Mixed combustion control system of oxygen-enriched and full-oxygen combustion ceramic roller kiln

An all-oxygen combustion and mixed combustion technology, applied in the combustion method, combustion control, fuel supply adjustment, etc., can solve the problems of high burner injection and combustion rate, affecting product qualification rate, temperature fluctuation, etc., to achieve constant kiln temperature , ideal firing effect, the effect of gentle temperature change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

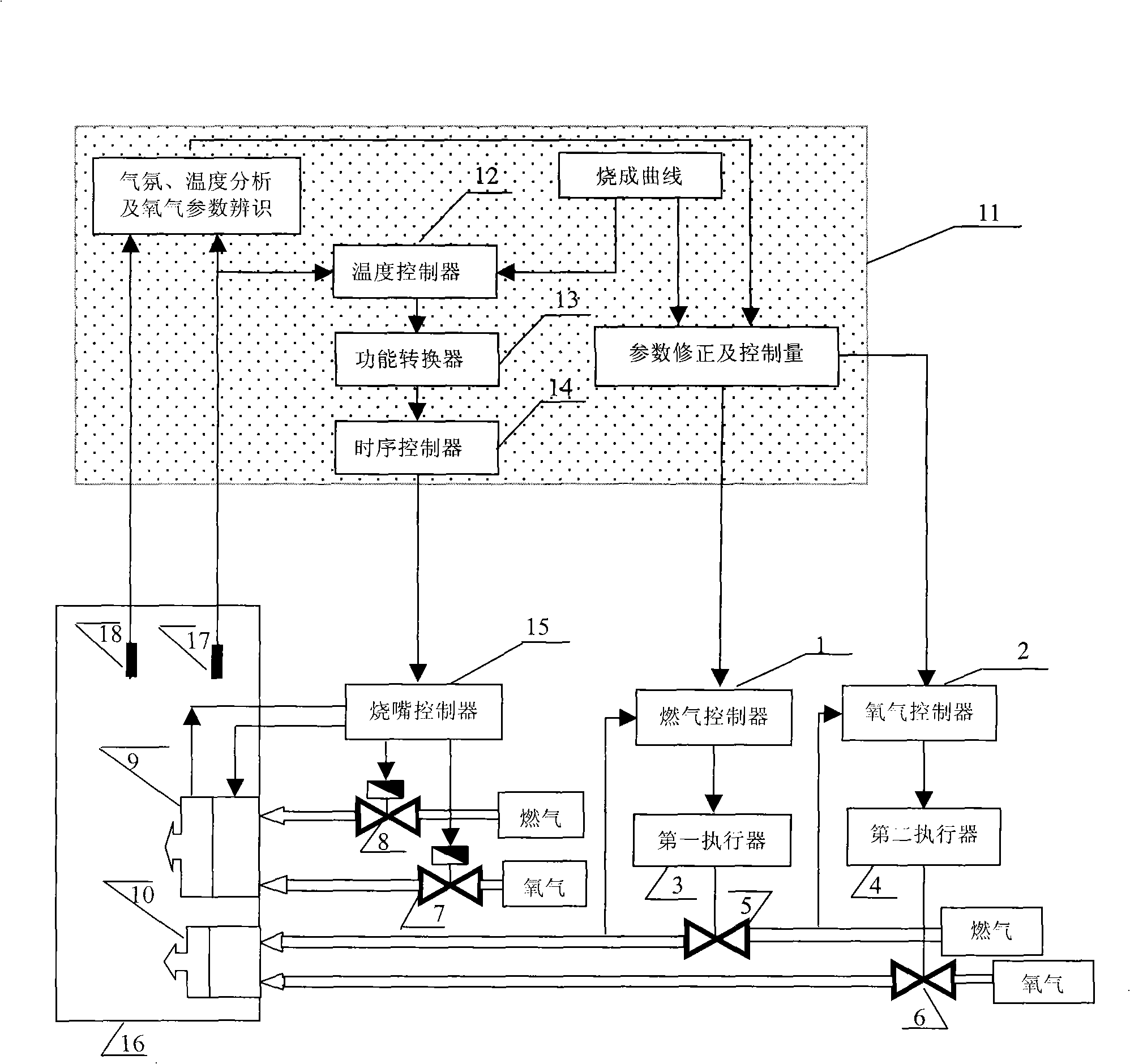

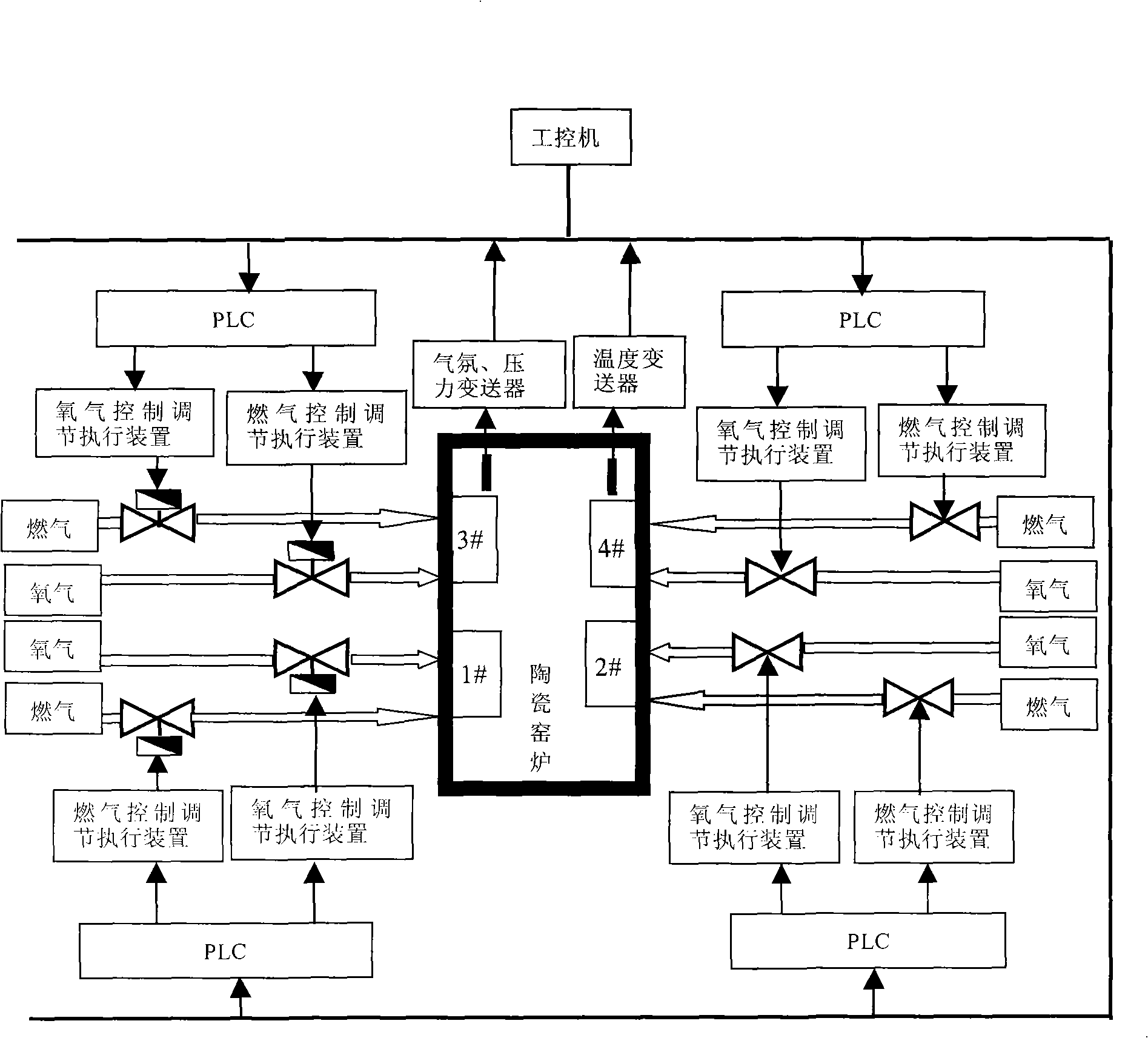

[0020] The oxygen-enriched and full-oxygen combustion ceramic roller kiln mixed combustion control system provided by the present invention has a structure such as figure 1 As shown: It is composed of a pulse combustion control subsystem and a proportional combustion automatic control subsystem, and the two subsystems simultaneously execute a firing curve determined by the host computer 11 . The pulse combustion control subsystem consists of a temperature sensor 17, a temperature controller 12, a function converter 13, a sequence controller 14, a burner controller 15, an oxygen solenoid valve 7, a gas solenoid valve 8 and a pulse combustion burner 9. , wherein: the temperature sensor 17, the temperature controller 12, the function converter 13, the timing controller 14 and the burner controller 15 are connected with cables in turn, and the temperature c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com