Method for solving section temperature difference of broad kiln

A wide-body and cross-section technology is applied in the field of solving the temperature difference of the wide-body kiln cross-section, which can solve the problems of economic losses of ceramic enterprises, uneven temperature in the firing zone, and large product size difference, so as to shorten the firing cycle and reduce unevenness. The effect of the qualified product rate and the product qualified rate increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

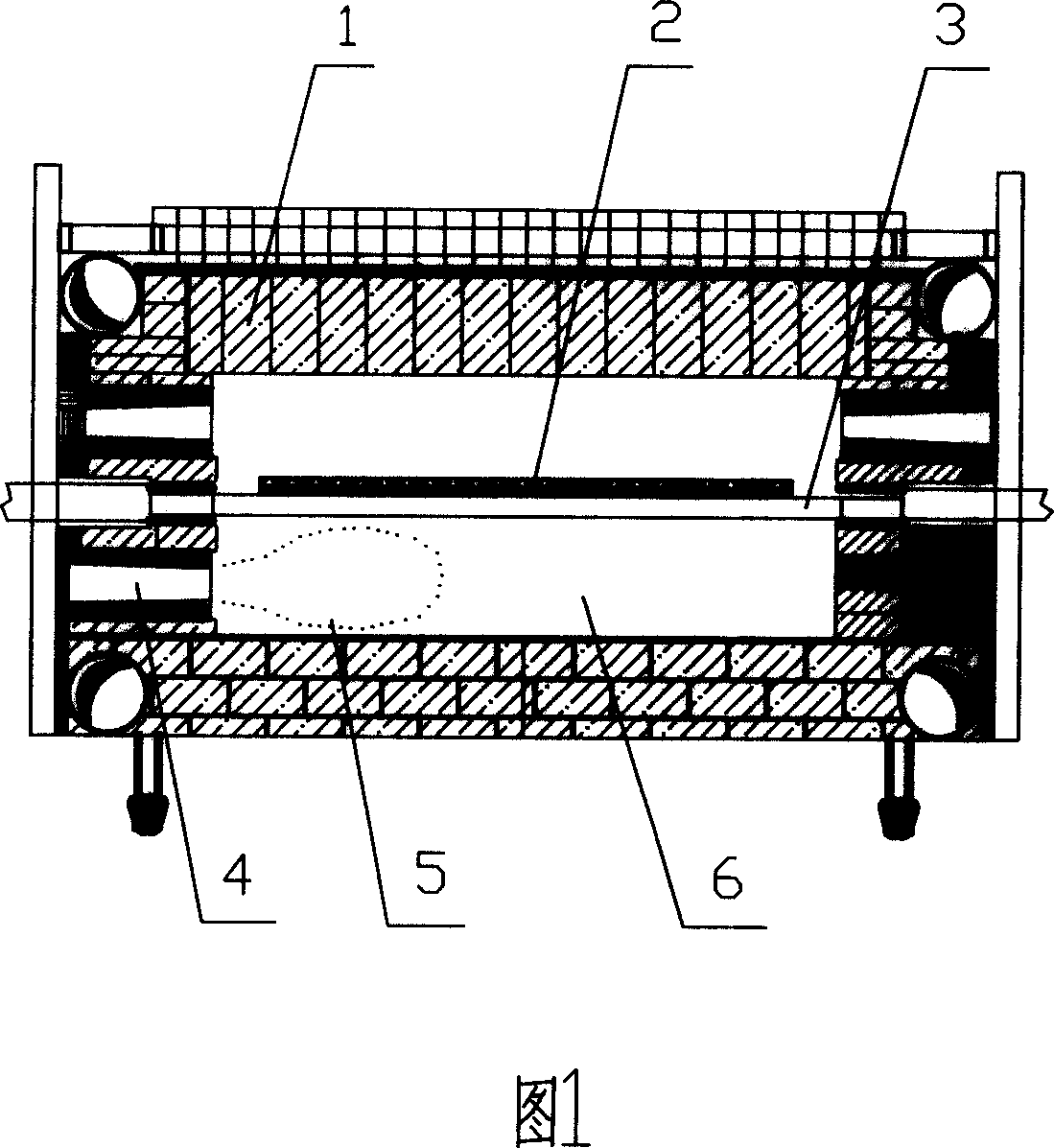

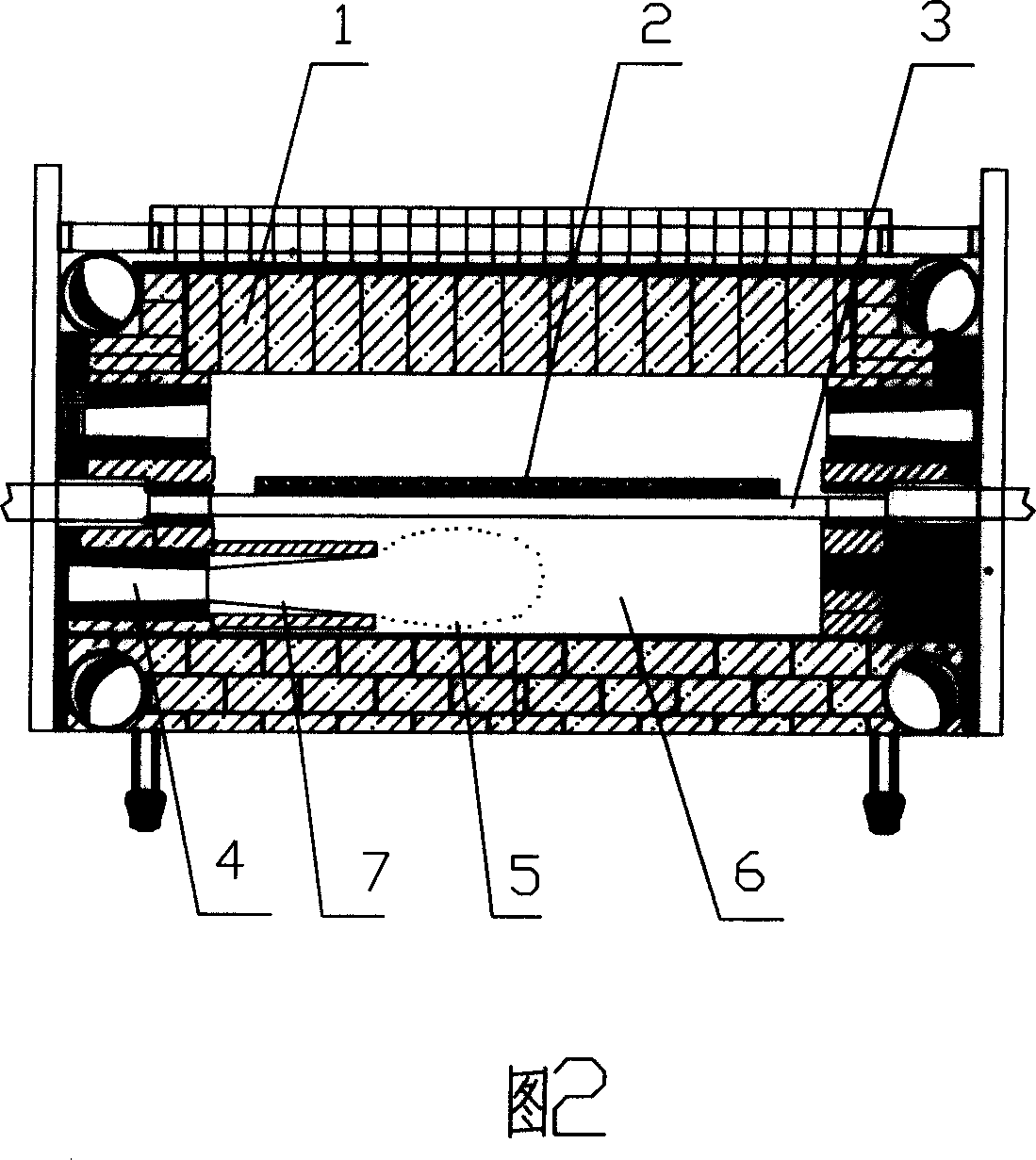

[0022] As shown in Figure 1

[0023] Fig. 1 is a schematic cross-sectional view of a kiln firing zone in the prior art. In Fig. 1, the in-process product 2 is placed on the porcelain roller 3, and the spray gun burner channel 4 passes through the kiln body to the inner wall of the kiln body 1. When the in-process product 2 enters a predetermined position, the flame 5 can only pass through the spray gun burner channel 4. Arriving at 1 / 4 of the inner diameter of the firing area 6, this structure requires a large amount of combustion-supporting air, and the temperature on both sides of the kiln body 1 is relatively high, and there is a cross-sectional temperature difference in the kiln body 1, so it takes a long time to increase the firing rate of the kiln body 1. Only the overall temperature in zone 6 can reach the firing temperature required for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com