Patents

Literature

46results about "Ceramic production plants" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

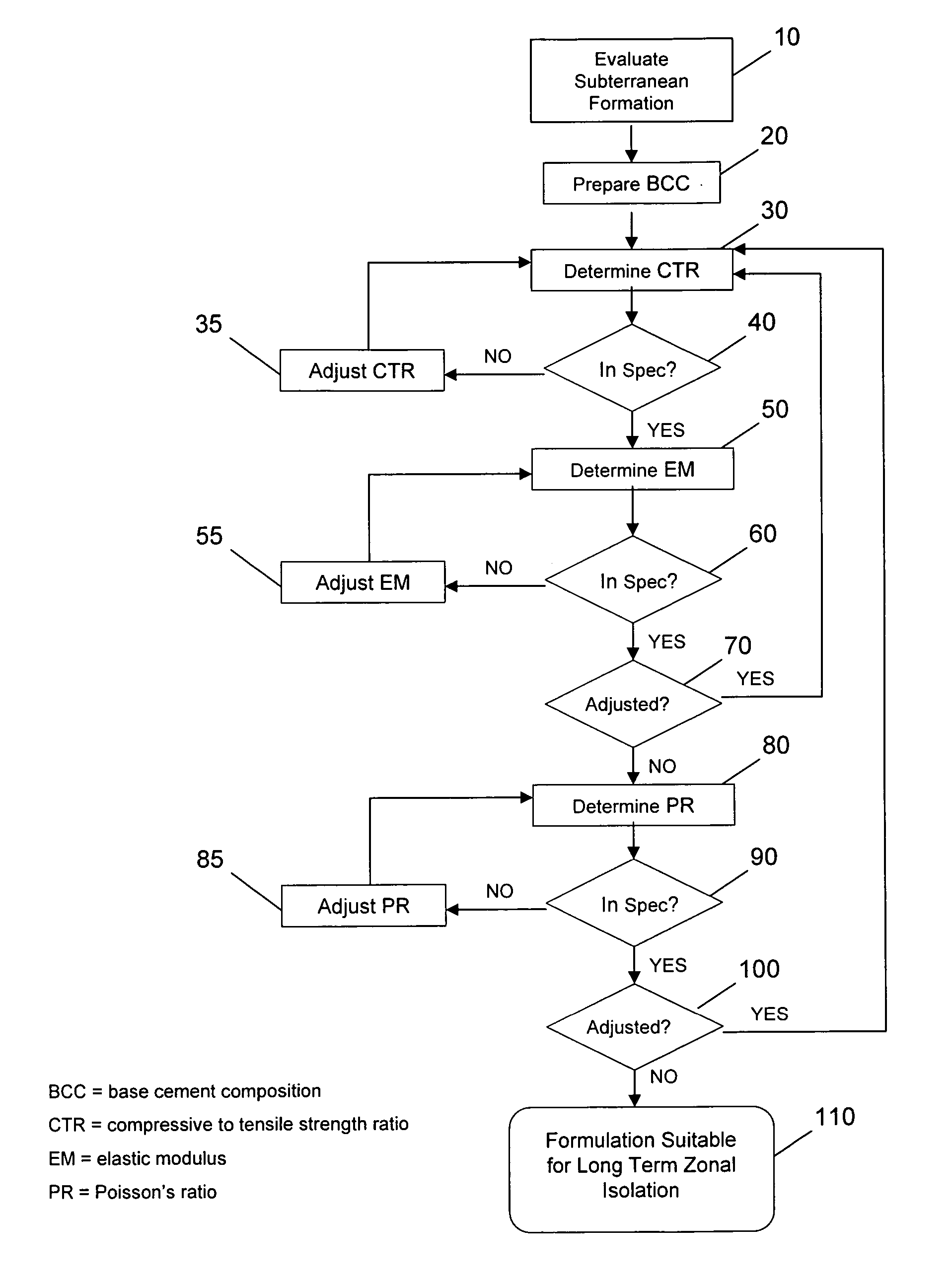

