Patents

Literature

164results about How to "Improve the fire effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

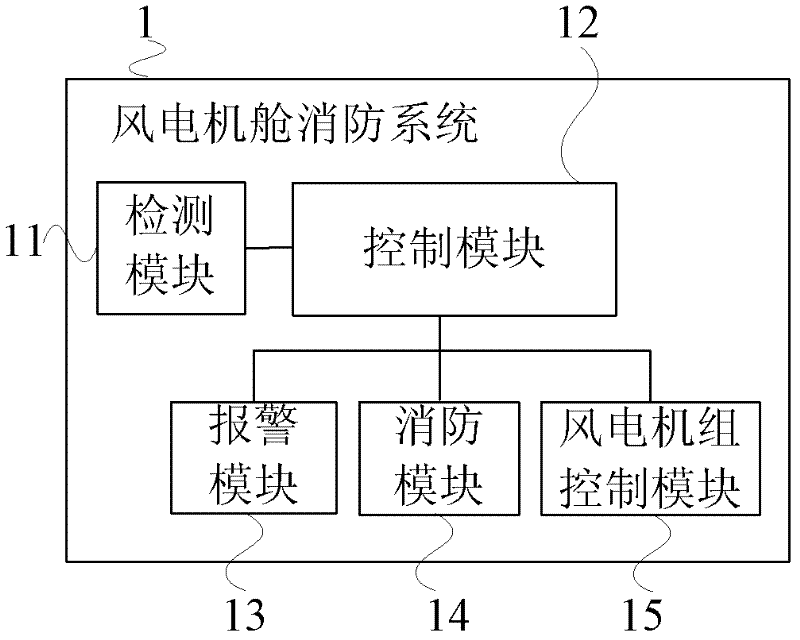

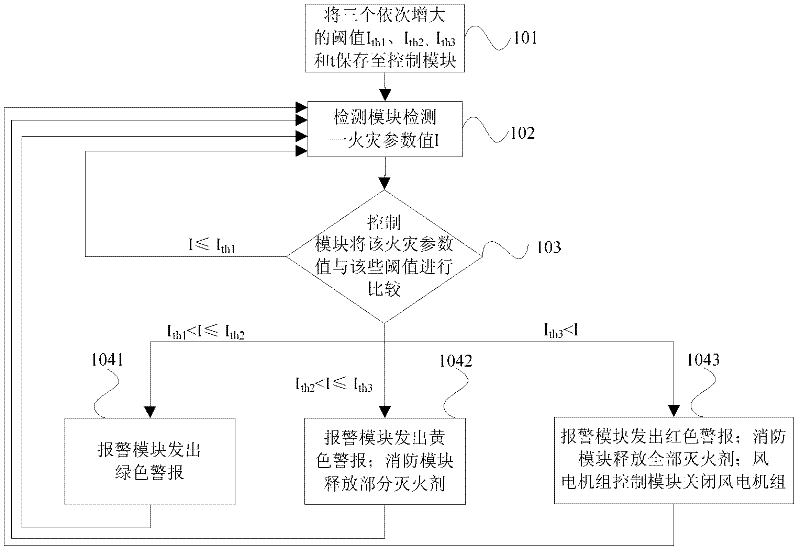

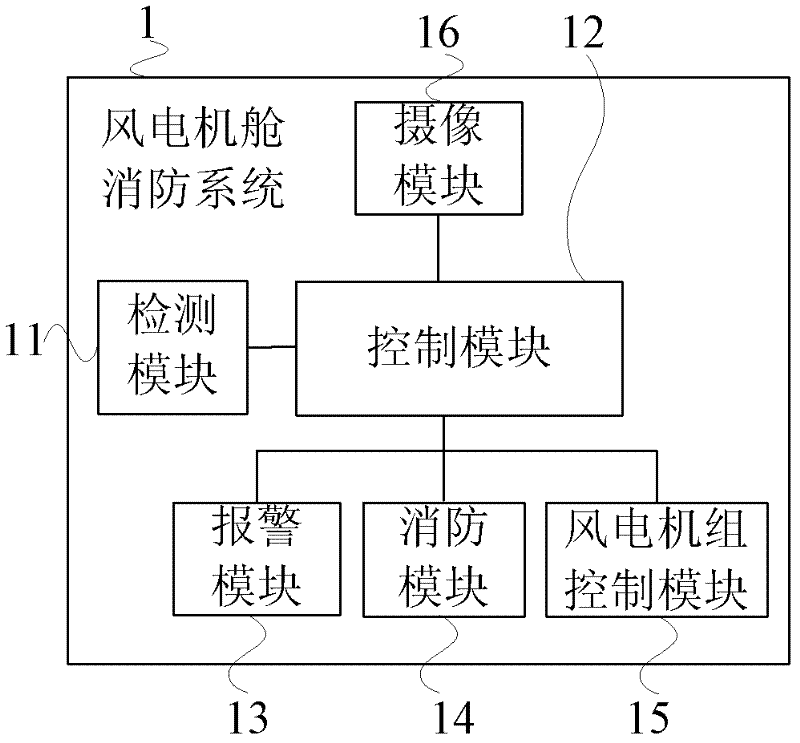

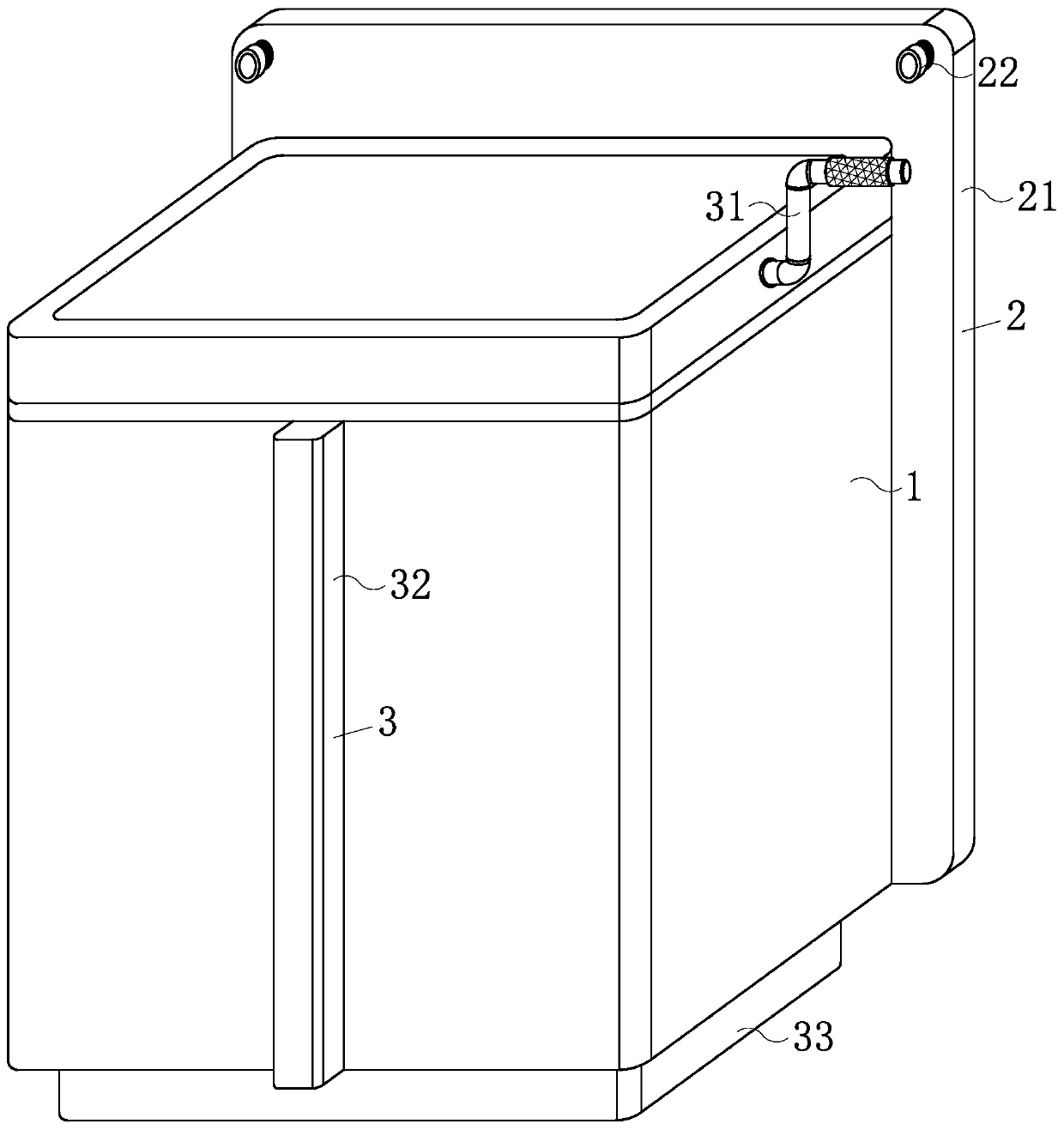

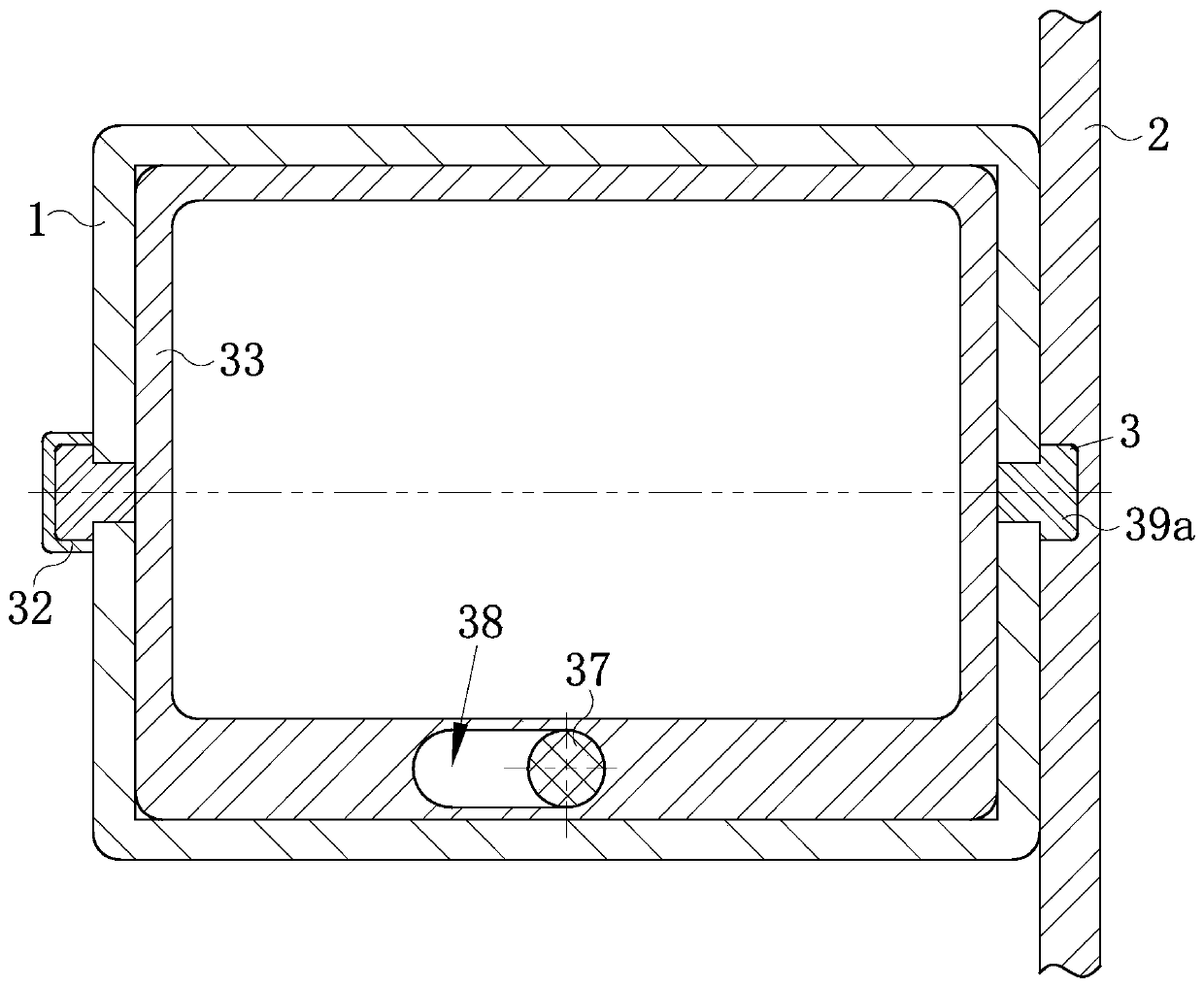

Wind power generator cabin fire-extinguishing system

The invention discloses a wind power generator cabin fire-extinguishing system, which comprises a detection module, a fire-extinguishing module, a wind generation set control module, an alarm module and a control module, wherein the detection module is used for periodically detecting a fire disaster parameter value in a wind power generator cabin; the fire-extinguishing module is used for distinguishing fire in the wind power generator cabin; the wind generation set control module is used for controlling the startup and shutdown of a wind generation set; the alarm module is used for alarming; the control module is used for saving at least two threshold values; these threshold values are used for classifying a fire disaster in the wind power generator cabin into a plurality of fire disaster levels according the severity degree; the alarm module has a plurality of alarm modes; the fire-extinguishing module has a plurality of fire-extinguishing modes; and the wind generation set control module is used for controlling the startup and shutdown of the wind generation set. These alarm modes, these fire-extinguishing modes and the startup and shutdown of the wind generation set can be combined into a plurality of different fire-fighting modes. According to the wind power generator cabin fire-extinguishing system, a fire-extinguishing way can be adopted in time according to the level of a fire disaster, so that a fire-fighting effect is more effective.

Owner:SHANGHAI AUSTRI WIND POWER TECH

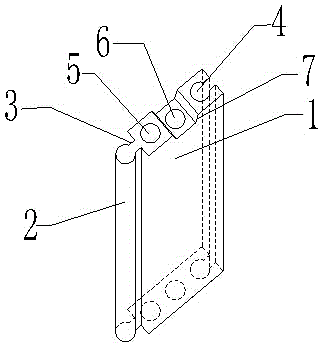

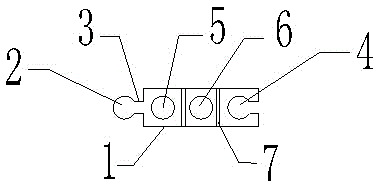

Tool for rapidly installing insulation piercing connector

InactiveCN106299765AWith self-hanging functionQuick installationApparatus for overhead lines/cablesFastening/insulating connecting partsEngineeringMechanical engineering

