Method of disposing of organic waste of high water content and disposal apparatus therefor

A technology of organic waste and high moisture content, applied in dewatering/drying/concentrating sludge treatment, combustion methods, heating devices, etc., can solve the problems of reduced sintering capacity of cement clinker, lower temperature, and difficulty in economical operation, etc. Achieving efficient and effective reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

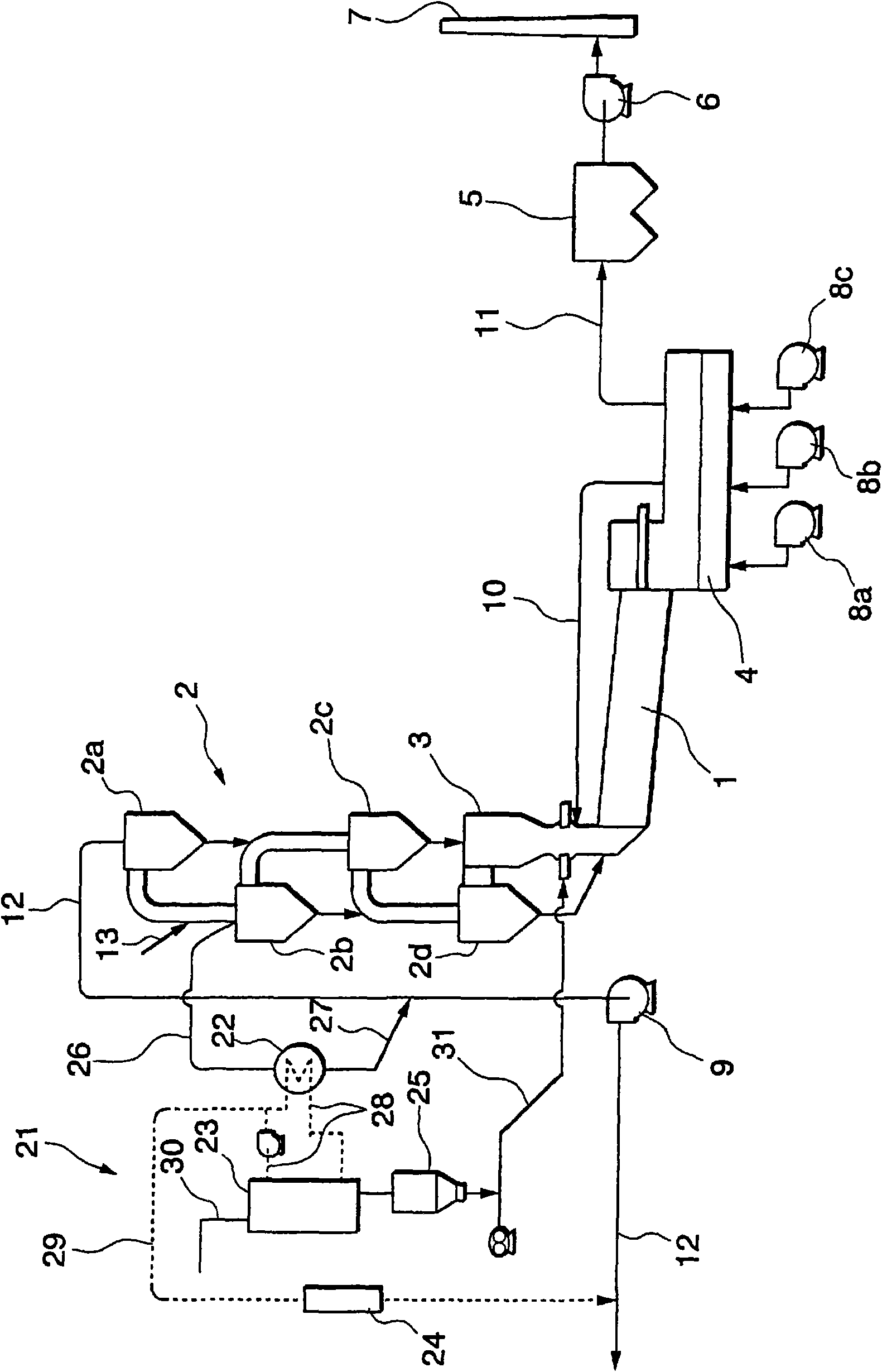

[0105] Fig. 1 is a schematic diagram showing a cement burning facility equipped with a high-moisture-content organic waste treatment device according to a first embodiment of the present invention. An example of a treatment device that dries the organic sludge to be converted into fuel by using high-temperature gas or extracted high-temperature gas, and burns the obtained dried organic sludge using cement burning equipment.

