Combined detachable high-temperature sintering-bearing saggar and preparation method and application thereof

A combined, high-temperature technology, applied in the direction of furnace components, lighting and heating equipment, furnaces, etc., can solve the problems of slow heat transfer rate of integrated saggers, affecting the yield of fired porcelain, and inconvenient firing of precision ceramic parts. Achieve the effect of improving the uniformity of heat transfer, good firing effect, and fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

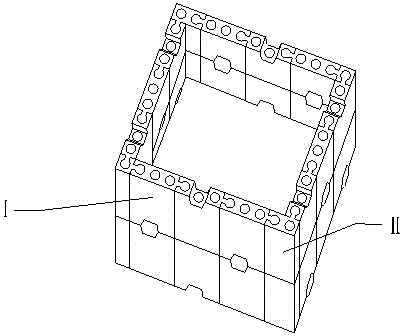

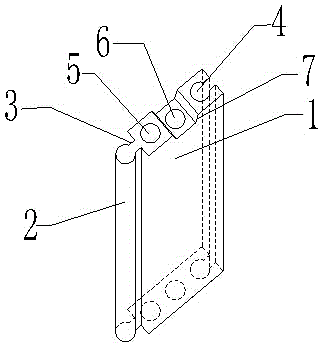

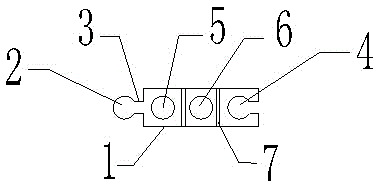

[0040] like Figure 1 to Figure 5 , Figure 8 As shown, the combined detachable high-temperature sagger of the present invention includes a plurality of first assemblies I and a plurality of second assemblies II, wherein the first assemblies I include first bumps 1, columnar bumps The strip 2 and the connecting part 3, the first bump 1 is connected to the columnar convex strip 2 through the connecting part 3, and a groove matching the connecting part 3 and the columnar convex strip 2 is provided on one side of the first bump 1 4. A first through hole 5 is set on the other side of the first bump 1, a second through hole 6 is set between the groove 4 and the first through hole 5, and a trapezoidal shape is set at the second through hole 6. The concave part 7, the width of the connecting part 3 is smaller than the diameter of the columnar convex strip 2; the second assembly II includes a second bump 8, and one side of the second bump 8 is arranged with the first assembly I The ...

Embodiment 2

[0050] like Figure 6 and Figure 7 As shown, the combined detachable high-temperature saggar of the present invention is different from Embodiment 1 in that the second assembly II is also provided with a third through hole 10, and the setting of the third through hole 10 can be Further enhance heat transfer efficiency.

[0051] The preparation method of the combined detachable high-temperature saggar comprises the following steps:

[0052] Step 1: Pulverize the leftovers of waste ceramic devices, remove iron impurities in them through a magnetic separator, and pass through a 50-100 mesh sieve to obtain basic powder;

[0053] Step 2: According to the parts by mass, 110 parts of the base powder obtained in Step 1, 20 parts of paraffin and 0.12 parts of oleic acid were mixed and stirred, and the temperature was raised to 65 ° C, and the pulp cake was obtained after natural cooling;

[0054] Step 3: raising the temperature of the slurry cake obtained in step 2 to 88°C, placing...

Embodiment 3

[0059] The structure of the combined detachable high-temperature firing sagger of this embodiment is the same as that of Embodiment 1, the difference is that its firing method is different from that of Embodiment 1, as follows:

[0060] The preparation method of the combined detachable high-temperature saggar comprises the following steps:

[0061] Step 1: Pulverize the leftovers of waste ceramic devices, remove the iron impurities through a magnetic separator, and pass through a 100-mesh sieve to obtain the basic powder;

[0062] Step 2: According to the number of parts by mass, mix and stir 100 parts of the base powder obtained in Step 1, 13.5 parts of paraffin and 0.1 part of oleic acid and heat up to 62 ° C, and naturally cool to obtain a slurry cake;

[0063] Step 3: raising the temperature of the slurry cake obtained in step 2 to 85°C, placing them in the molds of the first assembly and the second assembly respectively, and hot injection molding to obtain a green body; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com