Organic silicon-fluorine modified resin and coating preparation method

A silicon-fluorine modification and organosilicon technology, applied in the field of fluorine-modified resin and organosilicon, can solve the problems of easy contamination and cleaning on the surface of the coating, poor solvent resistance, and high surface tension of the coating, and achieve excellent comprehensive physical and chemical properties, The best physical and mechanical properties, the effect of low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

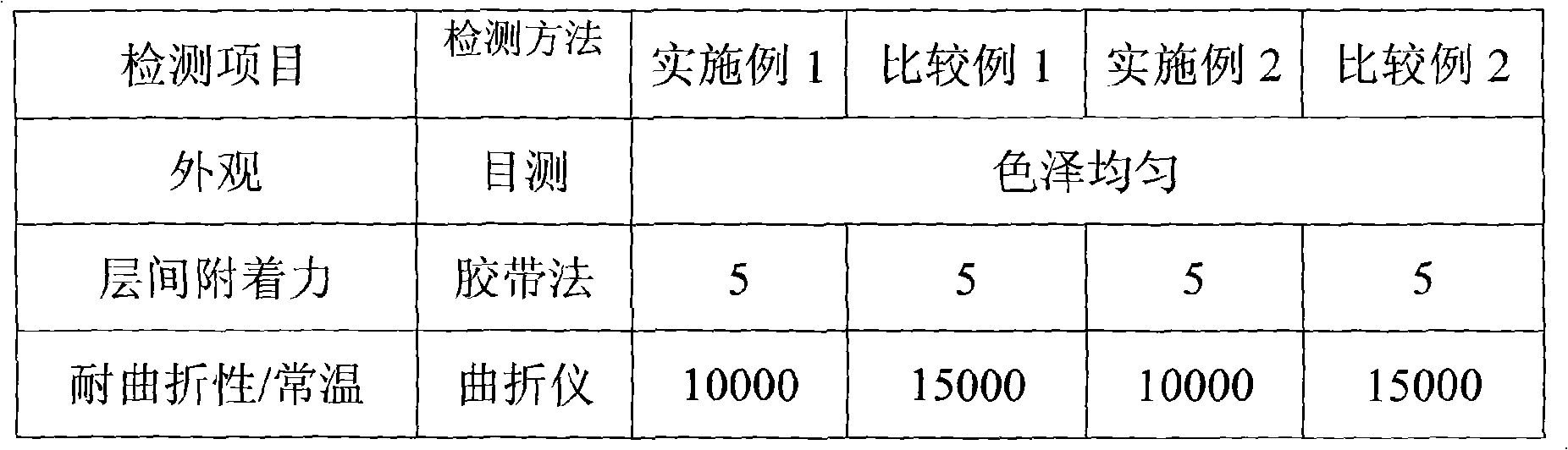

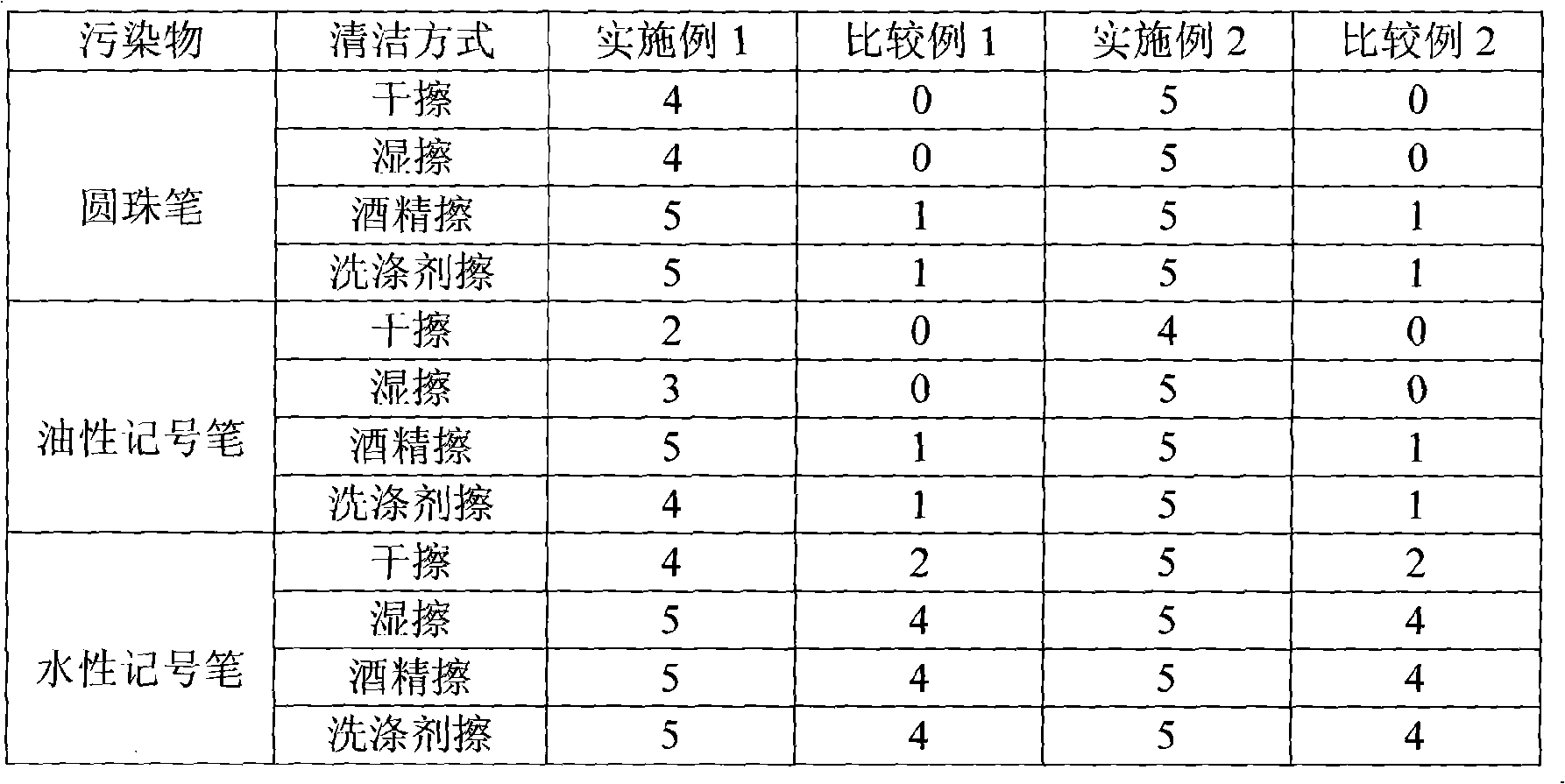

Embodiment 1

[0036] Preparation of silicon-fluorine modified resin: Dow Corning Z-6030 silane (DOW CORNING) 5wt%, fluororesin 23-28 (Waker) 2wt%, acrylic resin YD582-2 (Far East Chemical) 5wt%, polyurethane resin HDBU-6025 (Shanghai Huide Resin Co., Ltd.) 30wt%, xylene (Wenxin) 18wt%, MEK (wantuming) 15wt%, DMF 25wt%; mix the above raw materials in proportion to obtain organic silicon fluorine modified resin;

[0037] Preparation of coating slurry (by weight): Weigh 100 parts of silicon-fluorine modified resin, slowly add 25 parts of curing agent HDN-75 (Huide), stir evenly, and then slowly add 25 parts of accelerator HDC- 01 (Huide), stir while adding, until the mixture is uniform, adjust the viscosity to 800-1500cp with butyl acetate (Wenxin), and let it stand for later use;