Owner:CAS HEFEI INST OF TECH INNOVATION +3

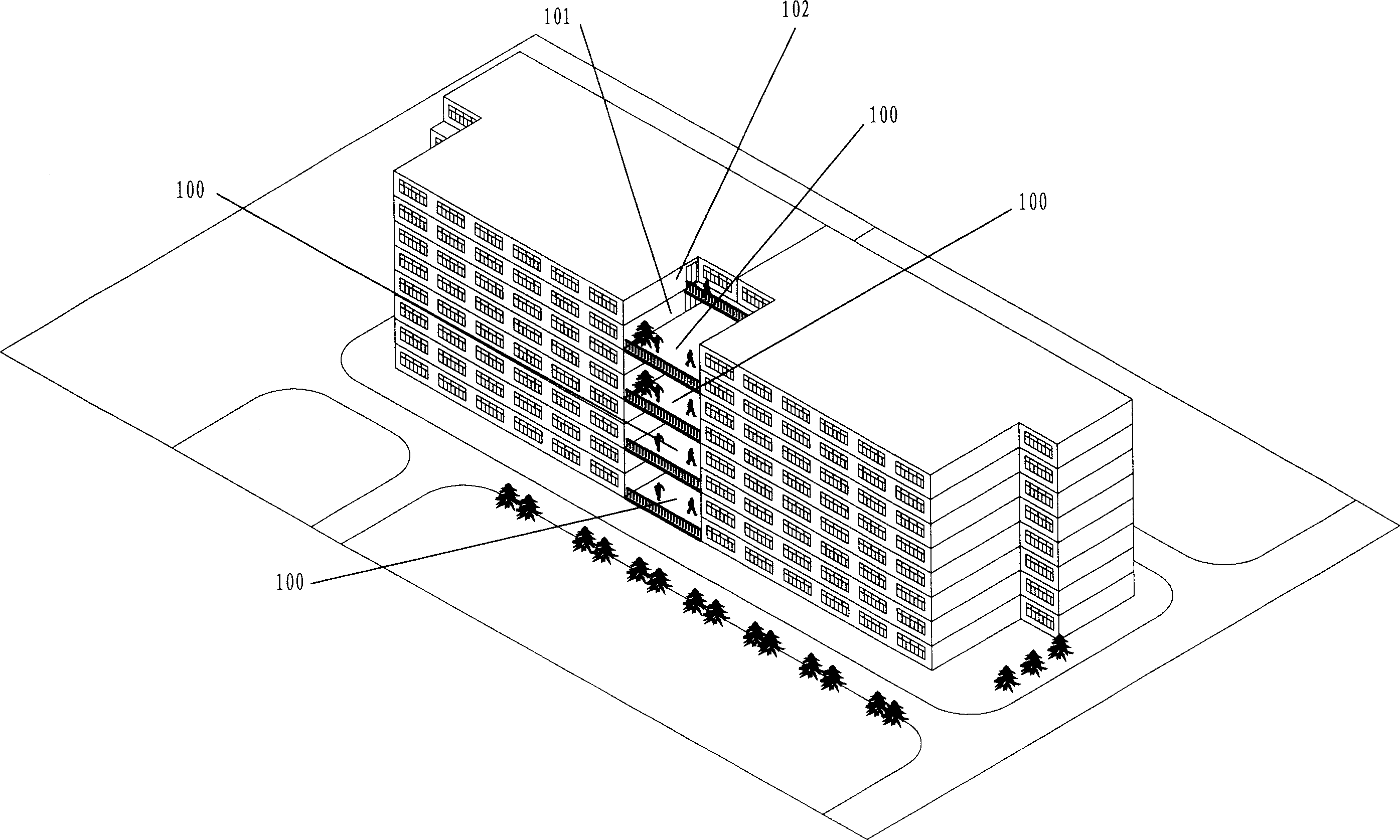

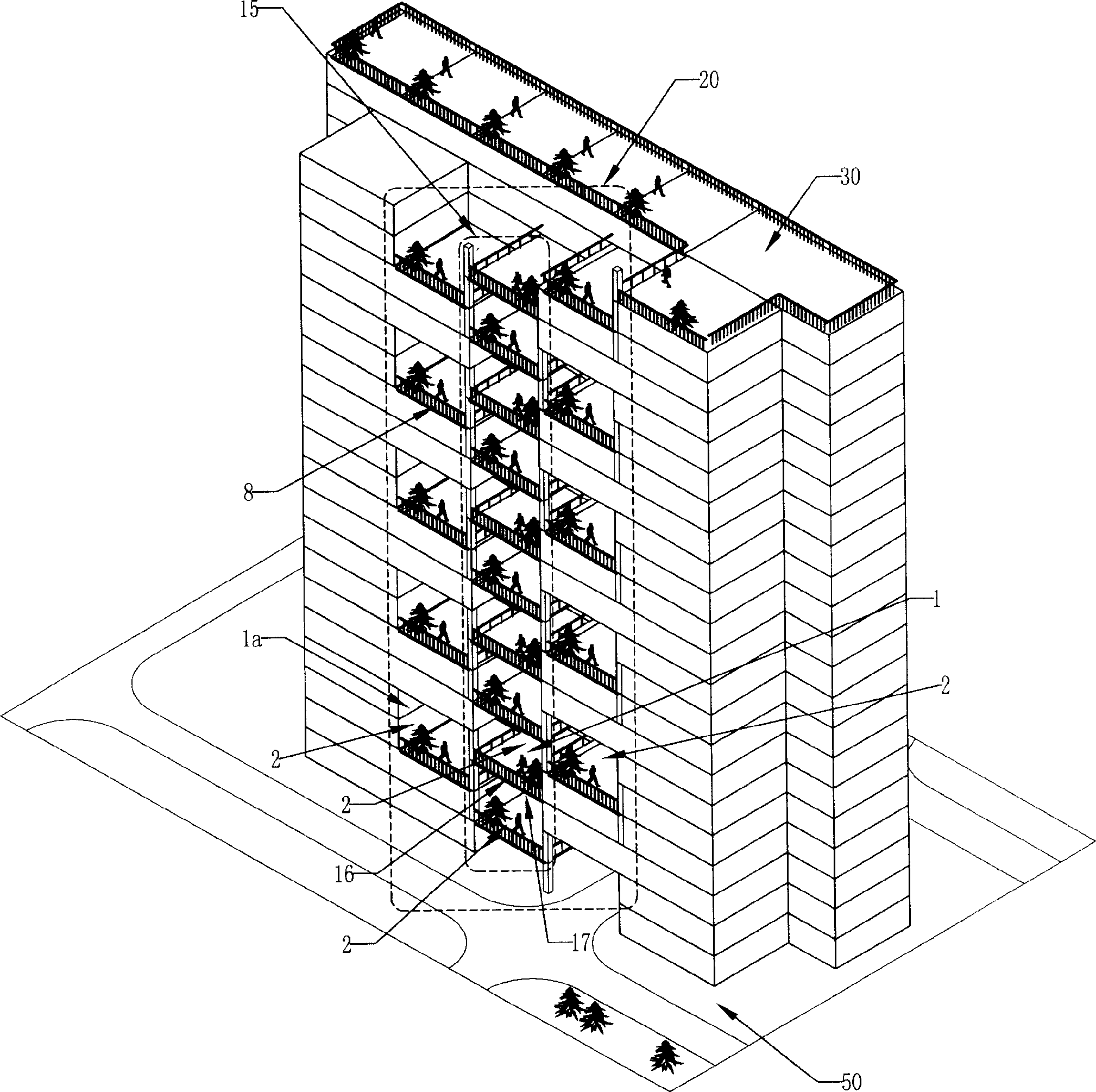

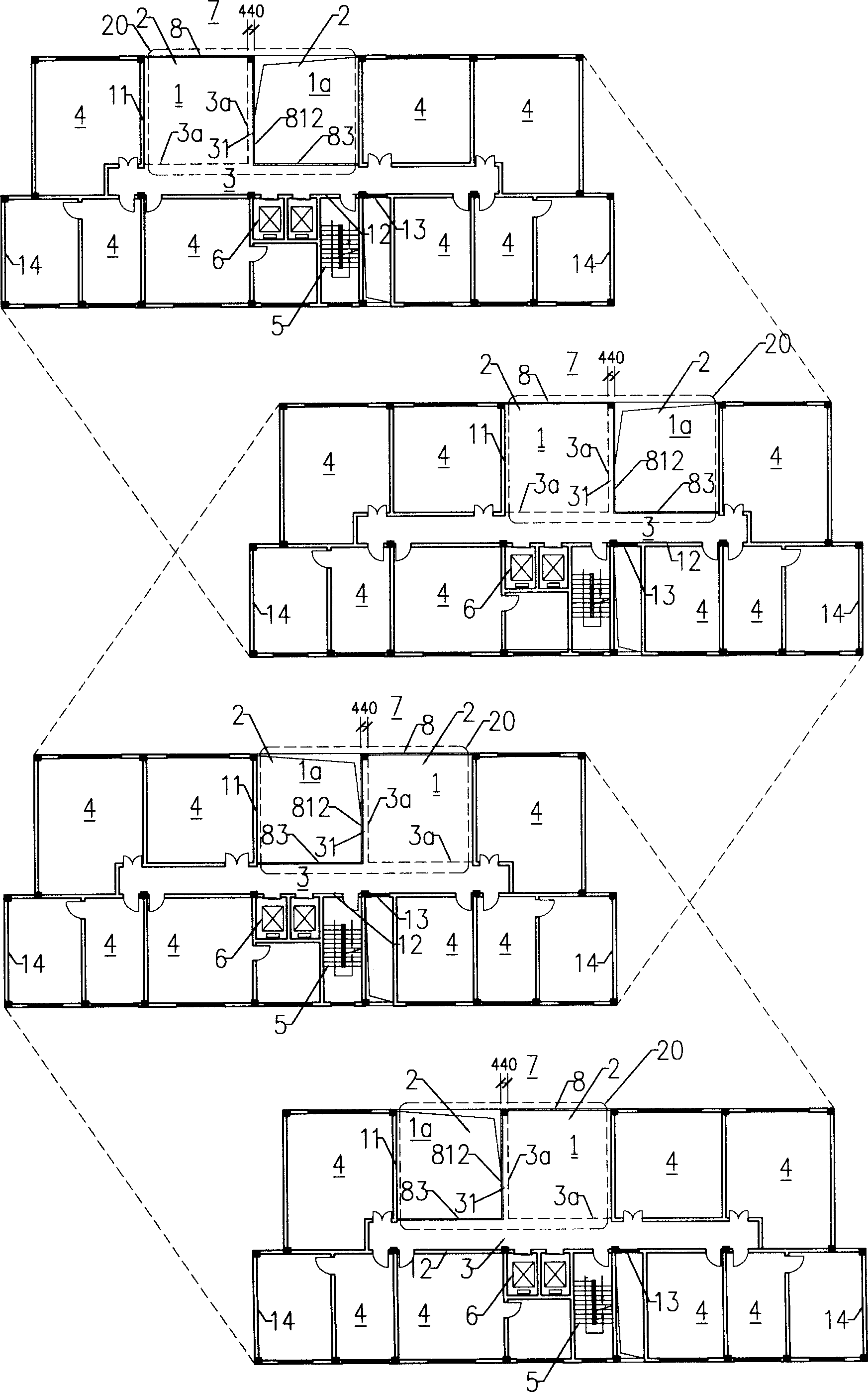

Multistory building

Owner:郭建军

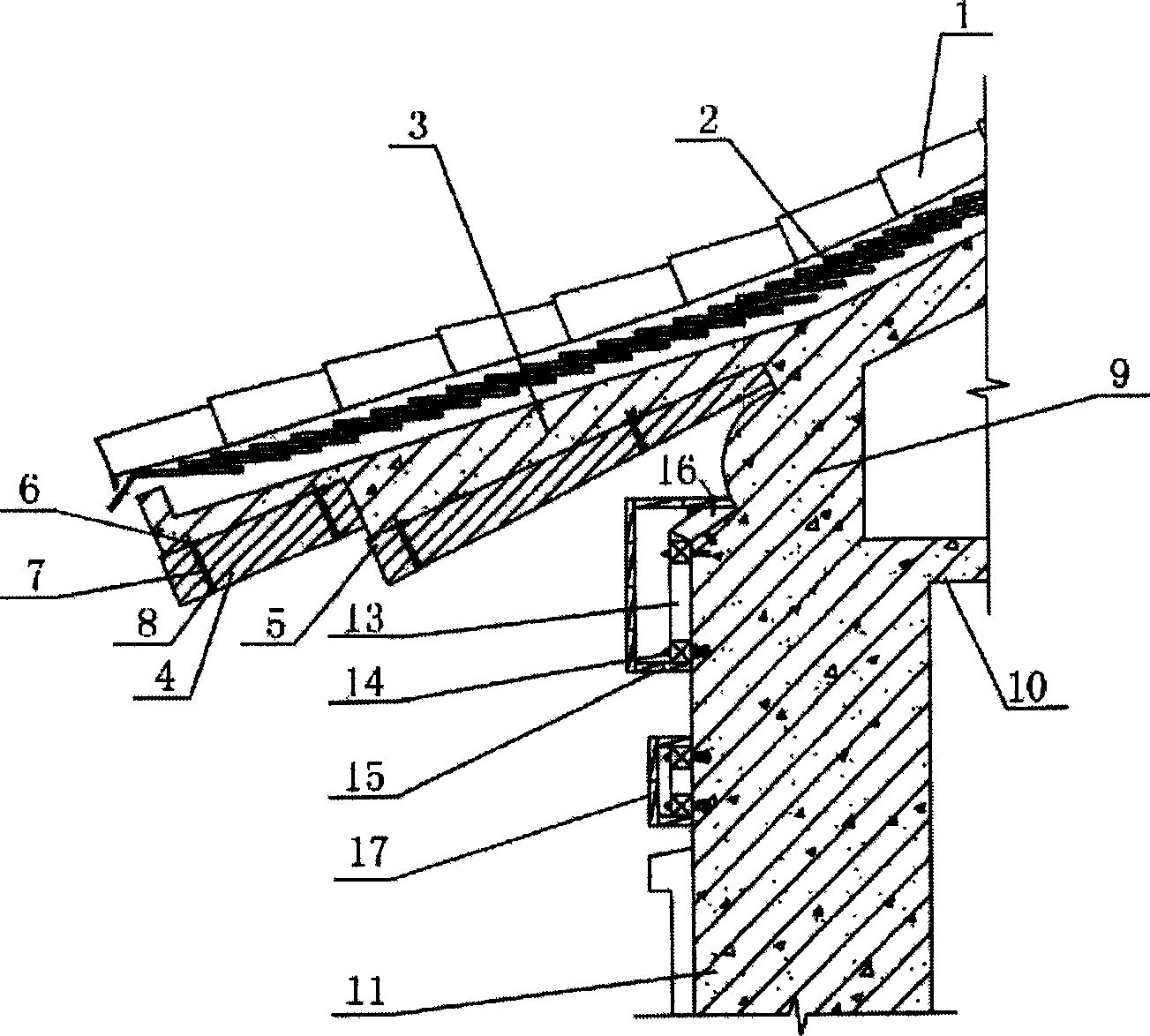

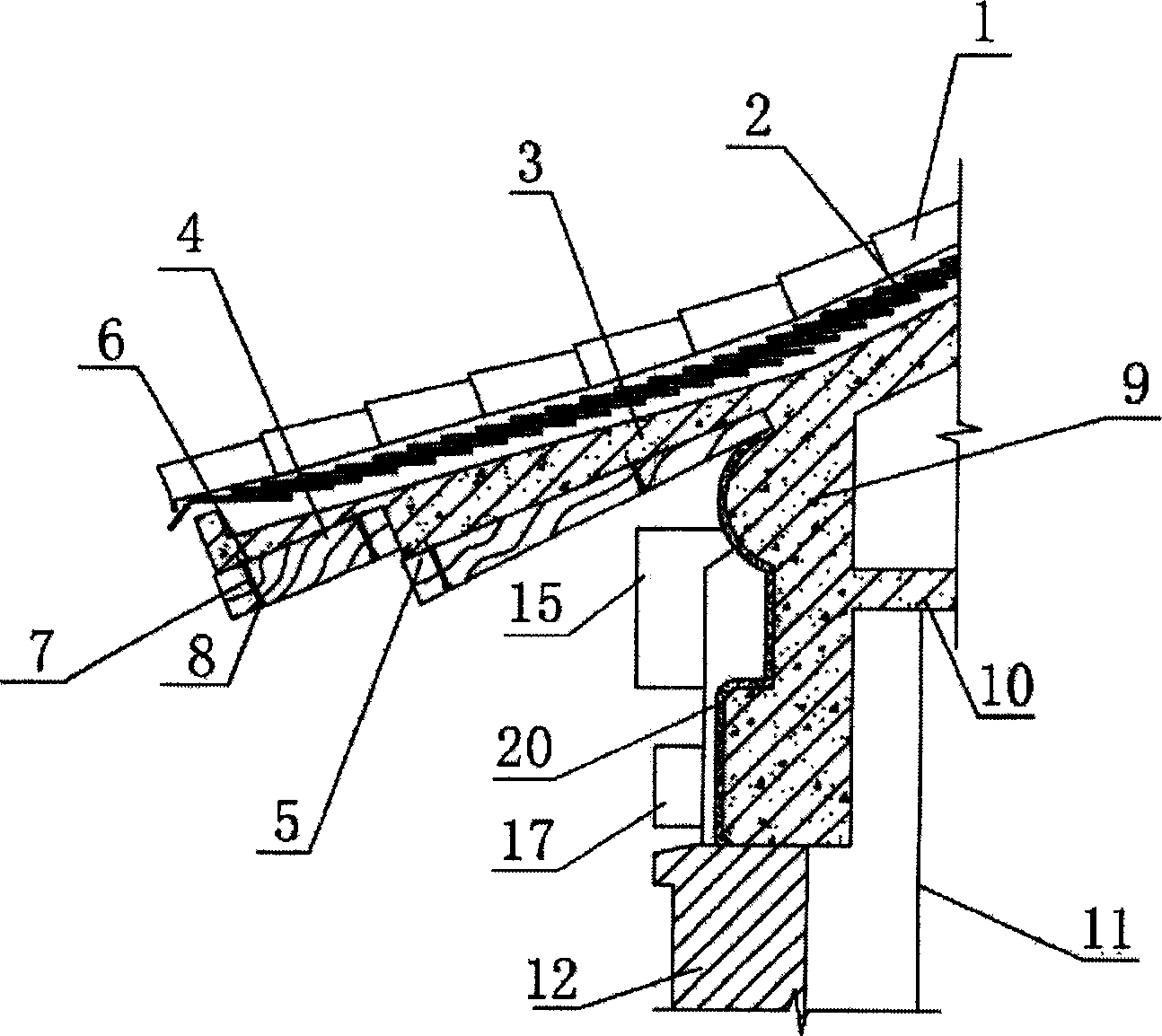

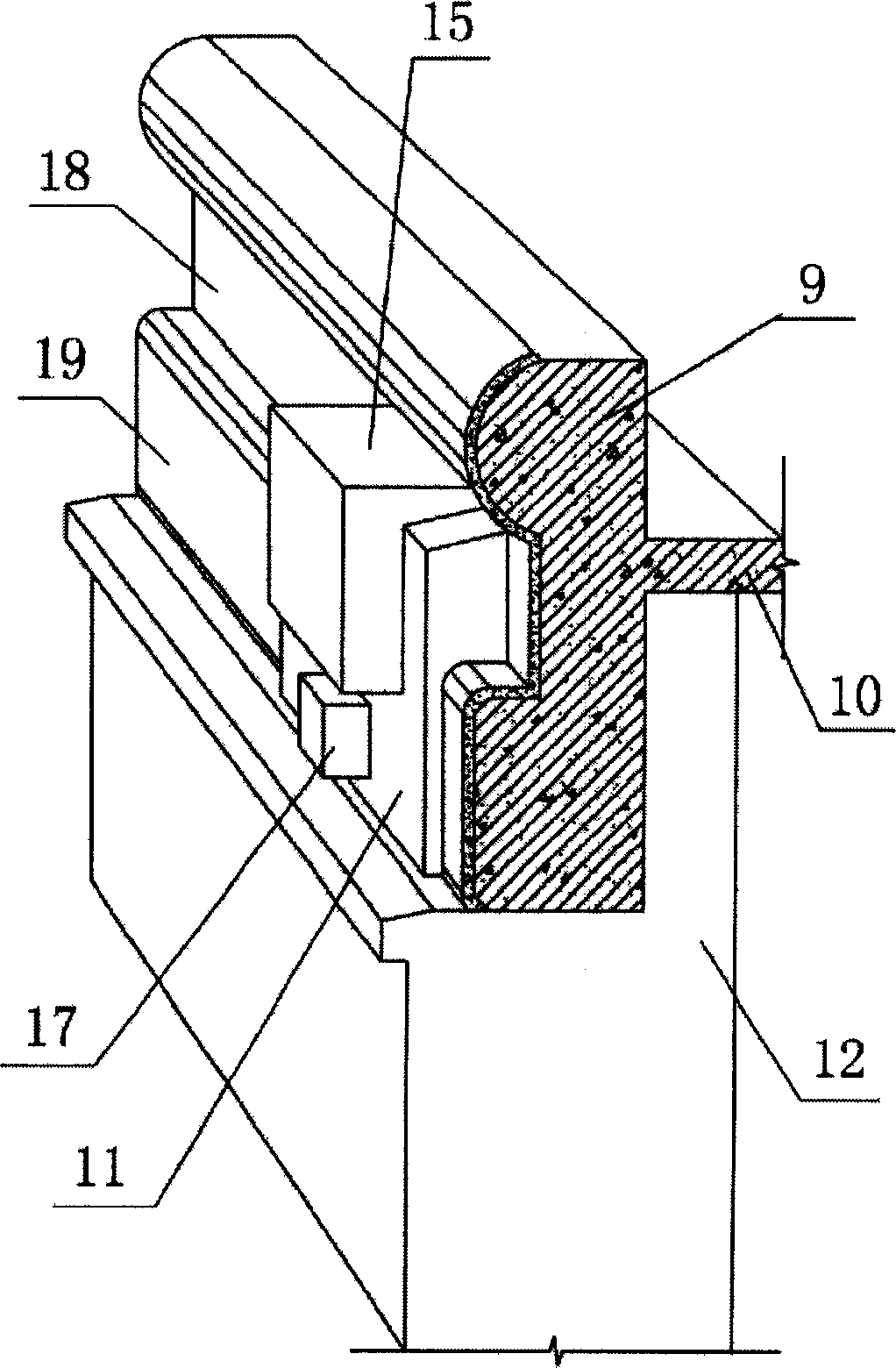

Archaized architecture and its construction method

The invention relates to a pseudo-classic building and relative method, wherein the eave is formed by cylinder tile, sheet tile, roof panel, flying eave, eave edge, and post head; the post head is formed by eave edge, eave sheet and eave beam; the roof panel and post head are poured integrated; the bottom eave open of concrete roof panel has two steps; the outer step is fixed with wooden flying eave; the inner step is fixed with wooden eave edge; each step has at least tow rows of pre-embedded flat iron; the pre-embedded flat iron is connected to the bolt rod; the bolt rod is through the wooden flying eave or wooden eave edge; the nut fixes the wooden flying eave and wooden eave edge on the bottom of eave open; the nut is sealed with pastern ash; the concrete post head is fixed with one ring of wooden keel via expanding bolt; the wooden box in post head shape is arranged on the wooden keel, to be fixed integrated via nails. The invention has better simulate effect and short construction time.

Owner:BEIJING URBAN CONSTR YATAI GRP

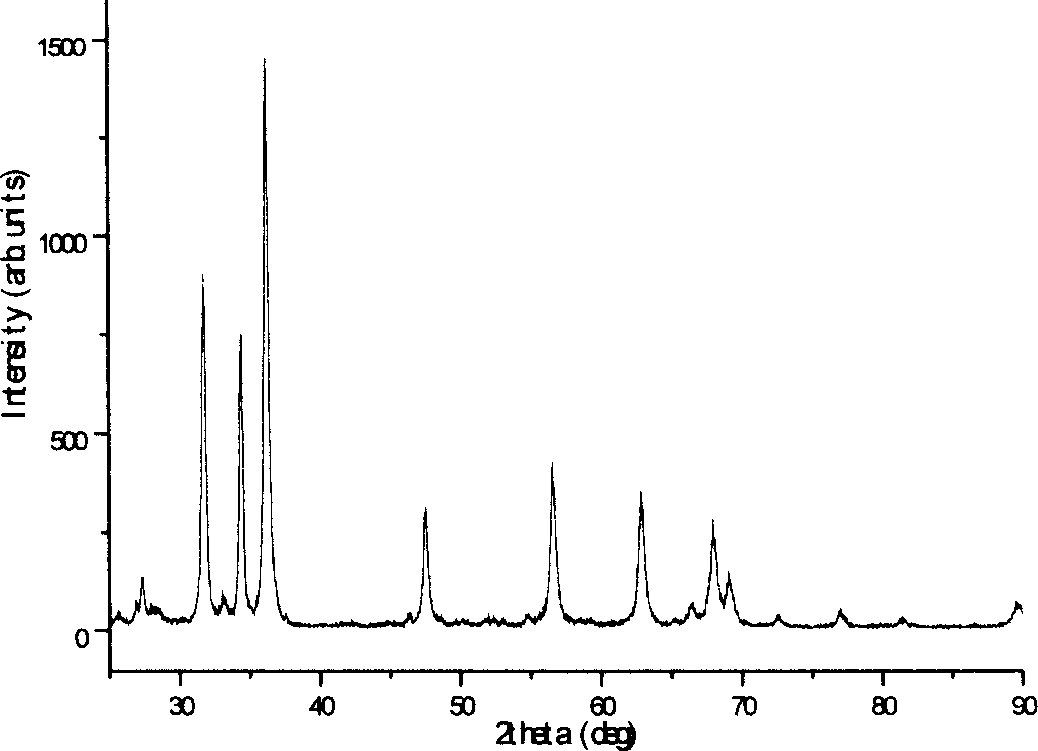

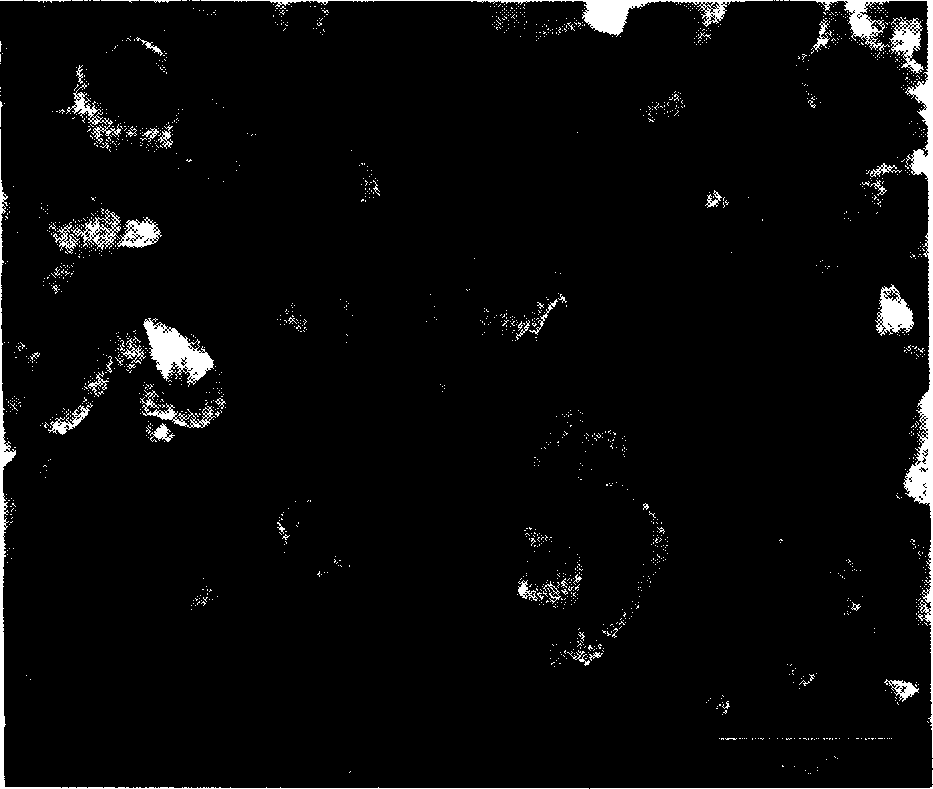

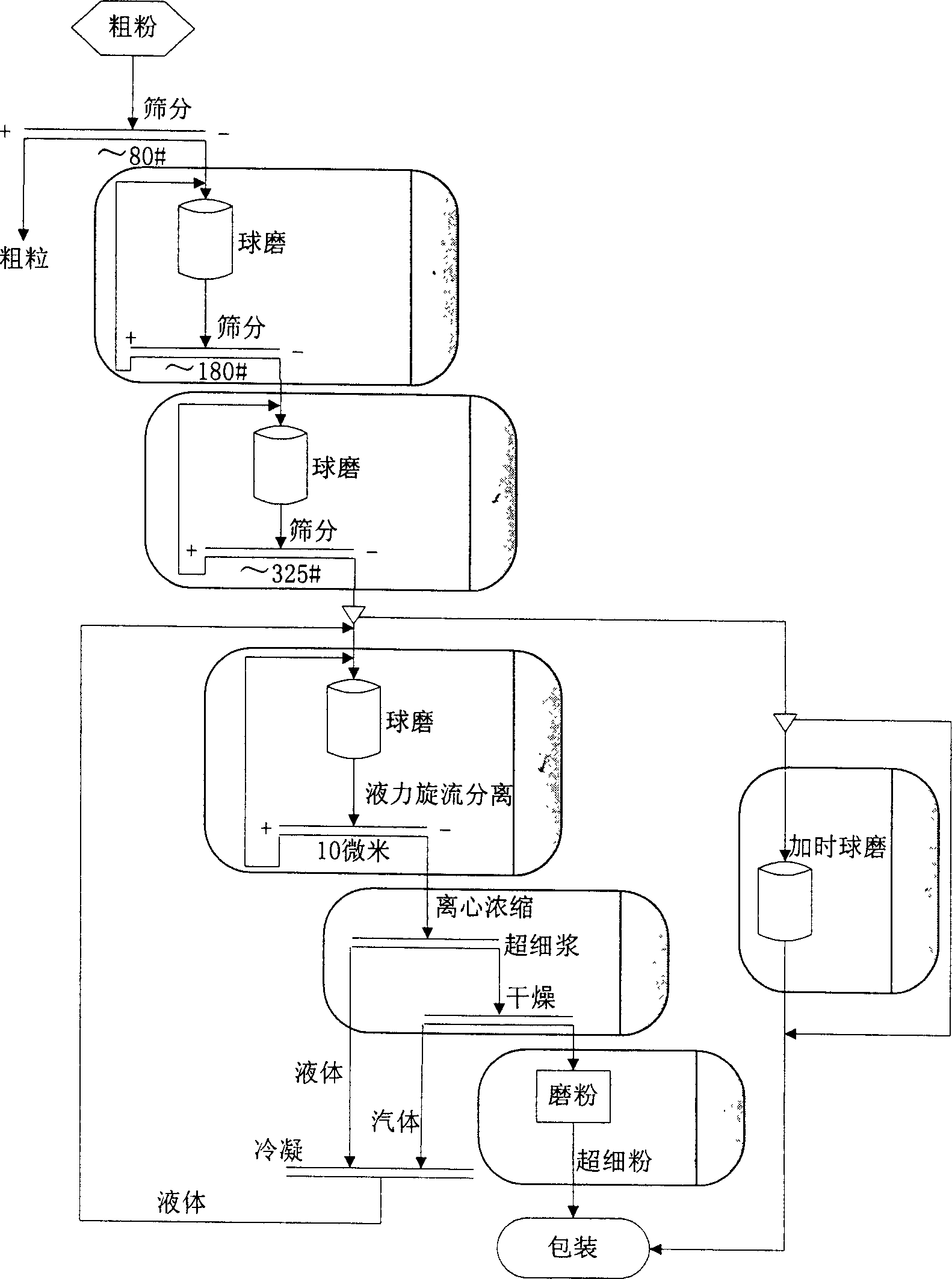

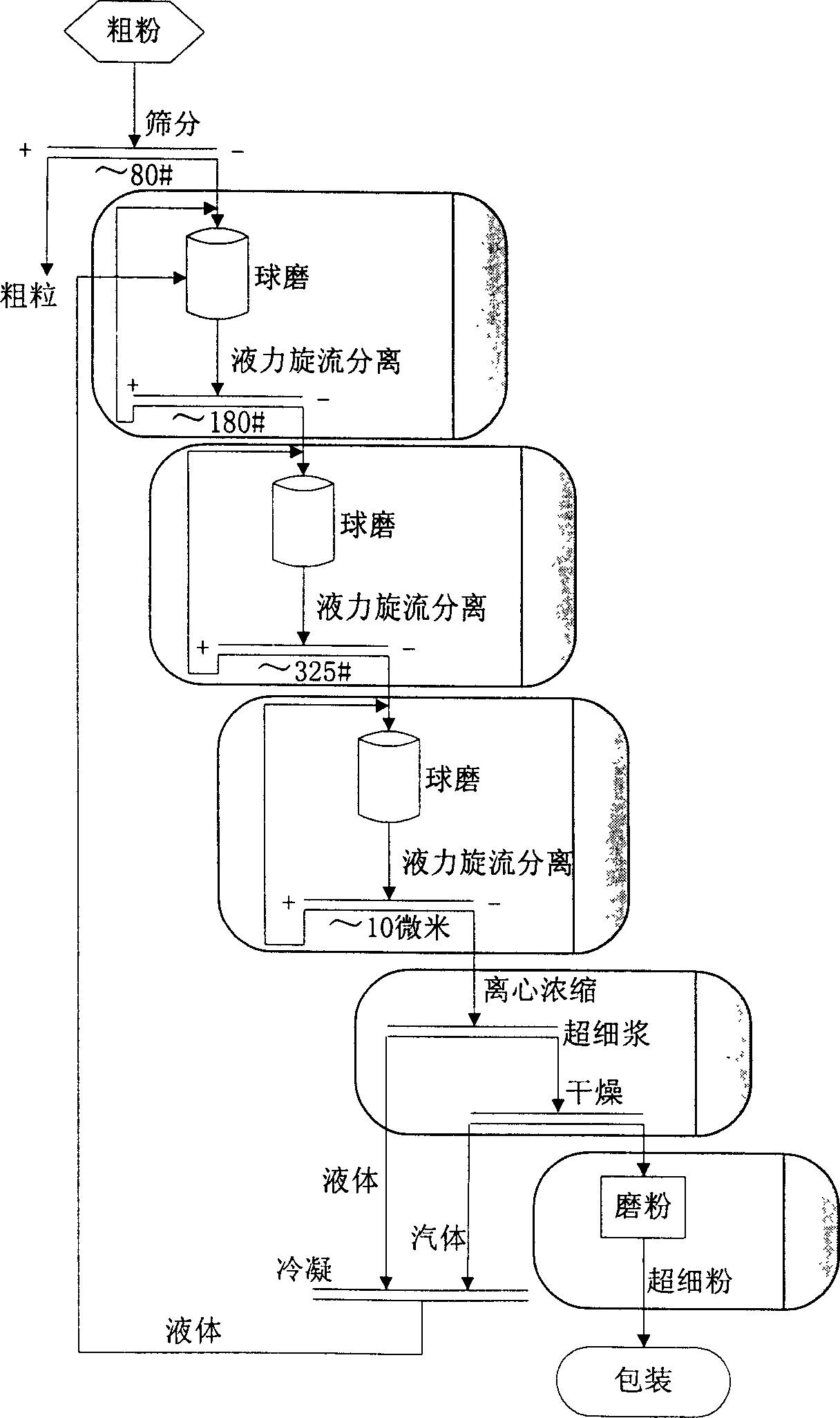

Preparation and application of high-potential gradient zinc oxide piezoresistor material

This invention relates to the preparation and application of a high potential gradient ZnO piezoresistive material including: mixing raw materials in the mol ratio of ZnO: Bi2O3:Sb2O3:Cr2O3:Co2O3:MnO2=96.5:0.7:1.0:0.5:0.8:0.5 to get the product by first and second time powerful fine grindings, low temperature sinter, which is taken as the raw material to be pressed to formation, sintered at low temperature, coated with electrode Ag pulp and welded with electrode lead to get the product of high potential gradient ZnO piezoresistors. This invention greatly refines the metal oxide mixed powder grain size by twice-powerful grindings, the sintered temperature is only 900deg.C and the grain is 1.5-3.5mum.

