Method and apparatus for measuring early-stage autogenous shrinkage of cement-based material

The technology of a cement-based material and a measuring device is applied in the field of measuring the performance of cement materials, and achieves the effects of simple device structure, convenient mold removal and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

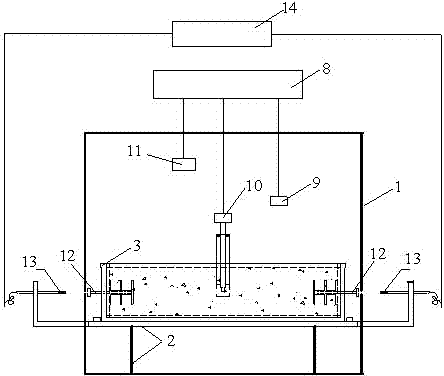

[0037] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0038] figure 1 The structure of a preferred embodiment of the measuring device of the present invention is shown. Such as figure 1 As shown, the measuring device includes a test box 1, a test piece mold 3 and a displacement testing system 5. A support 2 is provided at the bottom of the test box 1, and the test piece mold 3 is placed on the support 2. The test box 1 is equipped with a temperature and humidity adjustment system. 4.

[0039] The temperature and humidity adjustment system 4 in the present embodiment includes the environment temperature and humidity sensor 9 in the test chamber, the temperature and humidity sensor 10 inside the test piece, the temperature and humidity regulator 11, and the temperature and humidity control host outside the test chamber 1. 8. The temperature and humidity control host 8 monitors the temperature and humidity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com