Manufacturing method of laminated steel and laminated steel manufacturing apparatus

A manufacturing method and a manufacturing device technology, which are applied in lamination devices, electromechanical devices, magnetic core manufacturing, etc., can solve problems such as low productivity, achieve good flatness, shorten the time required for curing, and are not prone to stress concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

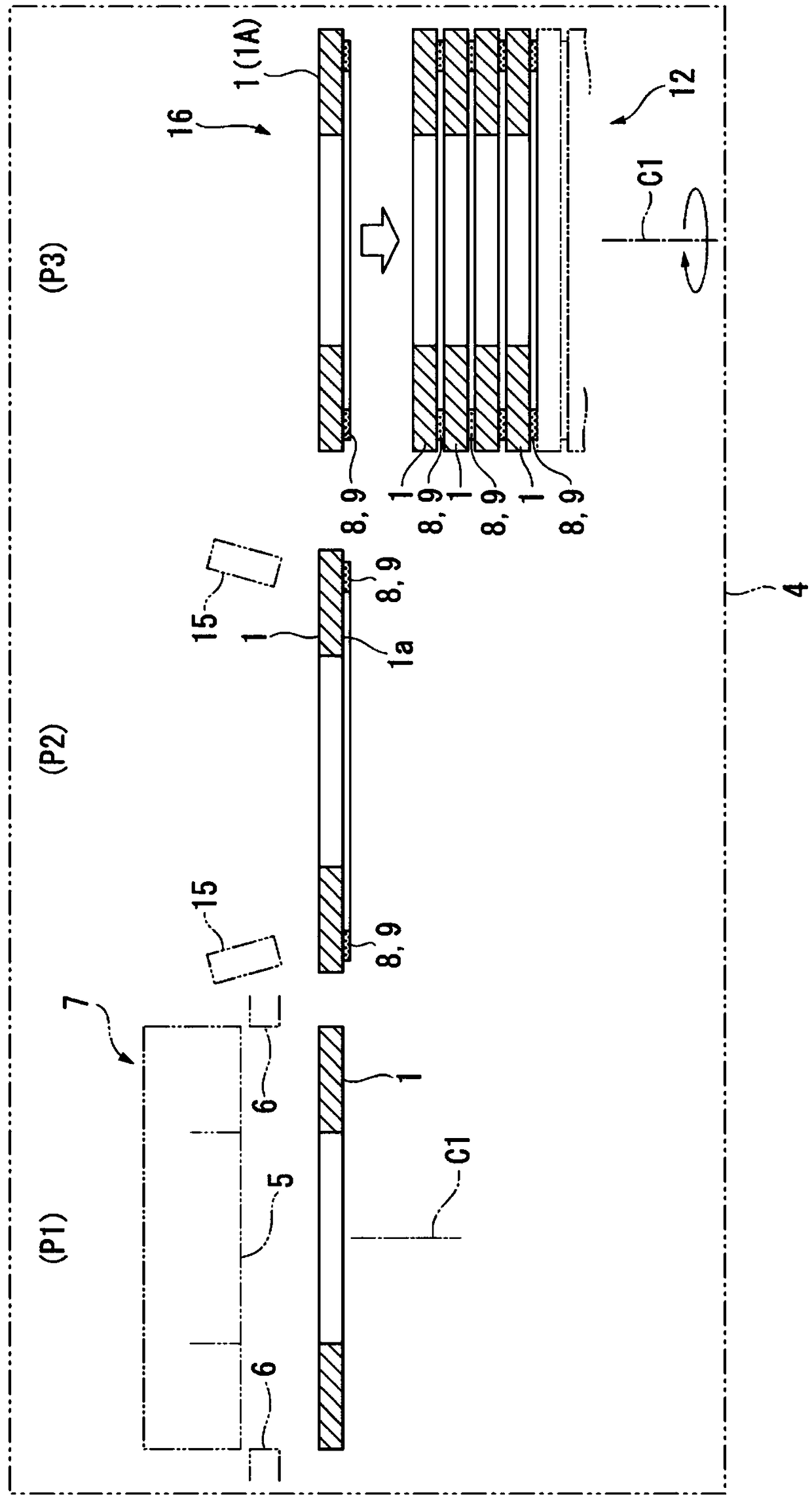

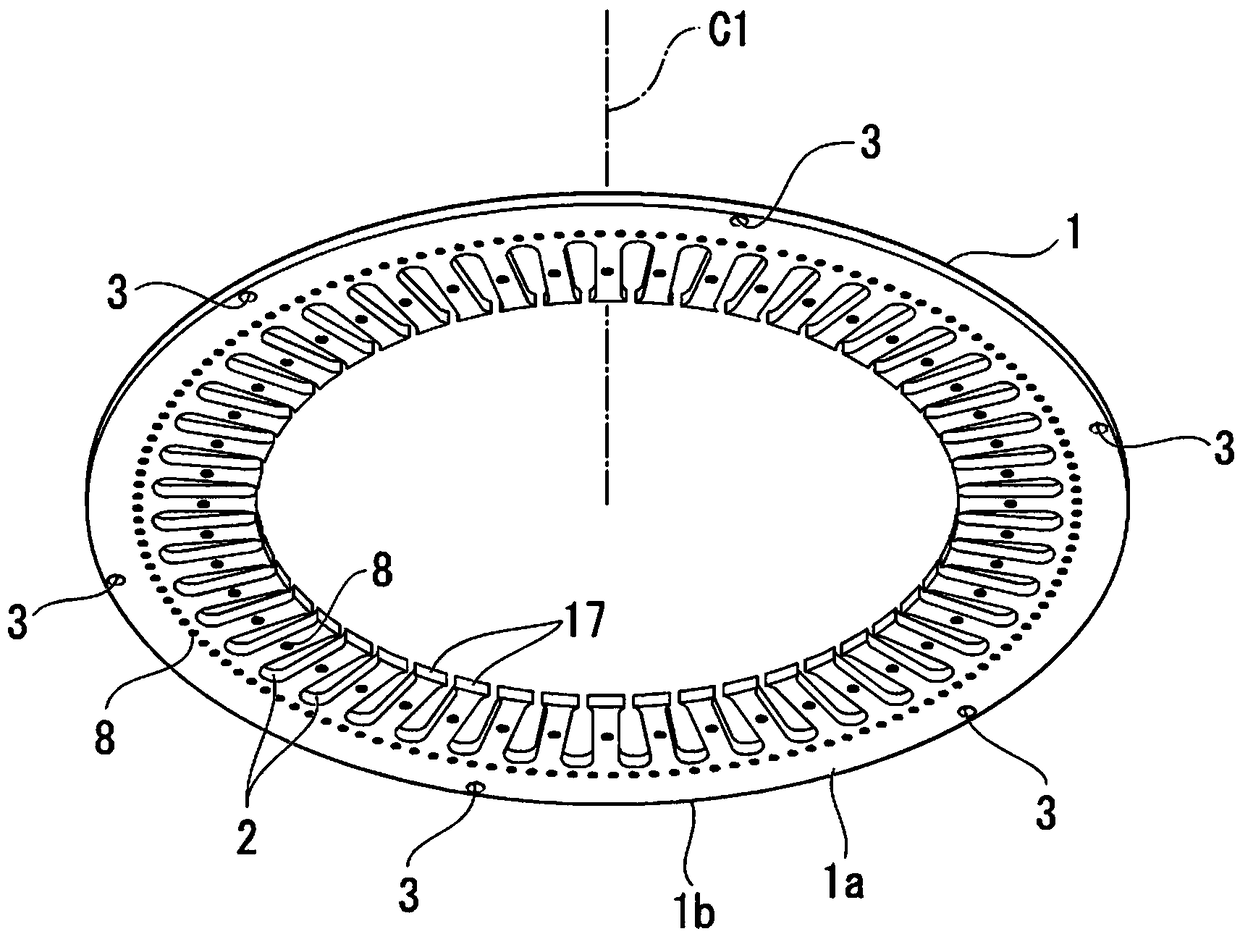