Owner:EAST CHINA NORMAL UNIVERSITY

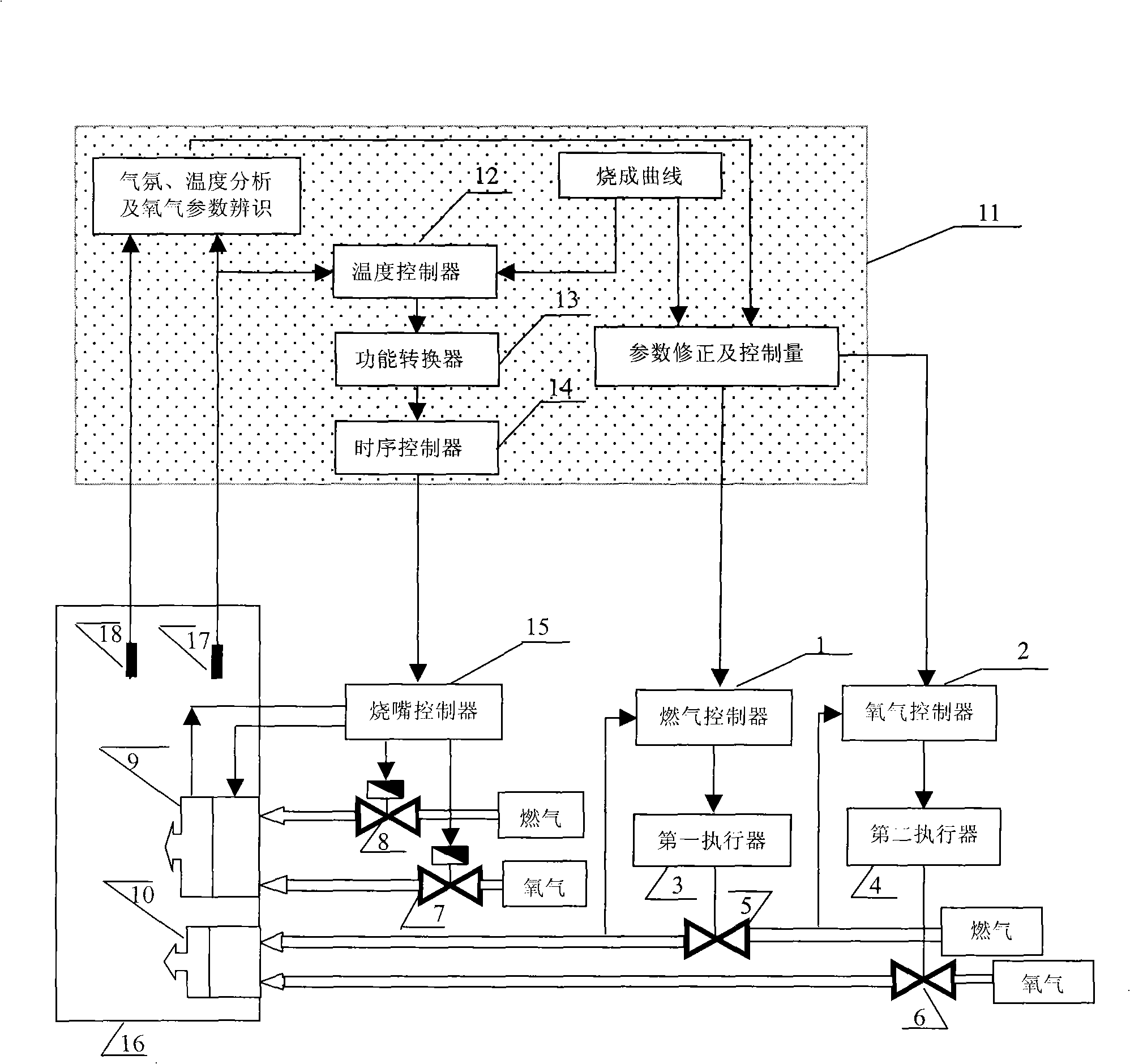

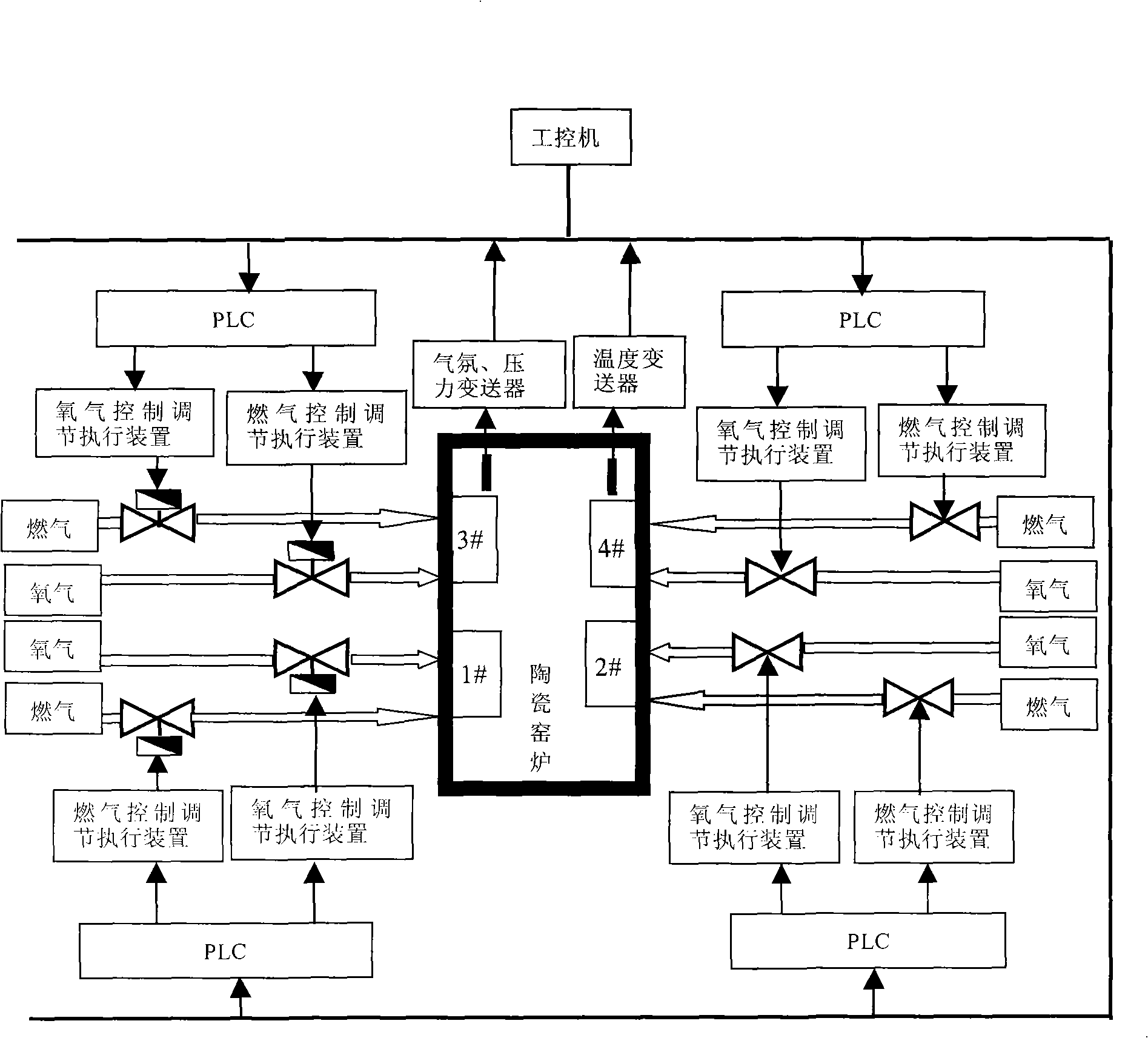

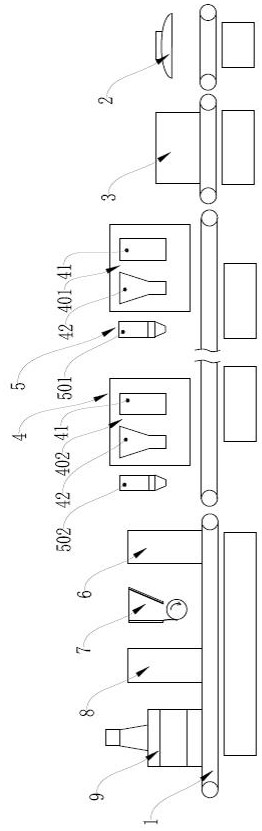

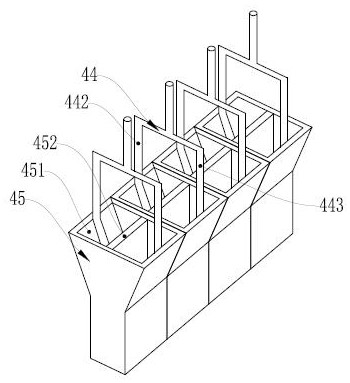

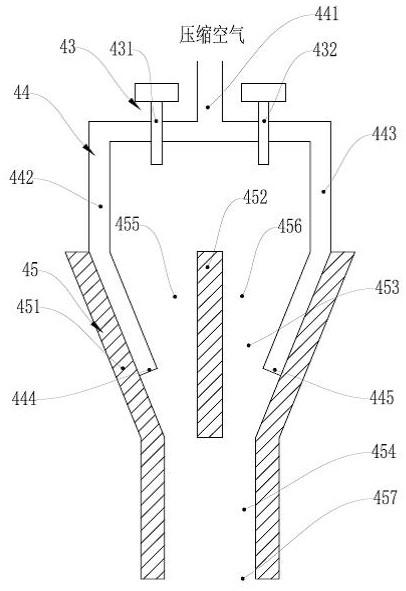

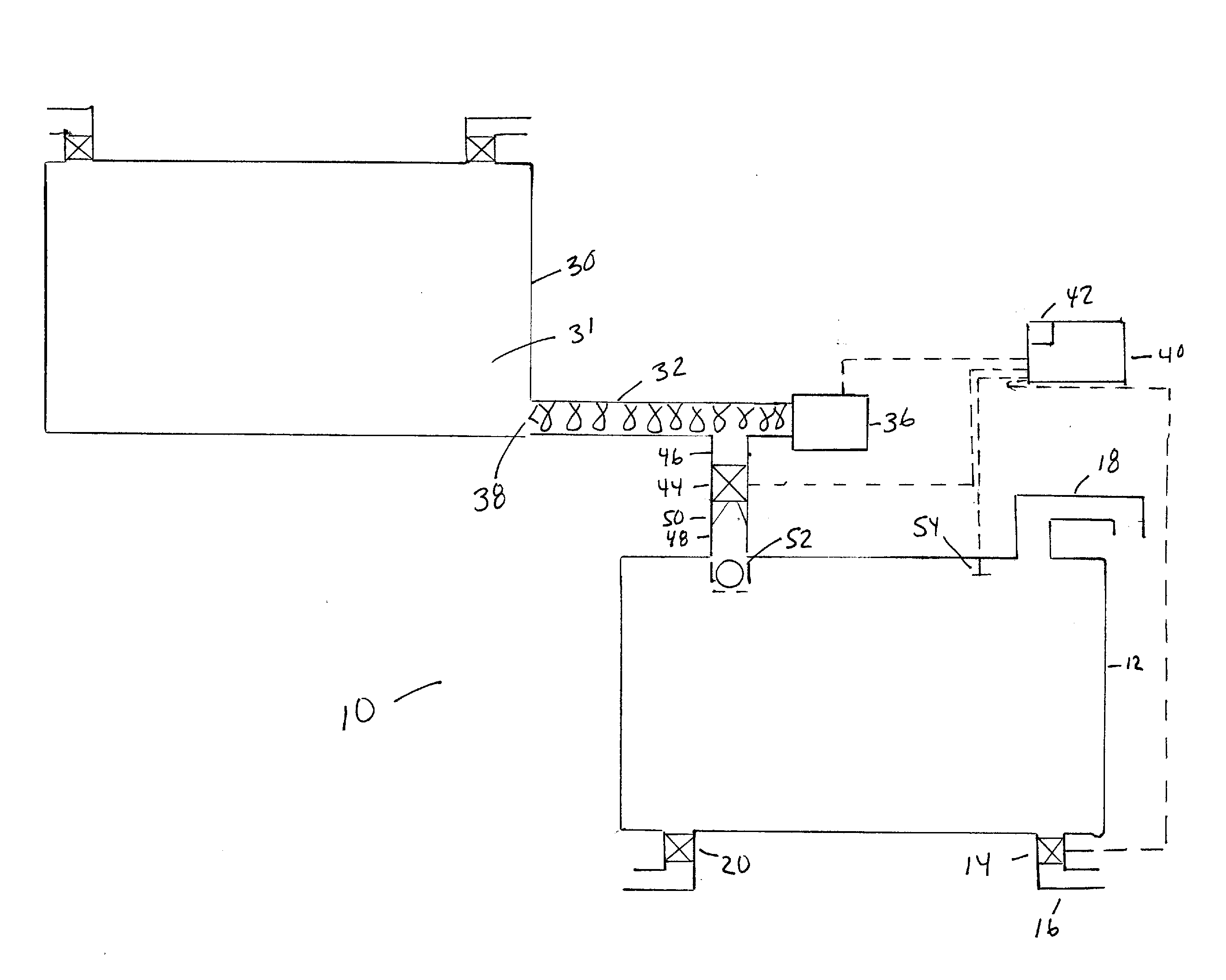

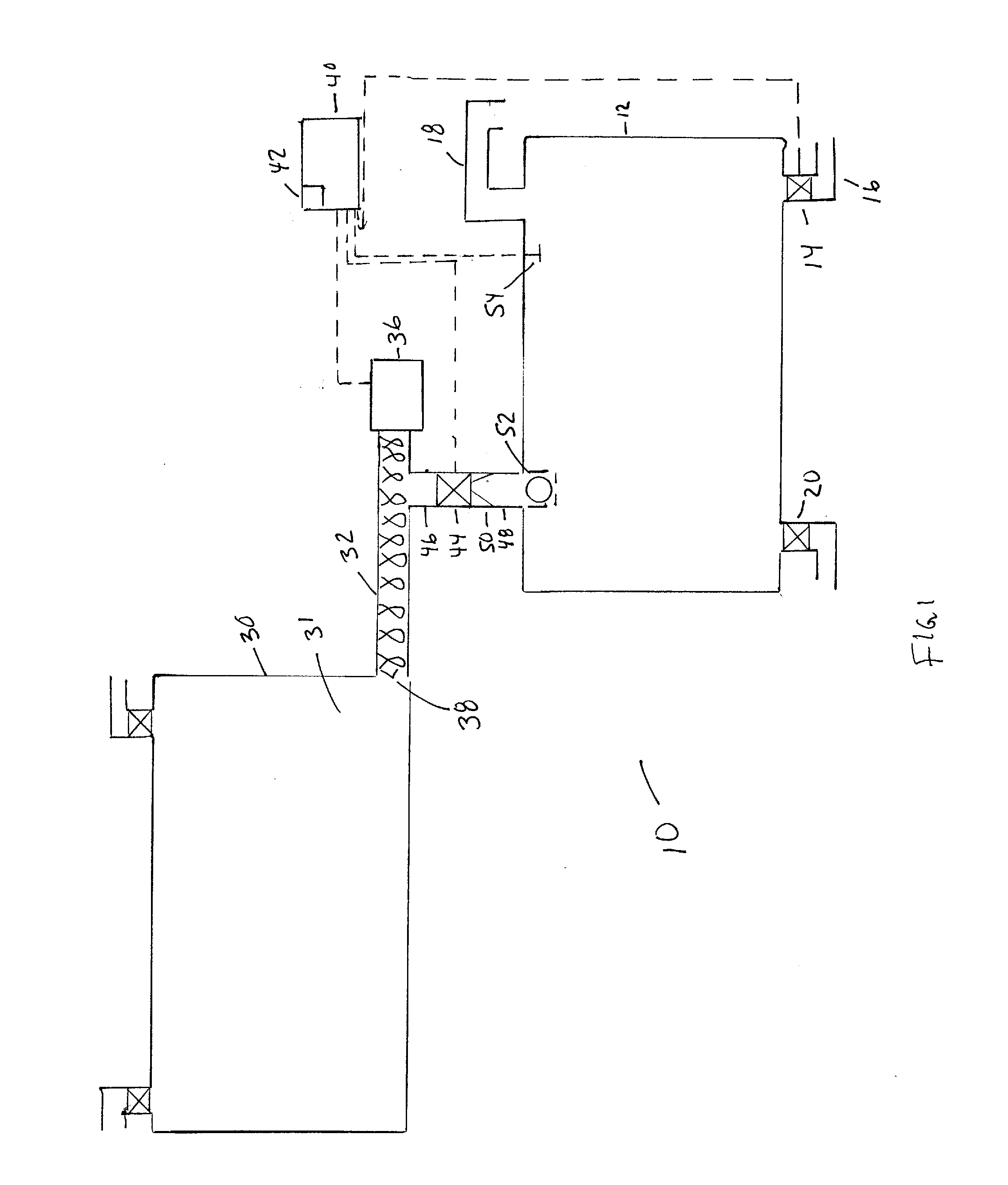

Mixed combustion control system of oxygen-enriched and full-oxygen combustion ceramic roller kiln

InactiveCN101344264AOvercoming the Shortcomings of Continuous CombustionImprove thermal effectFuel supply regulationIndirect carbon-dioxide mitigationAutomatic controlOxygen controller

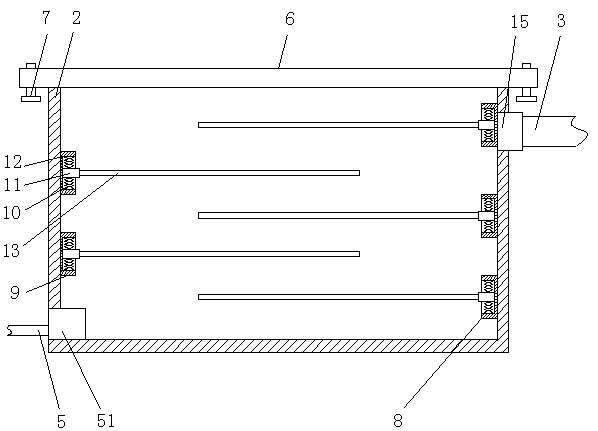

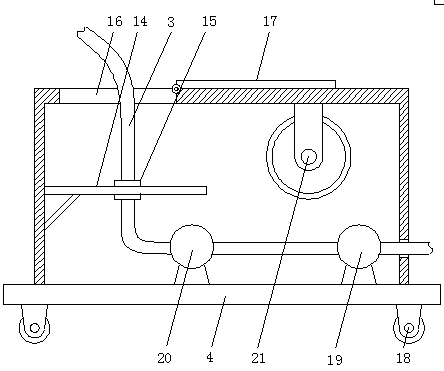

The invention relates to a mixed combustion control system of an oxygen-rich and total-oxygen combustion ceramic roller kiln, which is composed of a pulse combustion control subsystem and a proportion combustion automatic control subsystem, and a firing curve which is determined by an upper computer (11) is simultaneously implemented; the pulse combustion control subsystem is composed of a temperature measurement sensor (17), a temperature controller (12), a function converter (13), a time sequence controller (14), a burner controller (15), an oxygen electromagnetic valve (7), a gas electromagnetic valve (8) and a pulse combustion burner (9); and the proportion combustion control subsystem is composed of an atmosphere pressure sensor (18), the upper computer (11), a gas controller (1), an oxygen controller (2), a first actuator, a second actuator, a gas valve (5) and an oxygen valve (6). The mixed combustion control system of the invention is applicable to being used in the ceramic roller kiln, can better enhance the combustion performance of the ceramic roller kiln on the whole, save the energy, reduce the emission, improve the product quality, simplify the structure and facilitate the operation simultaneously.

Owner:WUHAN UNIV OF TECH

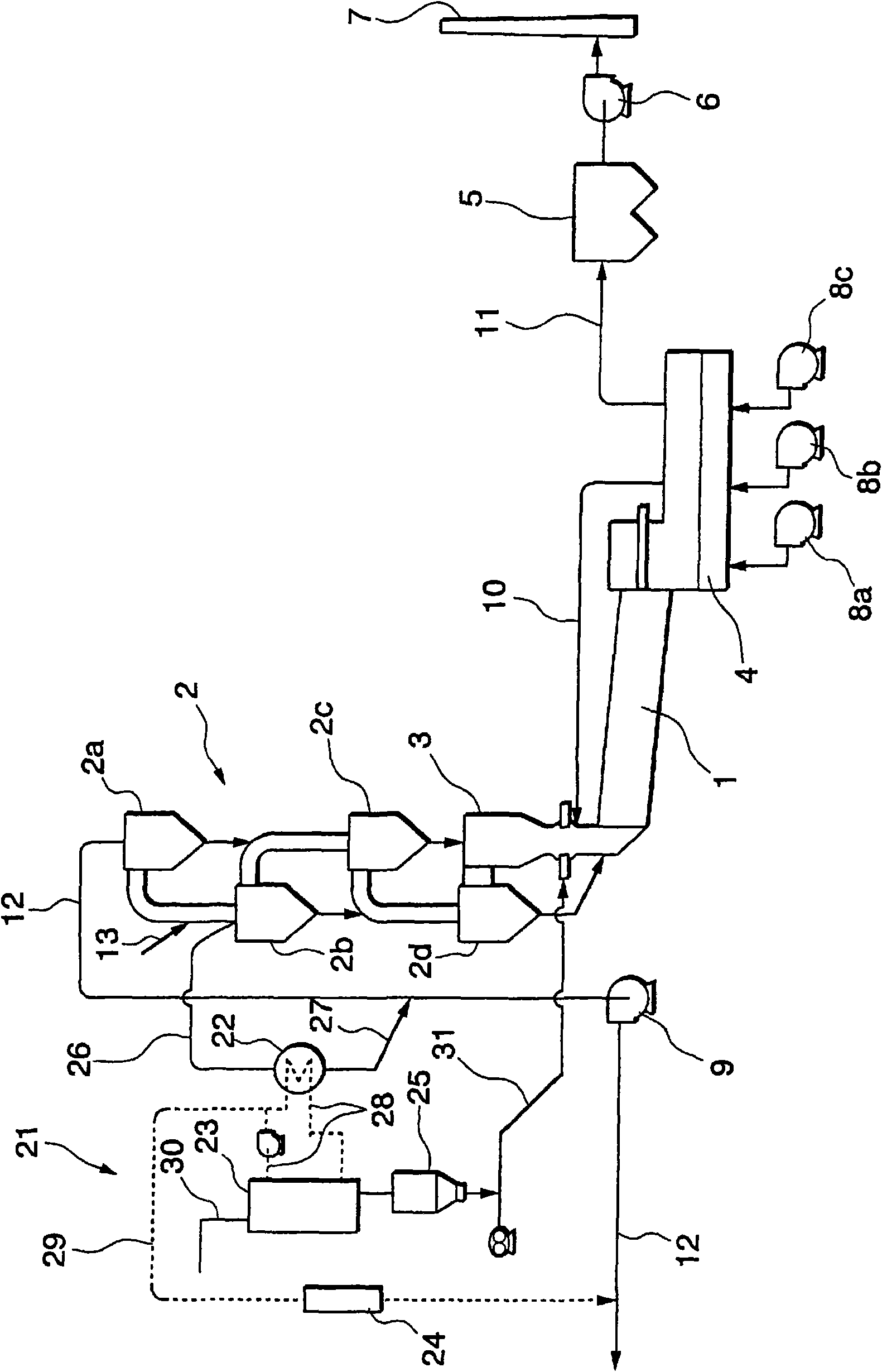

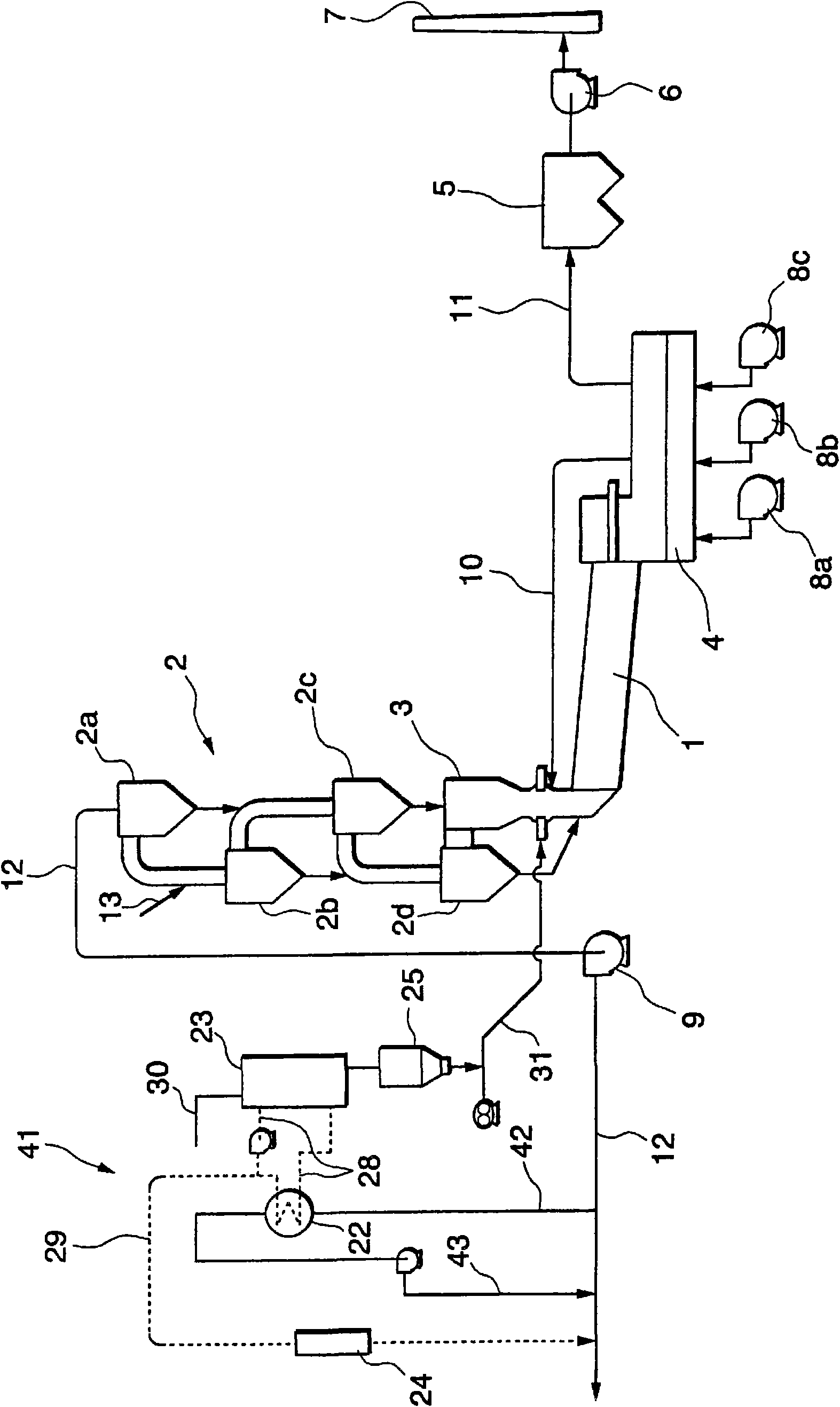

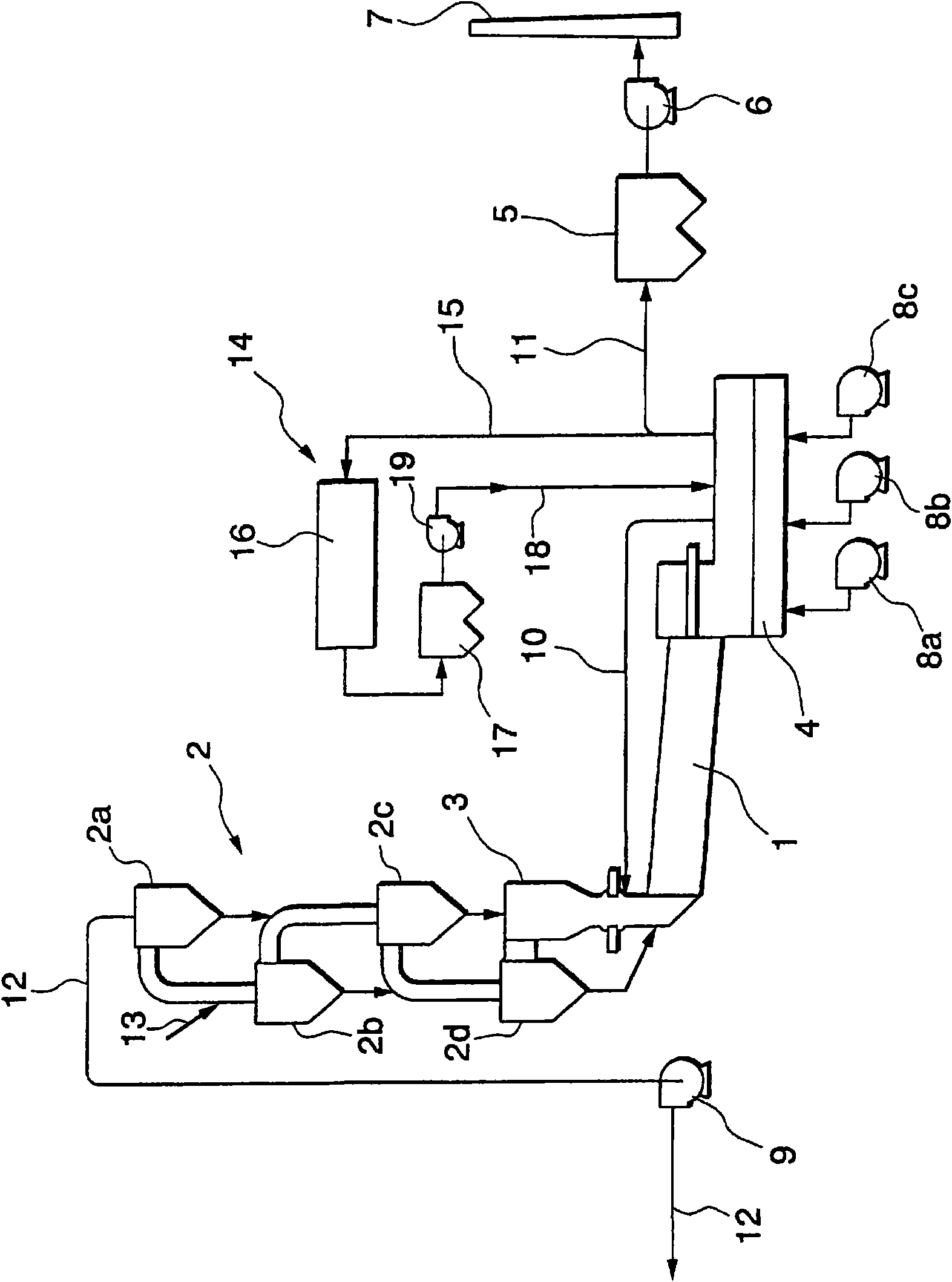

Method of disposing of organic waste of high water content and disposal apparatus therefor

ActiveCN101528614ADoes not affect operationEfficient use ofSludge treatment by de-watering/drying/thickeningDrying solid materials with heatSludgeHigh water content

The present invention discloses a method of disposing of an organic waste of high water content, and disposal apparatus therefor, with which effective utilization of the organic waste of high water content as fuel can be attained by drying the same with the use of cement calcination equipment, and with which the operation efficiency of cement calcination equipment can be enhanced without the danger of influences on the operation of the cement calcination equipment. The method of disposing of an organic waste of high water content comprises the steps of carrying out by means of heat exchanger (22) a heat exchange between superheated steam and exhaust gas separated by cyclone (2b) of suspension preheater (2) and not only introducing the superheated steam of high temperature after the heat exchange in dryer (23) to thereby dry any organic sludge into a dried organic waste but also carrying out once more by means of the heat exchanger (22) a heat exchange of the superheated steam after the drying to thereby attain circulatory use thereof in the drying of organic sludge; and feeding the resultant dried organic sludge to calciner (3) as fuel and combusting the same.

