Pre-grinding hob for machining micro-segment gears

A micro-segment and gear technology, which is applied in the direction of gear tooth manufacturing tools, components with teeth, metal processing equipment, etc., can solve the problem of inability to ensure the smooth connection between the contact section of the micro-segment gear tooth profile and the arc of the addendum, and the inability to adapt Problems such as pre-grinding of micro-segment gears and inability to produce undercuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0161] Table 3 Parameters of processed micro-segment gears

[0162] Modulus / mm

Number of teeth

Initial pressure angle / degree

Pressure angle increment / degree

Initial base circle / mm

Addendum height factor

Headspace coefficient

3

30

10.6

0.00085

818611.14

1.05

0.375

[0163] It is assumed that the basic parameters of the micro-segment gear to be processed are shown in Table 3 above.

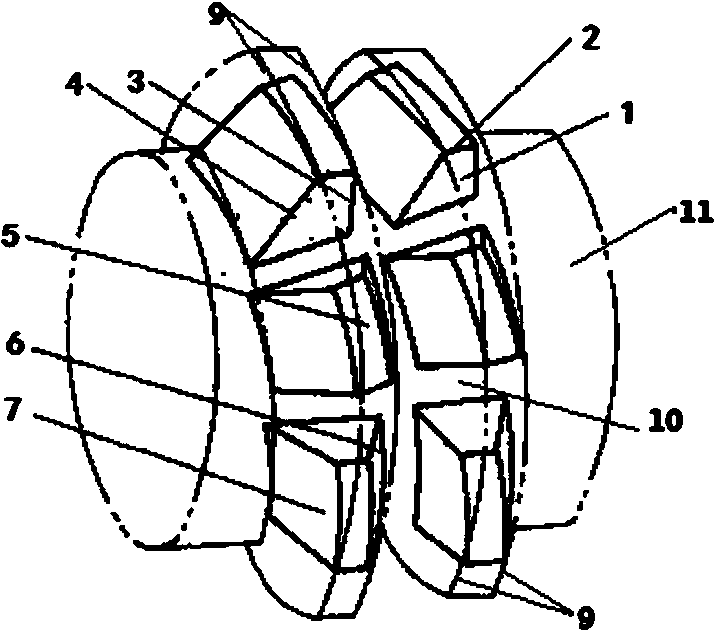

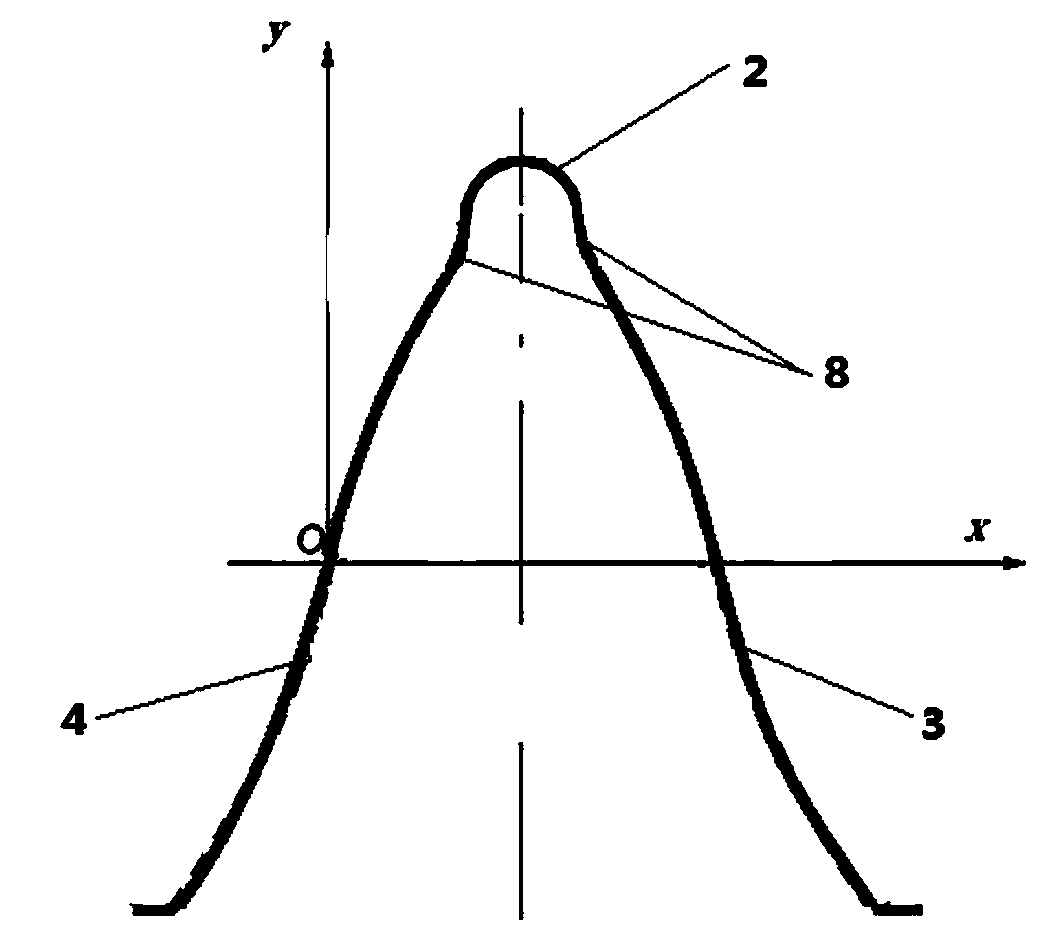

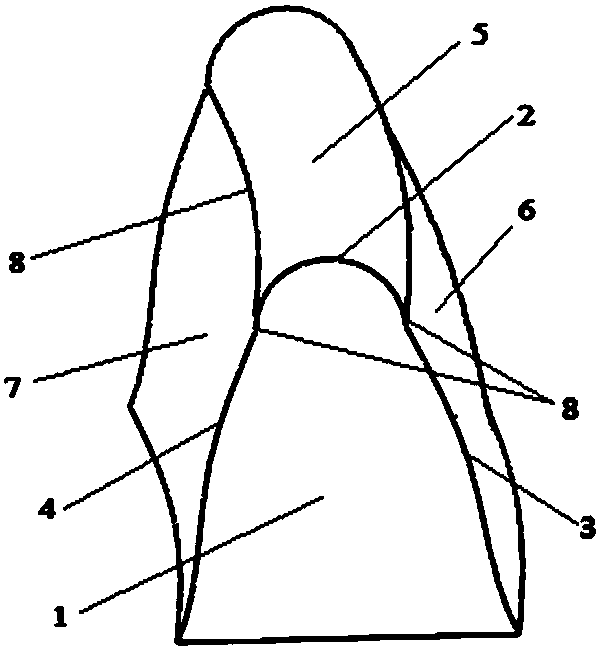

[0164] Such as figure 1 As shown, the pre-grinding hob used for micro-segment gear processing, the base cylinder of the pre-grinding hob is evenly distributed with cutter teeth, and each cutter tooth is respectively provided with a rake face 1, a top edge 2, and a right edge 3. The left side edge 4, the back of the back shovel top 5, the right side flank 6 and the left side flank 7, in which the right side 3 and the left side 4 are the main cutting edges, and the top side 2 and the flanks on both sides There are characteristic...

Embodiment 2

[0176] Table 5 Parameters of processed micro-segment gears

[0177] Modulus / mm

Number of teeth

Initial pressure angle / degree

Pressure angle increment / degree

Initial base circle / mm

Addendum height factor

Headspace coefficient

2.0

23

10.329

0.00065

796385.14

1.0

0.25

[0178] It is assumed that the basic parameters of the micro-segment gear to be processed are shown in Table 5 above.

[0179] Table 6 Hob parameters before grinding

[0180]

[0181] The parameters of the correspondingly designed pre-grinding hob are shown in Table 6 above.

Embodiment 3

[0183] Table 7 Parameters of processed micro-segment gears

[0184] Modulus / mm

Number of teeth

Initial pressure angle / degree

Pressure angle increment / degree

Initial base circle / mm

Addendum height factor

Headspace coefficient

1.15

19

10.178

0.000632

812568.32

1.0

0.25

[0185] It is assumed that the basic parameters of the micro-segment gear to be processed are shown in Table 7 above.

[0186] Table 8 Hob parameters before grinding

[0187]

[0188] The parameters of the correspondingly designed pre-grinding hob are shown in Table 8 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com