High surface activity pitch-based graphite fiber and preparation method thereof, and resin-based composite material prepared based on high surface activity pitch-based graphite fiber

A high surface activity, graphite fiber technology, applied in the direction of carbon fiber, fiber type, fiber treatment, etc., can solve the problem of low shear strength, etc., to improve the bonding ability, increase the interlayer shear strength, and increase the interlayer shear strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

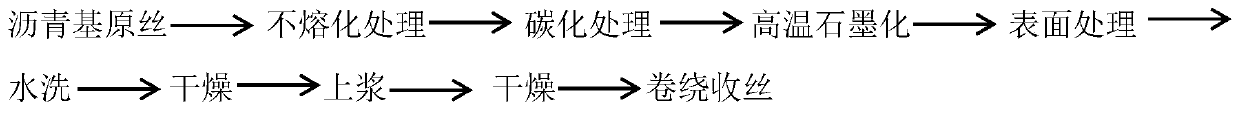

Method used

Image

Examples

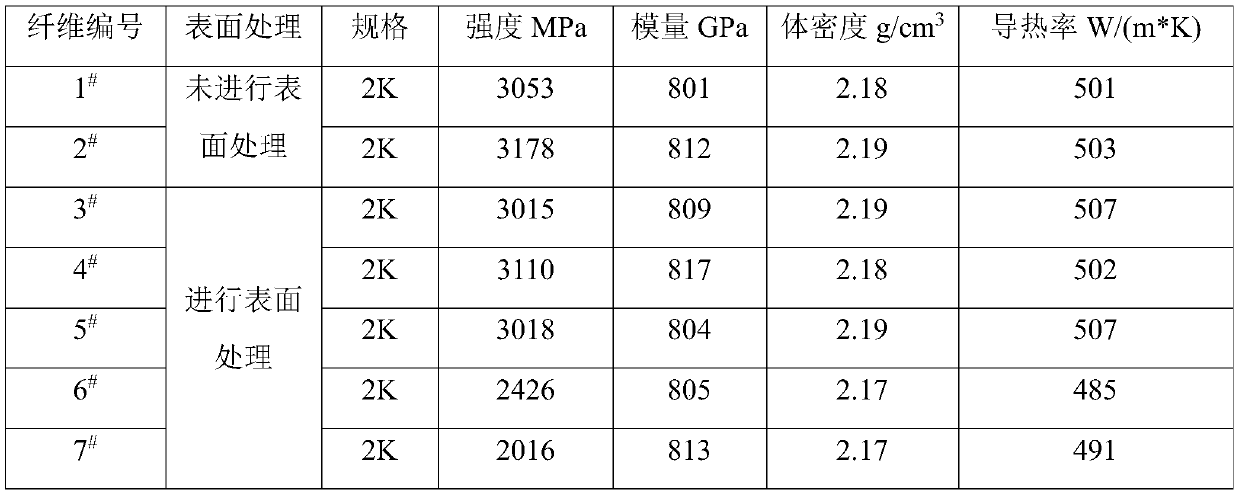

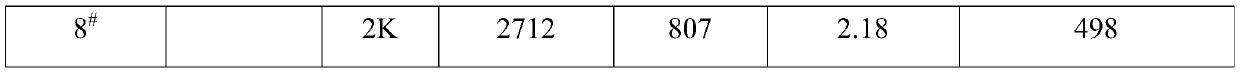

Embodiment 1

[0041] Using mesophase pitch as raw material, 2K pitch-based precursors were prepared by melt spinning, and the fiber diameter (average value) was 20 μm. After the wire unwinding machine automatically unwinds the wire, it is processed by three-roller rollers without melting. The processing temperature is 240°C-300°C (drawing 1%), and the compressed air flow rate is 3m. 3 / h, the residence time of the fiber in the furnace is controlled at 1000s; the low-temperature carbonization treatment is carried out by passing through three rollers, the treatment temperature is 450°C-700°C (drawing -1.5%), and the residence time of the fiber in the furnace is controlled at 300s under nitrogen protection. High-temperature carbonization treatment is carried out on three-roll rollers at a temperature of 800°C to 1500°C (drawing 0.5%), and graphitization treatment is carried out on five-roll rollers at a treatment temperature of 2600°C (drawing 0.5%) under argon protection. The residence time i...

Embodiment 2

[0043]Using mesophase pitch as raw material, 2K pitch-based precursors were prepared by melt spinning, and the fiber diameter (average value) was 20 μm. After the wire unwinding machine automatically unwinds the wire, it is processed by three-roller rollers without melting. The processing temperature is 240°C-300°C (drawing 1%), and the compressed air flow rate is 3m. 3 / h, the residence time of the fiber in the furnace is controlled at 1000s; the low-temperature carbonization treatment is carried out by passing through three rollers, the treatment temperature is 450°C-700°C (drawing -1.5%), and the residence time of the fiber in the furnace is controlled at 300s under nitrogen protection. High-temperature carbonization treatment with three rollers at a temperature of 800°C to 1600°C (drawing 0.5%), graphitization at five rollers at a temperature of 2600°C (drawing 0.5%), under argon protection, the fiber The residence time in the furnace is controlled at 100s, and the passing...

Embodiment 3

[0045] Using mesophase pitch as raw material, 2K pitch-based precursors were prepared by melt spinning, and the fiber diameter (average value) was 20 μm. After the wire unwinding machine automatically unwinds the wire, it is processed by three-roller rollers without melting. The processing temperature is 240°C-300°C (drawing 1%), and the compressed air flow rate is 3m. 3 / h, the residence time of the fiber in the furnace is controlled at 1000s; the low-temperature carbonization treatment is carried out by passing through three rollers, the treatment temperature is 450°C-700°C (drawing -1.5%), and the residence time of the fiber in the furnace is controlled at 300s under nitrogen protection. High-temperature carbonization treatment with three rollers at a temperature of 800°C to 1600°C (drawing 0.5%), graphitization at five rollers at a temperature of 2600°C (drawing 0.5%), under argon protection, the fiber The residence time in the furnace is controlled at 100s, and the passin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com