Composite enhanced baffle containing glass fibers and preparation method thereof

A glass fiber composite and reinforced technology, used in electrical components, circuits, battery pack components, etc., can solve problems such as fragile or cracked, low strength, brittle texture, etc., to prevent premature failure, long life, and pore size. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

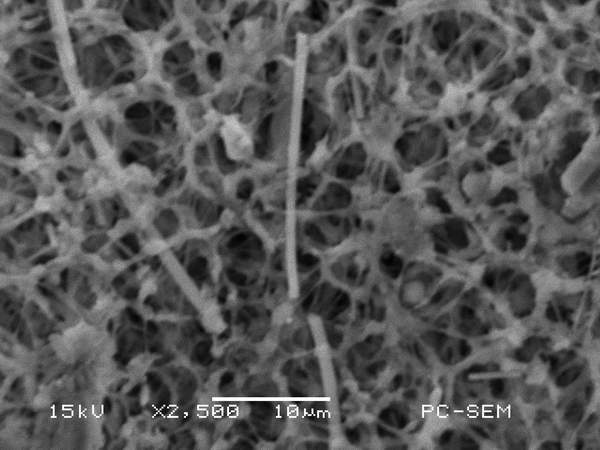

[0032] Weigh 35.0g of dry PVC resin powder according to the weight ratio, and the specific surface area is 150m 2 / g SiO 2 55 g of particles, 9.9 g of medium-alkali glass fiber wool with a diameter of 1 μm and a length of 0.5 mm, and 0.1 g of carbon black. Put the weighed raw materials in the reaction kettle, add acetone under the condition of stirring to make the system mix uniformly, and control the viscosity of the system to 200.0 Pa.s to obtain the mixture A. The above-mentioned mixture A was formed by extruding and calendering at room temperature to make a thin sheet with a thickness of 0.1 mm. After molding, it is leached in warm water at 40°C for 2 minutes, and then dried in a drying tunnel at 40°C for 40 minutes to obtain a glass fiber composite reinforced separator. The microscopic morphology of the separator surface is as follows figure 1 As shown, the glass fibers are evenly distributed in the porous structure, and the material has high porosity and uniform pore ...

Embodiment 2

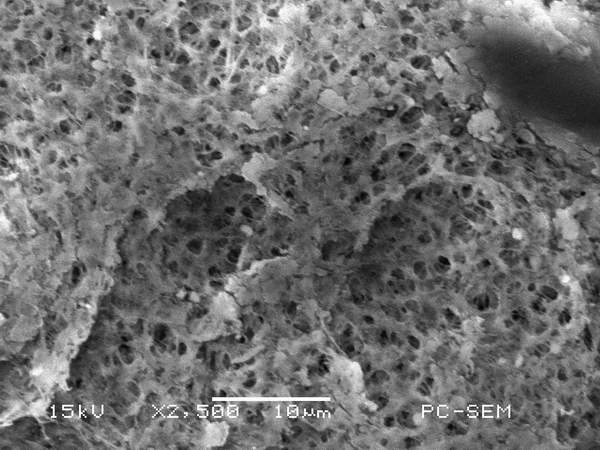

[0034] Weigh 89.0g of dry PVC resin powder according to the weight ratio, and the specific surface area is 200m 2 / g SiO 2 9 g of particles, 1.9 g of medium-alkali glass fiber cotton with a diameter of 10 μm and a length of 5 mm, and 0.1 g of graphite. Put the weighed raw materials in the reaction kettle, add tetrahydrofuran under stirring conditions to make the system uniformly mixed, and control the viscosity of the system to 10.0 Pa.s to obtain the mixture A. The above-mentioned mixture A was formed by extruding and calendering at room temperature to make a thin sheet with a thickness of 0.5 mm. After molding, it is leached in warm water at 30°C for 10 minutes, and then dried in a drying tunnel at 60°C for 20 minutes to obtain a glass fiber composite reinforced separator. The microscopic morphology of the separator surface is as follows figure 2 As shown, the glass fibers are uniformly distributed in the porous structure, and the material has high porosity and uniform p...

Embodiment 3

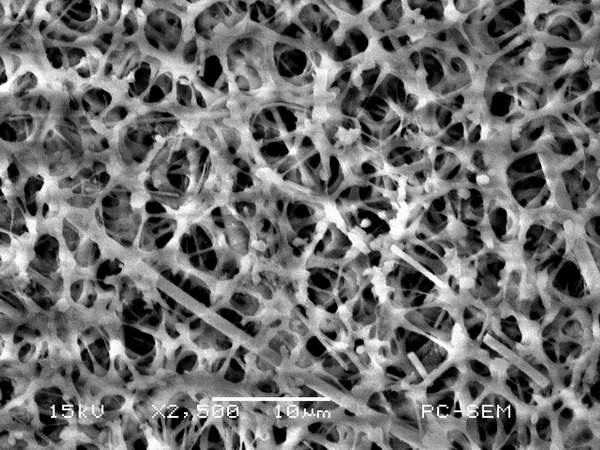

[0036] Weigh 52g of dry PVC resin powder according to the weight ratio, and the specific surface area is 200m 2 / g SiO 242.1 g of particles, 0.9 g of non-alkali glass fiber cotton with a diameter of 5 μm and a length of 2.5 mm, and 5.0 g of carbon black. Put the weighed raw materials in the reaction kettle, add dimethyl sulfoxide under stirring condition to make the system evenly mixed, and control the viscosity of the system to 102.3Pa.s to obtain the mixture A. The above-mentioned mixture A was formed by extruding and calendering at room temperature to make a thin sheet with a thickness of 1.0 mm. After molding, it is leached in warm water at 35°C for 5 minutes, and then dried in a drying tunnel at 56°C for 34 minutes to obtain a glass fiber composite reinforced separator. The microscopic morphology of the separator surface is as follows image 3 As shown, the glass fibers are evenly distributed in the porous structure, and the material has high porosity and uniform pore ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com