Photocuring coating composition, photocuring coating and application

A light-curing coating and composition technology, applied in the field of paint film repair, can solve the problems of long curing time, irritating odor and unenvironmental protection, and achieve the effects of low VOC content, small volume shrinkage, and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] In the preparation process of the above-mentioned oxetane resin, the catalyst can be selected from the types commonly used in the art. In a preferred embodiment, the catalyst includes but is not limited to quaternary ammonium salts, more preferably tetrabutylammonium bromide, cetyltrimethylammonium bromide and octadecyldimethylbenzyl bromide one or more of the group consisting of ammonium.

[0023] In the preparation process of the above-mentioned oxetane resin, a solvent commonly used in the art can be selected, such as toluene.

[0024] In a preferred embodiment, the oxetane monomers include but are not limited to 3-hydroxymethyl-3-ethyloxetane, 3,3'-[oxybismethylene]bis [3-ethyl]oxetane, 3-ethyl-3-[4-[(3-ethyloxetan-3-yl)methoxy]butoxymethyl]oxetane One or more of the group consisting of cyclobutane and 1,3-bis(3-ethyl-3-methoxyoxetane)-2-hydroxypropane. Compared with other types of oxetane monomers, the above several oxetane monomers have relatively suitable visc...

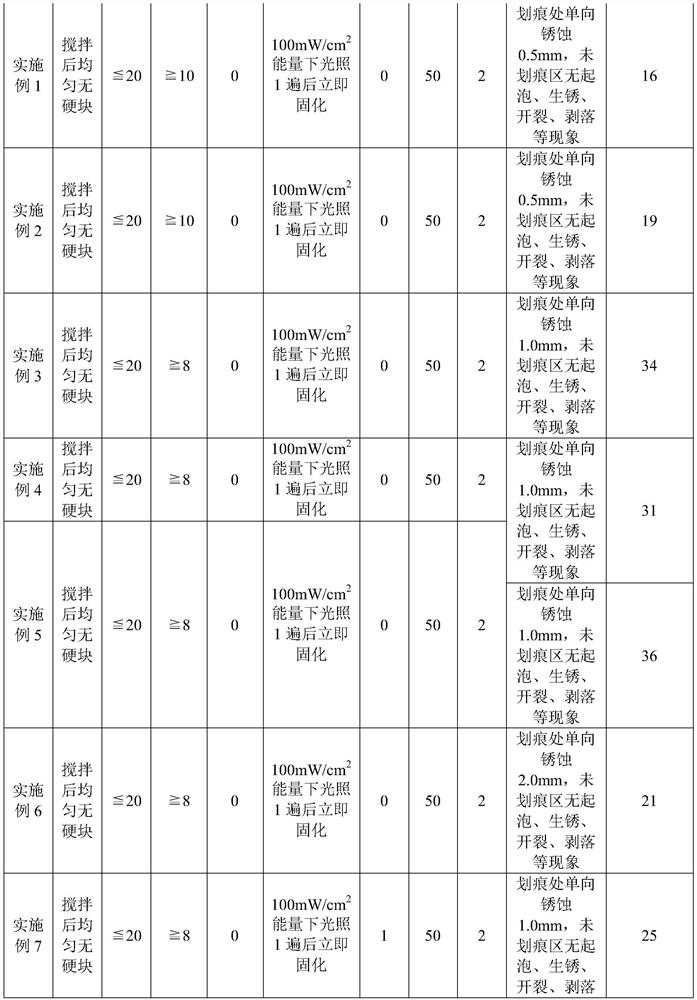

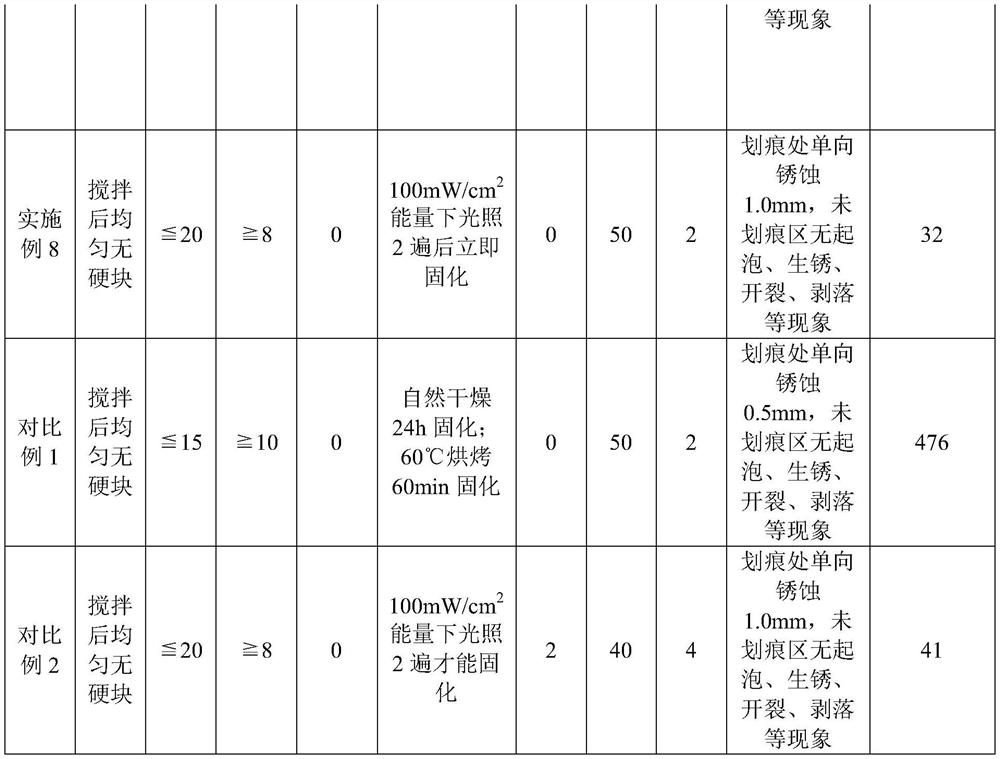

Embodiment 1

[0038] A quick-drying cationic light-curing auto repair primer, comprising in parts by weight: 20 parts of oxetane resin, 10 parts of 4-phenylthio triphenyl sulfur hexafluorophosphate, 3,3'- [Oxybismethylene]bis[3-ethyl]oxetane monomer 39.4 parts, 3-hydroxymethyl-3-ethyloxetane monomer 5 parts, BYK021 defoamer 0.3 parts, 0.3 parts of BYK180 dispersant, 15 parts of titanium dioxide, and 10 parts of superfine barium sulfate.

