Frame structure for backrest and method for manufacturing same

A structure and frame technology, applied in applications, seat frames, household appliances, etc., can solve problems such as high cost, high cost, and difficult molding, and achieve high rigidity, high productivity, and lightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

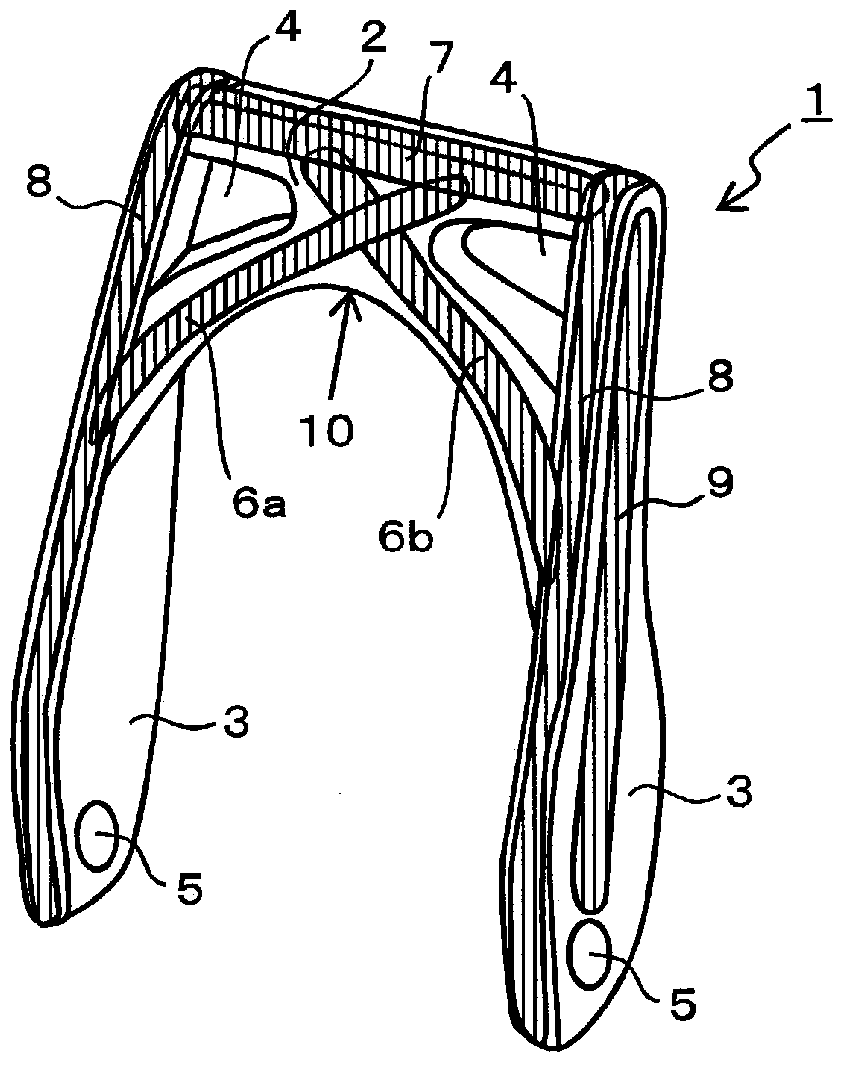

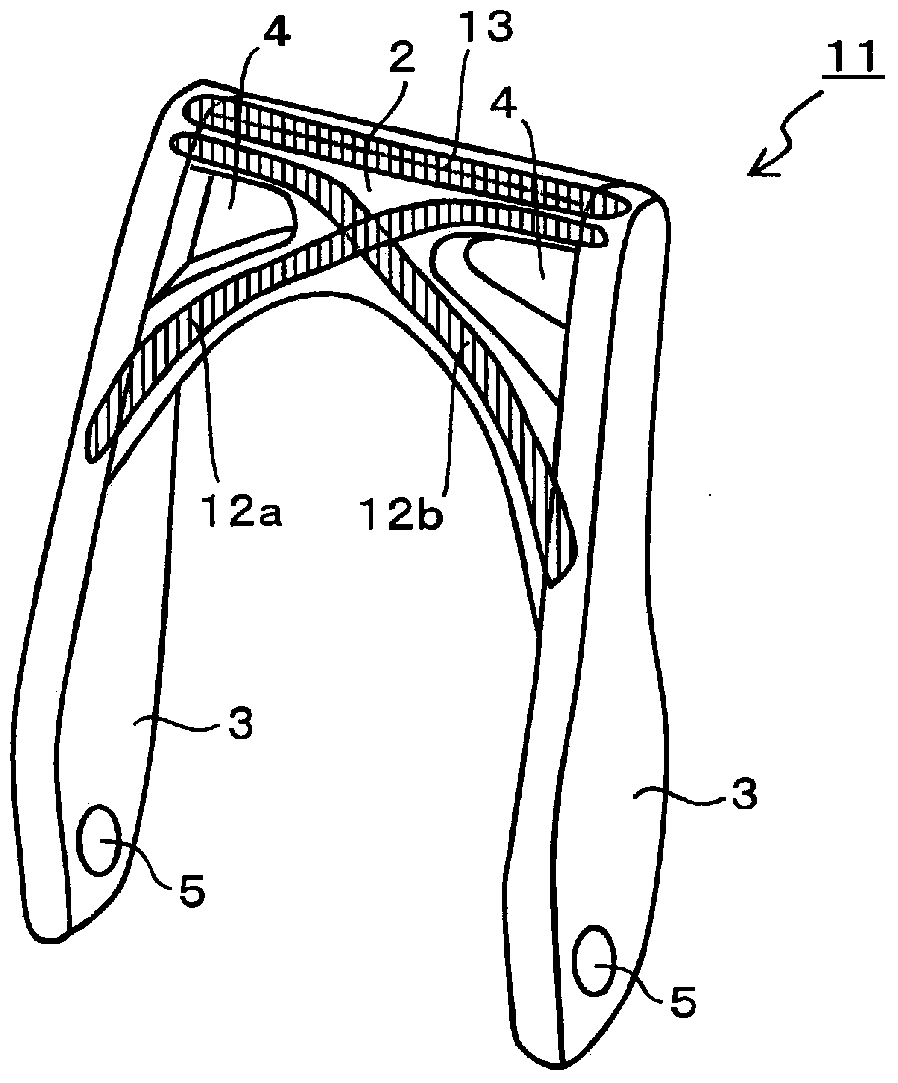

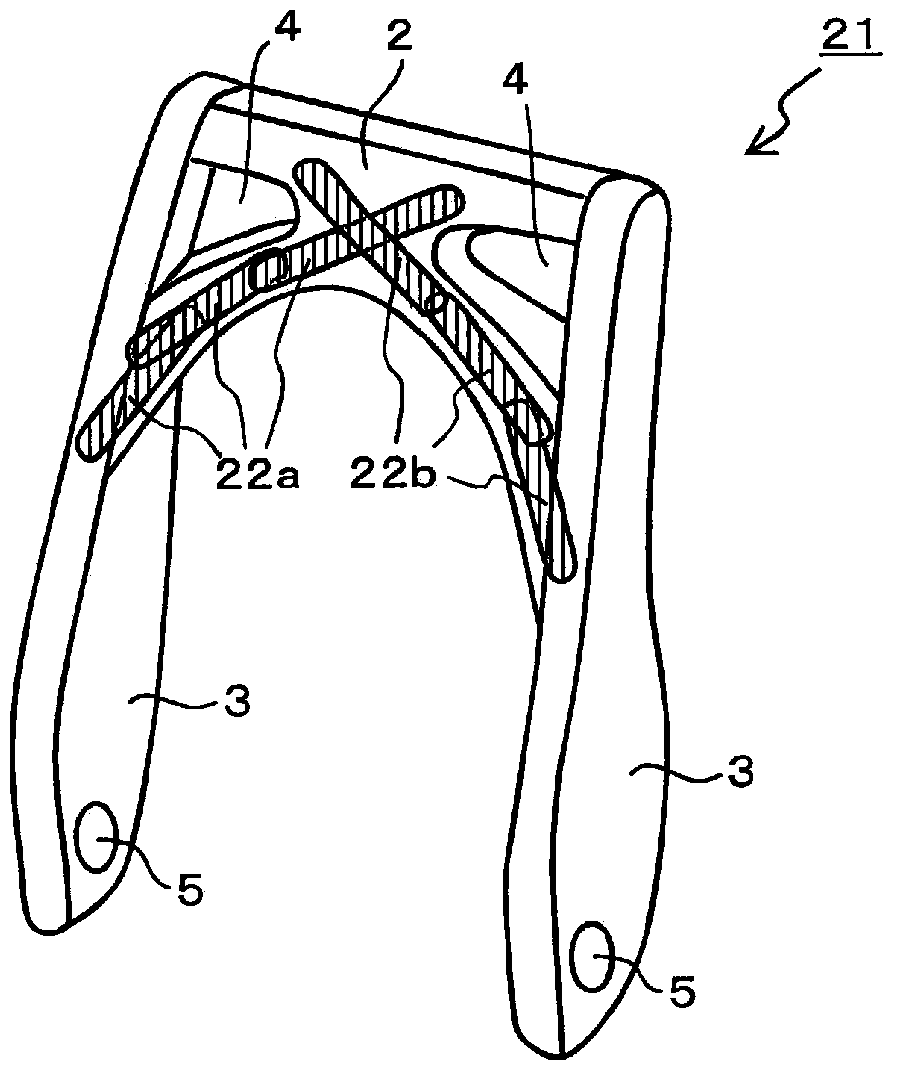

[0041] figure 1 A frame structure 1 for a backrest according to an embodiment of the present invention is shown. The frame structure 1 for the backrest is formed by integrally connecting side frames 3 extending parallel to each other on both sides and a horizontal frame 2 extending in the range between the upper parts of the frames 3 on both sides to form a gate shape as a whole. . A frame structure for a backrest made of a hard resin shows a frame structure for a backrest used in a vehicle seat. In this embodiment, openings 4 are provided on the left and right sides of the cross frame 2 mainly for weight reduction, and side frames 3 and support parts (support parts provided on vehicle seats) are formed on the lower parts of the side frames 3. , not shown in the figure), the connecting portion 5 (hole for connecting) supports the side frame 3 so that the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com