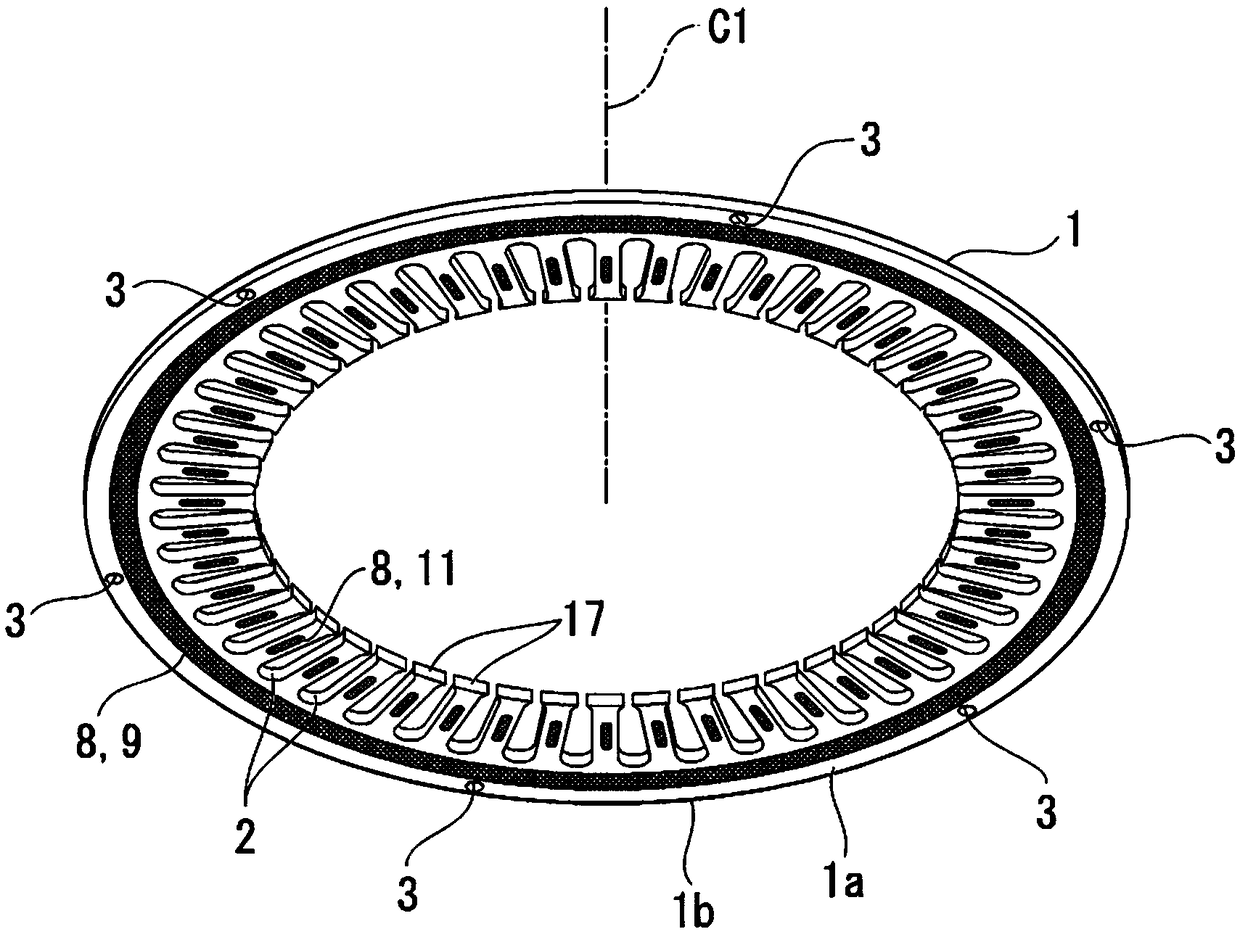

[0088] Figure 5A It is a perspective view showing the structure of the laminated body obtained by the manufacturing method of Example 1. Figure 5B It is a perspective view which schematically shows an adhesive bond layer. It should be noted that, in Figure 5A In, the adhesive agent 8 coated in dots by the second process P2 is shown (refer to Figure 2A ) is extruded and expanded in the third step P3 to form a continuous shape in the circumferential direction around the central axis C1.

[0089] Such as figure 1 As shown, the steel plate is introduced into the manufacturing apparatus 4, and the ring-shaped plate 1 is obtained by punching (first process P1).

[0090] Such as Figure 2A As shown, the adhesive 8, which is an acrylic anaerobic adhesive (room temperature curable), is applied at two places corresponding to the teeth 17, and one place is applied between adjacent teeth 17, and Each is applied in dots at equal intervals along the direction around the central ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com