[0038] Use a 100-mesh anilox wheel to print on the surface of cowhide, PU leather, and PVC leather respectively, dry at 150°C for 3 minutes, and dry at 170°C for 15 seconds, and the coating thickness is 1-10 μm.

Embodiment 2

[0042] Preparation of silicon-fluorine modified resin: silicone resin TEGO PROTECT 5001 (TEGO) 2.6wt%, acrylic resin YD582-2 (Far East Chemical) 3.4wt%, polyurethane resin HDBU-6025 (Huide) 24wt%, 150# solvent 20wt% %, butyl acetate 50wt%, the above-mentioned raw materials are mixed uniformly in proportion to obtain silicon-fluorine modified resin;

[0043]Preparation of coating slurry (by weight ratio): Weigh 100 parts of silicon-fluorine modified resin, slowly add 20 parts of curing agent HDN-75 (Huide), stir evenly, and then slowly add accelerator HDC-01 ( Huide) 5 parts, add and stir until the mixture is uniform, use about 150 parts of tetrahydrofuran (Wenxin) to adjust the viscosity to 800-1500cp, and let it stand for later use;

[0044] Use a 60-mesh screen roller to roll coat the surface of the PVC leather, dry at 130°C for 3 minutes, and dry at 160°C for 60 seconds, with a coating thickness of 10-30 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com