Pavement concrete channel steel forming formwork

A technology for shaping formwork and concrete, which is applied to roads, roads, road repair and other directions, can solve the problems of easy deformation of formwork, waste of materials, time-consuming and labor-intensive, etc., and achieves the effect of easy formwork removal, high reuse times and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

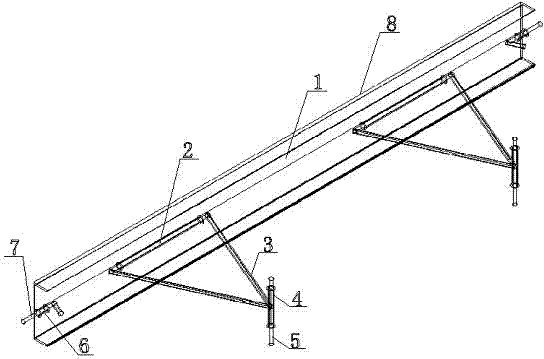

[0008] Such as figure 1 As shown, the present invention consists of (same thickness as the road surface) channel steel 1 and triangular bracket 3. The triangular bracket 3 is connected with the channel steel 1 through the casing 2 welded on the channel steel (concave surface), and the other end of the triangular bracket Connect with the straight casing 4, the straight casing 4 has inserting ribs 5, and the tripod can be adjusted up and down. The two ends of channel steel 1 have formwork joint place sleeve pipe 6, and formwork joint place sleeve pipe 6 has joint latch 7 in, avoids street position deformation. When removing the formwork, take out the pins at the joints, pull out the fixed ribs, and remove the formwork. The pins, fixed ribs, etc. can be reused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com