Owner:SUMITOMO OSAKA CEMENT CO LTD

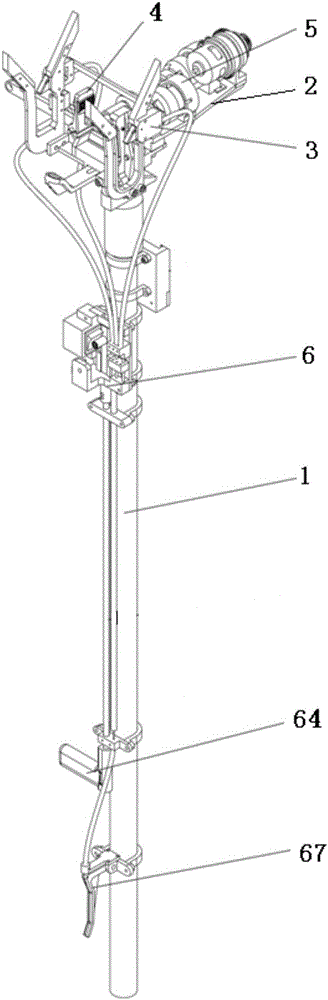

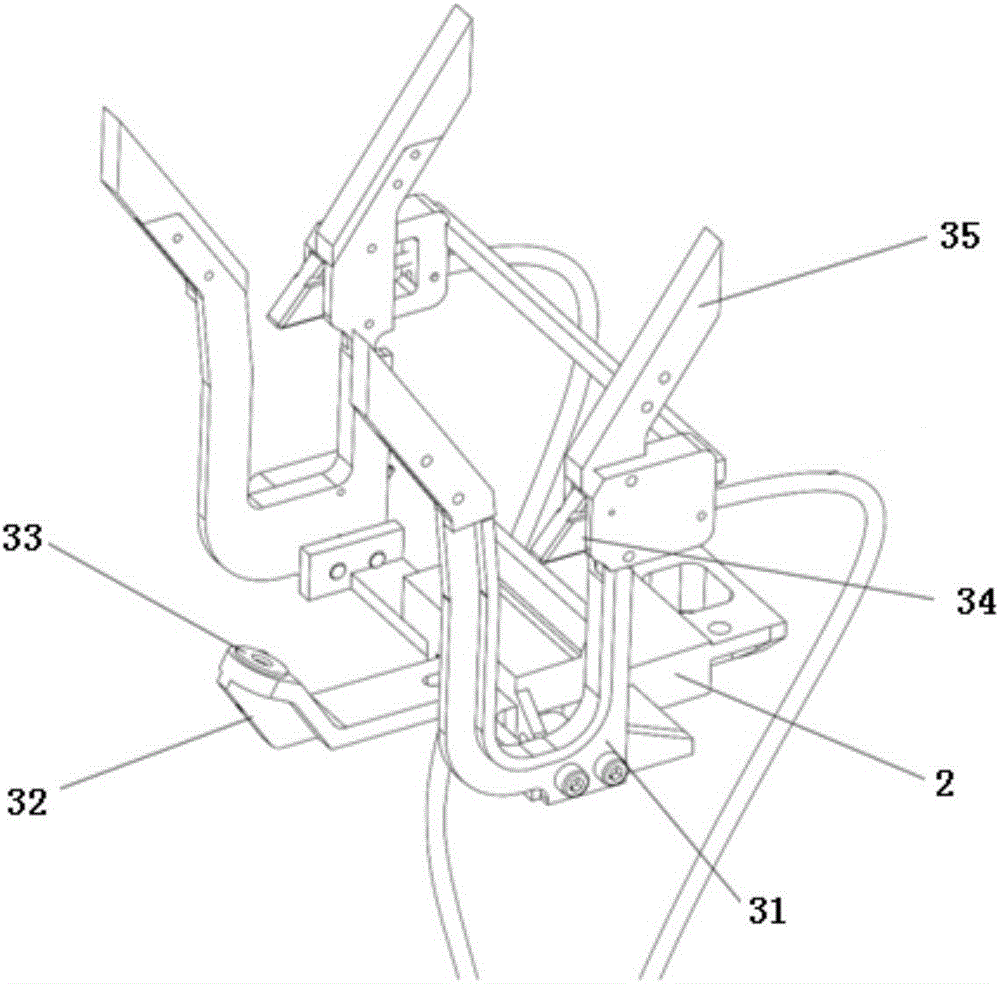

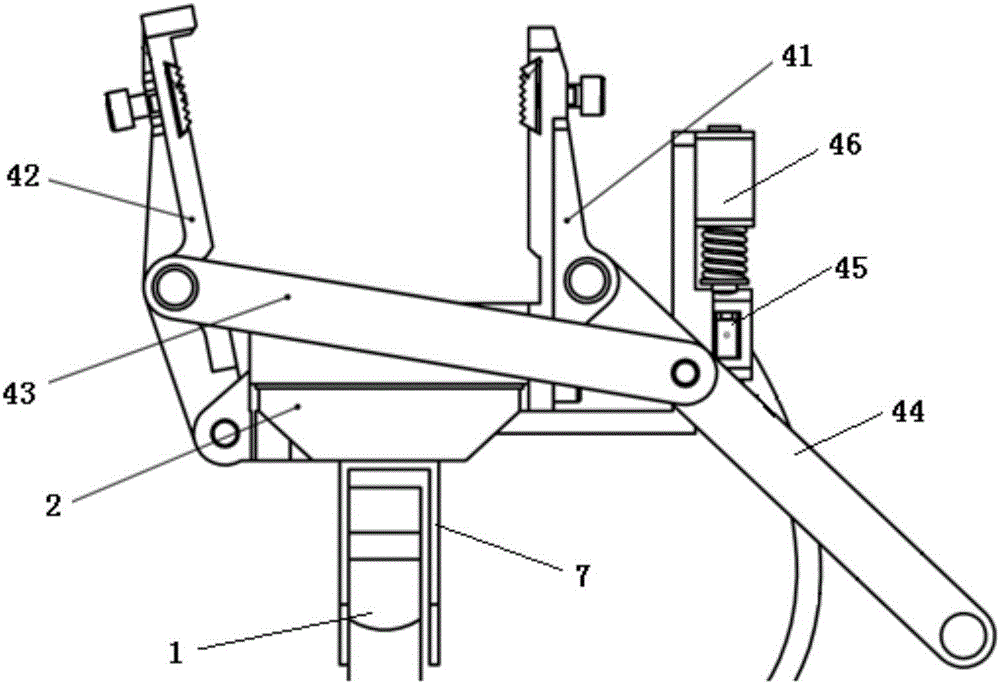

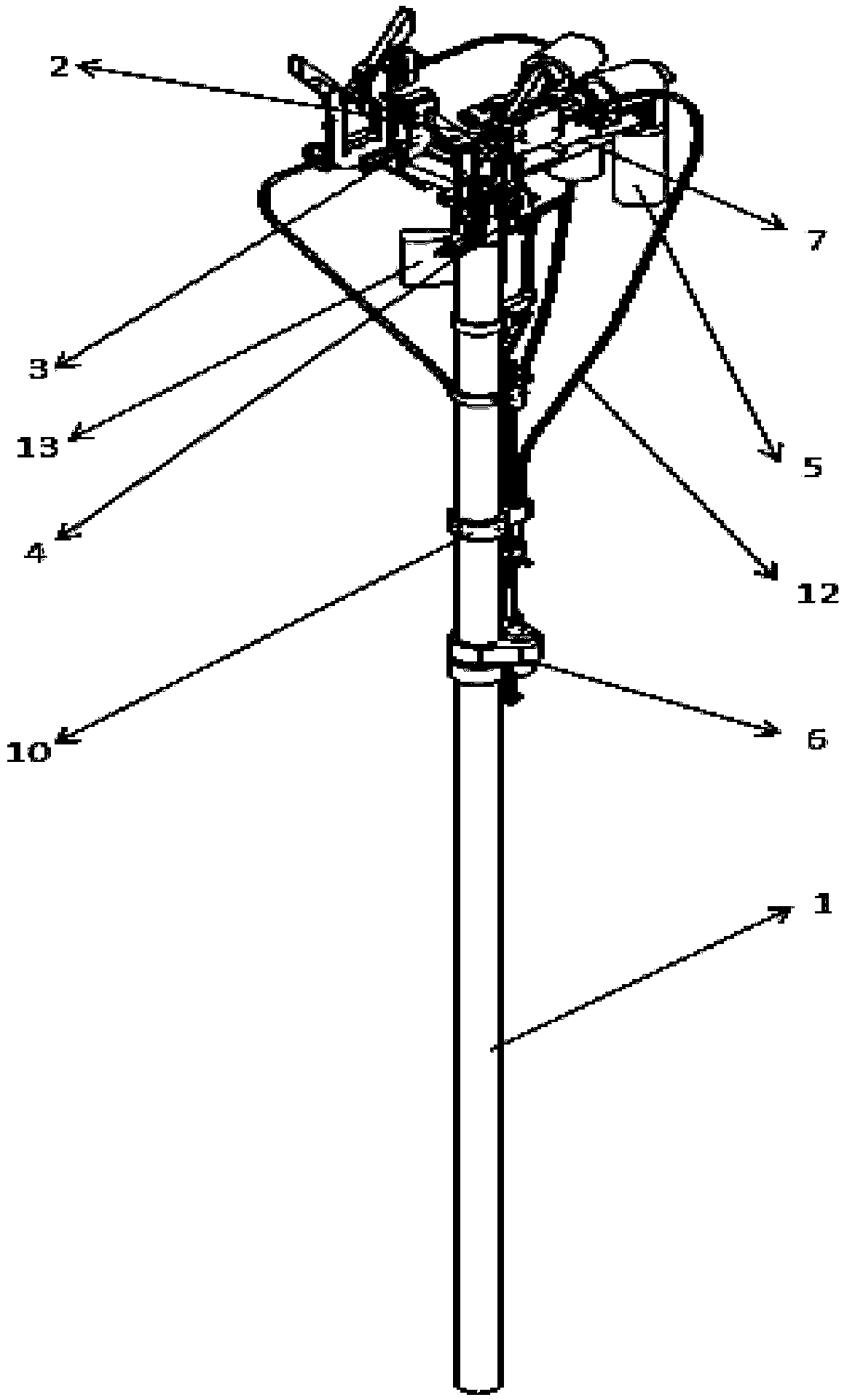

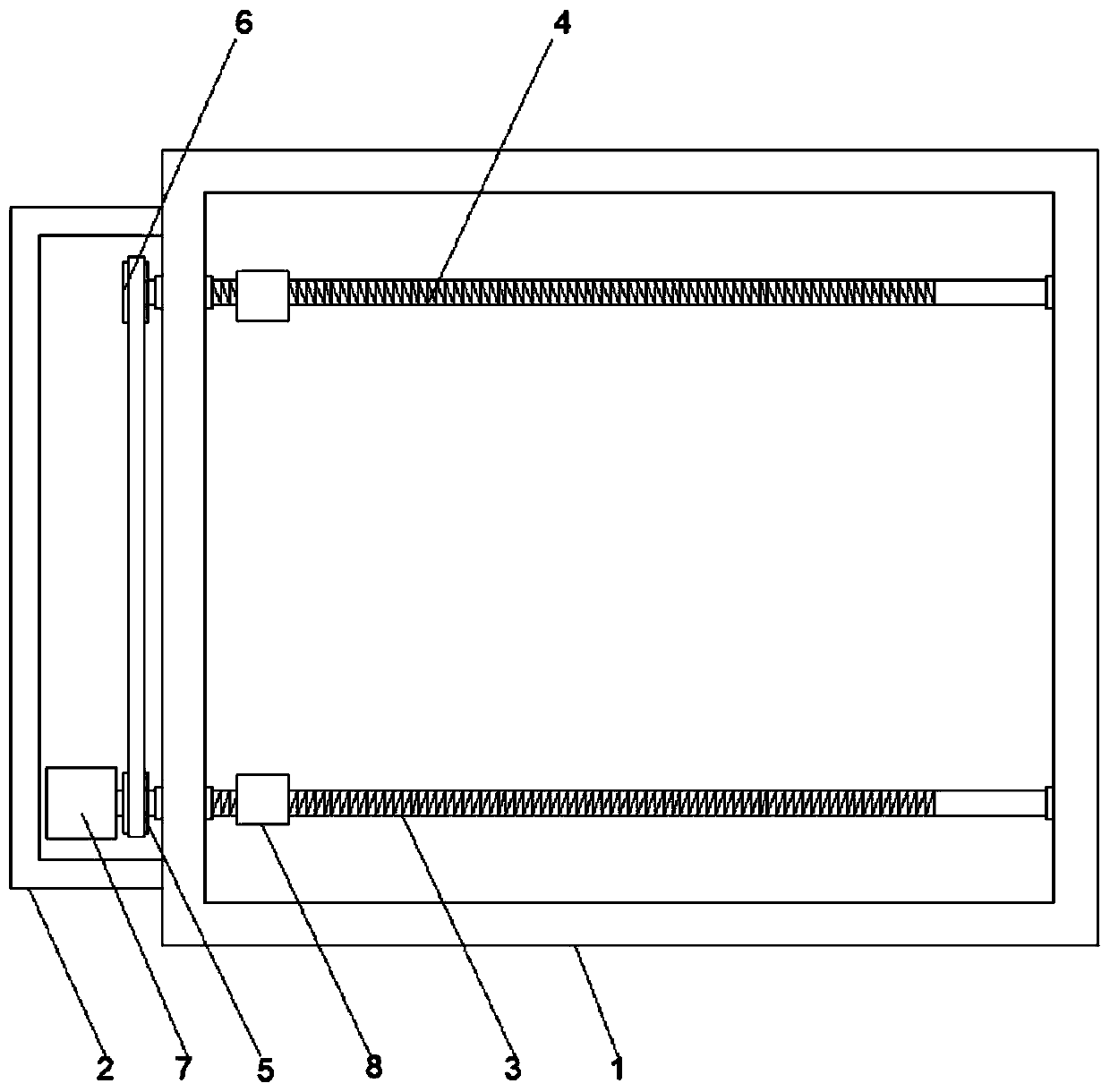

Double-screwdriver output-based insulation puncturing clamp installation work tool

ActiveCN108321728AWith self-hanging functionQuick installationApparatus for overhead lines/cablesRemote controlBusbar

The invention discloses a double-screwdriver output-based insulation puncturing clamp installation operation tool and belongs to the electric connection field. The installation work tool comprises aninsulated long rod, a bottom plate, a bus-bar positioning device which is arranged on the bottom plate, a clamp clamping device, a sub-line clamping device, a striking device, and a motor unlocking device which is disposed on the insulated long rod. Compared with the prior art, the installation tool has the advantages of small size, light weight, simplicity and easiness in use, and convenience insingle-person operation; the synchronous output of double screwdrivers is stable, the positioning of sub-busbars is reliable, and therefore, the reliability of an installation process is ensured, installation accuracy and installation efficiency can be improved; and the tool also has a long-distance remote control unlocking function, one-key unlocking can be realized, the insulation distance of manual operation is far, and therefore, personal safety can be ensured.

