Vault shear wall anti-explosion and drilling-resistant formwork erecting construction method

A construction method and shear wall technology, which are applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, on-site preparation of building components, etc., can solve the difficulty of formwork support and dismantling. , inconvenient transportation of materials, small working surface and other problems, to reduce the difficulty of formwork support and dismantling, ensure the construction quality, and facilitate the effect of vertical formwork and formwork dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] The construction method of explosion-proof and anti-drilling vertical formwork for the shear wall of the treasury in this embodiment, the specific steps of the construction method are as follows:

[0020] (1) Preliminary preparations: do a good job of technical disclosure, personnel and equipment preparation; at the same time, do a good job of working conditions and transportation preparations;

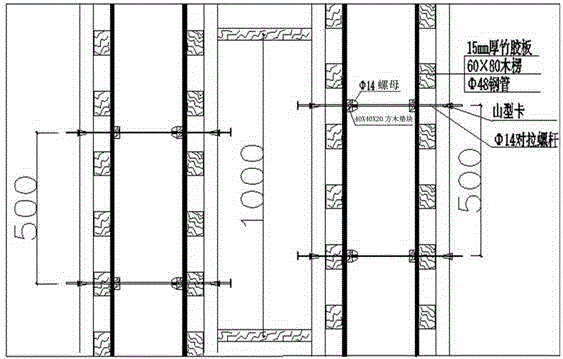

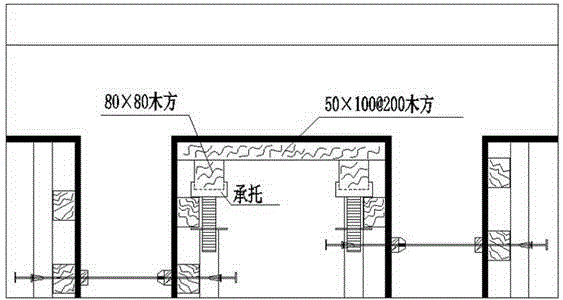

[0021] (2) Selected materials: 15mm thick bamboo plywood is used, the backing is 60×80 wooden corrugated, and the template is 200mm apart; the steel pipe is made of Φ48 double steel pipe; the tie rod is made of Φ14 secondary machining round steel;

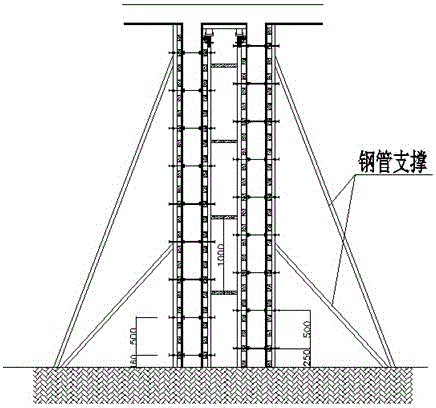

[0022] (3) Formwork for the corridor wall: such as figure 1 and 2 As shown, the outer wall of the corridor adopts the water-stop pair of tie rods with formwork limit braces, and the distance between them is set to 500mm. Nuts, the left side pull bolts are 160 mm from the bottom surface, and the right side pull bolts are 250 mm fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com