Refining ladle opening anti-sticking slag material and preparation method thereof

An anti-slag and ladle technology, applied in the direction of improving process efficiency, can solve the problems of large differences in expansion physical properties, large differences in chemical composition, and reduced high temperature resistance of materials, so as to achieve good resistance to slag infiltration and reduce cleaning. Slag workload and the effect of improving the life of the ladle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

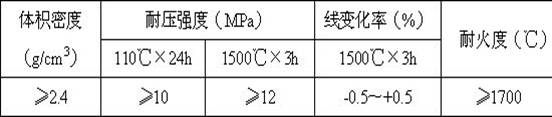

Image

Examples

Embodiment 1

[0044] Take 15kg of waste magnesia-carbon brick aggregate, 5kg of forsterite fine powder, 40kg of forsterite aggregate, 15kg of magnesia fine powder, 7kg of carbon material fine powder, 6kg of silicon carbide fine powder and 1kg of hardening accelerator, and put them in the mixing equipment Stir evenly for 10 minutes, add 11 kg of anhydrous resin to the obtained mixture, continue stirring for 3 to 5 minutes, and apply the prepared amorphous anti-sticking slag coating on the mouth of the ladle, and the coating thickness is ≥ 7mm. In this embodiment, the carbon material fine powder is graphite powder from waste electrodes, and the hardening accelerator is quicklime powder.

Embodiment 2

[0046] Take 25kg of waste magnesia-carbon brick aggregate, 10kg of forsterite fine powder, 25kg of forsterite aggregate, 20kg of magnesia fine powder, 3kg of carbon material fine powder, 2kg of silicon carbide fine powder and 2kg of hardening accelerator, and put them in the mixing equipment Stir evenly for 10 minutes, add 13 kg of anhydrous resin to the obtained mixture, continue stirring for 3 to 5 minutes, and apply the prepared amorphous anti-sticking slag coating on the mouth of the ladle, and the coating thickness is ≥ 7mm. In this embodiment, earthy graphite powder is used as the carbon material fine powder, and lightly burned magnesium powder is used as the hardening accelerator.

Embodiment 3

[0048] Take 20kg of waste magnesia-carbon brick aggregate, 6kg of forsterite fine powder, 30kg of forsterite aggregate, 22kg of magnesia fine powder, 4kg of carbon material fine powder, 3kg of silicon carbide fine powder and 3kg of hardening accelerator, and put them in the mixing equipment After stirring evenly for 10 minutes, add 12 kg of anhydrous resin to the obtained mixture, and continue stirring for 3 to 5 minutes. The prepared amorphous anti-sticking slag coating is applied to the opening of the ladle, and the thickness of the coating is ≥7mm. In this embodiment, earthy graphite powder is used as the carbon material fine powder, and lightly burned magnesium powder is used as the hardening accelerator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com