Electroplastic-effect-based elastic particle medium assisted electromagnetic forming device and forming method for light-alloy miniature complex component

A technology of elastic particles and electroplasticity, which is applied in the field of metal material processing and forming, can solve the problem that the forming method cannot take into account the quality and precision of the workpiece, and achieve the effects of reducing tissue defects, improving plasticity, and ensuring the quality of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

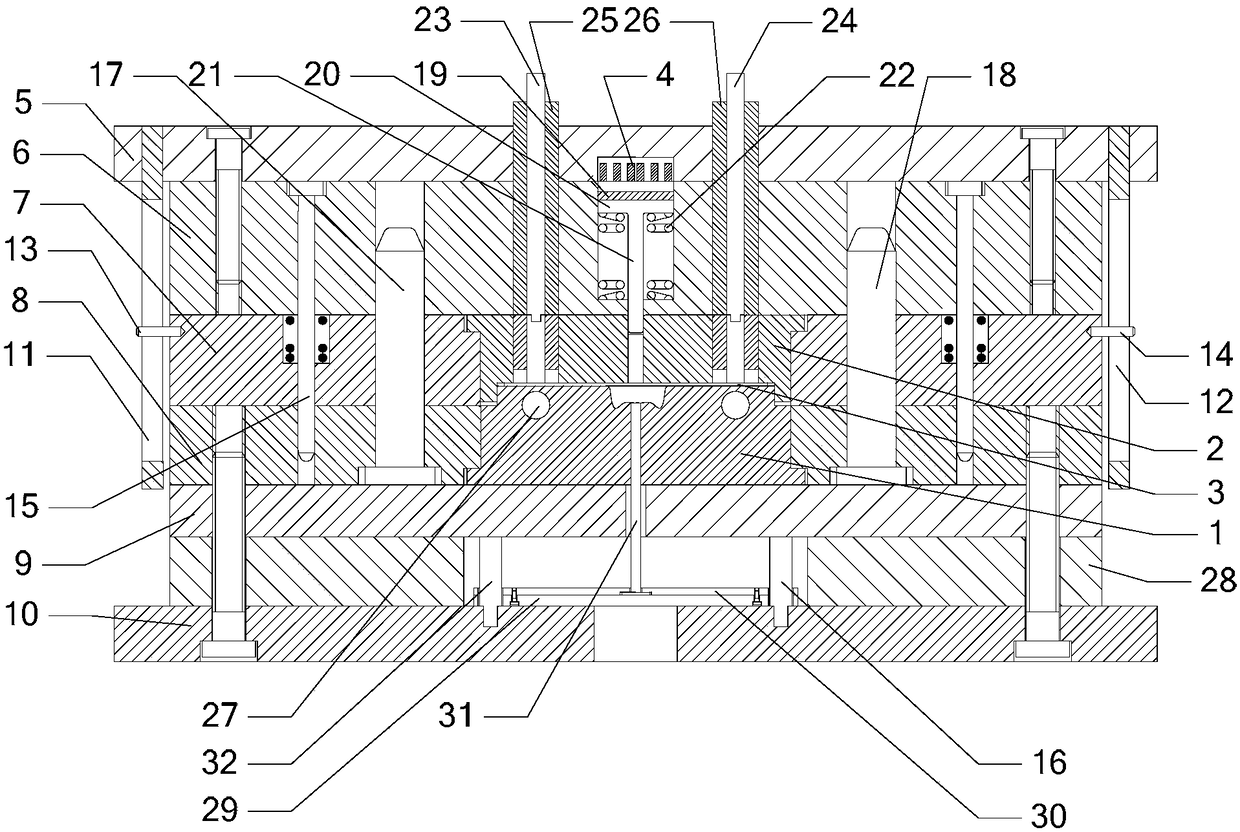

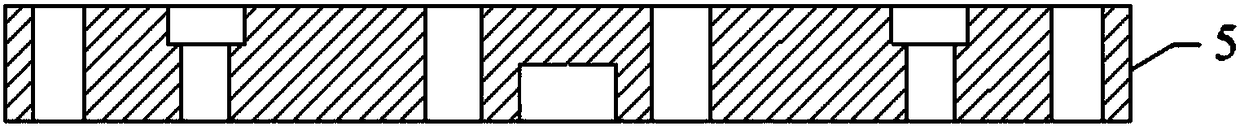

[0080] Embodiment: combine below Figure 1 to Figure 24 This embodiment will be described in detail.

[0081] The electromagnetic forming device of light alloy miniature complex components based on the electroplastic effect and elastic particle medium assistance described in this embodiment includes a combined mold unit, an electroplastic unit, a temperature measurement unit, an electromagnetic pulse generation unit and an impact unit;

[0082] The combined mold unit includes a die 1 and an elastic particle medium chamber 2, and a light alloy plate 3 is clamped between the die 1 and the elastic particle medium chamber 2;

[0083] The electroplastic unit is used to make the light alloy plate 3 undergo an electroplastic effect;

[0084] The temperature measuring unit is used to measure the surface temperature of the light alloy plate 3 in real time during the electroplastic effect of the light alloy plate 3;

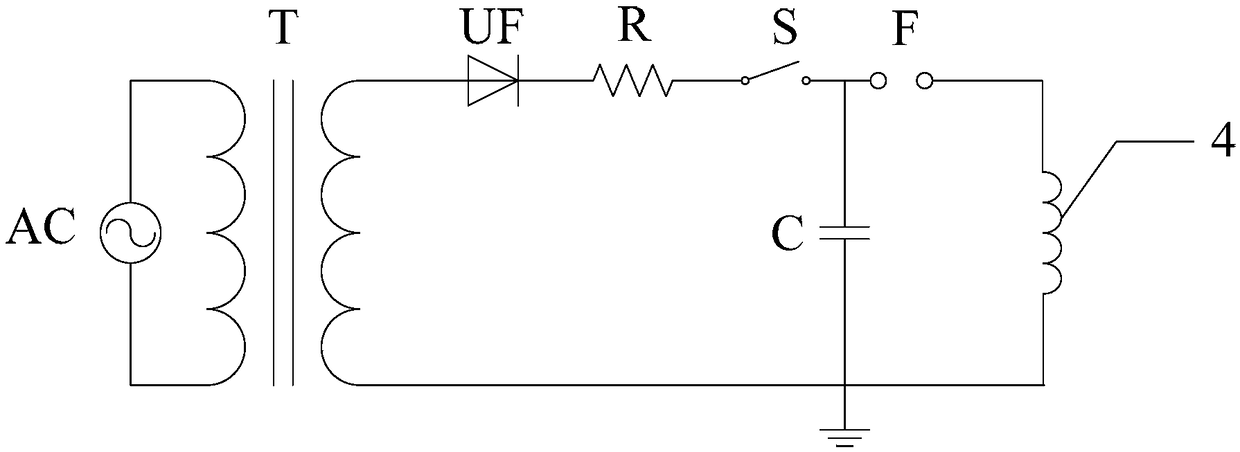

[0085] The electromagnetic pulse generating unit includes a first h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com