Novel oil bath rotary table

A technology of turntable and oil bath, applied in the direction of electrical components, antennas, etc., can solve the problems of shortened service life of turntable, fast component damage, easy oil leakage, etc., to achieve the effect of increasing service life and optimizing maintenance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

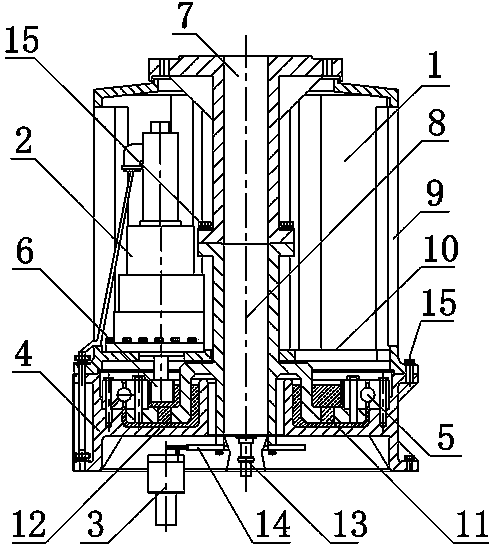

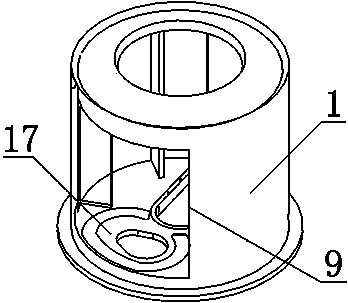

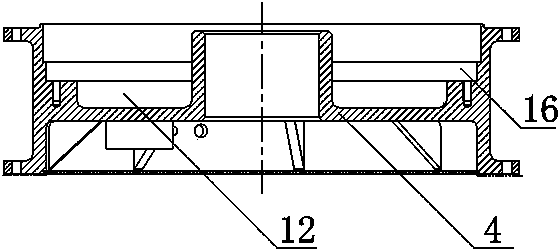

[0019] Such as figure 1 with figure 2 As shown, the new oil bath turntable includes a turntable shell 4, a turntable cover 1, an upper spindle 7, a lower spindle 8 and an azimuth reducer 2. An oil tank 12 is arranged on the upper part of the turntable shell 4, and the inside of the oil tank 12 is filled with lubricating oil 11. The outer wall of the oil tank 12 is provided with an annular stepped groove 16, the bearing 5 is installed in the annular stepped groove 16, the lower main shaft 8 is installed on the inner ring of the bearing 5, the lower end surface of the turntable outer cover 1 and the upper end surface of the turntable casing 4 are fixed by bolts 15 connection, the outer wall of the turntable cover 1 is provided with at least one door 9, the bottom of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com