[0039] Wherein, the oxetane resin is prepared from the following components in parts by weight: 50 parts of 3-ethyl-3-[(ethylene oxide-2-methoxy)methyl]oxetane, tetrabutylene 1 part of ammonium bromide, 24 parts of toluene and 25 parts of succinic anhydride.

[0040] The preparation method is as follows: add oxetane resin, cationic photoinitiator, oxetane monomer, defoamer and dispersant in sequence according to the proportion, and stir at a speed of 400r / min until uniform; then add pigments and fillers , stirred at a speed of 800r / min until uniform; gro...

Embodiment 2

[0043] A quick-drying cationic light-curing auto repair primer, comprising in parts by weight: 30 parts of oxetane resin, 5 parts of 4-phenylthiotriphenylsulfonium hexafluoroantimonate, 3-ethyl acetate -30 parts of 3-[4-[(3-ethyloxetan-3-yl)methoxy]butoxymethyl]oxetane monomer, 3-hydroxymethyl-3- 10 parts of ethyl oxetane monomer, 0.5 part of BYK019 defoamer, 0.5 part of BYK190 dispersant, 14 parts of titanium dioxide, and 10 parts of heavy calcium carbonate. The oxetane resin is prepared from the following components in parts by weight: 40 parts of 3-ethyl-3-[(ethylene oxide-2-methoxy)methyl]oxetane, hexadecyl 0.5 parts of trimethylammonium bromide, 39.5 parts of toluene, and 20 parts of succinic anhydride.

[0044] The preparation method is as follows: add oxetane resin, cationic photoinitiator, 3-ethyl-3-[4-[(3-ethyloxetane-3-yl)methoxy] sequentially according to the proportion Butoxymethyl]oxetane monomer, defoamer, dispersant, stir at a speed of 600r / min until uniform; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com