Double-spherical traction rubber joint and making method thereof

A technology of rubber joints and manufacturing methods, applied to railway car body parts, springs, bogies, etc., can solve problems such as low deflection stiffness, rubber bending deformation, etc., achieve low deflection stiffness, reduce rubber bulging, and increase deflection The effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

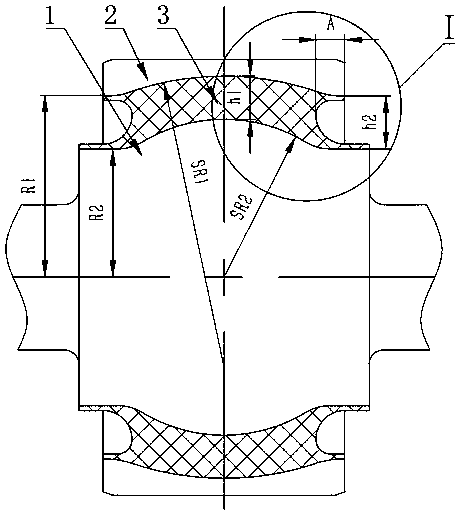

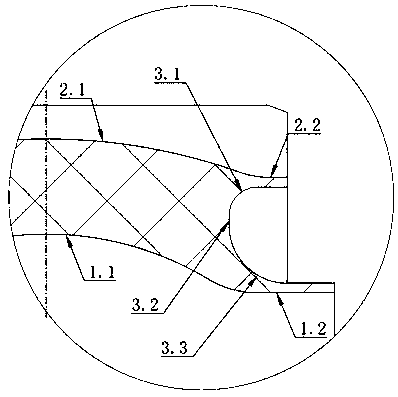

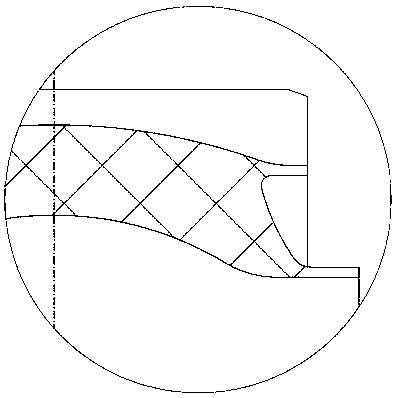

[0029] Please refer to Figure 1 to Figure 3 , a double spherical traction rubber joint, including a mandrel 1, a jacket 2 and a rubber layer 3 vulcanized and bonded between the mandrel 1 and the jacket 2. The rubber layer is vulcanized between the mandrel and the double spherical surface of the jacket, and the thickness h1 of the middle rubber layer (that is, the thickness in the middle of the rubber layer) is less than or equal to the thickness h2 of the rubber layers at both ends (that is, the thickness at both ends of the rubber layer). And the sum of the radius SR2 of the mandrel spherical section and the thickness h1 of the middle rubber layer is less than or equal to the radius SR1 of the outer casing spherical section. For the finished double spherical traction rubber joint, the rubber profiles at both ends of the rubber layer are formed by radially pre-compressing the rear-approaching rubber profile, and the rubber profile becomes a close-fitting rubber profile after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com