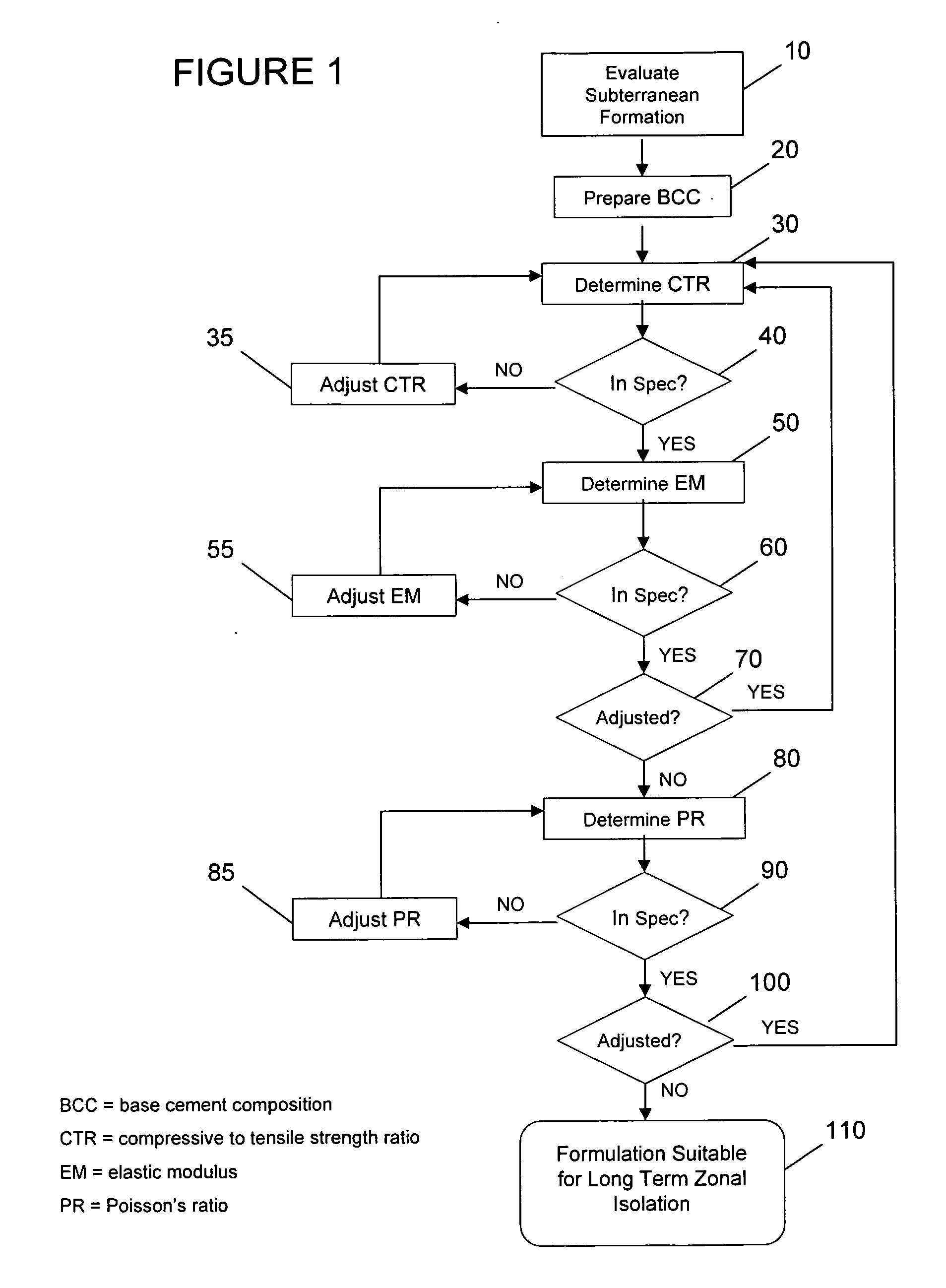

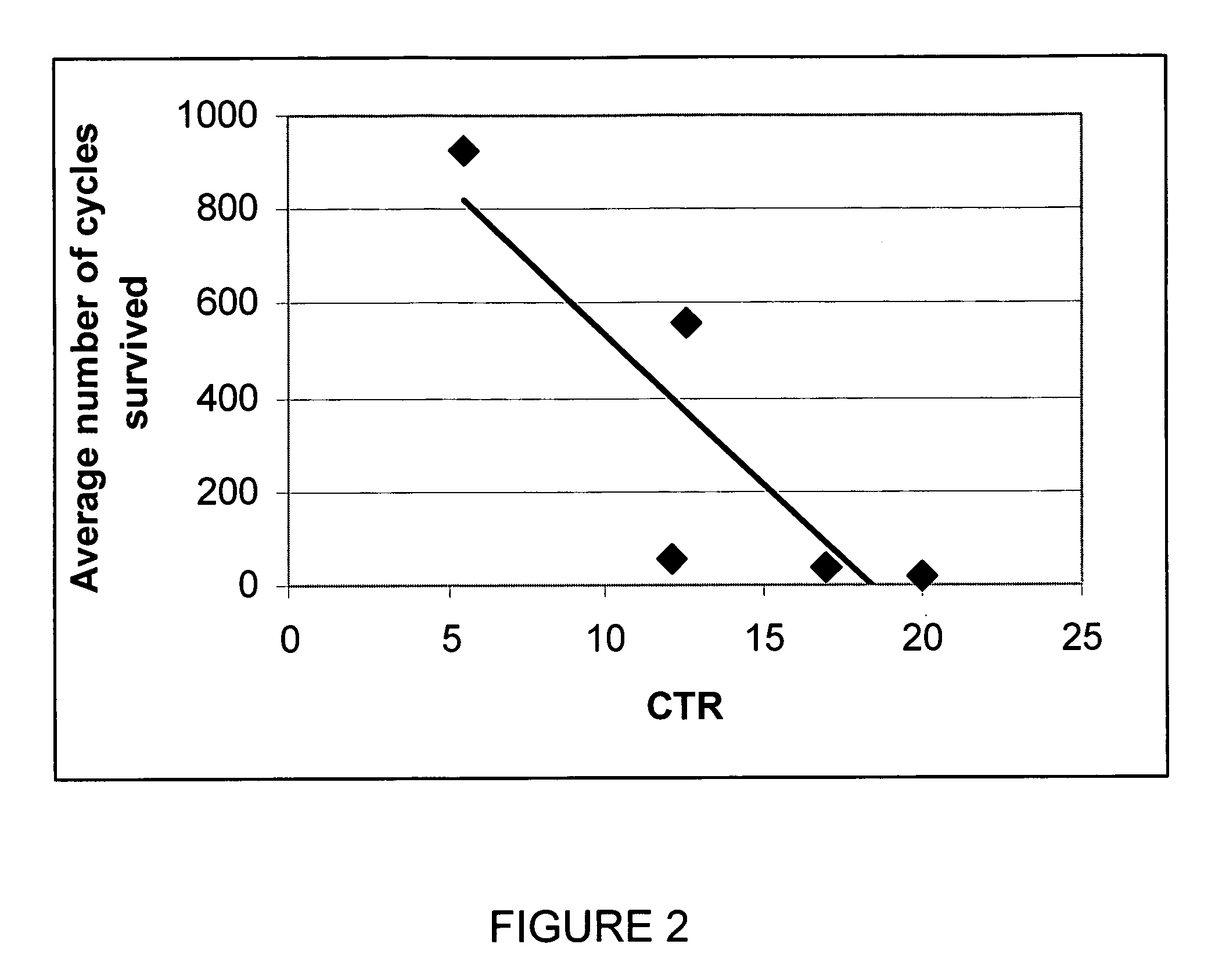

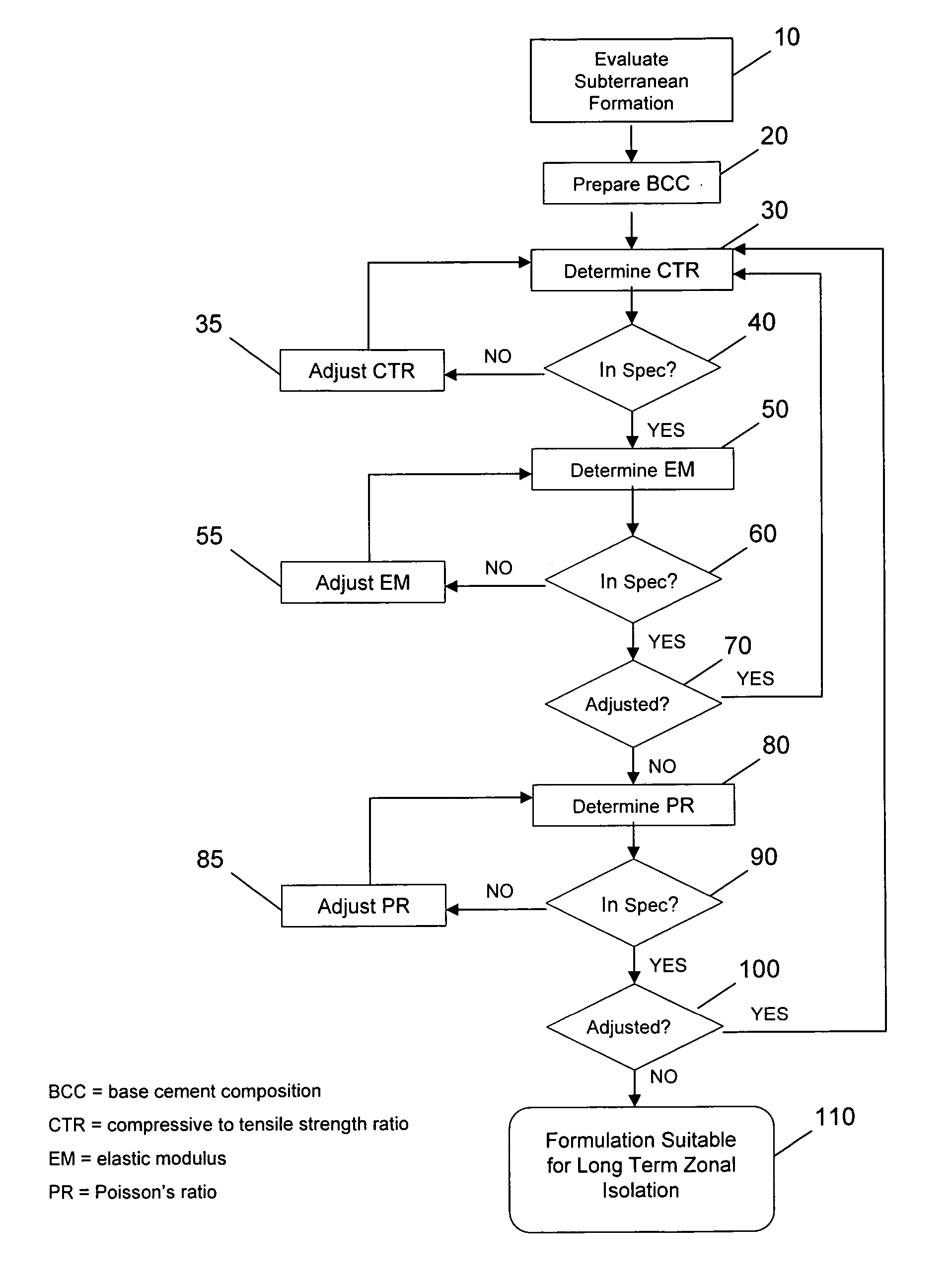

