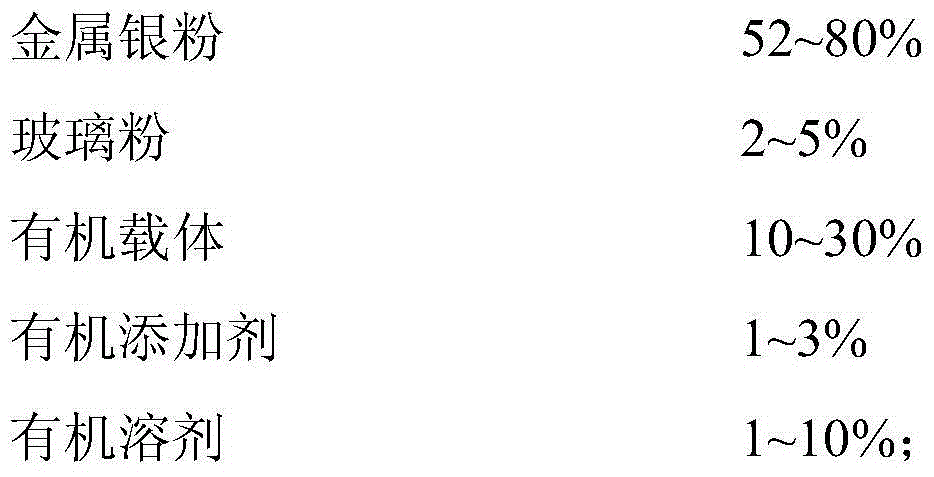

High-temperature and high-humidity resistant electrode silver paste for ZnO piezoresistor and preparation method for electrode silver paste

A varistor, high temperature resistant technology, applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. Wet performance and other issues, to achieve the effect of improving electrical conductivity, superior structural compactness, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

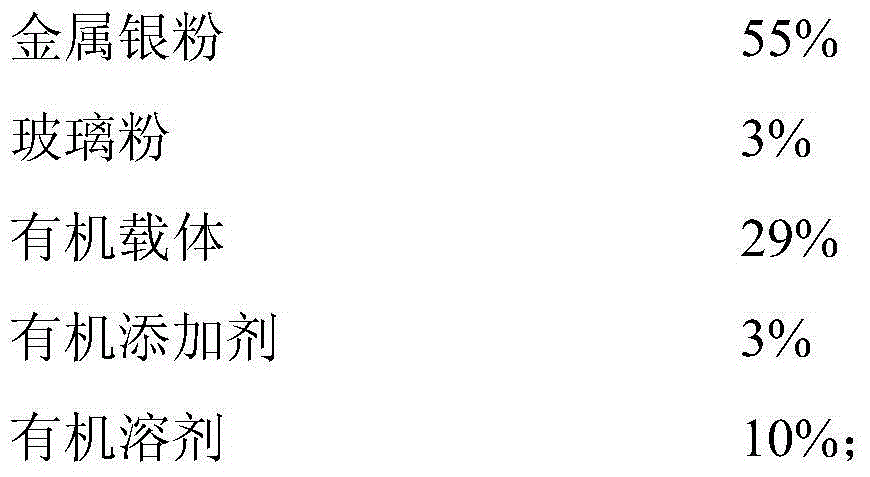

[0030] In this embodiment, a high temperature and high humidity resistant ZnO varistor electrode silver paste, the electrode silver paste includes the following components and weight percentages: metal silver powder 55%, glass powder 3%, organic carrier 29%, organic additives 3% and organic solvent 10%.

[0031] Among them, the metallic silver powder is spherical silver powder with a particle size of 0.95 μm and a tap density of 2.2 g / ml. The glass powder is lead-free glass powder, and the thermal expansion coefficient is 115×10 -7 / °C, the sintering temperature is 650°C, the glass powder includes the following components and weight percentages: Bi 2 O 3 79%, ZnO8%, B 2 O 3 7%, SiO 2 3%, Na 2 O2%, TiO 2 0.5% and Al2 O 3 0.5%.

[0032] The organic carrier is formed by mixing ethyl cellulose and terpineol, and the specific preparation method is as follows: according to the mass ratio of ethyl cellulose and terpineol being 1:4, adding ethyl cellulose into terpineol, heat...

Embodiment 2

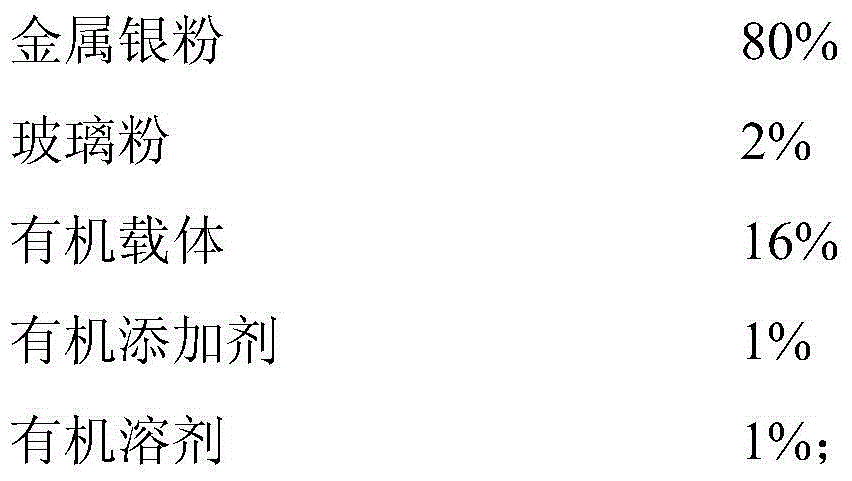

[0041] In this embodiment, a high temperature and high humidity resistant ZnO varistor electrode silver paste, the electrode silver paste includes the following components and weight percentages: 80% of metal silver powder, 2% of glass powder, 16% of organic carrier, organic additive 1% and organic solvent 1%.

[0042] Among them, the metallic silver powder is spherical silver powder, the particle size is 1.2 μm, and the tap density is 2.5 g / ml. The glass powder is lead-free glass powder, and the thermal expansion coefficient is 110×10 -7 / °C, the sintering temperature is 550°C, the glass powder includes the following components and weight percentages: Bi 2 O 3 81%, ZnO6.5%, B 2 O 3 6.5%, SiO 2 2%, Na 2 O3%, TiO 2 0.5% and Al 2 O 3 0.5%.

[0043] The organic carrier is formed by mixing nitrocellulose and tripropylene glycol monomethyl ether, and the specific preparation method is as follows: according to the mass ratio of nitrocellulose and tripropylene glycol monome...

Embodiment 3

[0052] In this embodiment, a high temperature and high humidity resistant ZnO varistor electrode silver paste, the electrode silver paste includes the following components and weight percentages: metal silver powder 70%, glass powder 5%, organic carrier 18%, organic additives 2% and organic solvent 5%.

[0053] The metallic silver powder is spherical silver powder with a particle size of 1.5 μm and a tap density of 3.0 g / ml. The glass powder is lead-free glass powder, and the thermal expansion coefficient is 120×10 -7 / °C, the sintering temperature is 750°C, the glass powder includes the following components and weight percentages: Bi 2 O 3 79%, ZnO8%, B 2 O 3 7%, SiO 2 3%, Na 2 O2%, TiO 2 0.5% and Al 2 O 3 0.5%.

[0054] The organic carrier is formed by mixing ethyl cellulose, nitrocellulose, diethylene glycol butyl ether and dipropylene glycol monomethyl ether, and the specific preparation method is as follows: press ethyl cellulose, nitrocellulose, diethylene glyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com