High-quality high-aluminum runner brick as well as preparation method and application thereof

A flow steel brick and high-alumina technology, applied in the field of high-alumina flow steel brick and its preparation, can solve the problems of affecting the cleanliness of steel varieties, increase of inclusions in molten steel, corrosion resistance of matrix by molten steel, etc., and increase the range of firing temperature range. , The effect of reducing the firing temperature and improving the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

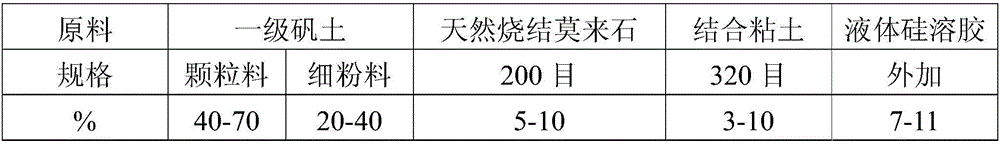

[0029] A high-quality high-alumina flow steel brick of the present invention is composed of the following raw materials in weight ratio:

[0030]

[0031] The first-grade bauxite is used as the granular aggregate, an appropriate amount of natural sintered mullite and bonded clay are added to the fine powder base material, and liquid silica sol is used as the binder.

[0032] Optionally, the solid content of the liquid silica sol is 20%, SiO 2 Colloidal particle diameter 8nm.

[0033] Optionally, the particle size of the primary alumina granular material is 3-0 mm, and the particle size of the fine powder material is 74 μm.

[0034] The present invention also provides a method for preparing the above-mentioned high-quality high-alumina flow steel brick, which includes the following specific steps:

[0035] Step S1, ingredients

[0036] According to the raw material composition of high-quality high-alumina flow steel bricks, the ingredients are:

[0037]

[0038] Step ...

Embodiment 2

[0048] A high-quality high-alumina flow steel brick of the present invention is composed of the following raw materials in weight ratio:

[0049]

[0050] The first-grade bauxite is used as the granular aggregate, an appropriate amount of natural sintered mullite and bonded clay are added to the fine powder base material, and liquid silica sol is used as the binder.

[0051] Optionally, the solid content of the liquid silica sol is 30%, SiO 2 The particle diameter is 15nm.

[0052] Optionally, the particle size of the primary alumina granular material is 3-0 mm, and the particle size of the fine powder material is 88 μm.

[0053] The present invention also provides a method for preparing the above-mentioned high-quality high-alumina flow steel brick, which includes the following specific steps:

[0054] Step S1, ingredients

[0055] According to the raw material composition of high-quality high-alumina flow steel bricks, the ingredients are:

[0056]

[0057] Step S2...

Embodiment 3

[0067] A high-quality high-alumina flow steel brick of the present invention is composed of the following raw materials in weight ratio:

[0068]

[0069] The first-grade bauxite is used as the granular aggregate, an appropriate amount of natural sintered mullite and bonded clay are added to the fine powder base material, and liquid silica sol is used as the binder.

[0070] Optionally, the solid content of the liquid silica sol is 25%, SiO 2 Colloidal particle diameter 10nm.

[0071] Optionally, the particle size of the primary alumina granular material is 3-0 mm, and the particle size of the fine powder material is 74 μm.

[0072] The present invention also provides a method for preparing the above-mentioned high-quality high-alumina flow steel brick, which includes the following specific steps:

[0073] Step S1, ingredients

[0074] According to the raw material composition of high-quality high-alumina flow steel bricks, the ingredients are:

[0075]

[0076]

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com