Production process of ceramic tile capable of accurately positioning dry particles, and product thereof

A technology of precise positioning and production process, applied in the field of architectural ceramics, can solve the problems of poor performance and poor stereoscopic effect of ceramic tiles, and achieve the effect of good texture pattern, bright color and texture, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to facilitate the understanding of the present invention, a more complete description of the present invention follows. The present invention can be implemented in many different forms and is not limited to the embodiments described herein. On the contrary, these embodiments are provided to make the understanding of the disclosure of the present invention more thorough and comprehensive.

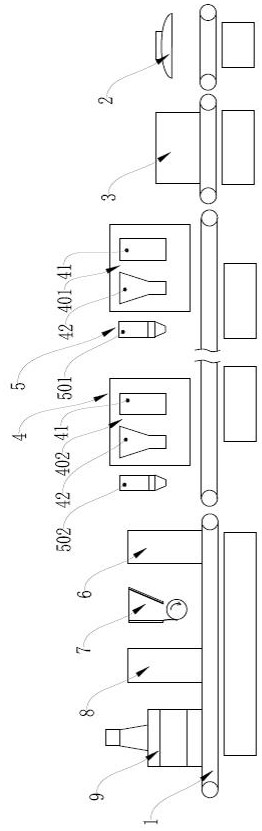

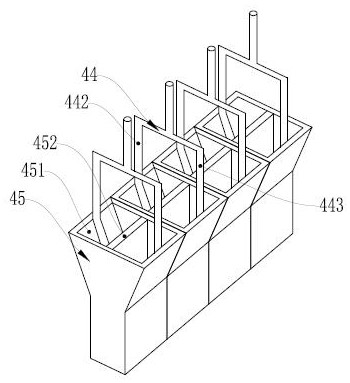

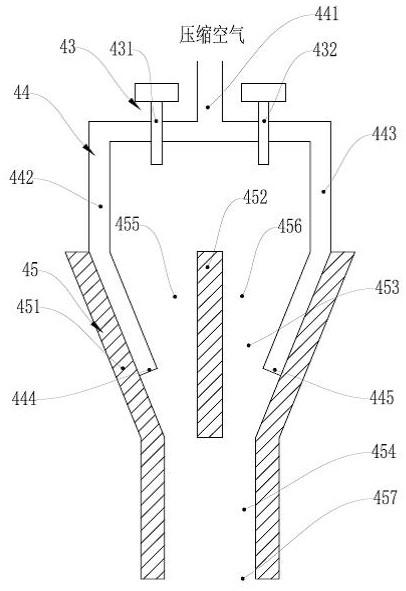

[0044] Such as Figure 1 to Figure 4 Shown, a kind of production technology of the ceramic tile of precise positioning dry grain, comprises the following steps:

[0045] A, apply the bottom glaze on the ceramic tile surface through the glazing device 2;

[0046] B. Digitally print the surface glaze through the glaze printing device 3;

[0047] C. Print the glue ink pattern on the first limited area of the ceramic tile surface through the glue sizing unit 41 of the dry particle printing device 4, and then position and distribute in the first limited area through the dry p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com