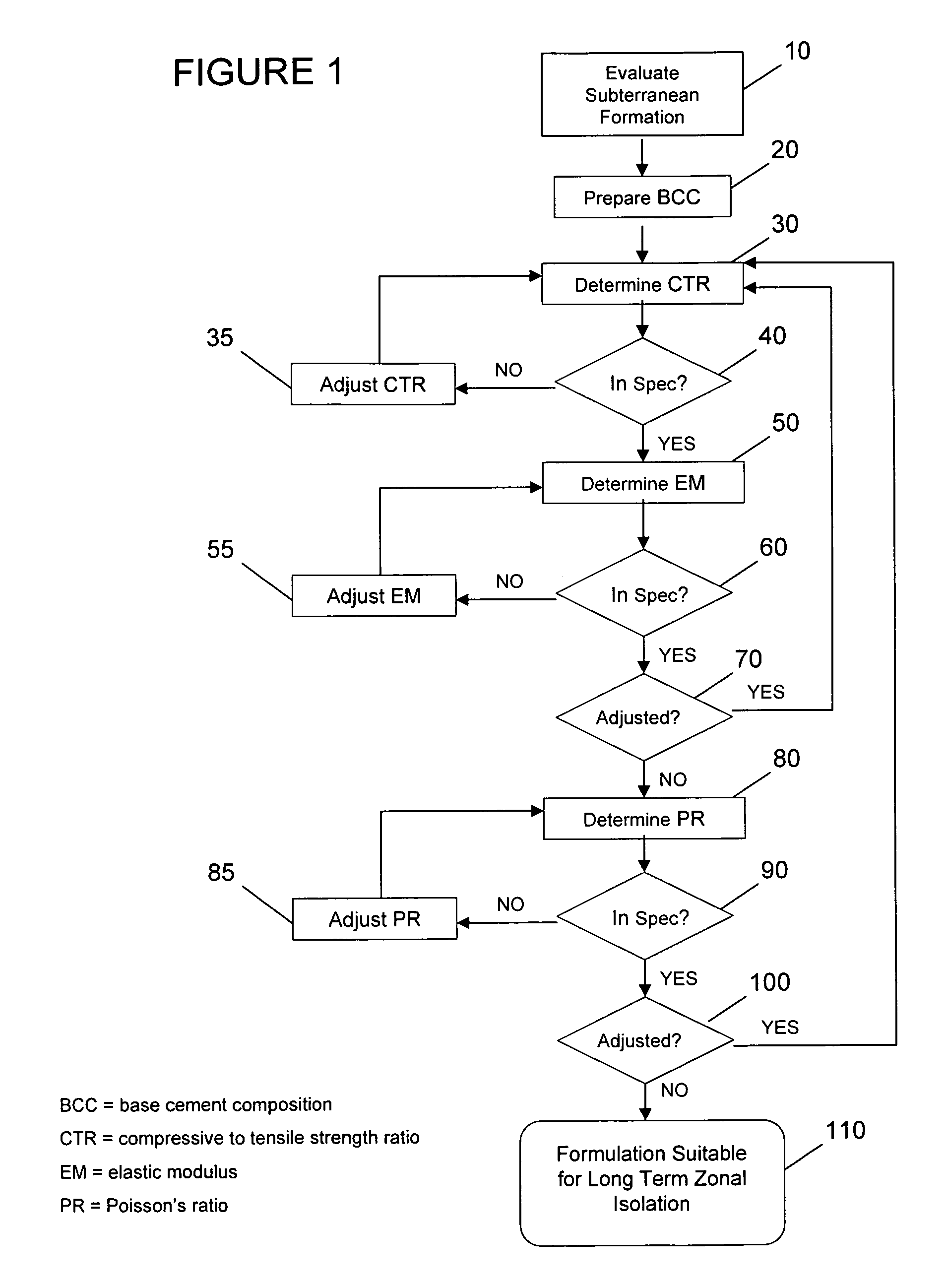

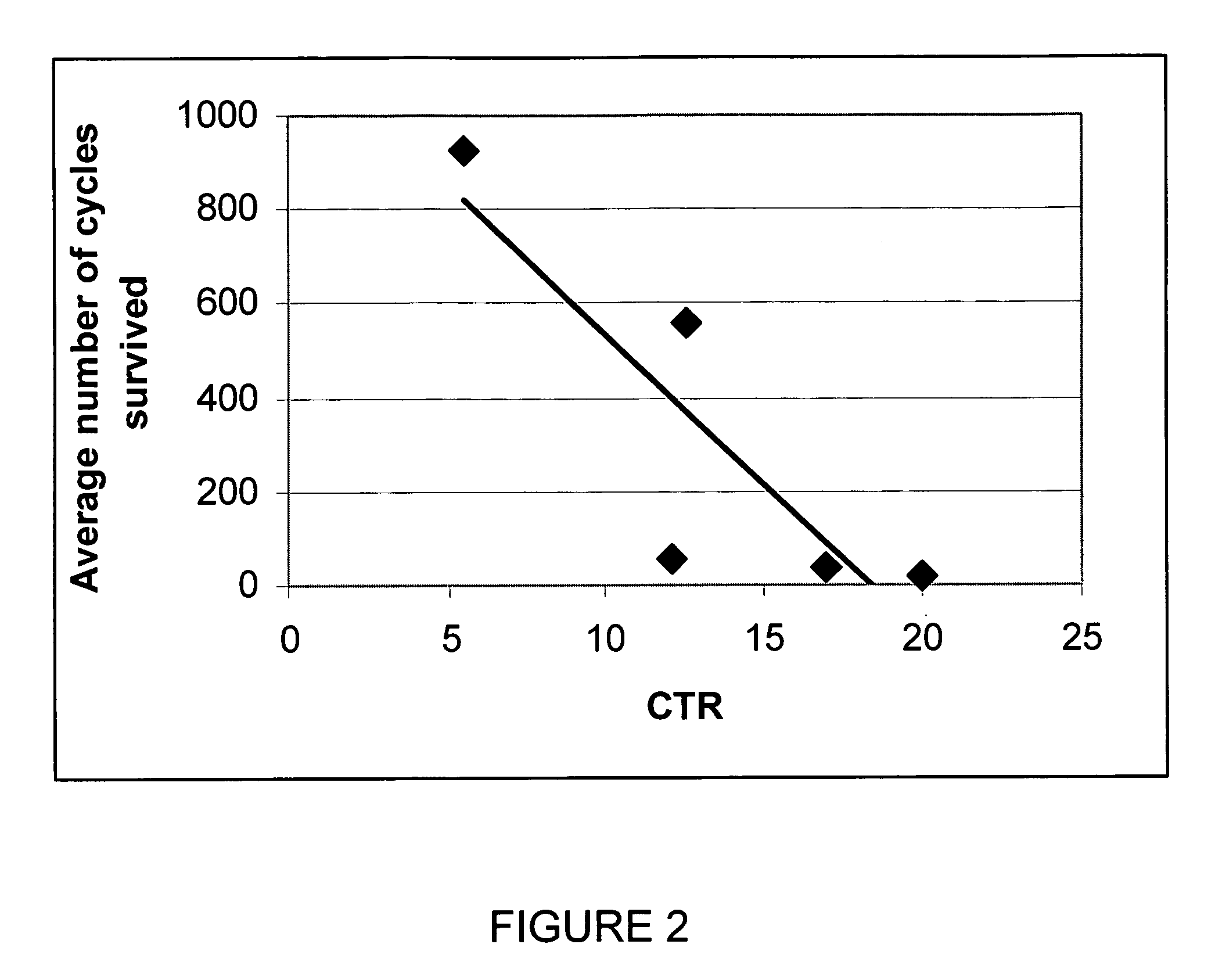

Methods of formulating a cement composition

