Rotary fluid machine

A fluid mechanical and rotary technology, applied in the direction of rotary piston machines, rotary piston pumps, mechanical equipment, etc., can solve the problems of refrigerant leakage, poor efficiency, and lack of consideration of the gap between the cylinder wall and piston wall, etc., to achieve suppression Leakage, the effect of achieving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

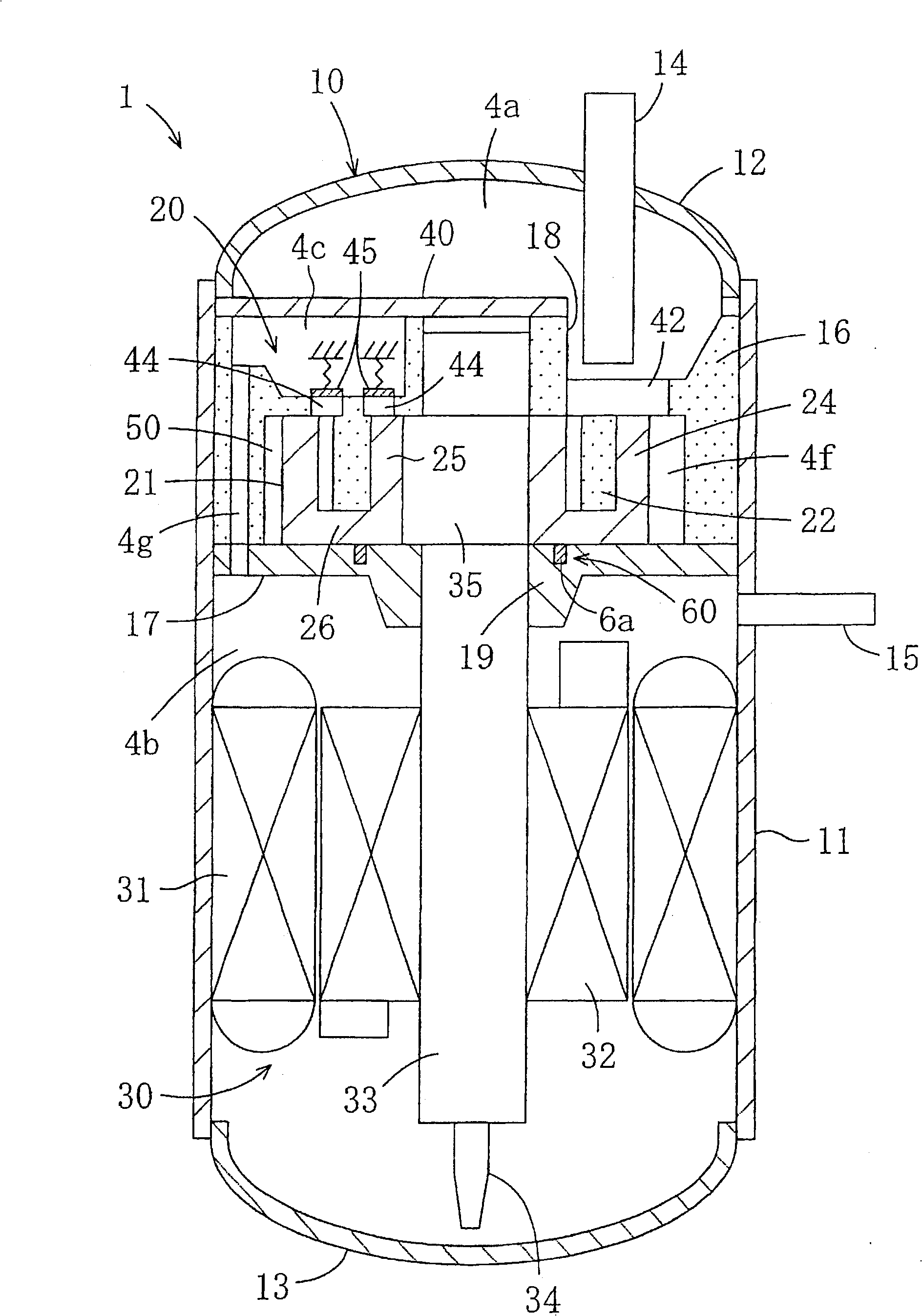

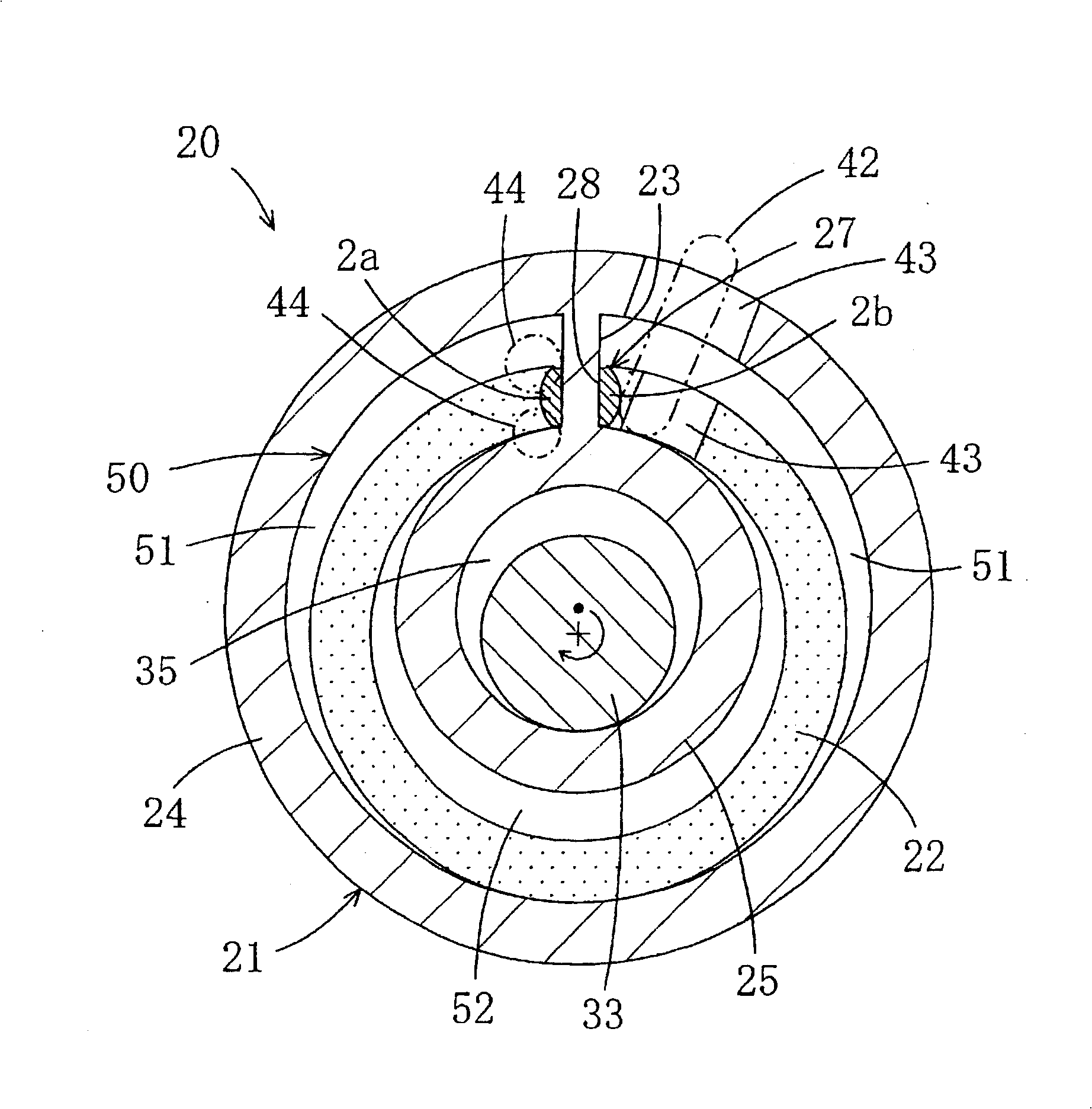

[0063] Such as figure 1 ~ As shown in FIG. 3 , this embodiment stipulates that the present invention is applicable to the compressor 1 . The compressor 1 described above is provided in, for example, a refrigerant circuit.

[0064] The refrigerant circuit is configured to perform, for example, at least one of cooling and heating operations. That is, the refrigerant circuit is formed by connecting, for example, an outdoor heat exchanger on the heat source side of the compressor 1, an expansion valve that is an expansion mechanism, and an indoor heat exchanger that is a heat exchanger on the utilization side in the above order. of. And, the refrigerant compressed in the compressor 1 expands in the expansion valve after dissipating heat in the outdoor heat exchanger. The expanded refrigerant absorbs heat in the indoor heat exchanger and returns to the compressor 1 . This cycle is repeated, and the indoor air is cooled by the indoor heat exchanger.

[0065] The above-mentioned...

Embodiment 2

[0121] Next, Embodiment 2 of the present invention will be described in detail with reference to the accompanying drawings.

