Shock-resistance segmented wind power blade and assembly method thereof

A wind turbine blade and segmented technology, applied in the field of impact-resistant segmented wind turbine blades and their assembly, can solve the problems of segmented blade damage, poor impact resistance, etc., to ensure strength, improve impact resistance, and increase impact resistance. The effect of a large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

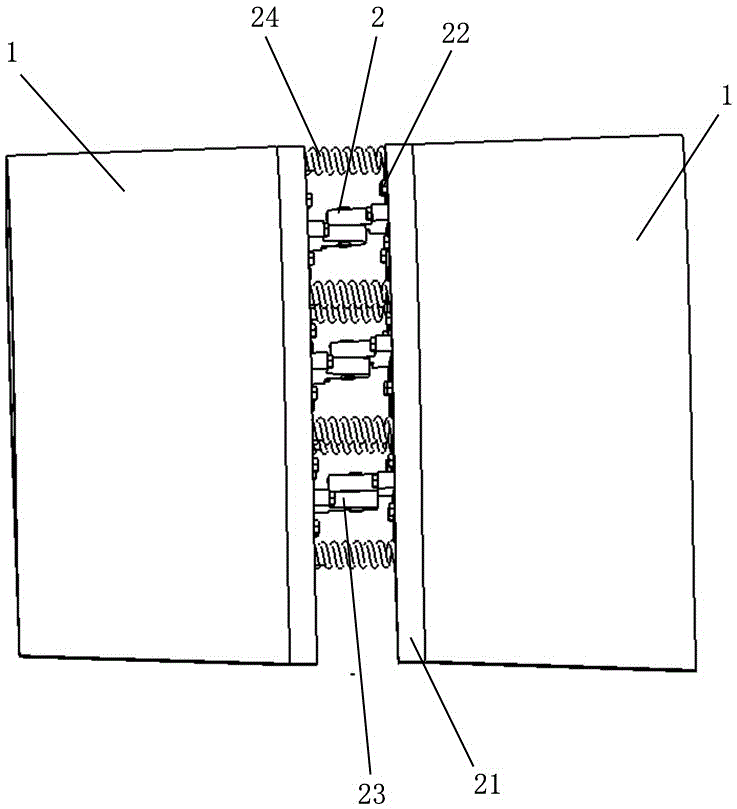

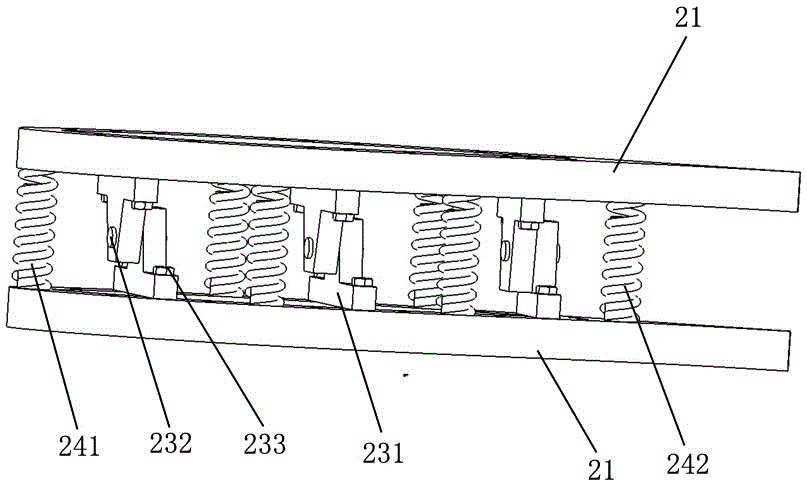

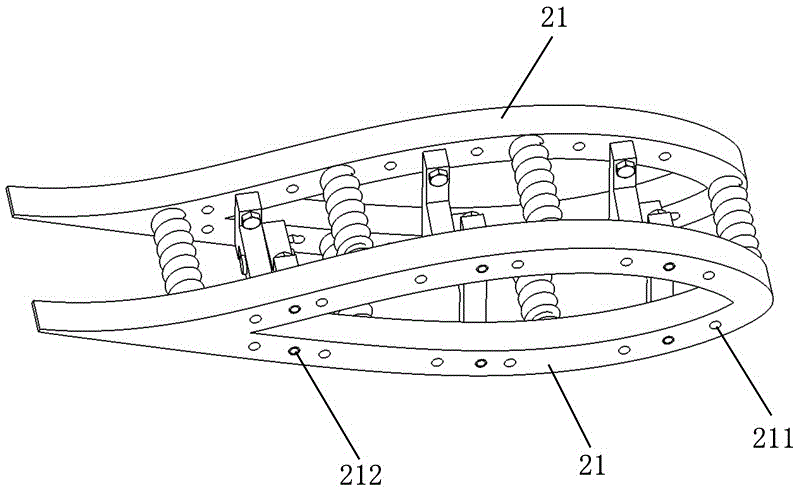

[0031] Figure 1 to Figure 4 It shows an embodiment of the impact-resistant segmented wind power blade of the present invention, the wind power blade includes at least two blade segments 1, and a connecting device 2 is connected between each blade segment 1, and the connecting device 2 includes two connecting frames 21. Each connection frame 21 is adapted to the shape of the connection end surface of each blade segment 1, and each connection frame 21 is provided with a first installation hole 211, and the first installation hole 211 is provided with a first bolt for fastening connection with the blade segment 1 22. A plurality of hinges 23 for buffering are connected between the two connection frames 21, and the rotation direction of each hinge 23 is consistent with the force direction of the blade section 1. There is also a connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com