Organic silicon-fluorine modified resin and coating preparation method

A technology of silicon-fluorine modification and fluorine resin, which is applied in the field of preparation of anti-fouling and easy-to-clean surface modification coatings to achieve the effect of low surface tension, good physical and mechanical properties, and not easy to peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

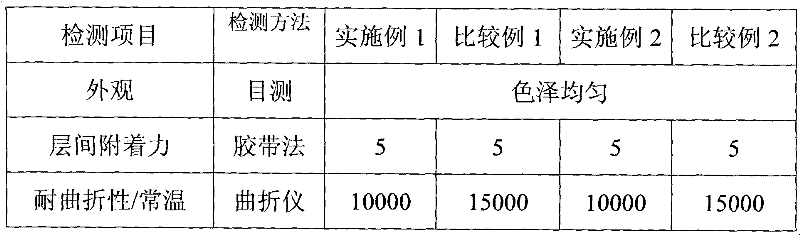

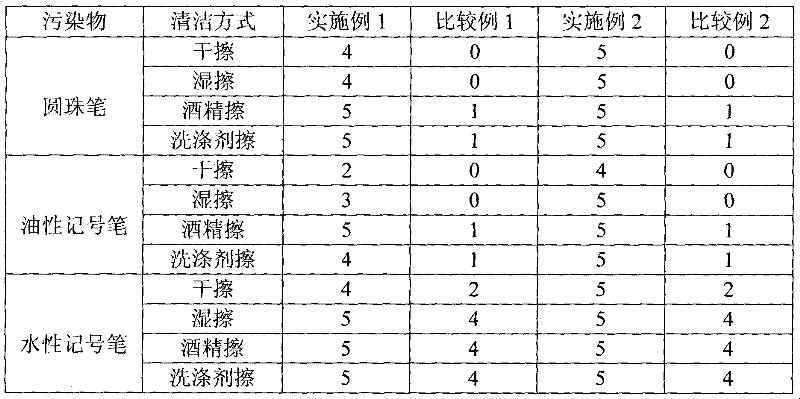

Embodiment 1

[0038] Preparation of silicon-fluorine modified resin: Dow Corning Z-6030 silane (DOW CORNING) 5wt%, fluororesin 23-28 (Waker) 2wt%, acrylic resin YD582-2 (Far East Chemical) 5wt%, polyurethane resin HDBU-6025 (Shanghai Huide Resin Co., Ltd.) 30wt%, xylene (Wenxin) 18wt%, MEK (wantuming) 15wt%, DMF 25wt%; mix the above raw materials in proportion to obtain organic silicon fluorine modified resin;

[0039] Preparation of coating slurry (by weight): Weigh 100 parts of silicon-fluorine modified resin, slowly add 25 parts of curing agent HDN-75 (Huide), stir evenly, and then slowly add 25 parts of accelerator HDC- 01 (Huide), stir while adding, until the mixture is uniform, adjust the viscosity to 800-1500cp with butyl acetate (Wenxin), and let it stand for later use;

[0040] Use a 100-mesh anilox wheel to print on the surface of cowhide, PU leather, and PVC leather respectively, dry at 150°C for 3 minutes, and dry at 170°C for 15 seconds, and the coating thickness is 1-10 μm.

Embodiment 2

[0044]Preparation of silicon-fluorine modified resin: silicone resin TEGO PROTECT 5001 (TEGO) 2.6wt%, acrylic resin YD582-2 (Far East Chemical) 3.4wt%, polyurethane resin HDBU-6025 (Huide) 24wt%, 150# solvent 20wt% %, butyl acetate 50wt%, the above-mentioned raw materials are mixed uniformly in proportion to obtain silicon-fluorine modified resin;

[0045] Preparation of coating slurry (by weight ratio): Weigh 100 parts of silicon-fluorine modified resin, slowly add 20 parts of curing agent HDN-75 (Huide), stir evenly, and then slowly add accelerator HDC-01 ( Huide) 5 parts, add and stir until the mixture is uniform, use about 150 parts of tetrahydrofuran (Wenxin) to adjust the viscosity to 800-1500cp, and let it stand for later use;

[0046] Use a 60-mesh screen roller to roll coat the surface of the PVC leather, dry at 130°C for 3 minutes, and dry at 160°C for 60 seconds, with a coating thickness of 10-30 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com