[0106] Among the figure, 21 is the treatment device of organic sludge, which is composed of the following parts: heat exchanger (heat exchange device) 22, exhaust gas (high temperature gas) and steam separated from the suspension preheater 2 of cement burning equipment heat exchange between (heat medium); drier (drying treatment device) 23, use the superheated steam (heat medium) after the heat exchange to dry the organic sludge to form dry organic sludge; deodorizer (deodorizer) Processing device) 24, deodorizing superheated steam; hopper 25, storing dry...

no. 2 approach

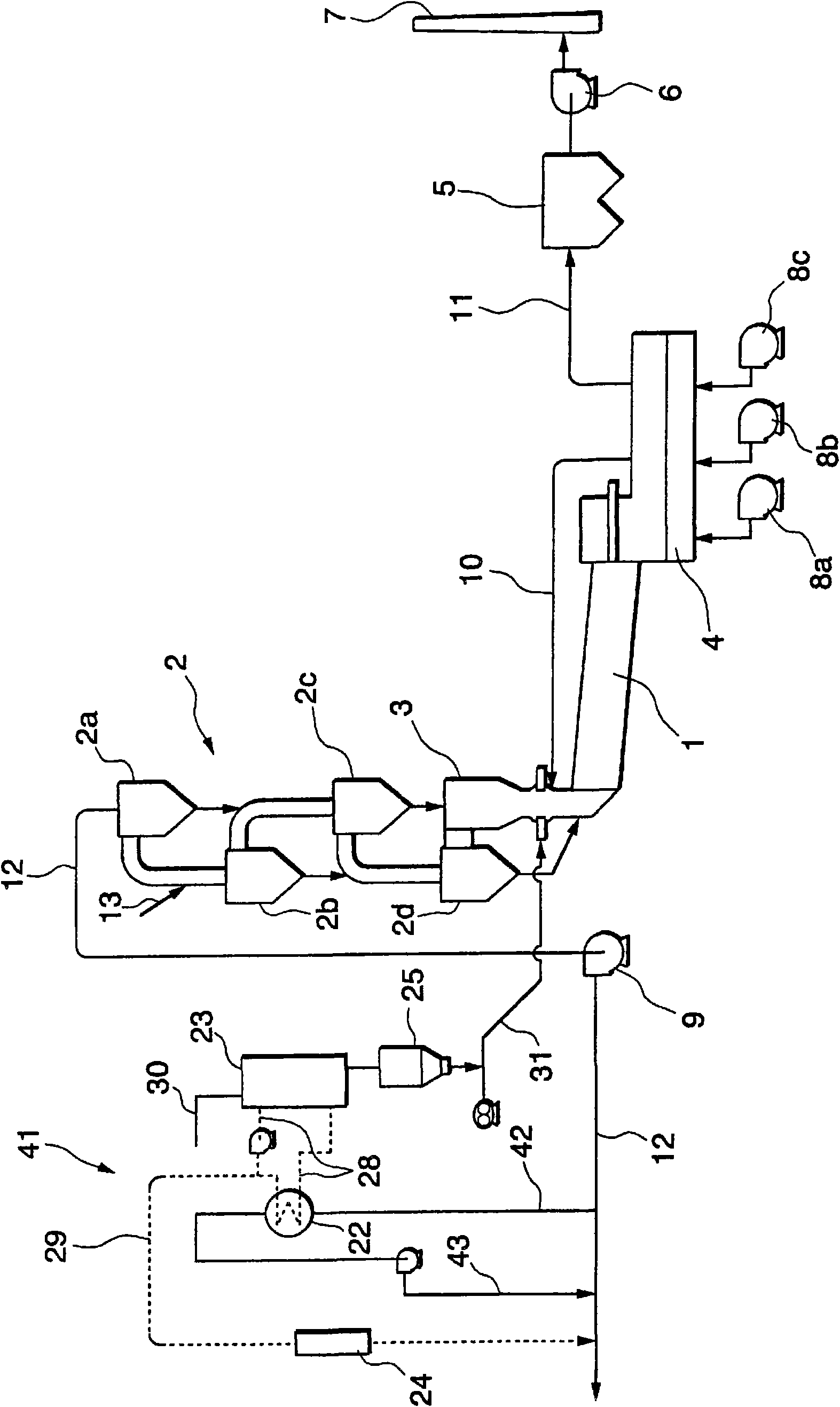

[0143] Fig. 2 is a schematic view showing a cement burning facility equipped with an organic sludge treatment device 41 according to a second embodiment of the present invention. The difference between the organic sludge treatment device 41 and the organic sludge treatment device 21 according to the first embodiment is that , replace the high-temperature gas extraction pipe 26 and the exhaust pipe 27 with the high-temperature gas extraction pipeline 42 and the high-temperature gas exhaust pipeline 43, and use the exhaust pipe from the downstream side of the exhaust fan (IDF) 9 of the suspension preheater 2 The 12-split high-temperature exhaust gas is used as high-temperature gas for drying by the dryer 23 .

[0144] In this organic sludge treatment device 41 , the high-temperature exhaust gas used as a heat source for drying is branched from the exhaust pipe 12 of the suspension preheater 2 and sent to the heat exchanger 22 through the high-temperature gas suction line 42 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com