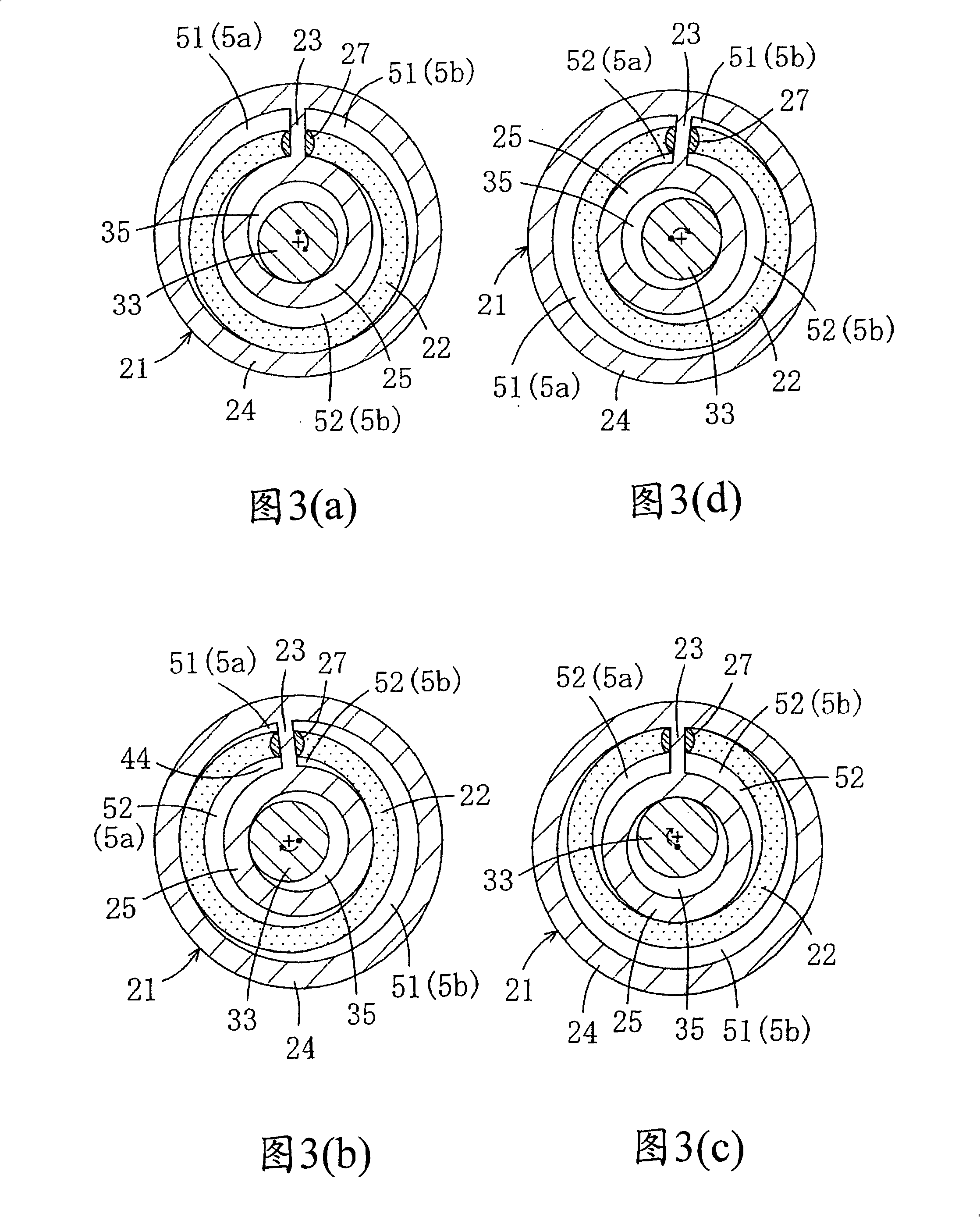

[0122] In the above-mentioned first embodiment, the width T1 of the cylinder chamber and the width T2 of the piston are changed in two areas. Instead, this implementation makes it change in four areas, such as Figure 7 ~ Figure 9 shown.

[0123] Specifically, the cylinder chamber 50 is divided into four regions on the circumference, and the wide regions Z1 and Z3 with wide widths and the narrow regions Z2 and Z4 with narrow widths are alternately connected to each other. On the other hand, the piston 22 is divided into four regions on the circumference, and the narrow narrow regions W1, W3 and the wide wide regions W2, W4 are alternately connected to each other.

[0124] That is, the above-mentioned cylinder chamber 50, such as Figure 7 As shown, the first region Z1 sandwiching the blade 23 is formed as the wide region Z1 in a range of 90 degrees. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com