Environment-friendly aqueous battery and preparation method thereof

An environmentally friendly, water-based electrolyte technology, which is applied to battery pack components, circuits, electrical components, etc., can solve problems such as poor water resistance, poor insulation, and short life, and achieve poor water resistance and maintenance. The effect of deformation and strength increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

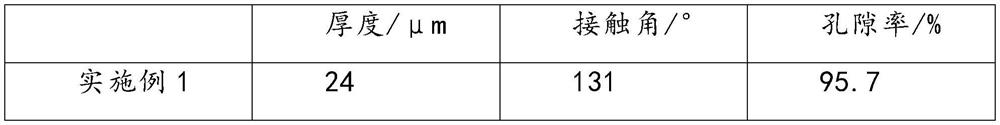

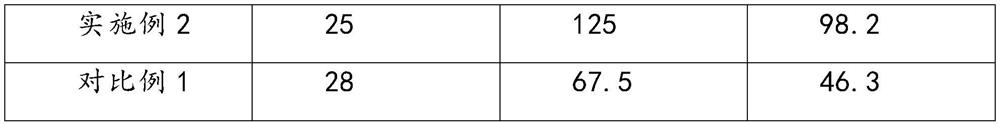

Embodiment 1

[0028] In this example, a hydrophobic reinforced diaphragm is prepared, and the specific implementation process is as follows:

[0029] Step A1: Weigh 200g of nano-silica, measure 800mL of ethanol aqueous solution with a volume concentration of 10%, add nano-silica to the ethanol solution, ultrasonically disperse at 28kHz for 10min to form a suspension, and then let it stand at room temperature Soak for 30 minutes, so that a large amount of silicon hydroxyl groups are formed on the surface, and then the reaction solution is suction-filtered, and the filter cake is stirred and dried after suction filtration, and the water content of the filter cake is controlled below 20%, so as to obtain pretreated nano-silica;

[0030] Step A2: Measure 24mL of perfluorooctyltrichlorosilane and 200mL of isopropanol, add the perfluorooctyltrichlorosilane dropwise into the isopropanol, stir and mix, and weigh 200g of the pretreated nanometer dichlorosilane prepared in step A1. Silicon oxide, the...

Embodiment 2

[0034] In this example, a hydrophobic reinforced diaphragm is prepared, and the specific implementation process is as follows:

[0035] Step A1: Weigh 200g of nano-silica, measure 1L of ethanol aqueous solution with a volume concentration of 10%, add nano-silica to the ethanol solution, ultrasonically disperse at 28kHz for 15min to form a suspension, and then let it stand at room temperature Soak for 50 minutes, so that a large amount of silicon hydroxyl groups are formed on the surface, and then the reaction solution is suction-filtered, and the filter cake is stirred and dried after suction filtration, and the water content of the filter cake is controlled below 20%, so as to obtain pretreated nano-silica;

[0036] Step A2: Measure 34mL of perfluorooctyltrichlorosilane and 220mL of isopropanol, add the perfluorooctyltrichlorosilane dropwise into the isopropanol, stir and mix, and weigh 200g of the pretreated nanometer dichlorosilane prepared in step A1. Silicon oxide, the mi...

Embodiment 3

[0055] In this example, a zinc water-based battery is prepared by using the hydrophobic reinforced diaphragm prepared in Example 2. The specific implementation process is as follows:

[0056] Positive grid: use the known molybdenum trioxide coil, the coil thickness is 40μm;

[0057] Negative grid: choose zinc foil, the thickness of zinc foil is 45μm, and the purity of zinc foil is >99.9%;

[0058] Aqueous electrolyte: zinc trifluoromethanesulfonate electrolyte (commercially available)

[0059] The positive grid, the negative grid, the hydrophobic reinforced separator prepared in Example 2, and the water-based electrolyte were assembled into the casing by adopting the roll-core battery structure to obtain a zinc water-based battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com