Horizontal floor tile laying method for house construction

A laying method and horizontal technology, which is applied in the direction of construction and building construction, can solve the problems of insufficient water soaking of tiles, hollow tiles, hollow tiles, etc., and achieve the effect of improving the thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

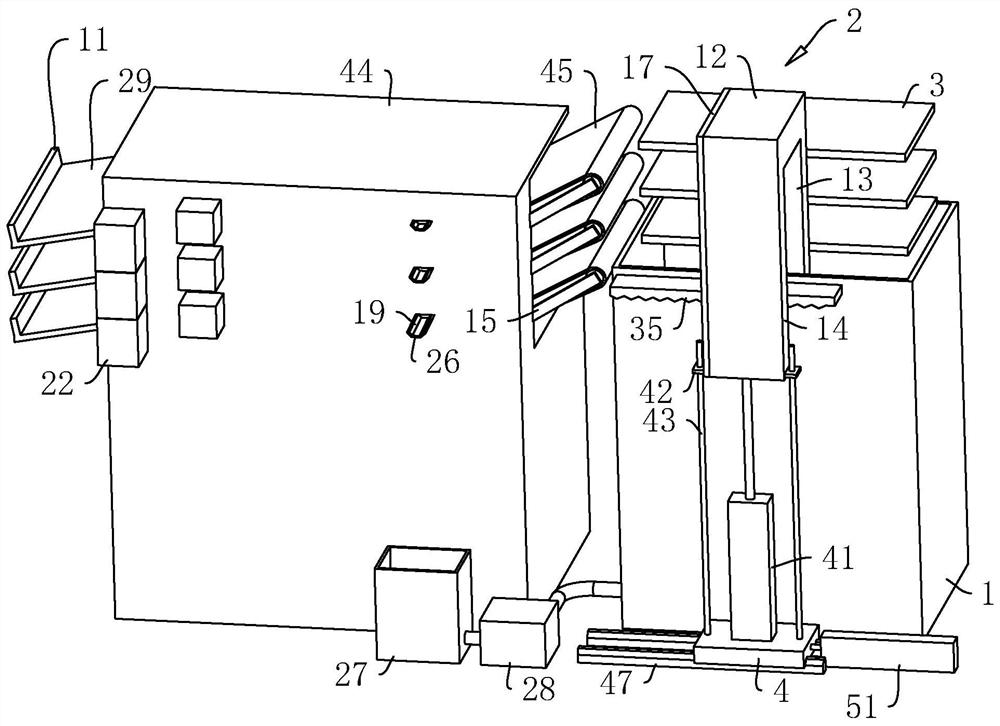

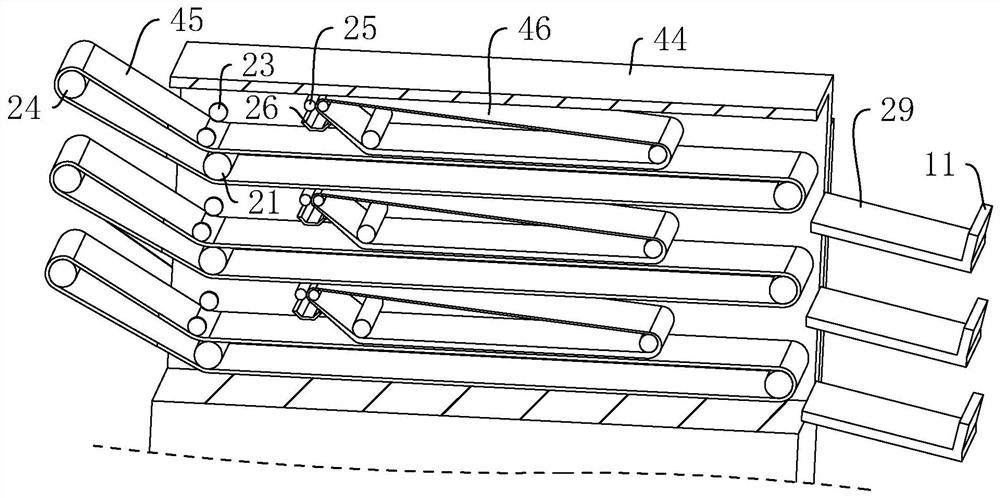

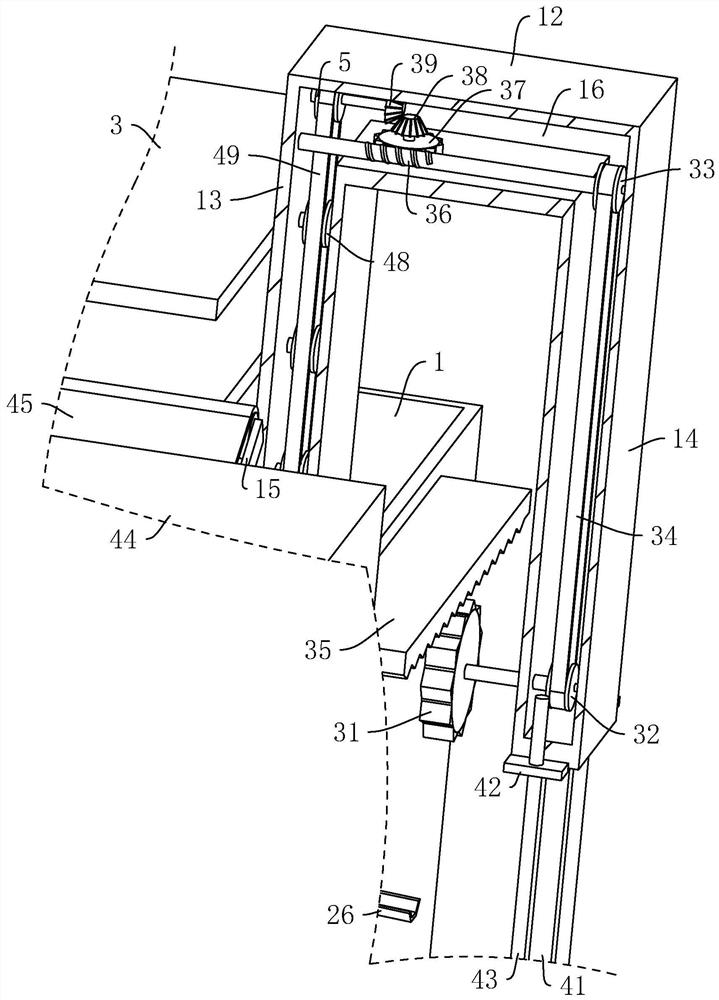

[0040] The application will be described in further detail below in conjunction with the accompanying drawings.

[0041] The embodiment of the present application discloses a method for laying horizontal floor tiles for house construction, which specifically includes the following steps:

[0042] Step 1. Clean the ground. Lay tiles in one area every day. When laying tiles in one area, remove foreign objects or dust on the ground, and then spray water mist on the ground to moisten;

[0043] Step 2. Soak the tiles in water. While performing step 1, use the tile soaking equipment to soak the tiles;

[0044] Step 3. Lay the base. Lay a row of tiles and a row of tiles respectively. The tile at the end of a row of tiles and a row of tiles is the same tile. Keep the distance between adjacent tiles and knock the tiles flat with a rubber hammer;

[0045] Step 4, tile laying, each tile corresponds to similar tiles and is laid flush;

[0046] Step 5. Gap treatment. Wait until the cemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com