Owner:HEFEI UNIV OF TECH

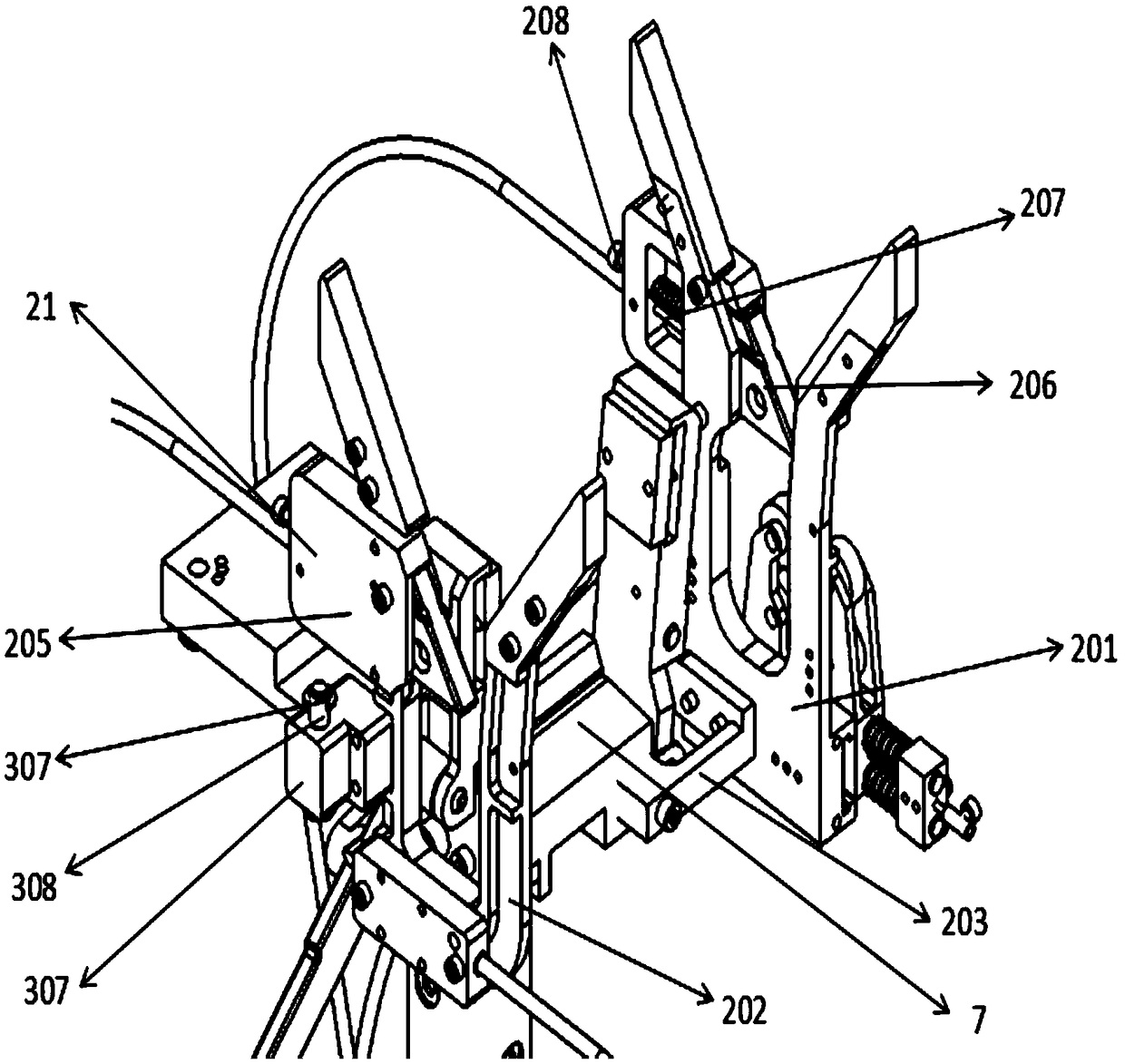

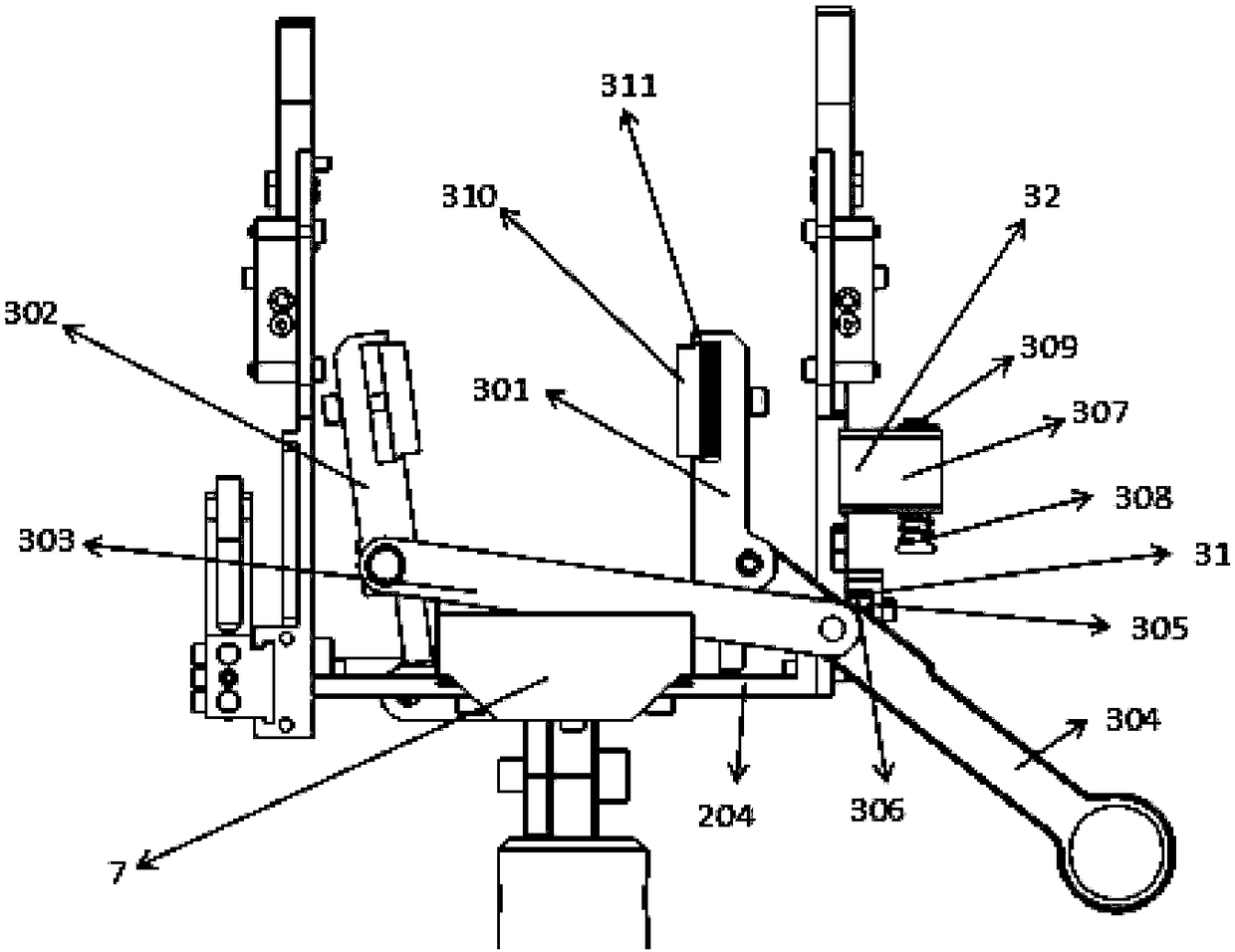

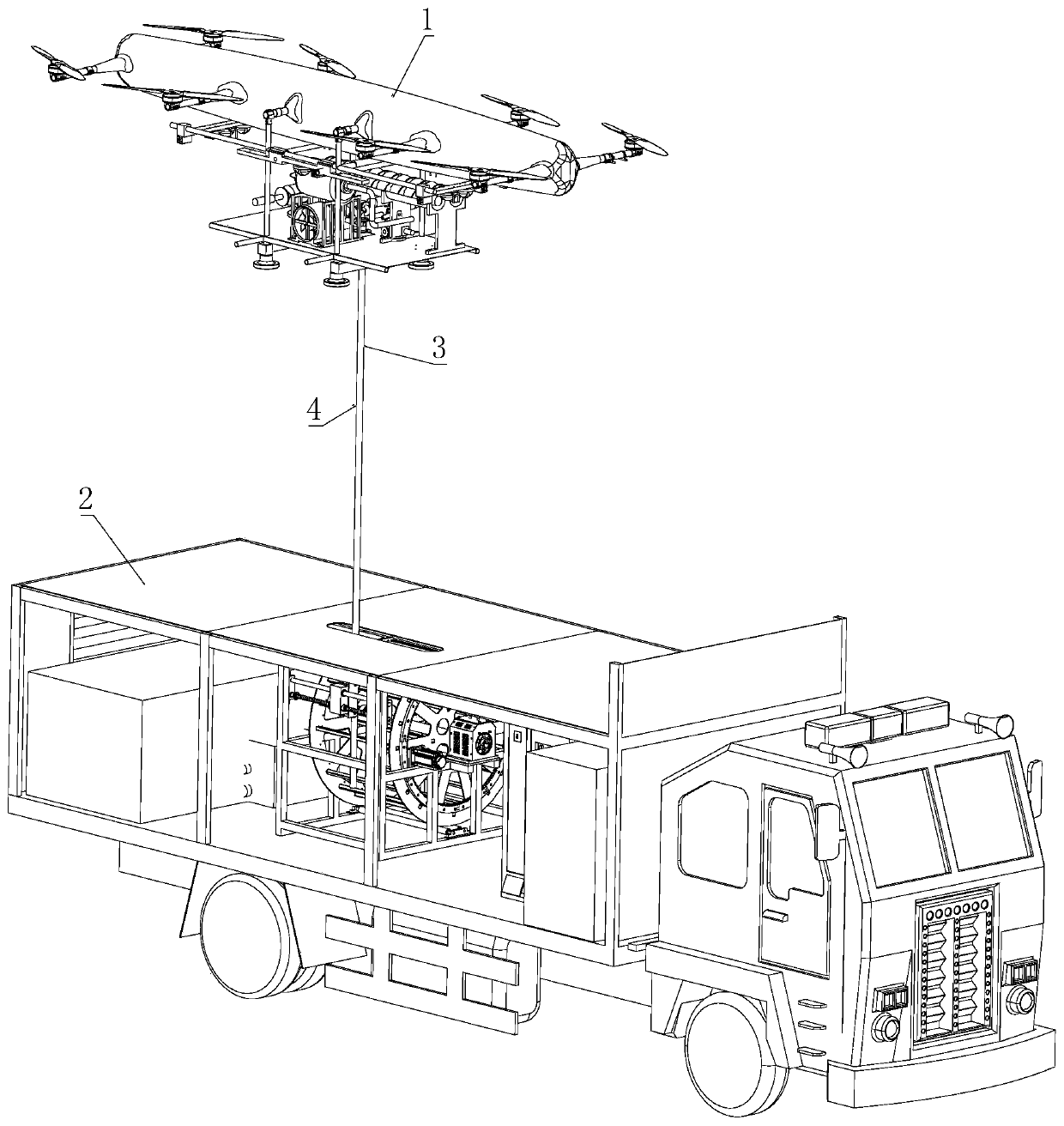

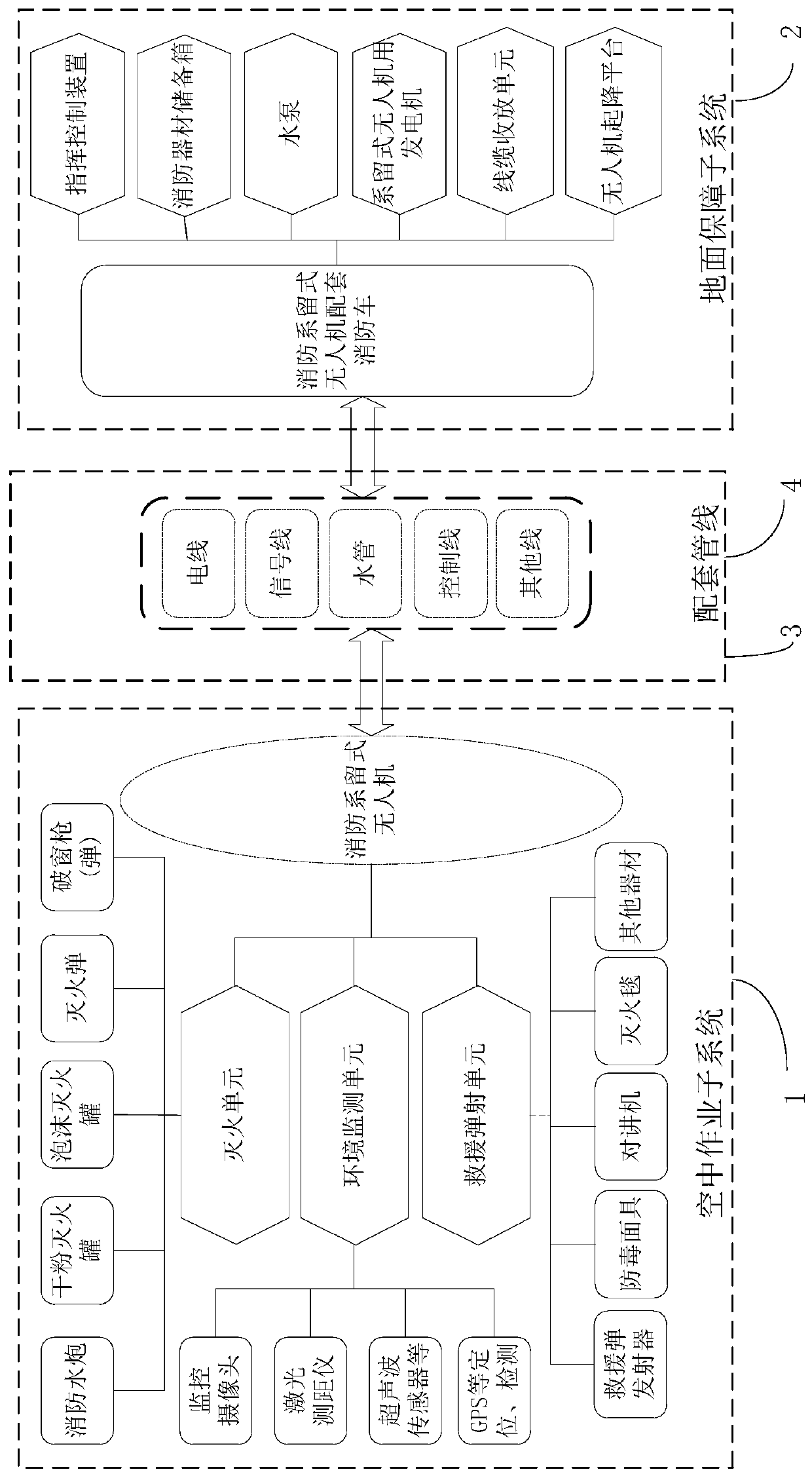

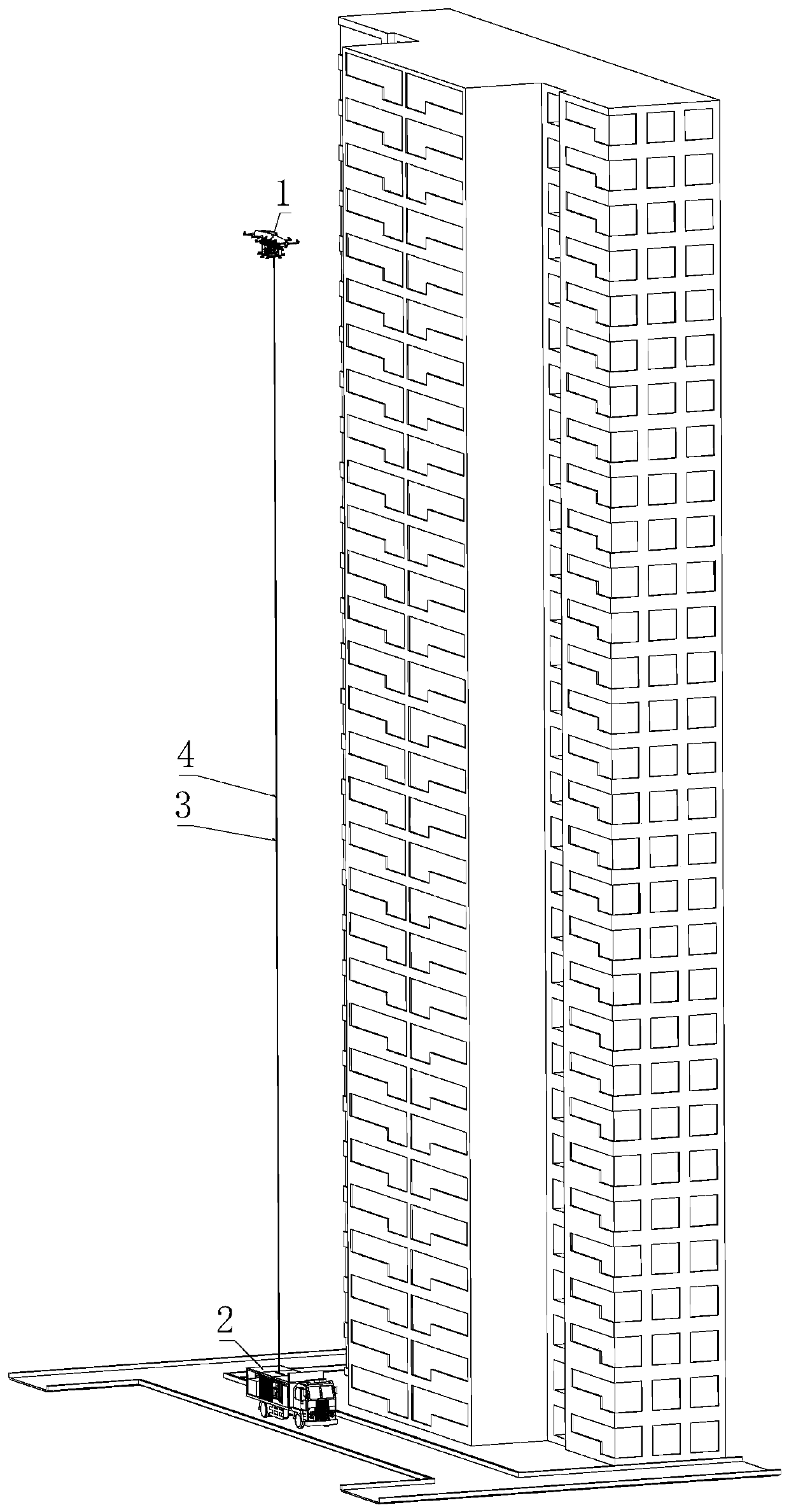

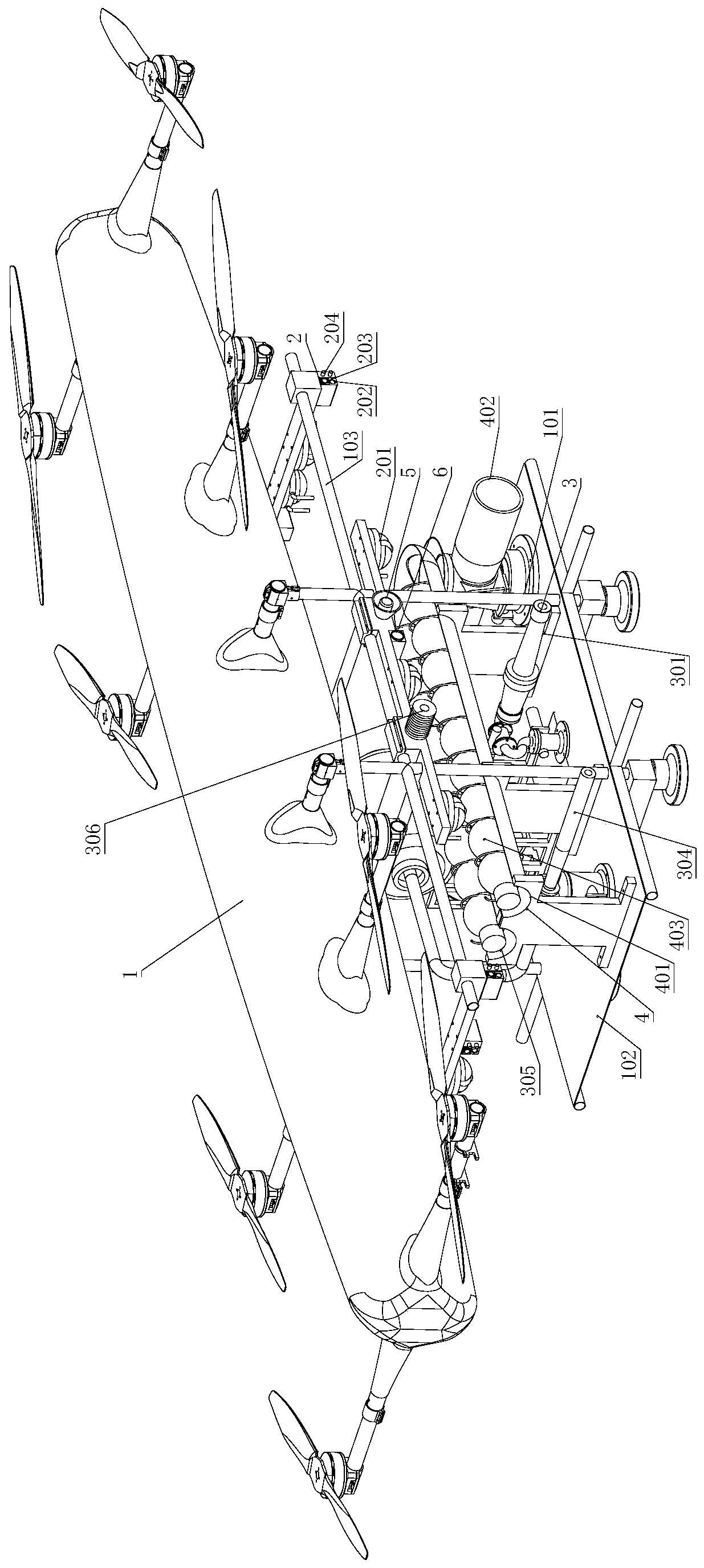

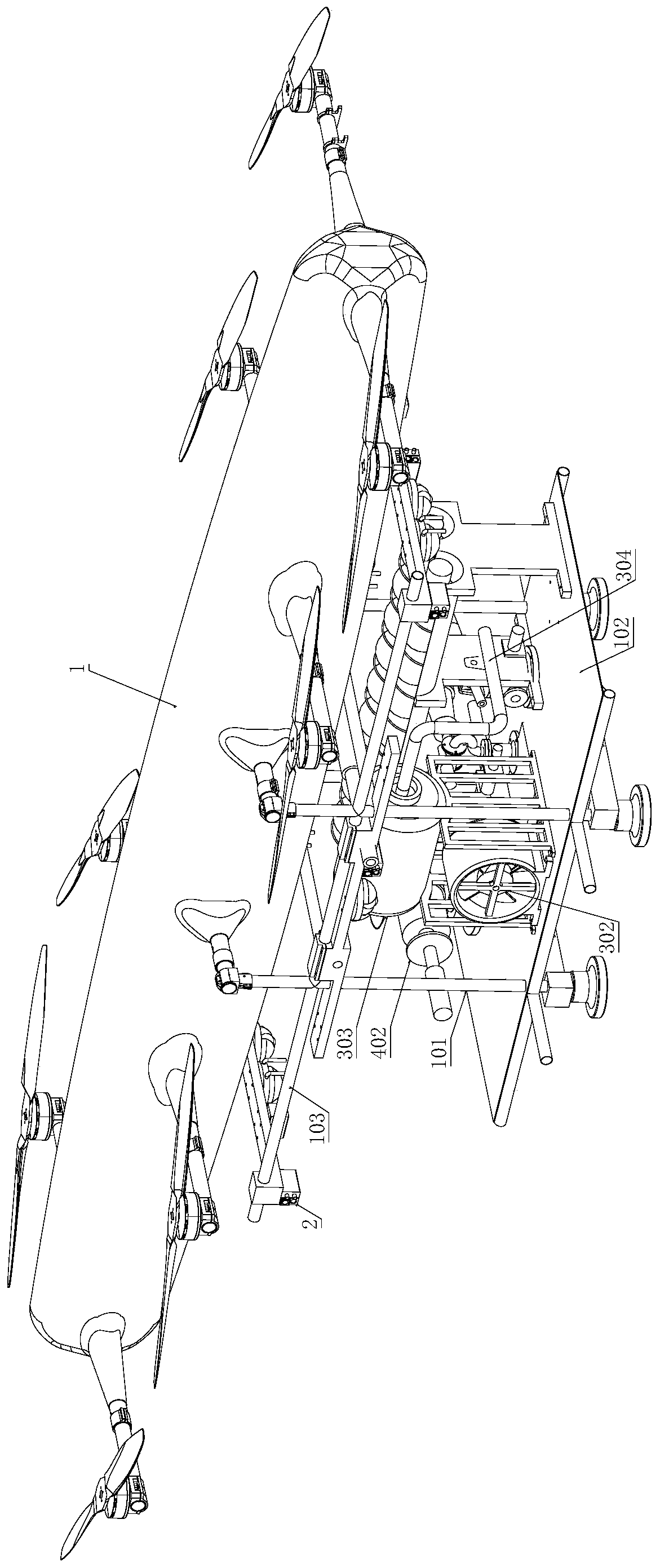

High-altitude mooring unmanned aerial vehicle firefighting rescue system and method

PendingCN111167046AImprove responsivenessImprove securityFire rescueBuilding rescueMarine engineeringFirefighting

The invention discloses a high-altitude mooring unmanned aerial vehicle firefighting rescue system, and belongs to the technical field of firefighting. The high-altitude mooring unmanned aerial vehicle firefighting rescue system is used for solving the technical problem that at present, high-rise firefighting rescue is difficult. The specific structure of the system comprises a high-altitude operation subsystem and a ground support subsystem; the high-altitude operation subsystem comprises a mooring unmanned aerial vehicle, a fire extinguishing unit, an environment monitoring unit and a rescuecatapulting unit, wherein the fire extinguishing unit, the environment monitoring unit and the rescue catapulting unit are located on the mooring unmanned aerial vehicle; the ground support subsystemcomprises a fire fighting vehicle, a fire extinguishing agent supply unit, a power source unit and a pipeline winding-unwinding unit, wherein the fire extinguishing agent supply unit, the power source unit and the pipeline winding-unwinding unit are installed on the fire fighting vehicle; the power source unit is connected with the mooring unmanned aerial vehicle through a mooring cable and usedfor providing a power source for the mooring unmanned aerial vehicle; the fire extinguishing agent supply unit is connected with the fire extinguishing unit through a supply pipe and used for providing a fire extinguishing agent to the fire extinguishing unit; and the pipeline winding-unwinding unit is used for conducting winding and unwinding operation on the mooring cable or / and the supply pipe.The high-altitude mooring unmanned aerial vehicle firefighting rescue system has the advantages of being long in endurance, large in carrying capacity, fast in response, safe, reliable and capable ofbeing integrated with the high-rise firefighting rescue function.

Owner:长沙市云智航科技有限公司

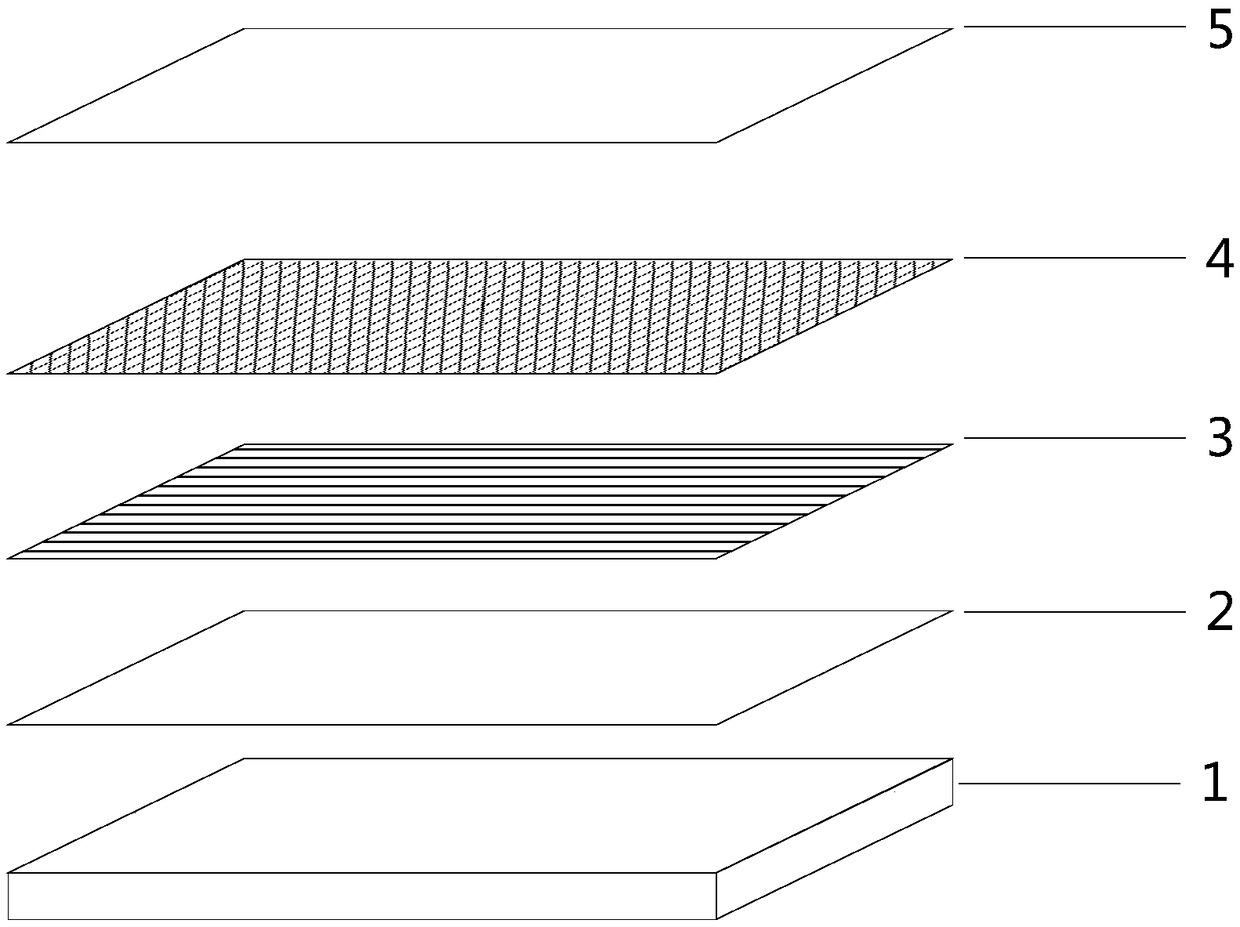

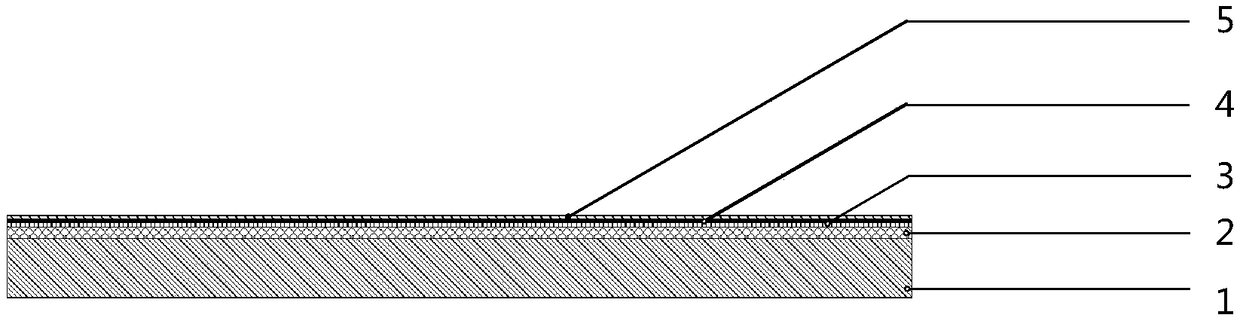

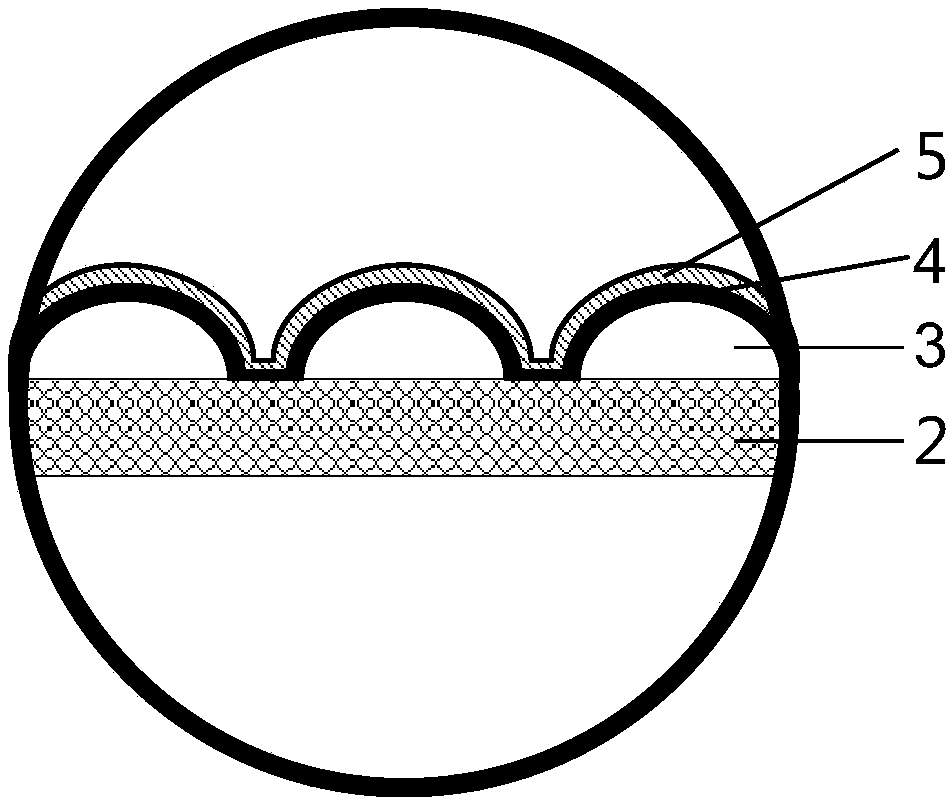

Stereoscopic surface woodgrained ceramic tile, stereoscopic surface woodgrained ceramic tile emboss effect glaze layer and decoration technology

InactiveCN109291723AGood printing performance and firing performanceEasy to operateSpecial ornamental structuresCalciteCeramic glaze

The invention relates to a stereoscopic surface woodgrained ceramic tile, a stereoscopic surface woodgrained ceramic tile emboss effect glaze layer and a decoration technology. The ceramic tile is composed of a green body layer, a cover glaze layer, an emboss effect glaze layer, a pattern decoration layer and a surface protective glaze layer which are sequentially compounded. The stereoscopic surface woodgrained ceramic tile emboss effect glaze layer comprises the following materials including, by weight, 2.5-3 parts of zinc oxide, 20-30 parts of feldspar, 15-20 parts of frit, 10-12 parts of washed kaolin, 8-10 parts of calcite, 8-10 parts of burning talc and 20-30 parts of home-made quartz. The decoration technology comprises the steps that (1) long-strip-shaped green bodies are obtainedby pressing woodgrained brick powder, the surfaces of the green bodies are coated with cover glaze, and formulated emboss effect glaze materials are printed on the surfaces of the green bodies, coatedwith the cover glaze, in a rubber covered roller engraving mode; (2) decoration is performed by means of ink jet patterns, and the ink jet patterns cover the glaze surface and the printed emboss effect glaze on the whole; and (3) the green bodies are coated with clear protective glaze, and then kiln firing is performed.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +3

Firecracker pouring leading line technology method

ActiveCN102679822ATo achieve the discharge effectImprove ergonomicsFireworksFirecrackerEconomic benefits

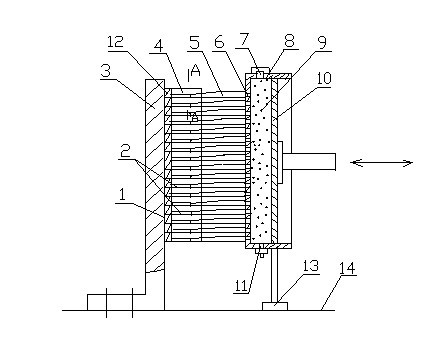

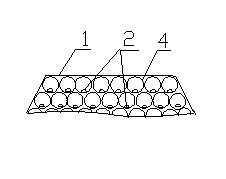

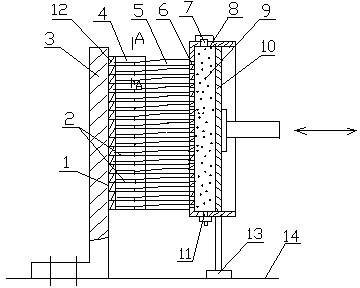

The invention discloses a firecracker pouring leading line technology method that a bottom-sealed firecracker cake (1) is vertically fixed on a mold plate (3); a pouring and leading device is arranged in the axis direction of the firecracker cake; pouring and leading needles (5) correspond with the paper cylinders on the firecracker cake in number and position; the pouring leading line needles (5) can extend into the paper cylinders (4); and when the leading line slurry (9) in the pouring leading line needles flows into the inner walls of the paper cylinders in line shape under the pressure, the pouring leading line needles move from inside to outside till the pouring leading line needles move out of the firecracker cake, and the solidified line-shaped leading line slurry can be fixed on the inner walls of the paper cylinders to serve as the leading lines (2). According to the firecracker pouring leading line technology method, the leading lines are safe to make, the material consumption and waste are reduced, the making cost of the leading lines is reduced; and as the leading lines are uniform in size and correct in position, leading line breaking and splitting are avoided, the fire joining performance is excellent, and all the paper cylinders of the firecracker cake can be simultaneously poured and led once for all, the inserting leading line procedure is reduced, the inserting leading line efficiency of the firecrackers is improved, the inserting leading line cost is reduced, and the economic benefits are improved.

