Large-scale bent cap semi-prefabrication construction technical method

A construction technology and semi-prefabrication technology, applied in the direction of bridges, bridge materials, bridge construction, etc., can solve the problems of increasing the control requirements of the prefabrication stage, prolonging the labor time, affecting the durability, etc., to avoid the complicated procedures and the easy stress concentration of the prefabrication method. , the effect of reducing the degree of environmental impact and saving necessary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

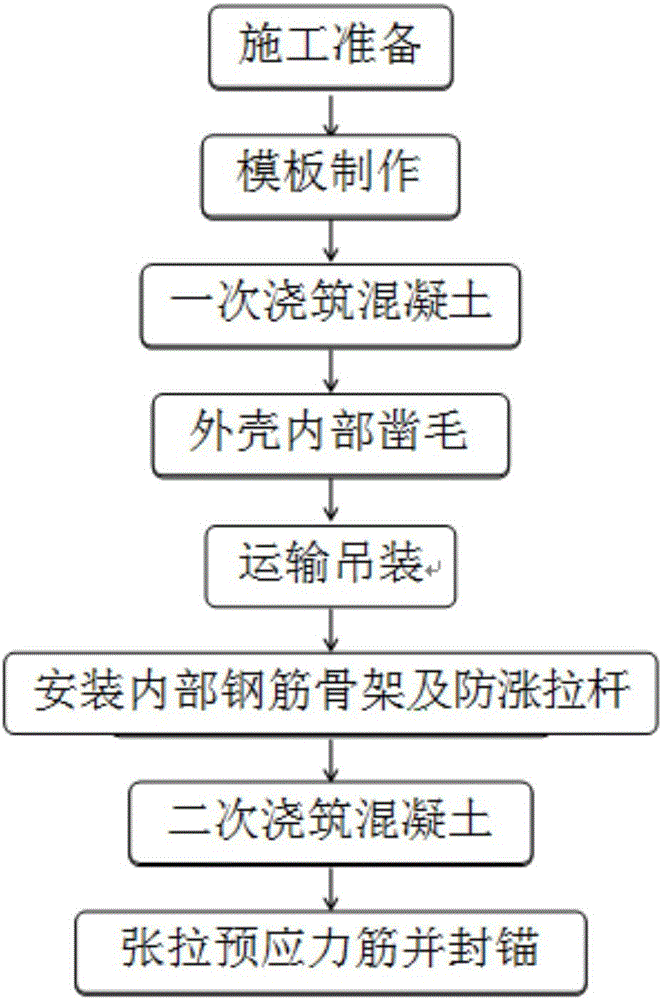

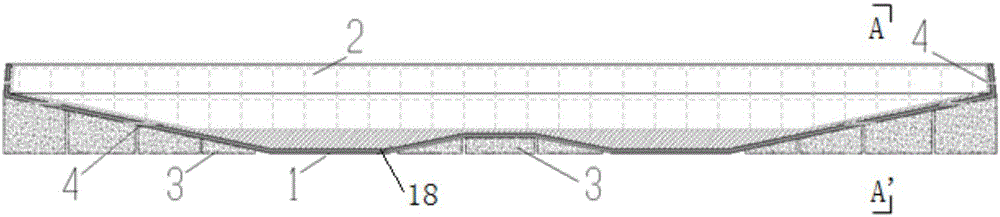

[0059] Taking the cover beam with a total longitudinal length of 31m as an example, its construction technical method specifically includes the following steps:

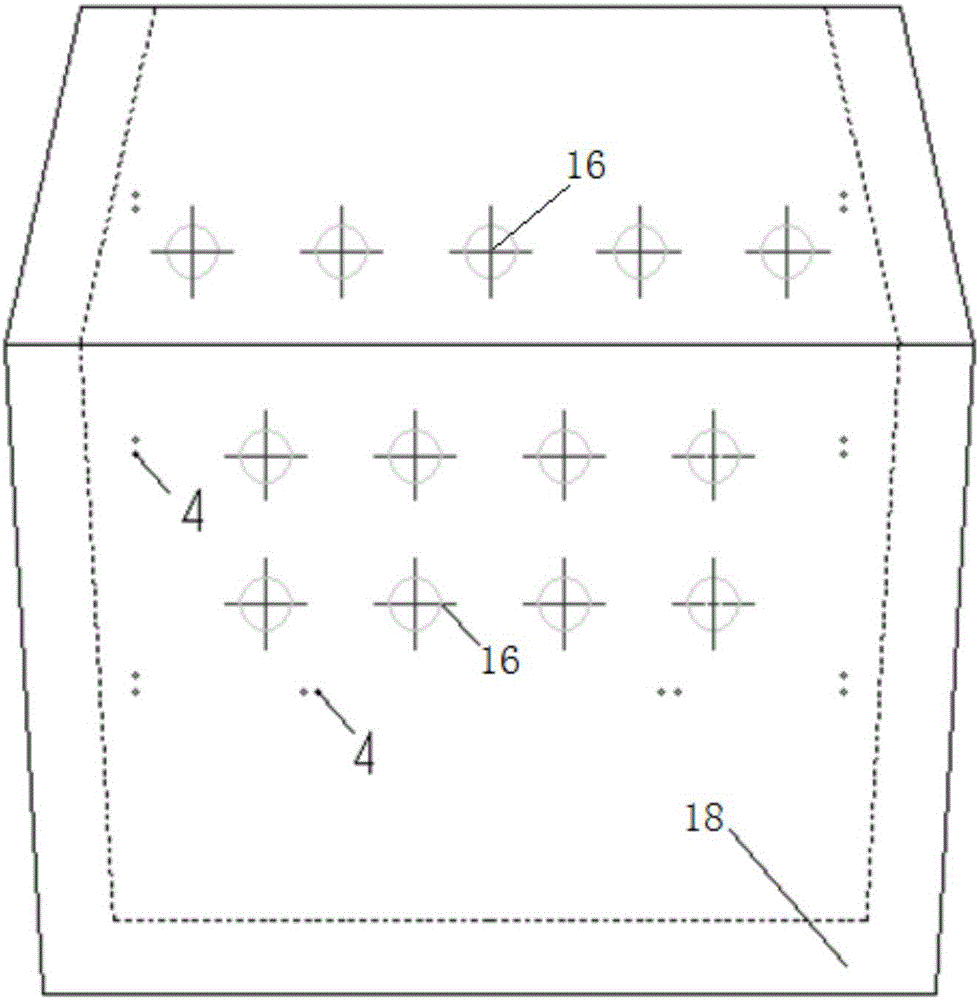

[0060] (1) Fabrication of open trough shell formwork

[0061] Set up the outer ring template 1 of the open trough housing 18, set up a pad 3 at the bottom of the outer ring template 1, and install a steel mesh 5 with a model number of ф10 on the open trough housing 18, and at the same time Binding the first U buckle steel bar 6 with a model of ф10, the outer ring template 1 is respectively provided with a number of interspersed steel bar holes 4, a number of anti-expansion tie rod holes (not marked in the accompanying drawings) and a number of prestressed tendon holes 16;

[0062] (2) The first pouring of concrete

[0063] Spray fiber concrete with strength C45 first to complete the pouring of the bottom of the open trough shell 18, pour at low speed, and vibrate with a small vibrator at the same time. It is strictl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com