Gypsum mortar production method, construction method and system

A gypsum mortar and production method technology, applied in the field of building materials, can solve the problems of weakened water resistance, lack of toughness, and water resistance, and achieve the effects of excellent anti-mildew and antibacterial properties, improved comprehensive performance, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

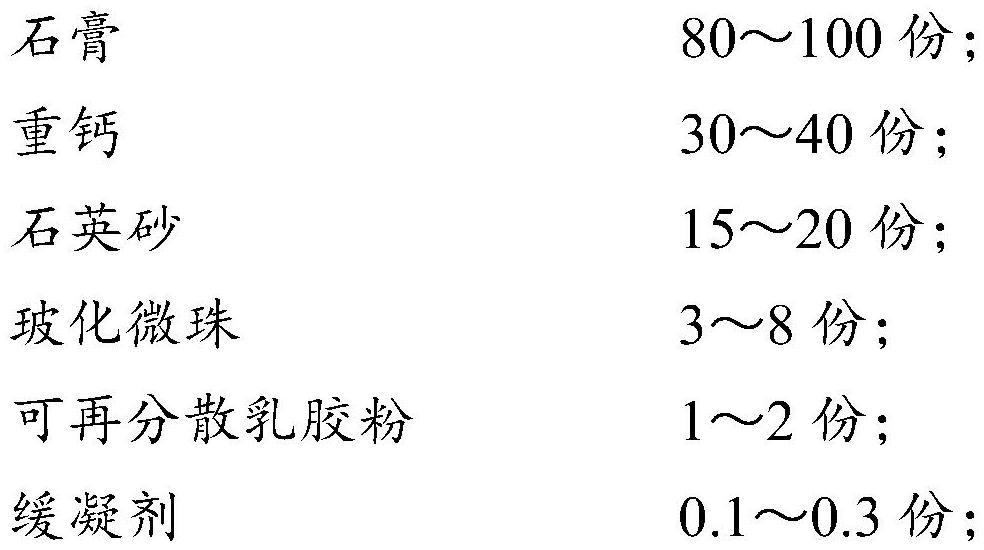

[0033] A kind of gypsum mortar of the present embodiment, its raw material comprises following components by weight:

[0034]

[0035]

[0036] Wherein, the grade of the polyvinyl alcohol is PVA-1788; the fiber is wood fiber, the retarder is a protein retarder, and the viscosity of the HPMC is 6000-8000Pa·S;

[0037] In addition, there are 4 parts of deionized water in 60 parts of water.

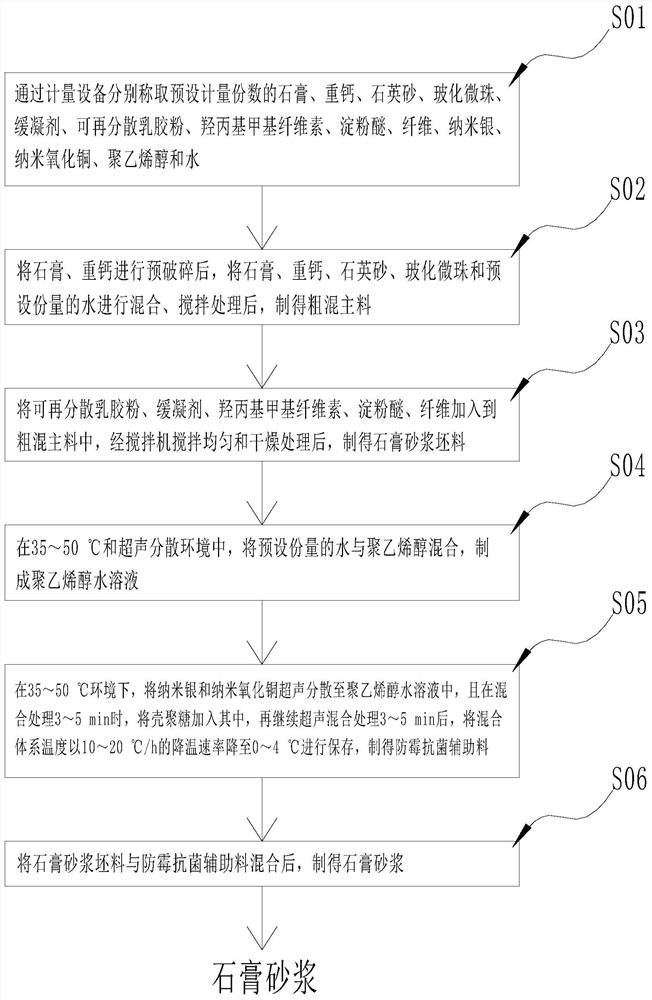

[0038] Based on the above formulation scheme, the present embodiment provides a production method corresponding to gypsum mortar, which specifically includes the following steps:

[0039] S01 Weigh gypsum, heavy calcium, quartz sand, vitrified microbeads, retarder, redispersible latex powder, hydroxypropyl methylcellulose, starch ether, fiber, nano Silver, nano copper oxide, chitosan, polyvinyl alcohol and water;

[0040] S02 After pre-crushing gypsum and heavy calcium, mixing and stirring the gypsum, heavy calcium, quartz sand, vitrified microspheres and 56 parts of water to obtain ...

Embodiment 2

[0046] A kind of gypsum mortar of the present embodiment, its raw material comprises following components by weight:

[0047]

[0048] Wherein, the grade of the polyvinyl alcohol is PVA-1788; the fiber is wood fiber, the retarder is a protein retarder, and the viscosity of the HPMC is 6000-8000Pa·S;

[0049] In addition, 80 parts of water, there are 8 parts of deionized water.

[0050]Based on the above formulation scheme, the present embodiment provides a production method corresponding to gypsum mortar, which specifically includes the following steps:

[0051] S01 Weigh gypsum, heavy calcium, quartz sand, vitrified microbeads, retarder, redispersible latex powder, hydroxypropyl methylcellulose, starch ether, fiber, nano Silver, nano copper oxide, chitosan, polyvinyl alcohol and water;

[0052] S02 After pre-crushing gypsum and heavy calcium, mixing and stirring the gypsum, heavy calcium, quartz sand, vitrified microspheres and 72 parts of water to obtain a rough mix mai...

Embodiment 3

[0058] A kind of gypsum mortar of the present embodiment, its raw material comprises following components by weight:

[0059]

[0060] Wherein, the grade of the polyvinyl alcohol is PVA-1788; the fiber is wood fiber, the retarder is a protein retarder, and the viscosity of the HPMC is 6000-8000Pa·S;

[0061] In addition, there are 6 parts of deionized water in 70 parts of water.

[0062] Based on the above formulation scheme, the present embodiment provides a production method corresponding to gypsum mortar, which specifically includes the following steps:

[0063] S01 Weigh gypsum, heavy calcium, quartz sand, vitrified microbeads, retarder, redispersible latex powder, hydroxypropyl methylcellulose, starch ether, fiber, nano Silver, nano copper oxide, chitosan, polyvinyl alcohol and water;

[0064] S02 After pre-crushing gypsum and heavy calcium, mixing and stirring the gypsum, heavy calcium, quartz sand, vitrified microspheres and 64 parts of water to obtain a rough mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com