Owner:崔立波

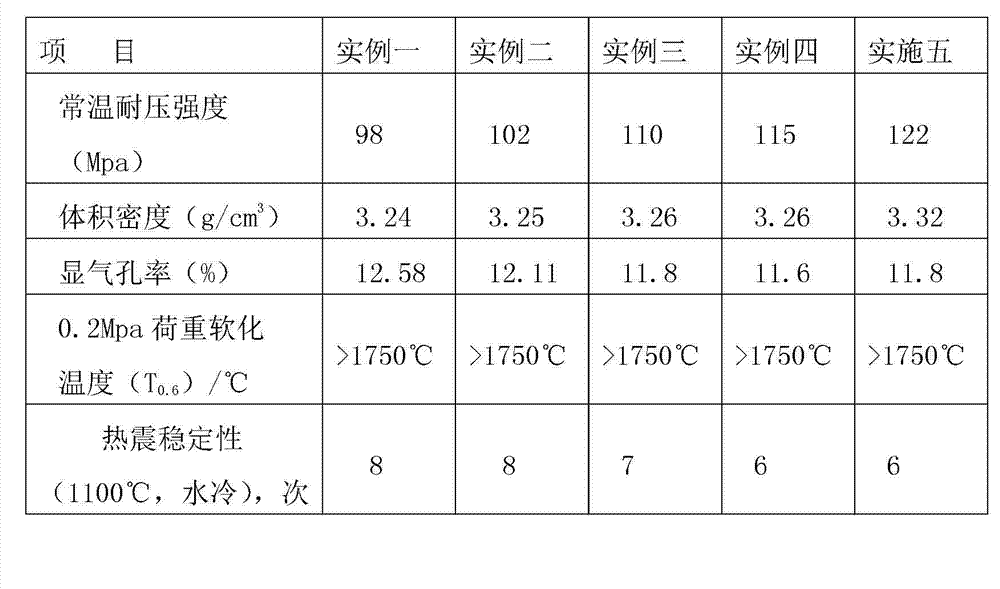

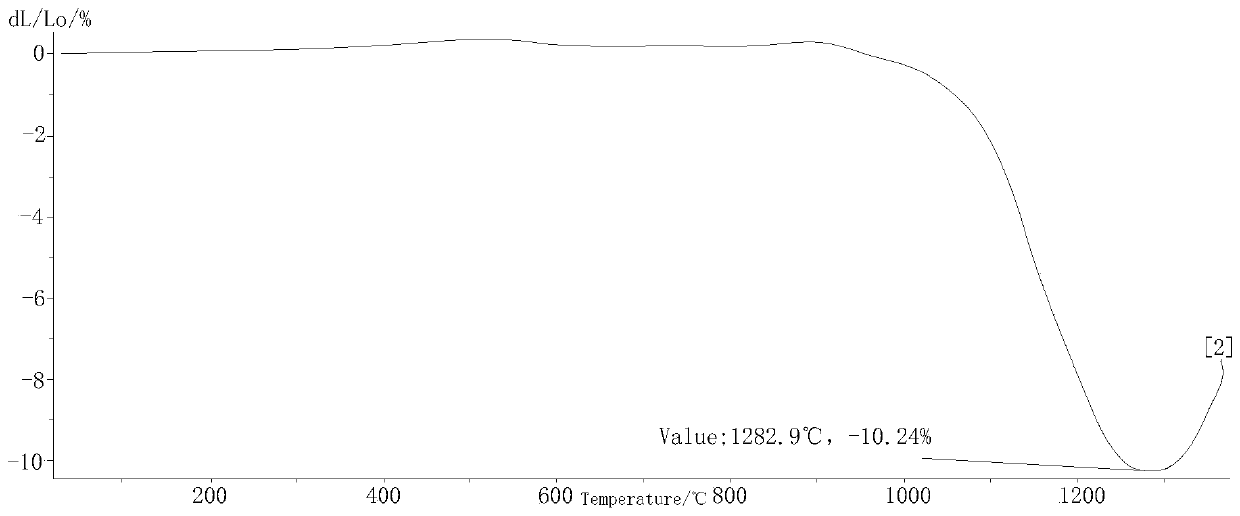

Fused-rebonded magnesite-chrome brick with excellent thermal shock resistance and production process

The invention provides a fused-rebonded magnesite-chrome brick with excellent thermal shock resistance and a production process. The fused-rebonded magnesite-chrome brick comprises the following raw materials in parts by weight: 5-25 parts of high-purity magnesia, 20-40 parts of large-crystal electro-fused magnesia, 30-40 parts of fused magnesia-chrome sand, 5-16 parts of chromite, 2-8 parts of MgCO3, 2-10 parts of chromium concentrate submicron powder, 0.1-1 part of rare earth agglutinant and 2-3 parts of sulfite pulp waste liquid, wherein the specific gravity delta of the sulfite pulp waste liquid is greater than or equal to 1.28g / cm<3> and smaller than or equal to 1.32g / cm<3>. The production process comprises the steps of: 1) mixing the raw materials, adding high-purity magnesia, large-crystal electro-fused magnesia, fused magnesia-chrome sand, chromite, MgCO3, the chromium concentrate submicron powder and rare earth agglutinant into a mixing pan to uniformly mix according to the weight ratio, adding sulfite pulp waste liquid of which the specific gravity is greater than or equal to 1.28g / cm<3> to mix for 25-30 minutes, and discharging the mixture; 2) molding the mixture by a friction brick press of 800or 1000t, and drying for 48 hours at 110-200 DEG C; 3) sintering the brick blank inside a tunnel kiln, wherein the highest temperature is 168-1700 DEG C, and the heat preservation time is 5 hours; and 4) soaking by salt and baking the brick.

Owner:武钢集团有限公司

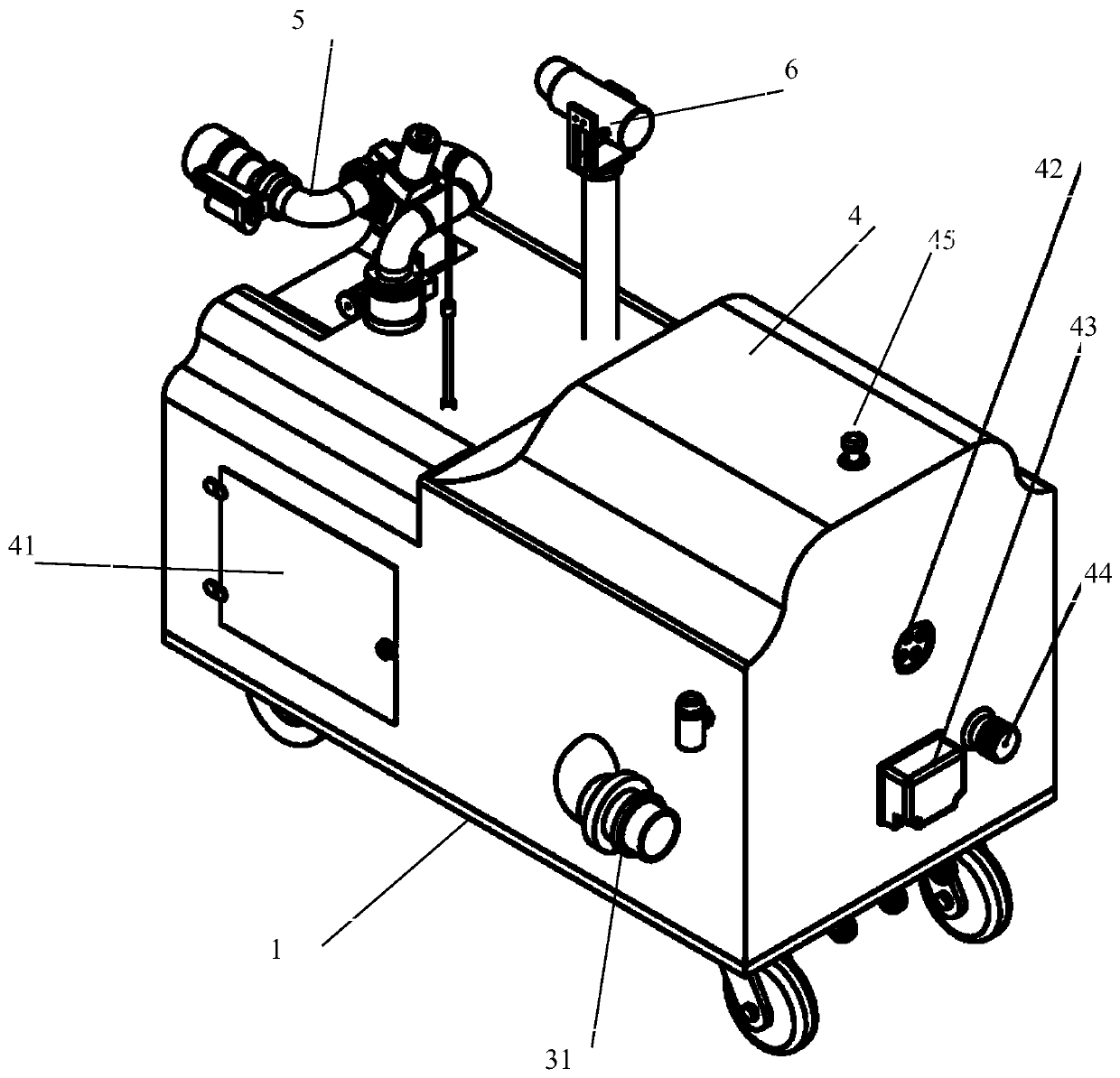

Tunnel fire-fighting robot and fire-fighting device

PendingCN109779671AReduce volumeImprove efficiencyDust removalSpraying vehiclesAgricultural engineeringOperation mode

The invention discloses a tunnel fire-fighting robot and a fire-fighting device. The tunnel fire-fighting robot comprises a wheel type chassis, a control cabinet and a booster pump arranged on the chassis, a protective cover covering the control cabinet and the booster pump, and a water cannon arranged on the protective cover, and a water inlet of the water cannon communicates with a water outletof the booster pump. The tunnel fire-fighting robot can move easily through the chassis, has a brake function and ensures that all parts of the robot are firm and reliable, the fire-fighting robot isadditionally provided with a pressurization assembly, a system can conduct pressurization automatically, it is ensured that fire-fighting water has enough fire-fighting pressure, and the water cannonhas a larger shot range. The tunnel fire-fighting robot is very useful especially under the conditions that the fire is difficult to approach and the fire behavior is large, is small in size, high inefficiency and good in fire-fighting effect, replaces an original manual fire-fighting operation mode, and is waterproof and heat-insulated through the protective cover, the whole machine is protected, and especially a control unit is particularly free of water and high-temperature erosion.

Owner:TIANJIN HENGTONGLI RAILWAY ENG MACHINERY PARTS

Imitation technology method for celeste glaze of Yaozhou porcelain

The invention relates to an imitation technology method for celeste glaze of Yaozhou porcelain. The imitation technology method comprises the steps: using potash feldspar, quartz, clay, calcite, Suzhou clay and talc as main raw materials and using ferric oxide as a colorant; mixing the raw materials and the colorant with zinc oxide, sodium methylcellulose and sodium polyphosphate to prepare glaze slip; uniformly applying the glaze slip on a ceramic green body after biscuit firing, and firing the ceramic green body with a glazing color close to an ancient celeste glaze. The physical performance, the chemical composition and the microstructure of the celeste glaze fired according to the imitating technological method are all close to those of the ancient celeste glaze, and a good firing effect is achieved; when the imitation technology method is used to fire the celeste glaze of Yaozhou porcelain, the raw materials are basically generalized, the production cost can be lowered, and a mature preparation process is provided to the industrial production of the celeste glaze of Yaozhou porcelain in future; the imitation technology method has the characteristic of cost and energy saving.

Owner:SHAANXI UNIV OF SCI & TECH

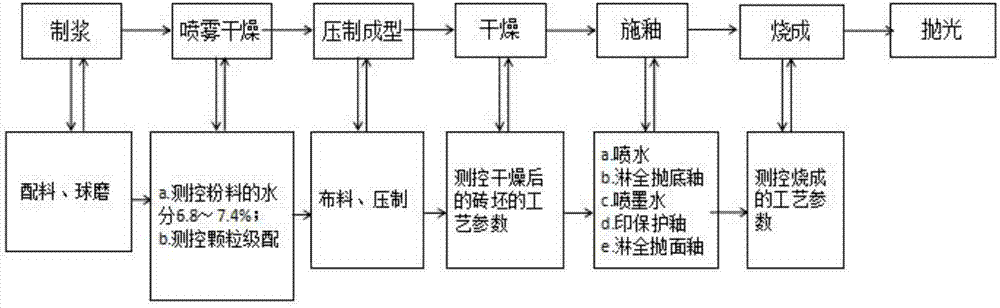

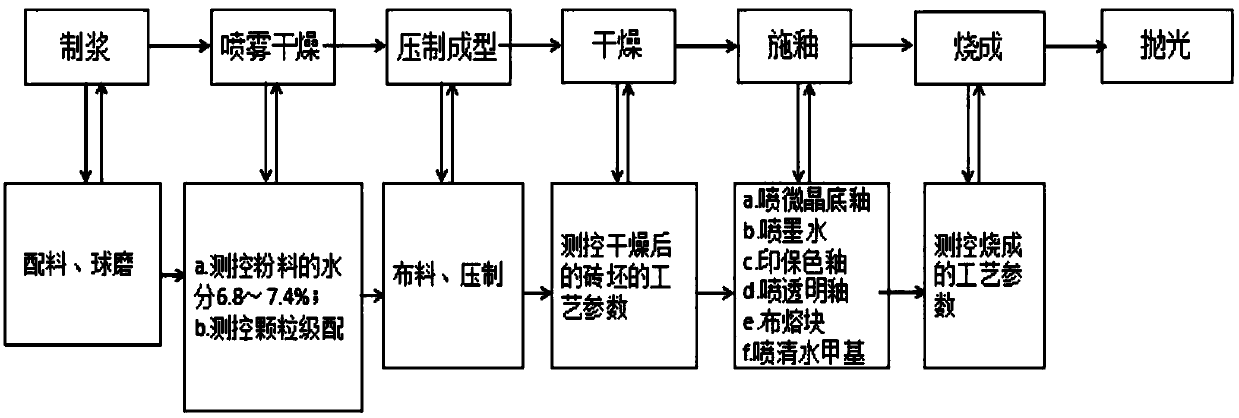

Process for producing full polished glazed tiles

The invention discloses a process for producing full polished glazed tiles. The process comprises the following steps: (1) selecting mineral raw materials, burdening, and carrying out ball milling soas to obtain slurry; (2) performing spray drying on the slurry so as to obtain powder, measuring and controlling the moisture of the powder to be 6.8-7.4%, wherein the grain composition is as follows:less than 1% of 20-mesh grain compositions, 35-47% of 40-mesh grain compositions, 50-62% of 80-mesh grain compositions, and less than 3% of 100-mesh grain composition; (3) performing compression molding on the powder so as to obtain a green brick; (4) drying the green brick, and measuring and controlling technological parameters of the green brick; and (5) glazing, namely a, spraying water onto the surface of the green brick, wherein the usage is 30+ / -6g per tray; b, sprinkling full polished ground coat on the surface of the green brick, wherein the usage is 105+ / -4g per tray, and the specific gravity is 1.89+ / -0.04g / ml; c, jetting ink on the surface of the green brick; d, performing screen printing on protective glaze by adopting a 100-mesh sieve on the surface of the green brick, wherein the specific gravity is 1.55+ / -0.02g / ml; and e, sprinkling full polished glaze on the surface of the green brick, wherein the usage is 105+ / -4g per tray, and the specific gravity is 1.89+ / -0.04g / ml,firing, and polishing, thereby obtaining the full polished glazed tiles. According to the process for producing the full polished glazed tiles disclosed by the invention, the quality control is accurate, the yield is high, the production quality is stable, and the production cost is reduced.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD

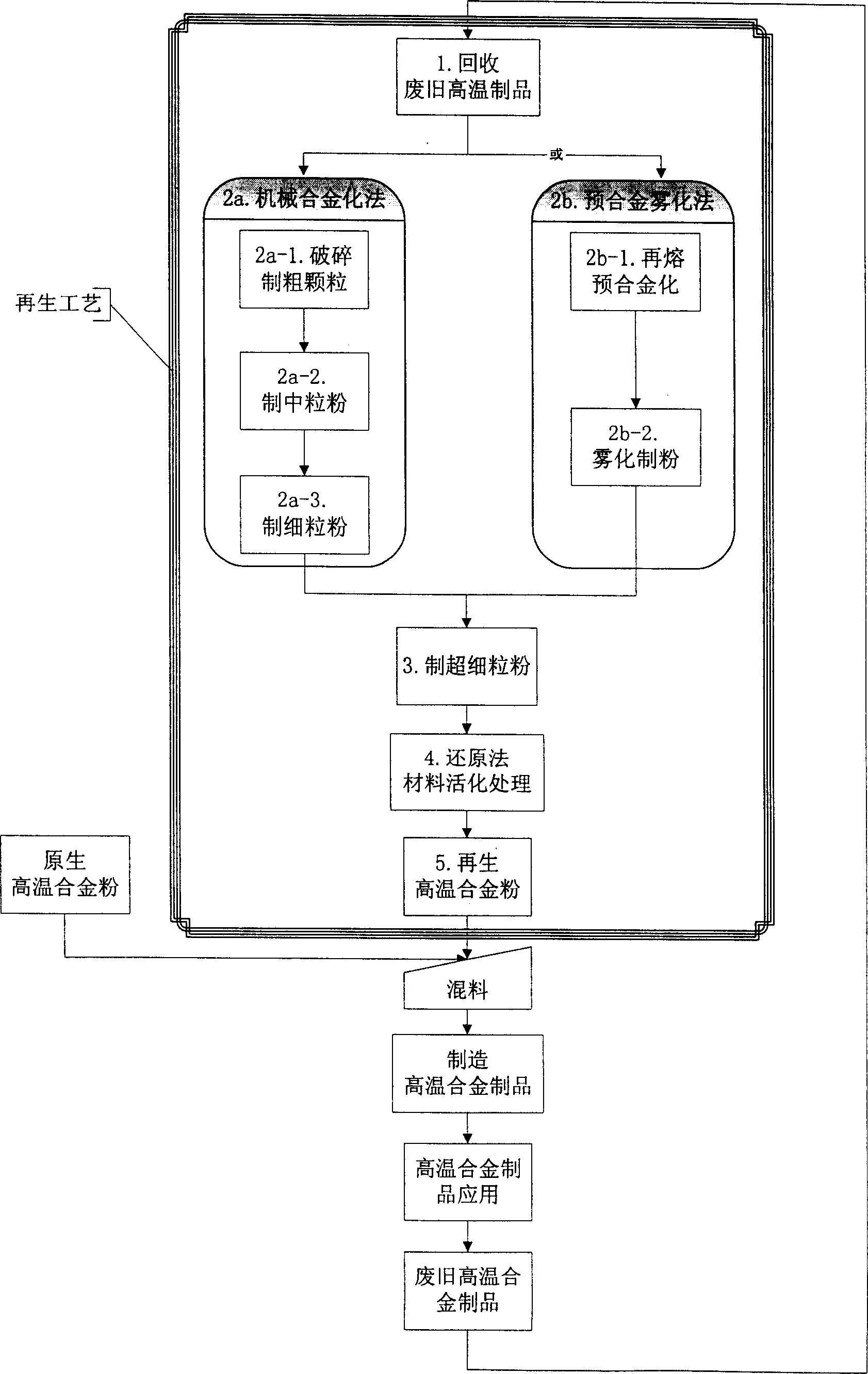

High temperature alloy product material regenerative cycle utilizing method

The invention is related to a method to reuse a superalloy ware in a cycle. It includes the steps of: The recycle superalloy is milled to very small particles and powder, then activate it use reduction method, then the superalloy is regenerated. The invention mills the waste superalloy is ware to small particles, and powder the particles, and make the size of powder below superfine powder. So it can improve such performances as transformation, strain relaxation, mechanical fatigue and thermal fatigue of the superalloy wares. The surface activation handling using reduction method can decrease the oxygen index of the recycle powder, and reduce various factors that baffle the sintering. It improves the sinter performances of the regenerated superalloy wares. The invention reduces and activates the recycle powder which is produced use hydrogen reduction in the condition of high temperature. The reduction and activation can eliminate the gas, oxide film and volatile production of chemical reaction that adsorbed in the surface of particles.

Owner:杨斌

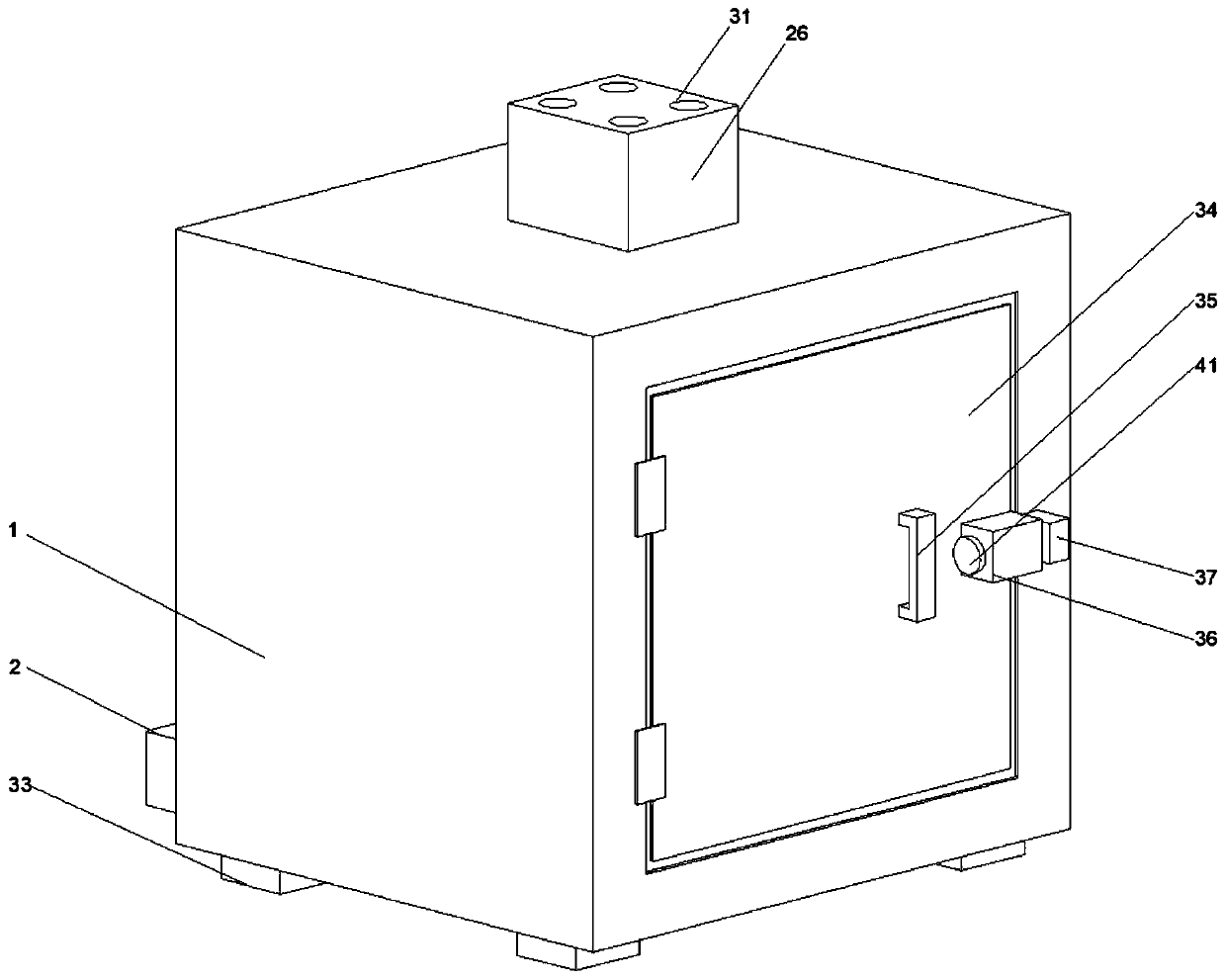

Height-adjustable fire extinguisher storage device

The invention relates to the technical field of fire extinguishing devices, in particular to a height-adjustable fire extinguisher storage device. The height-adjustable fire extinguisher storage device comprises a protection box, a fixing mechanism, a lifting mechanism, a limiting mechanism, a transmission mechanism and a placing mechanism. When a fire disaster occurs, a user rotates a handle andpushes the handle, so that the handle drives a connecting rod to move towards the inside of the protection box; and then a clamping block at the end portion of the connecting rod is clamped in a toothgroove, the connecting rod drives the transmission rod to rotate, the transmission rod drives a third gear to rotate, the third gear drives a fourth gear to rotate, the fourth gear rotates at a faster speed due to the fact that the diameter of the third gear is larger than that of the fourth gear, the fourth gear rotates to drive a rotating shaft to rotate, the rotating shaft drives a disc to rotate, and the disc drives a fire extinguisher body to rotate, so that the fire extinguisher body is fully shaken before being used, uniform distribution of chemical extinguishing substances in the fireextinguisher body is guaranteed, operation steps and time for the fire extinguisher body are saved for a user, and the use effect of the fire extinguisher body is guaranteed.

