Copper-ceramic interface structure of high-reliability silicon nitride copper-coated ceramic substrate and preparation method of copper-ceramic interface structure

A technology of silicon nitride copper cladding and silicon nitride ceramics, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of affecting the etching process, poor uniformity of copper-ceramic interface, and unclean etching, and avoid environmental problems. Contamination, less stress concentration, uniform welding layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

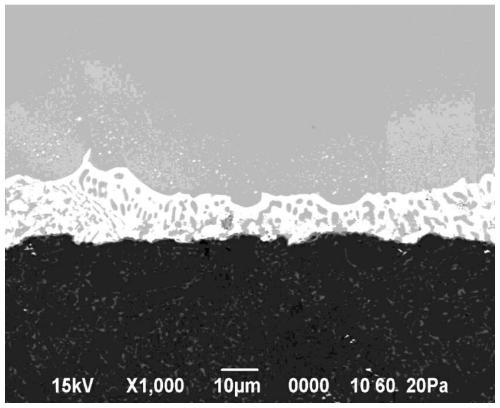

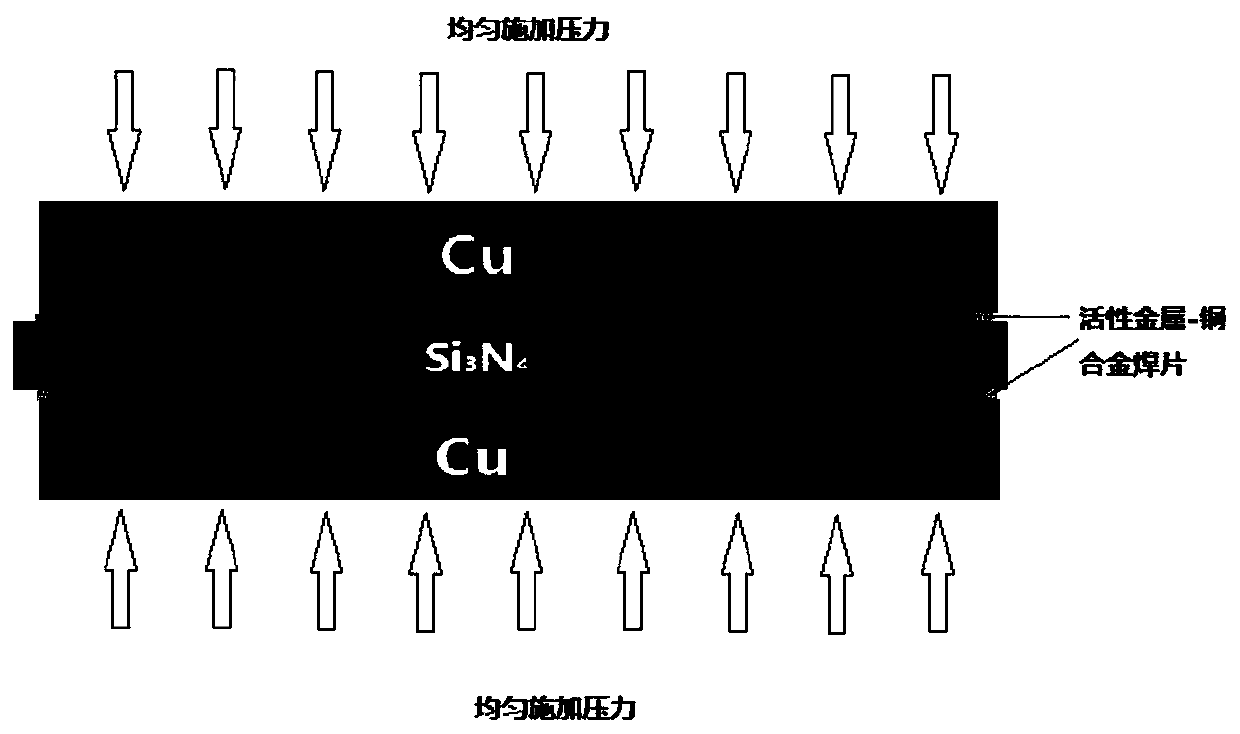

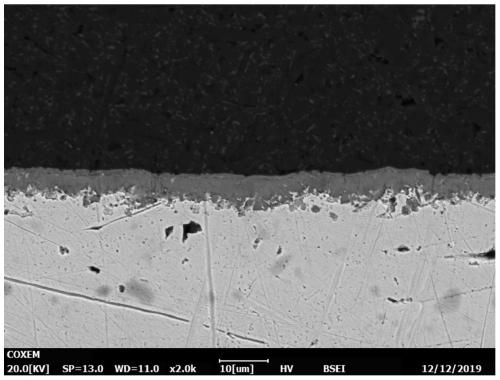

Embodiment 1

[0037] The invention provides a copper-silicon nitride ceramic connection interface structure for a silicon nitride copper-clad ceramic substrate, the interface structure uses figure 2 The method shown is sintered. The specific implementation method is to use a copper-zirconium alloy sheet with a thickness of 10 microns as a prefabricated welding piece, place it between copper and silicon nitride ceramics, and clamp it into a copper-copper-zirconium alloy welding piece-silicon nitride ceramics-copper zirconium Alloy solder sheet-copper laminated structure, place the laminated structure in the fixture, apply uniform pressure on the copper surface of the laminated structure, the pressure is 1kg / cm 2 . Place the above-mentioned stacked structure in a vacuum sintering furnace to raise the temperature to 980°C at a rate of 10°C / min, keep it warm for 60min, and cool down to room temperature. Wherein, in the copper-zirconium alloy flakes used, the content of active metal element z...

Embodiment 2

[0039]The invention provides a copper-silicon nitride ceramic connection interface structure for a silicon nitride copper-clad ceramic substrate, the interface structure uses figure 2 The method shown is sintered. The specific implementation method is to use a copper-hafnium alloy sheet with a thickness of 20 microns as a prefabricated solder sheet, place it between copper and silicon nitride ceramics, and clamp it into a copper-copper hafnium alloy solder sheet-silicon nitride ceramic-copper hafnium Alloy solder sheet-copper laminated structure, place the laminated structure in the fixture, apply uniform pressure on the copper surface of the laminated structure, the pressure is 0.6kg / cm 2 . Place the above-mentioned stacked structure in a vacuum sintering furnace to raise the temperature to 1060°C at a rate of 10°C / min, keep it warm for 60min, and cool down to room temperature. Wherein, in the copper-hafnium alloy flakes used, the content of the active metal element hafniu...

Embodiment 3

[0041] The invention provides a copper-silicon nitride ceramic connection interface structure for a silicon nitride copper-clad ceramic substrate, the interface structure uses figure 2 The method shown is sintered. The specific implementation method is to use a copper-titanium alloy sheet with a thickness of 5 microns as a prefabricated soldering sheet, place it between copper and silicon nitride ceramics, and clamp it into copper-copper-titanium alloy soldering sheet-silicon nitride ceramics-copper titanium Alloy solder sheet-copper laminated structure, place the laminated structure in the fixture, apply uniform pressure on the copper surface of the laminated structure, the pressure is 0.1kg / cm 2 . The above-mentioned laminated structure was placed in an atmospheric pressure sintering furnace, and the temperature was raised to 1050° C. at a rate of 10° C. / min, kept in an argon atmosphere for 60 minutes, and cooled to room temperature. Wherein, in the copper-titanium alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com