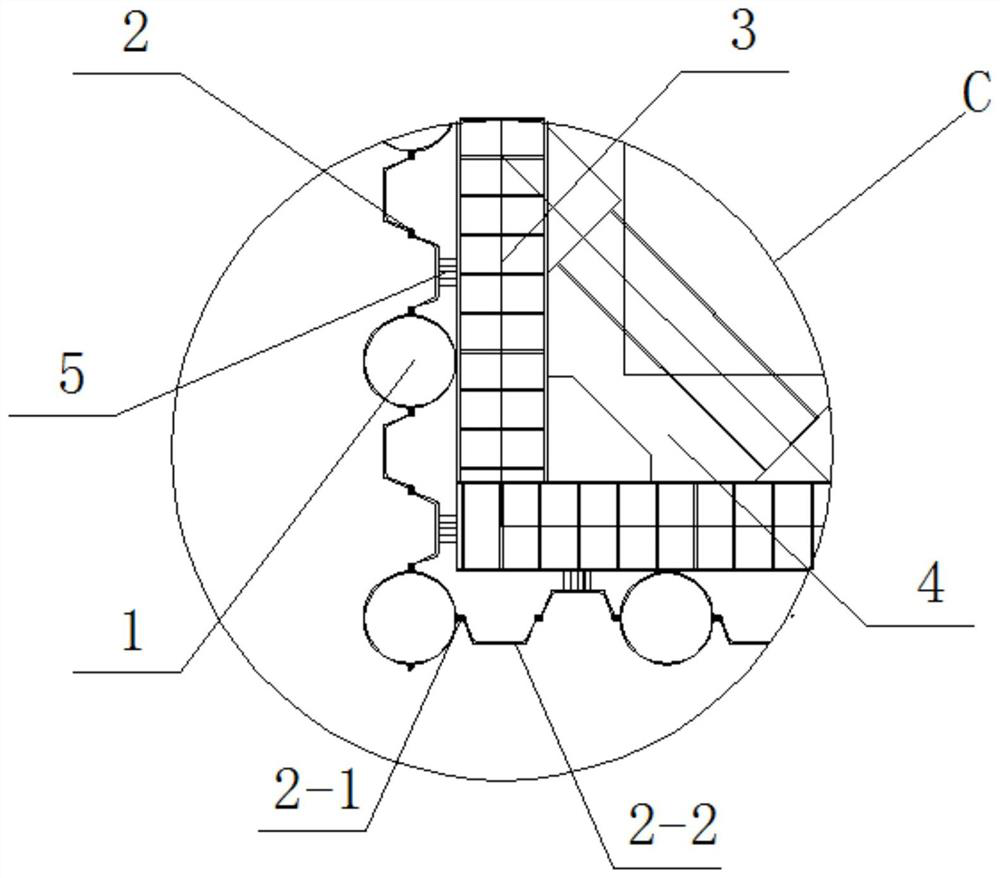

[0018] The technical solutions of the present invention are further illustrated in conjunction with the accompanying drawings.

[0019] like Figure 1 to 5 As shown, a combination cofferdam for sea large volume bearing construction includes a plurality of steel pipe directions 1, a plurality of connection lock 2, a plurality of steel 3, a plurality of field steels 5 and a plurality of temporary The bracket 6, multiple sockets 4 are divided into multiple sets, each column is vertically disposed in parallel, and each of the peripheral welding of each collar 4 has a circle steel 3, and each of the type steel is the first tail of multiple steel. Successfully welded, and arranged in two layers of steel; the multi-steel pipe main pipe 1 is arranged, and the adjacent two steel pipe main pipes are connected between the connecting lock 2, and the row of steel pipe main pipe On the periphery of the multi-column bench and soldered on the steel 3, the adjacent two colors are displaced and conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com