Owner:深圳市卓安消防设备有限公司

Production process of microcrystalline tile

The invention provides a production process of a microcrystalline tile. The production process of the microcrystalline tile comprises the following steps: (1) selecting raw mineral materials, mixing and carrying out ball milling to obtain slurry; (2) carrying out spray drying of the slurry to obtain powder, and wherein by measuring and controlling, the content of water in the powder to beis 6.8-7.4% of water, and measuring and controlling the particle grading composition to beis formed by less than 1% of 20-mesh particles, 35-47% of 40-mesh particles, 50-62% of 80-mesh particles and less than3% of particles with size being smaller than 100 meshes; (3) pressing and molding the powder to obtain a tile blank; (4) drying the tile blank, and measuring and controlling the process parameters ofthe tile blank; and (5) glazing through the substeps of a, spraying microcrystalline ground glaze on the surface of the tile blank according to a dosage of 130+ / -2g / tray and a specific gravity ratio of 1.45+ / -0.02g / ml; b, spraying ink on the surface of the tile blank; c, carrying out screen printing of color protecting glaze on the surface of the tile blank by using a 100-mesh sieve according to aspecific gravity ratio of 1.55+ / -0.02g / ml; d, spraying transparent glaze on the surface of the tile blank according to a dosage of 60-70g / tray and a specific gravity ratio of 1.47+ / -0.02g / ml; e, coating applying frit on the surface of the tile blank according to a dosage of 780+ / -20g / tray; f, spraying clear water methyl on the surface of the tile blank according to a dosage of 40+ / -2g / tray; firing and polishing to obtain the microcrystalline tile. The production process of the microcrystalline tile is has the advantages of being more accurate in quality control, higher in rate of finished products and more stable in production quality; the production cost is reduced.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD +2

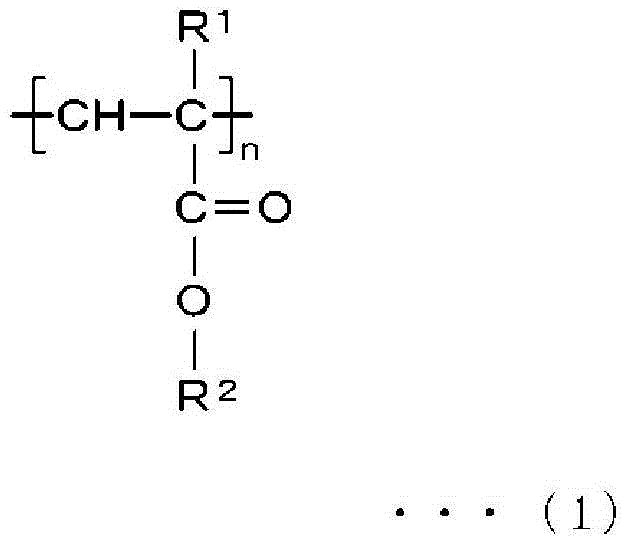

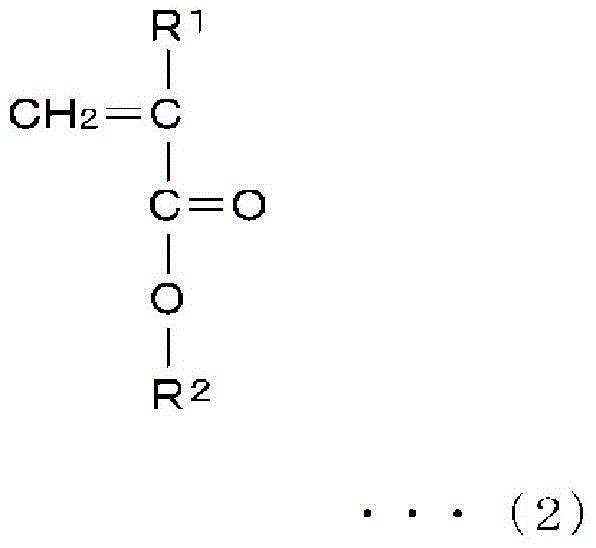

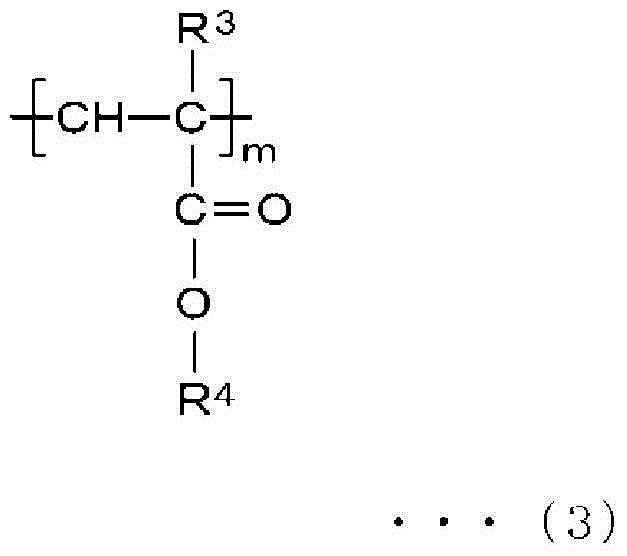

Paste composition, and sintered body and method for producing same

ActiveCN104822766AModerately viscousGood spreadabilityFixed capacitor dielectricStacked capacitorsHydrogenHydrogen atom

[Problem] To provide a paste composition that has an appropriate viscosity and exhibits good coating properties and good sintering properties, a method for producing a sintered body using the paste composition, and a sintered body. [Solution] A paste composition characterized by comprising a (meth)acrylic (co)polymer that contains 20-100 mol% of structural unit (A) represented by general formula (1). In general formula (1): R1 represents a hydrogen atom or a methyl group; R2 represents a group which satisfies the requirements X<13.5 Å and Y>6.15 Å [wherein X represents the diameter in the long side direction, and Y represents the diameter in the short size direction] and has a volume greater than 80 Å3, and which is a functional group having a hydrogen bonding ability, a group having an alkoxy group or a group having an aryloxy group; and n is a number of 5-2000.

Owner:SOKEN CHEM & ENG CO LTD

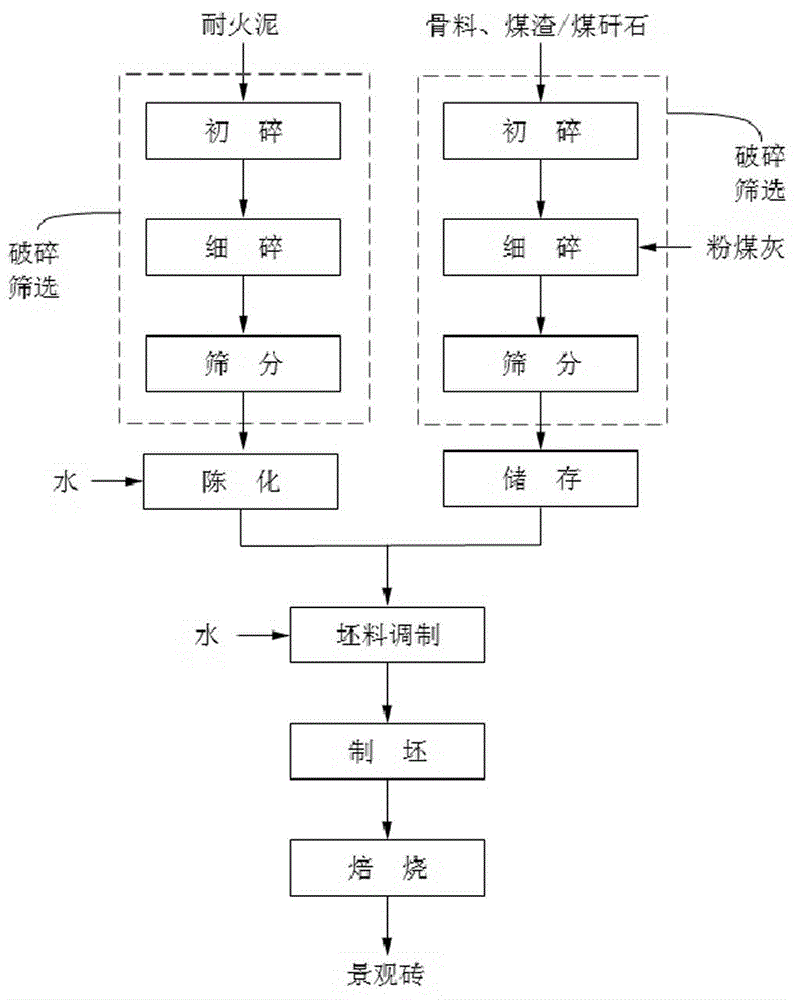

Yellow sintered landscape brick and production method thereof

InactiveCN104556962AImprove firing performanceReduce deformation of finished productFire clayHigh pressure

The invention discloses a yellow sintered landscape brick and a production method thereof. The yellow sintered landscape brick comprises 30 to 50 percent of fire clay and 50 to 70 percent of aggregate, wherein the sum of mass percent of all raw materials is not more than 100 percent. The production method comprises the steps of crushing, screening, blank mixing, blank preparation and roasting. According to the yellow landscape brick, aggregate is adopted as a main material, fire clay is adopted as an auxiliary material, and particularly hard fire clay and / or half-hard fire clay is adopted, so that the plasticity of the aggregate can be realized, and the blank is good in moldability; meanwhile, the raw materials are sintered at a high temperature of a specific range, the fire clay is thermally decomposed and toughened and covers and is bonded to the aggregate to present in faint yellow color and yellow color effects, so that the landscape brick has the characteristics of pure yellow color, relatively high pressure resistance and bending resistance and small deformation. The production method is pure in color, simple in process and stable in product quality.

Owner:楚雄诚鑫工贸有限公司

Method for solving section temperature difference of broad kiln

InactiveCN101059310AReduce the temperatureReduce cross section temperature differenceFurnace typesSize differenceCombustion

The present invention discloses a method solving wide kiln cross-section temperature difference, the wide kiln includes the ejection gun burning mouth channel passing through kiln bulk and the ceramic roller installed in kiln bulk calcined zone and used for laying products; the steps of the method solving wide kiln cross-section temperature difference as follows: a. said kiln bulk calcined zone is equipped with the fuse channel additionally which is penetrated with the ejection gun burning mouth channel; b. two sides temperature of the wide kiln is reduces; c. combustion air amount is reduced; the circumference of said fuse channel about is 1 / 4 of inner diameter of kiln bulk calcined zone; the circumference of said fuse channel about is 1 / 3of inner diameter of kiln bulk calcined zone. The invention increases the length of the calcined channel, can guide flame into the middle zone of kiln bulk calcined zone, so reduces the cross-section temperature difference of kiln bulk; it decreases the calcined time of products, the size differences in left, central and right direction of calcined products are controlled in 2-3 mm, the color-difference is reduced, the products passing percent is significantly increased, product quality is stable, the product cost is reduced and it has vast market economic benefits.

Owner:霍镰泉

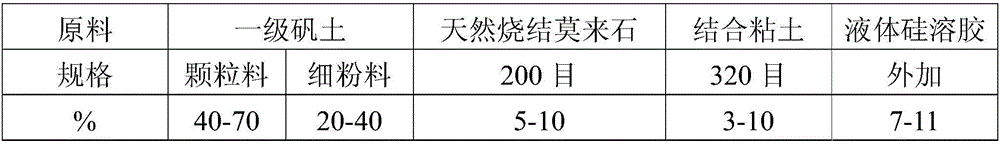

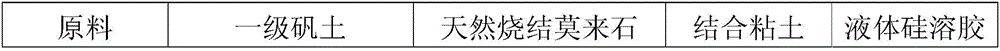

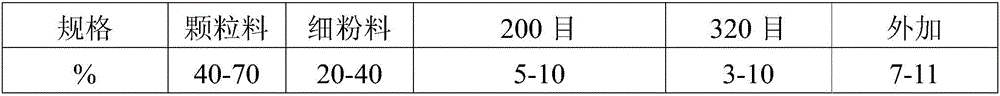

High-quality high-aluminum runner brick as well as preparation method and application thereof

The invention discloses a high-quality high-aluminum runner brick as well as a preparation method and an application thereof. According to the high-quality high-aluminum runner brick, first-grade alumina is taken as aggregate, a proper amount of naturally sintered mullite and binding clay are added to a powdery matrix material, and liquid silica sol is taken as a binding agent. According to the high-quality high-aluminum runner brick, due to the good performance of silica sol, the firing temperature of a product is effectively reduced, the interval range of the firing temperature is increased, and additionally, the physical and chemical indexes of the prepared high-aluminum rubber brick product are superior to those of rubber bricks produced with a conventional binding agent; ingredients of poured quality steel are uniform and stable if the high-quality high-aluminum runner brick is used in mold casting and steel pouring sites, the cleanness is high, and requirements of users are effectively met.

Owner:瑞泰马钢新材料科技有限公司 +1

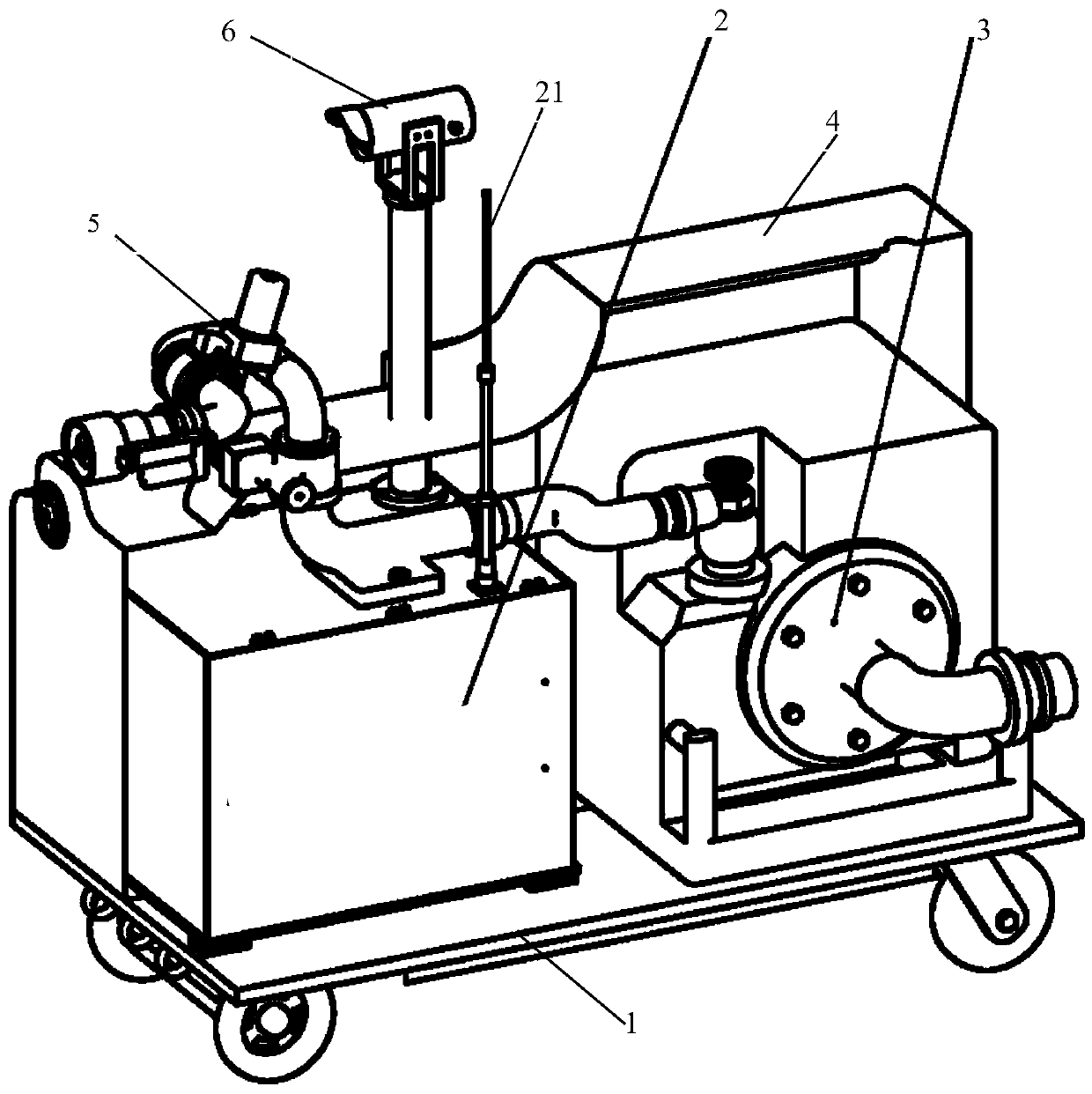

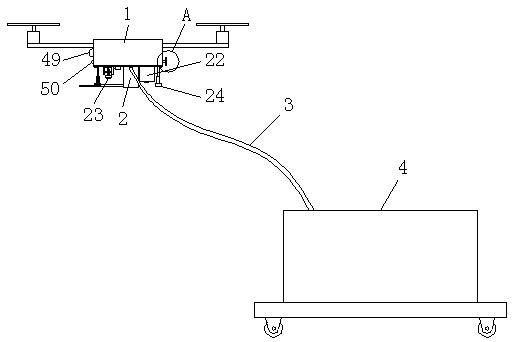

An unmanned aerial vehicle (UAV) connected with ground-movable fire fighting device

PendingCN109050921AGuaranteed accuracyEasy detectionAircraft componentsFire rescueEngineeringWater spray

The invention discloses an unmanned aerial vehicle (UAV) connected with a ground movable fire fighting device, include an unmanned aerial vehicle body, A light device is sequentially arranged at thatbottom end of the body of the unmanned aerial vehicle, water tanks and bomb delivery tanks, At that bottom end of the main body of the unmanned aerial vehicle, the cushioning device is arranged on thelighting device, Outside of the water tank and the bomb drop tank, A fire-fighting water pipe is connected to the water tank through a rotary joint, the other end of the fire water pipe is connectedto a ground movable fire fighting device, one end side wall of the water tank is provided with a mounting opening, A miniature pump is installed in the mounting port, the input end of the miniature pump is arranged inside the water tank, The output end is provided with a water spraying head, and the UAV body is provided with a camera and an infrared temperature sensor. The invention has simple structure and is convenient to use, and can detect fire situation under dim conditions. Due to the flexible characteristics of the UAV, water can be sprayed from the high altitude to an area that is difficult to enter on the ground, thereby improving fire fighting effect and fire extinguishing efficiency.

Owner:ANHUI ZHONGTIAN SECURITY SERVICE GRP CO LTD

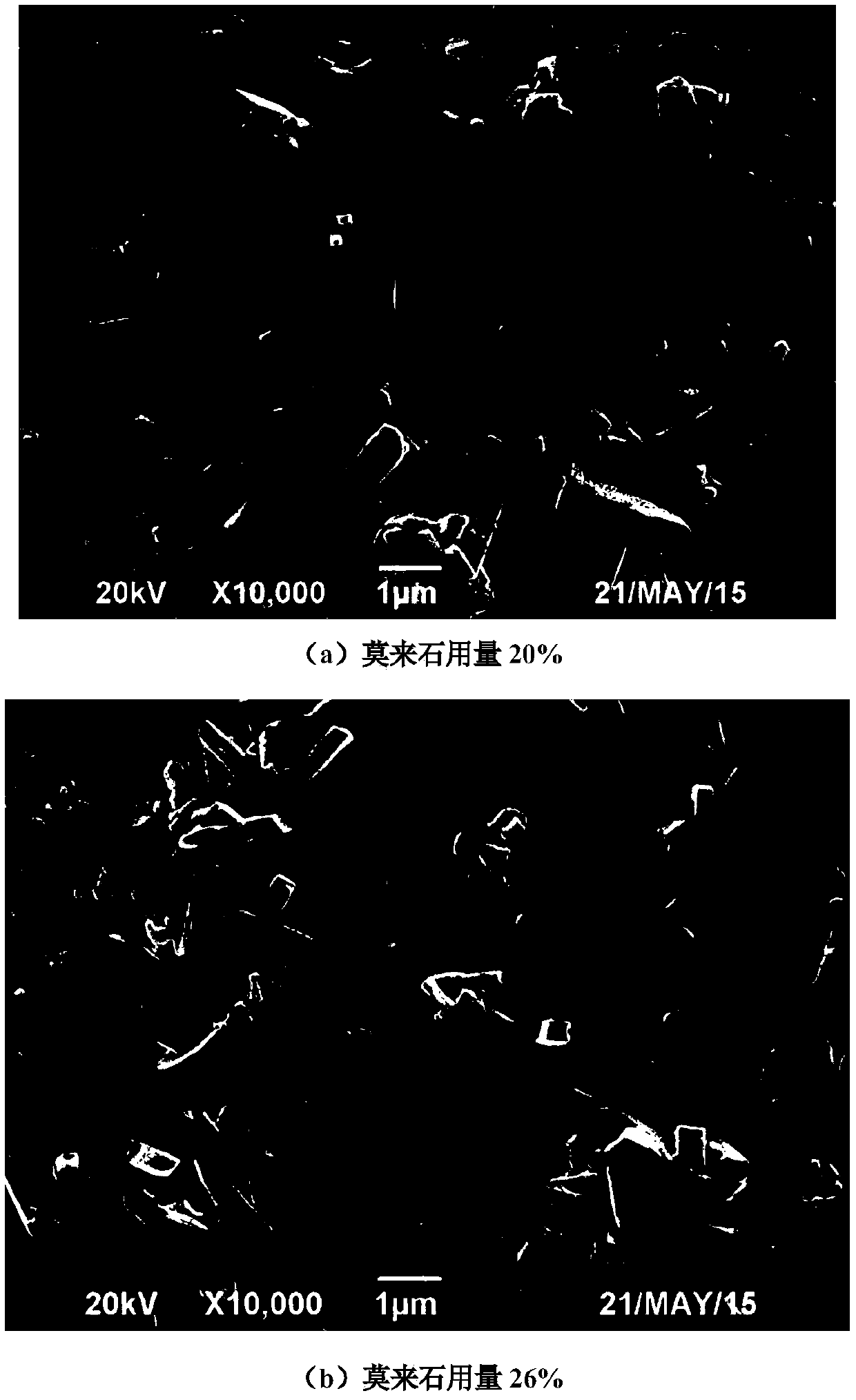

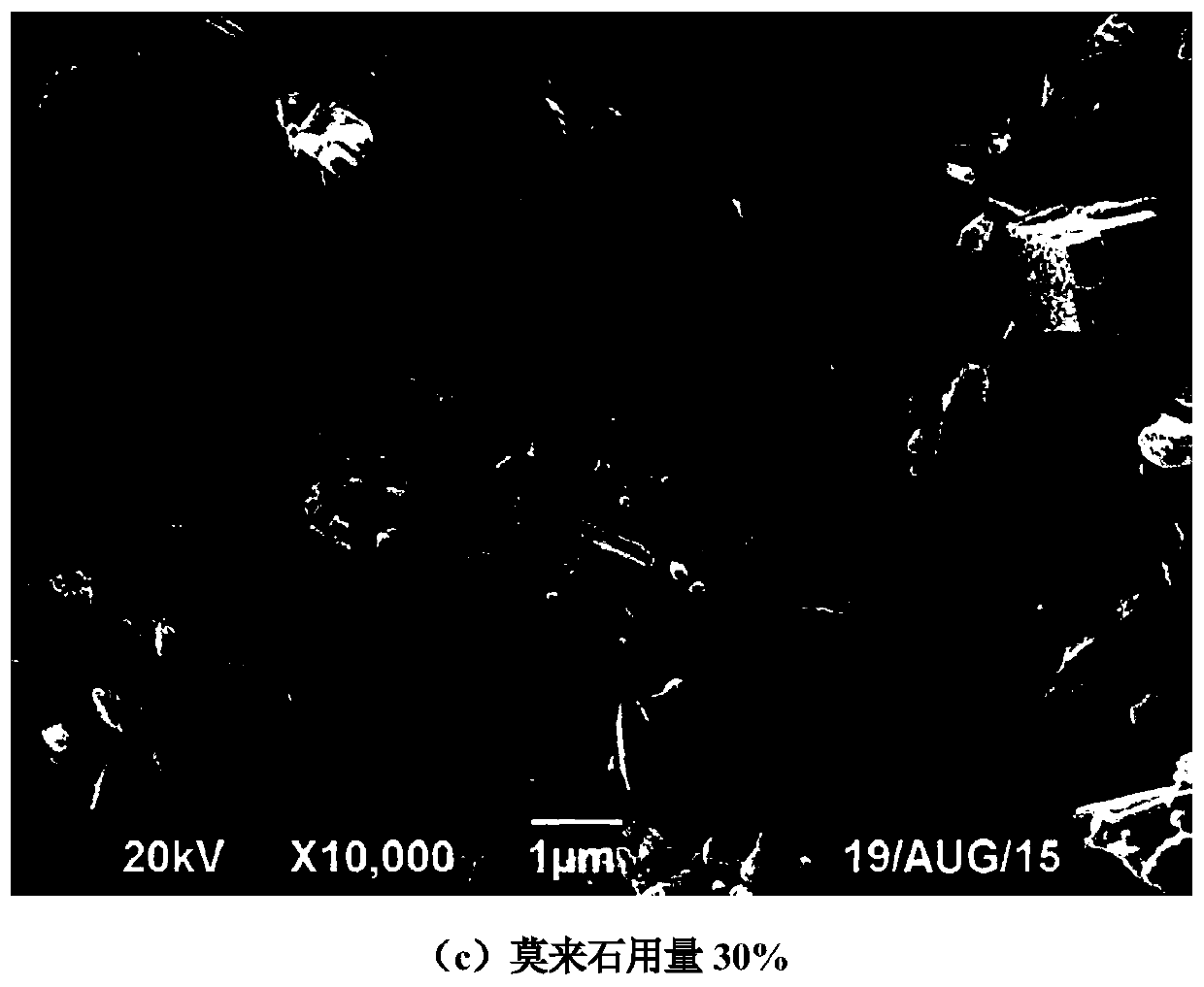

Novel material for high-strength electric ceramies and preparation method of novel material

The invention discloses a novel material for high-strength electric ceramies and a preparation method of the novel material. The novel material for the high-strength electric ceramies is prepared fromthe following components: 5-15% of calcined industrial aluminum oxide powder, 20-30% of calcined mullite powder, 20-30% of kaolin and binding clay, 15-20% of special-grade potassium feldspar powder and 1-5% of an addition agent. The preparation method of the novel material comprises the steps that the obtained calcined mullite is subjected to ball-milling into powder by adopting ball-milling equipment, sieving is carried out, the elutriated kaolin and special-grade potassium feldspar are selected and subjected to ball-milling into powder by adopting the ball-milling equipment as well, sievingis carried out, a powder material is mixed with the calcined industrial aluminum oxide powder, the addition agent is added to obtain slurry, a pressed powder material is made and extruded to blank materials of the electric ceramies with the required size by using a vacuum deairing machine after coarse milling, the blank materials of the electric ceramies are placed in a kiln for firing more than24 hours by adopting an oxidizing flame, and cooling is carried out to obtain the novel material for the high-strength electric ceramies. According to the novel material for the high-strength electricceramies and the preparation method of the novel material, structure defects in the ceramic quality are overcome, the ceramic quality structure and uniformity of a product are improved, the percent of pass of the product manufacturing process is increased, stabilization and reliability of the product performance are ensured, and the fuel cost is saved.

