Preparation method and product of double-base wood-plastic composite material

The technology of wood-plastic composite material and wood powder is applied in the field of preparation of double-base wood-plastic composite material, which can solve the problems of limiting the application scope of wood-plastic material, cannot be further promoted, and cannot be used to manufacture high performance and high strength, etc. Achieve the effect of excellent comprehensive physical and chemical properties and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of the double-base wood-plastic composite material provided by this embodiment comprises the following steps:

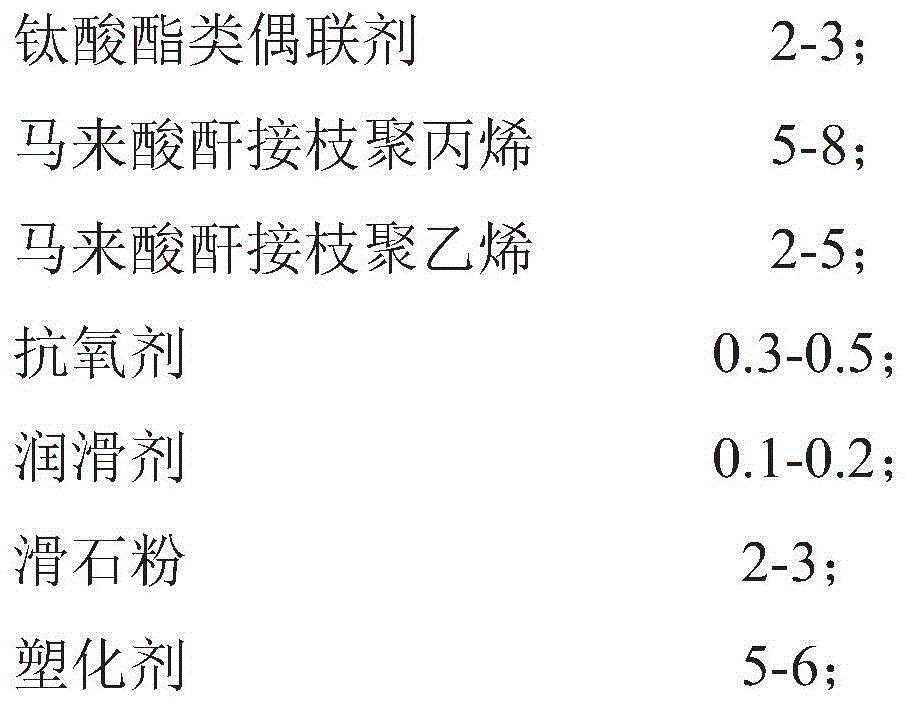

[0022] 1) Prepare the following components in parts by weight:

[0023]

[0024] Wherein: the quality of wood powder is the sum of the quality of PP, PE; And, the quality of PP is equal to the quality of PE than the quality of maleic anhydride grafted polypropylene than the quality of maleic anhydride grafted polyethylene;

[0025] 2) Treatment of wood powder: heat and dry the wood powder at 190-230°C, and set aside; take the dried wood powder equal to the quality of PP for stirring, keep the temperature at 90-100°C, add titanate couple Mix the joint agent evenly to get PP-type modified wood powder; take the dried wood powder equal to the quality of PE for stirring, add impregnating agent butyl acrylate, joint initiator benzoyl peroxide, and polymerization accelerator dimethylaniline The mixture is added to the wood flour, soaked for...

Embodiment 2

[0033] The preparation method of the double-base wood-plastic composite material provided by this embodiment comprises the following steps:

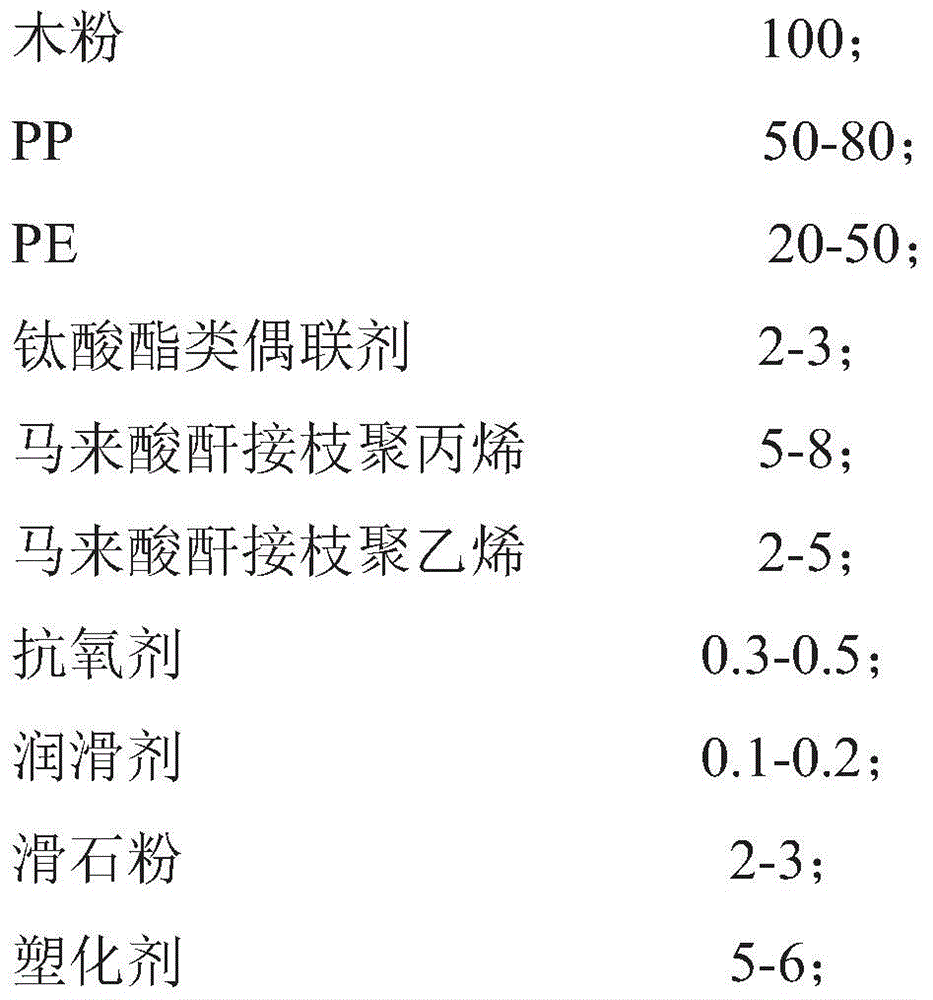

[0034] 1) Prepare the following components in parts by weight:

[0035]

[0036]

[0037] Wherein: the quality of wood powder is the sum of the quality of PP, PE; And, the quality of PP is equal to the quality of PE than the quality of maleic anhydride grafted polypropylene than the quality of maleic anhydride grafted polyethylene;

[0038] 2) Treatment of wood powder: heat and dry the wood powder at 190-230°C, and set aside; take the dried wood powder equal to the quality of PP for stirring, keep the temperature at 90-100°C, add titanate couple Mix the joint agent evenly to get PP-type modified wood powder; take the dried wood powder equal to the quality of PE for stirring, add impregnating agent butyl acrylate, joint initiator benzoyl peroxide, and polymerization accelerator dimethylaniline The mixture is added to the wood flour...

Embodiment 3

[0044] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0045] 1) Prepare the following components in parts by weight:

[0046]

[0047] Wherein: the mass of wood flour is the sum of the mass of PP and PE; and, the mass ratio of PP to the mass of maleic anhydride grafted polypropylene is equal to the mass of PE to the mass of maleic anhydride grafted polyethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com