Owner:湖南省醴陵市华电电瓷制造有限公司

Production process of ceramic tile capable of accurately positioning dry particles, and product thereof

InactiveCN112010677AGood effectBright color and textureAuxillary shaping apparatusBrickAdhesive glue

The invention discloses a production process of a ceramic tile capable of accurately positioning dry particles, and a product thereof. The production process comprises the following steps: A, applyingground coat to the surface of a ceramic tile blank through a glazing device; B, digitally printing surface glaze through a glaze printing device; and C, printing a glue and ink pattern in a first limited area on the surface of the ceramic tile blank through a gluing unit of a dry particle printing device, and then positioning and distributing the dry particles in the first limited area through adry particle positioning and distributing unit of the dry particle printing device. The production process of the ceramic tile capable of accurately positioning dry particles is simple; and firing canbe carried out after rapid drying, and the sintering effect is good, so the problems of long-time drying or cracking of the brick body and large dosage of the dry particles when the dry particles andthe protective glaze are purely applied are solved, the prepared ceramic tile has the advantages of high wear resistance, hardness and flatness, high texture pattern definition, strong permeability and strong three-dimensional contrast, and the problems of poor use performance and poor three-dimensional effect of the ceramic tile purely coated with dry particles and protective glaze are solved.

Owner:佛山市东鹏陶瓷发展有限公司

Mooring type fire rescue unmanned aerial vehicle system

PendingCN111268128AAchieve integrationGuaranteeAircraft componentsTethered aircraftAerospace engineeringEnvironmental monitoring

The invention discloses a mooring type fire rescue unmanned aerial vehicle system, which is applied to the technical field of high-altitude fire fighting, is used for solving the technical problem ofsingle function of the existing mooring unmanned aerial vehicle, and innovatively combines fire fighting and rescue. The mooring type fire rescue unmanned aerial vehicle system specifically and structurally comprises a mooring unmanned aerial vehicle, an environment monitoring unit, a fire extinguishing unit and a rescue ejection unit; the environment monitoring unit is used for monitoring information of the environment where the mooring unmanned aerial vehicle is located; the rescue ejection unit is used for ejecting rescue materials; the fire extinguishing unit is used for spraying a fire extinguishing agent; and the environment monitoring unit, the fire extinguishing unit and the rescue ejection unit are all installed on the mooring unmanned aerial vehicle. The mooring type fire rescueunmanned aerial vehicle system has the advantages of fire protection and rescue functions, good fire rescue effect and the like.

Owner:长沙市云智航科技有限公司

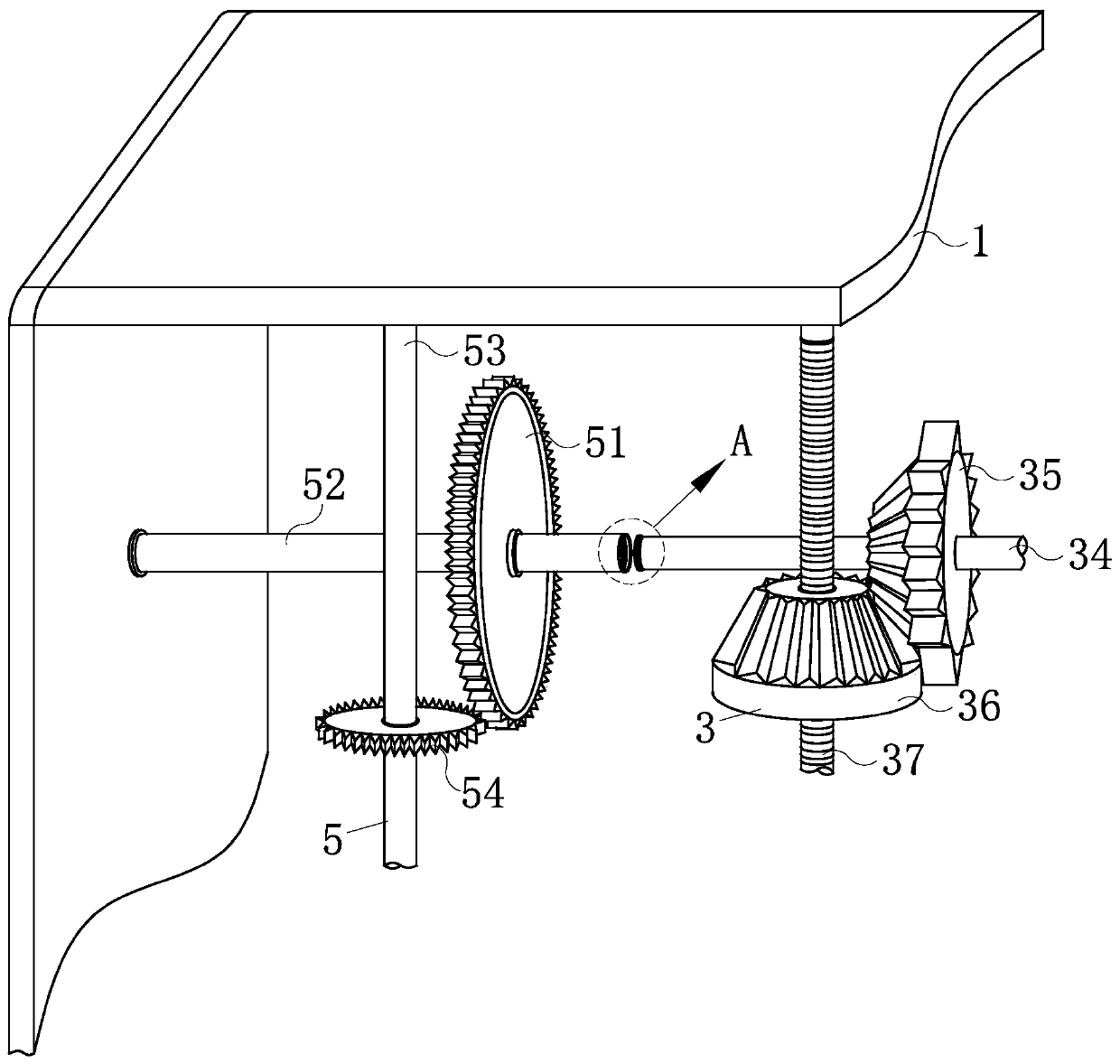

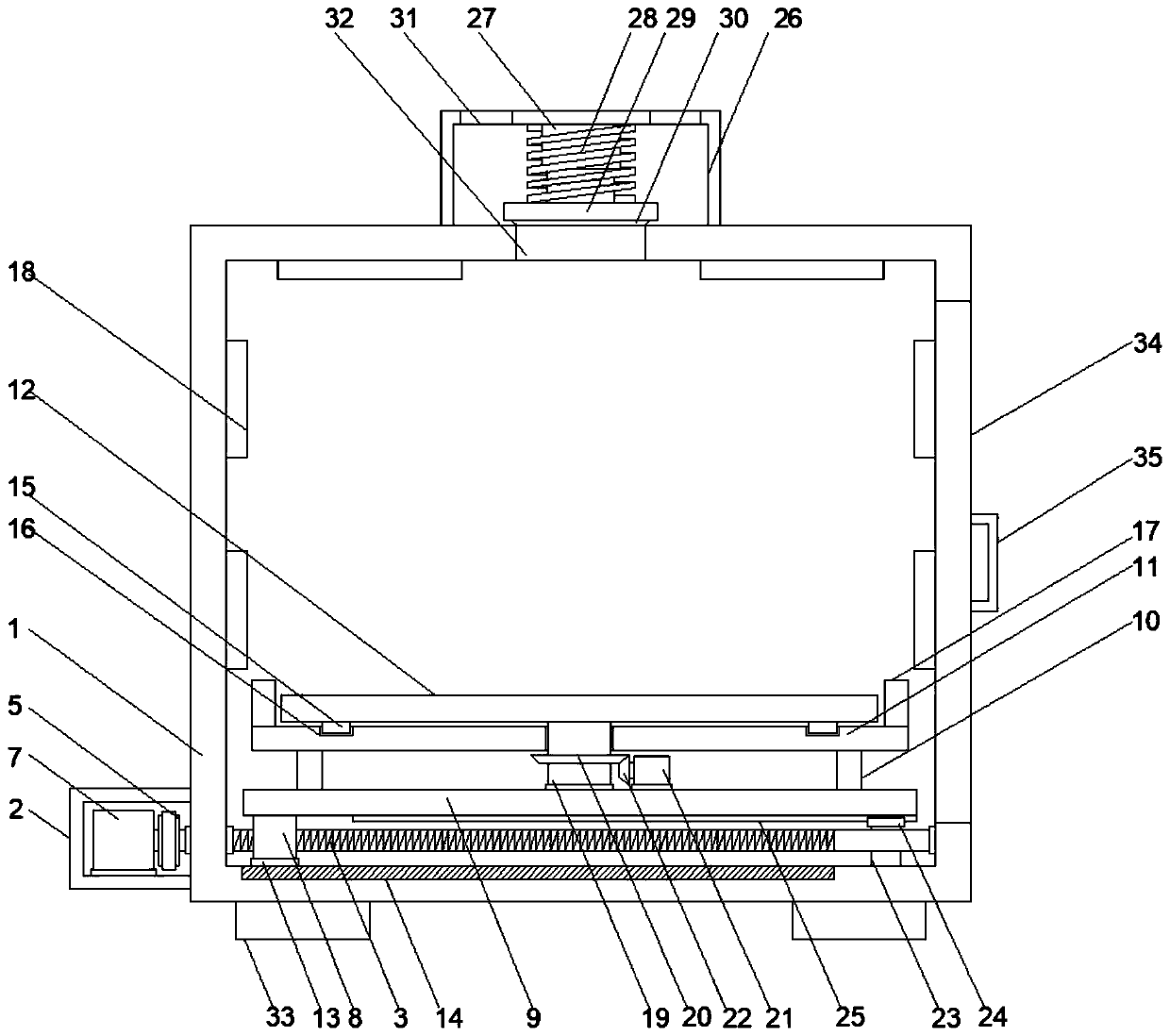

Processing and firing device for healthy and environment-friendly domestic ceramic

InactiveCN111397371AEvenly heatedAvoid crackingCharge supportsMaintainance of heating chambersElectric machineryEngineering

The invention discloses a processing and firing device for healthy and environment-friendly domestic ceramic. The processing and firing device comprises a furnace body. A first fixed shell is fixedlyinstalled on the back portion of the furnace body. The bottom of the furnace body is rotationally connected with a first threaded rod and a second threaded rod. A first motor is fixedly installed in the first fixed shell. A first gear is fixedly installed at the output end of the first motor. The first gear is fixedly connected with the first threaded rod. A second gear is fixedly installed at oneend of the second threaded rod. In the processing and firing device, a first bevel gear is driven by a second motor to rotate, the first bevel gear drives a second bevel gear meshing with the surfaceof the first bevel gear to rotate, the second bevel gear drives a connecting shaft and a placing table to rotate so as to drive the ceramic on the placing table to rotate, and therefore the ceramic is more evenly heated, it is avoided that cracks appear on the ceramic due to uneven heating, the finished product quality of the ceramic is improved, and in cooperation with second sliders fixedly installed on the lower side of the placing table and second slide grooves formed in the surface of a supporting plate, the rotating stability of the placing table and the ceramic is improved.

Owner:广东怡泰龙实业发展股份有限公司

Amphibious Aircraft Fire Fighting Enhancement

InactiveUS20160107011A1Increase water productionImprove the fire effectAircraft componentsFire rescueJet aeroplaneSuper absorbent

The instant invention relates to a system for enhancing the fire extinguishing properties of water. A volumetric screw feeder is employed to transfer super absorbent polymers from a storage vessel into a liquid reservoir employed with fire fighting equipped amphibious airplanes.

Owner:REGER MICHAEL L

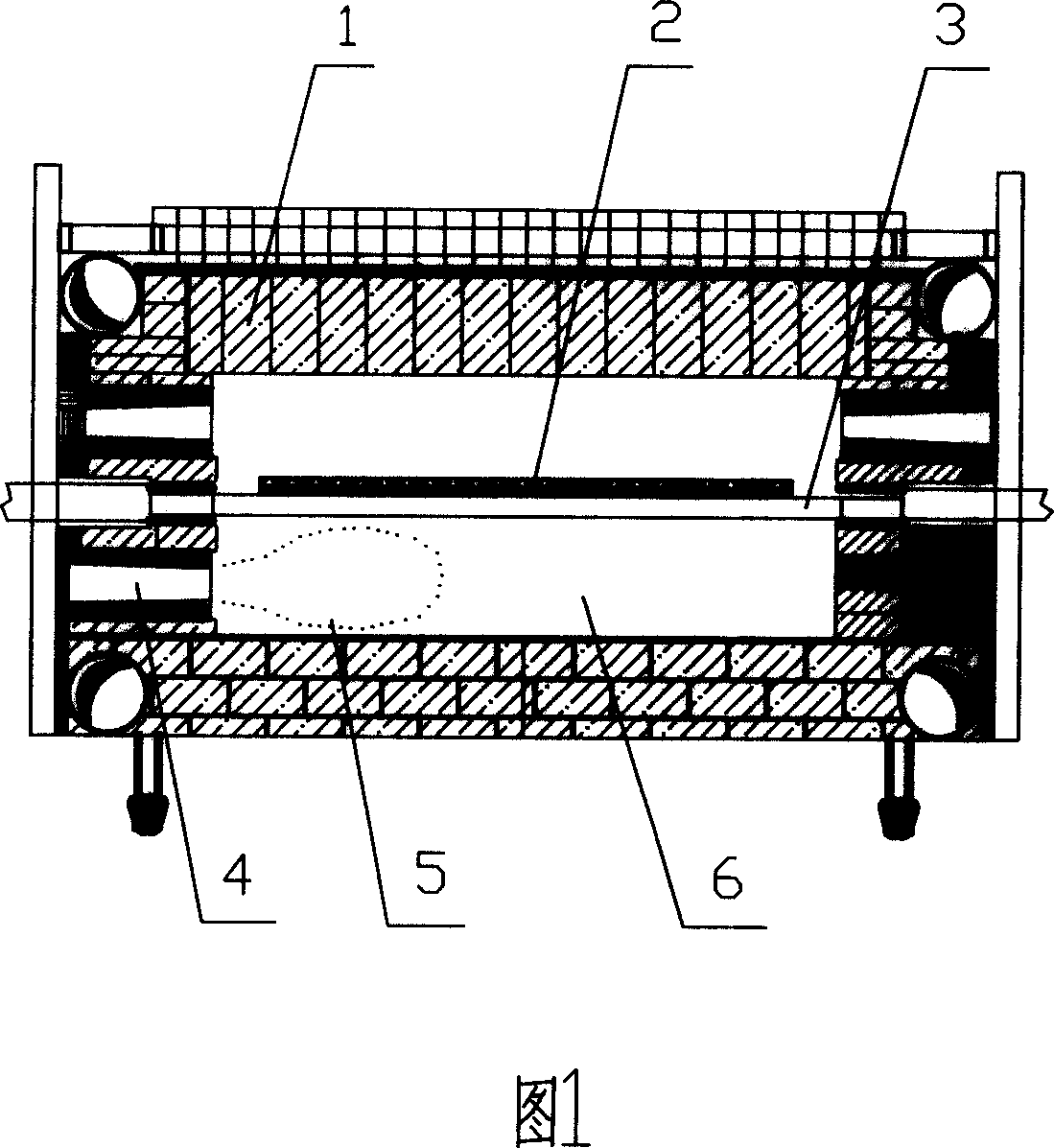

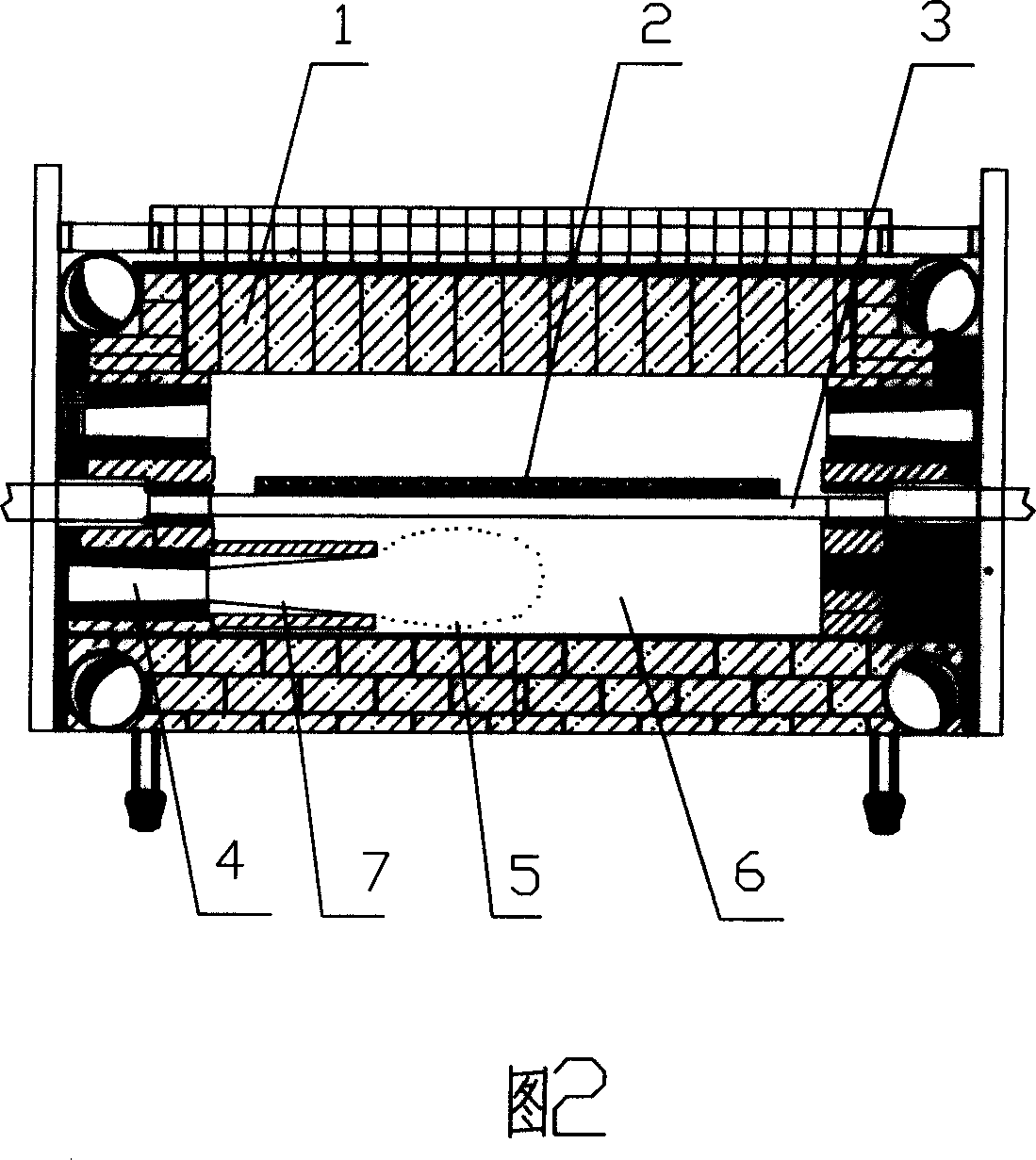

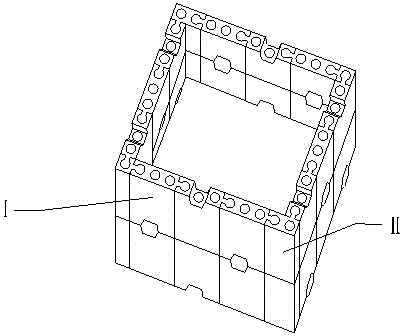

Combined detachable high-temperature sintering-bearing saggar and preparation method and application thereof

ActiveCN104913642AEfficient deliveryIncrease heat transfer rateCharge supportsCeramic sinteringSaggar

The invention relates to a combined detachable high-temperature sintering-bearing saggar and a preparation method and application thereof, and belongs to the technical field of appliances for ceramic sintering. The combined detachable high-temperature sintering-bearing saggar comprises a plurality of first assemblies and a plurality of second assemblies, wherein the plurality of first assemblies are mutually connected in a matched manner through grooves of the first assemblies and columns ribs and connecting portions of adjacent first assemblies; second grooves of the second assemblies are connected with the columnar ribs and connecting portions of the first assemblies in a matched manner. The sintering-bearing saggar provided by the invention has the advantages that the structure is reasonable and simplified, the heat can be effectively transferred, the heat is uniformly transferred, and the rate of finished products of sintered precision ceramic parts is effectively improved.

Owner:山东龙湖信息产业集团有限公司

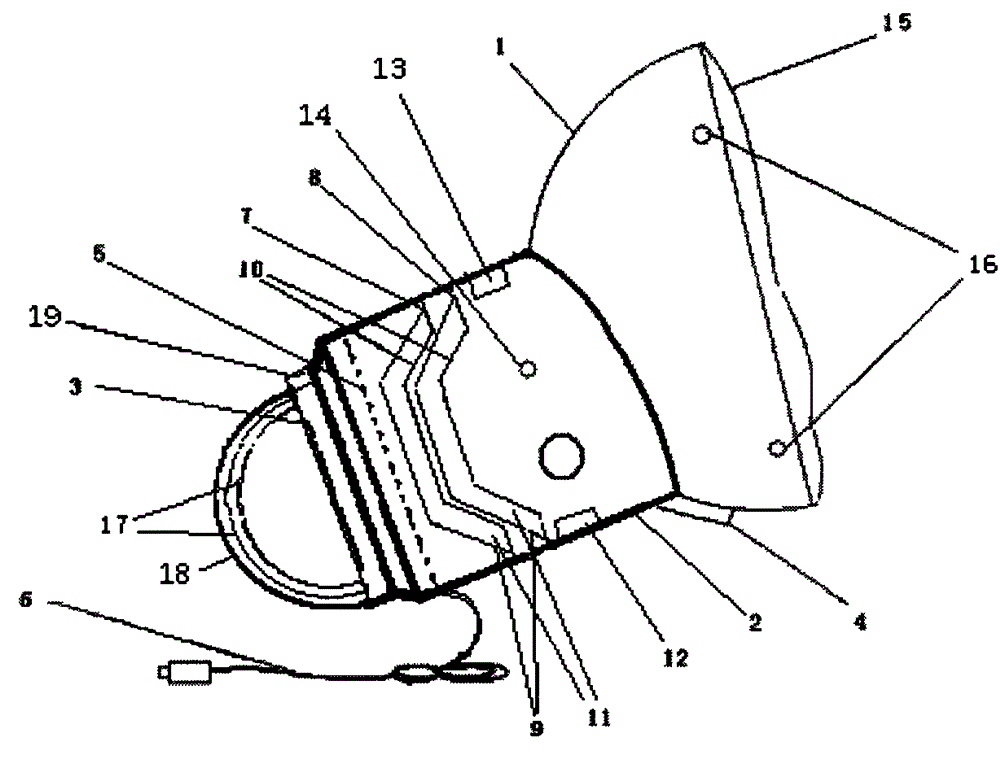

Respiratory system protecting mask

InactiveCN104027903AImprove the ability to prolong lifeImprove disease resistanceRespiratory masksFire rescueElectric heatingAtmosphere

Disclosed is a respiratory system protecting mask. The respiratory system protecting mask is a nose-and-mouth covering bowl. The nose-and-mouth covering bowl is provided with an electric heating net, a medicament atomizer, a mini-type anion generator, an oxygen inhalation joint, a medicine gauze frame combination and the like which are arranged in a cylindrical surface type air inhaling passage. Under action of the respiratory system protecting mask filled with medicines, air inhaled in a human body contains various effective medicine atmosphere with a certain physicochemical function and constantly directly acts on a principal part, namely a mucosal surface of an organ wall of the body respiratory system. The mucosal surface of an organ wall is weakest, most susceptible and hard to cure according to conventional method. Thus a dedusting and sterilizing function is achieved to improve curative effect and antitoxic and disease prevention capacity of people to environment, prevent some respiratory diseases and improve living quality. With wide application of the auxiliary health protection device with high use frequency and standby degree, the respiratory system protecting mask serves as an antitoxic mask in emergency to win evacuating time, so that survival chance of victims in accidental fire scene can be increased.

Owner:吕明华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com