A method of cementing a wellbore in a subterranean formation, comprising formulating a cement composition that may be suitable for long-term zonal isolation of the subterranean formation by evaluating a subterranean formation, preparing a base cement composition, determining the compressive strength of the base cement composition, determining the tensile strength of the base cement composition, and adjusting the ratio of compressive strength to tensile strength as need to within a first optimizing range to form a first optimized cement composition, and placing the optimized cement composition in the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

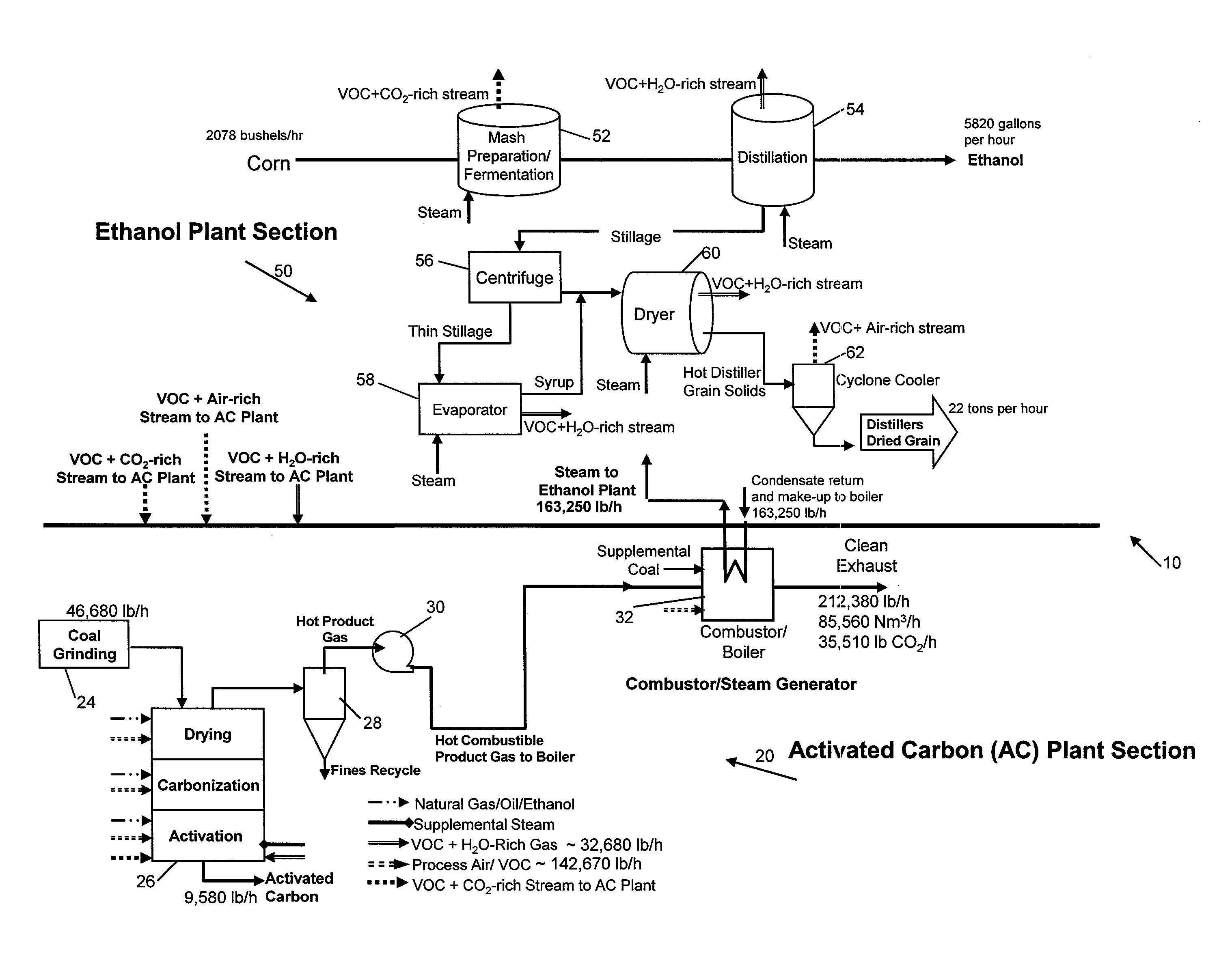

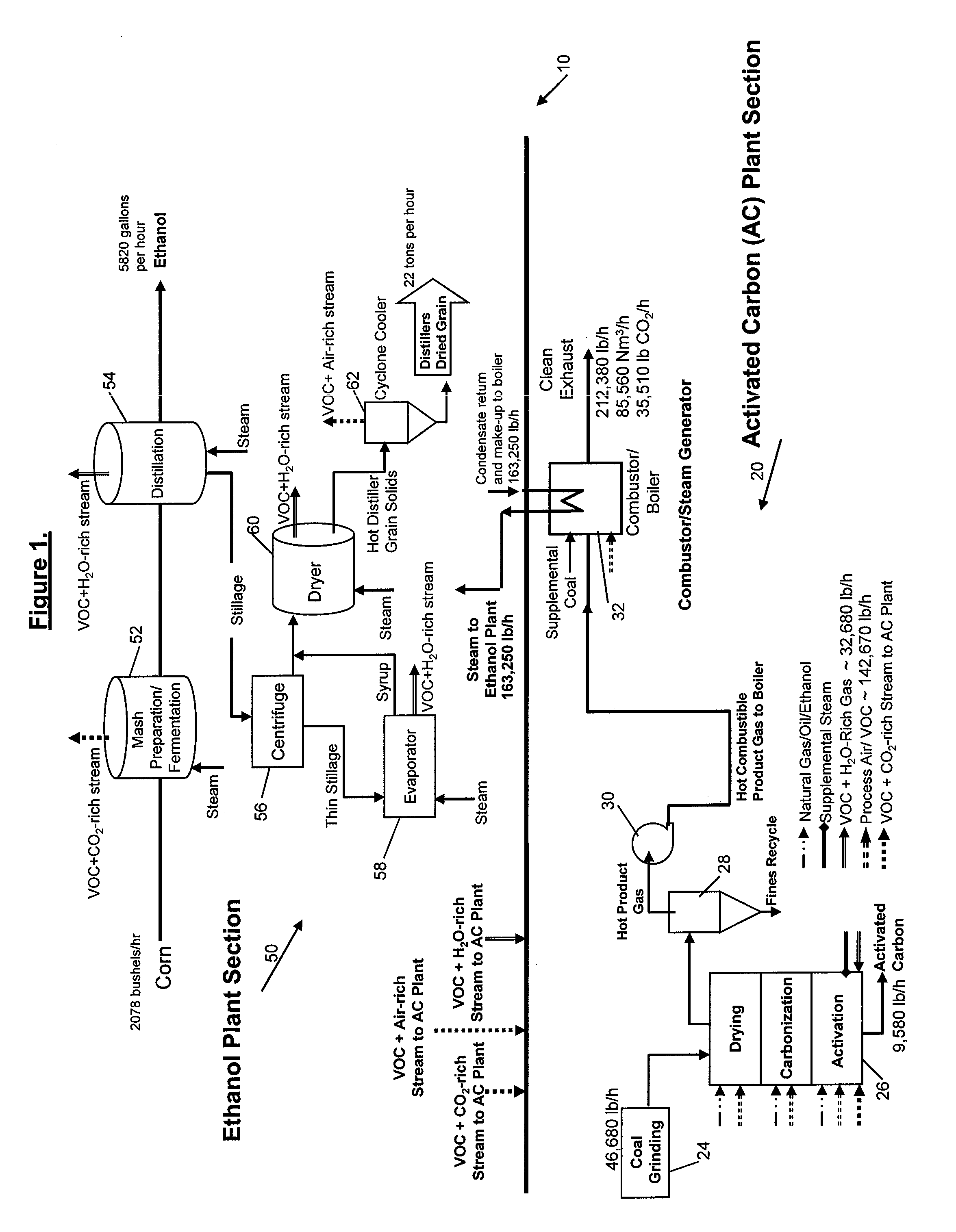

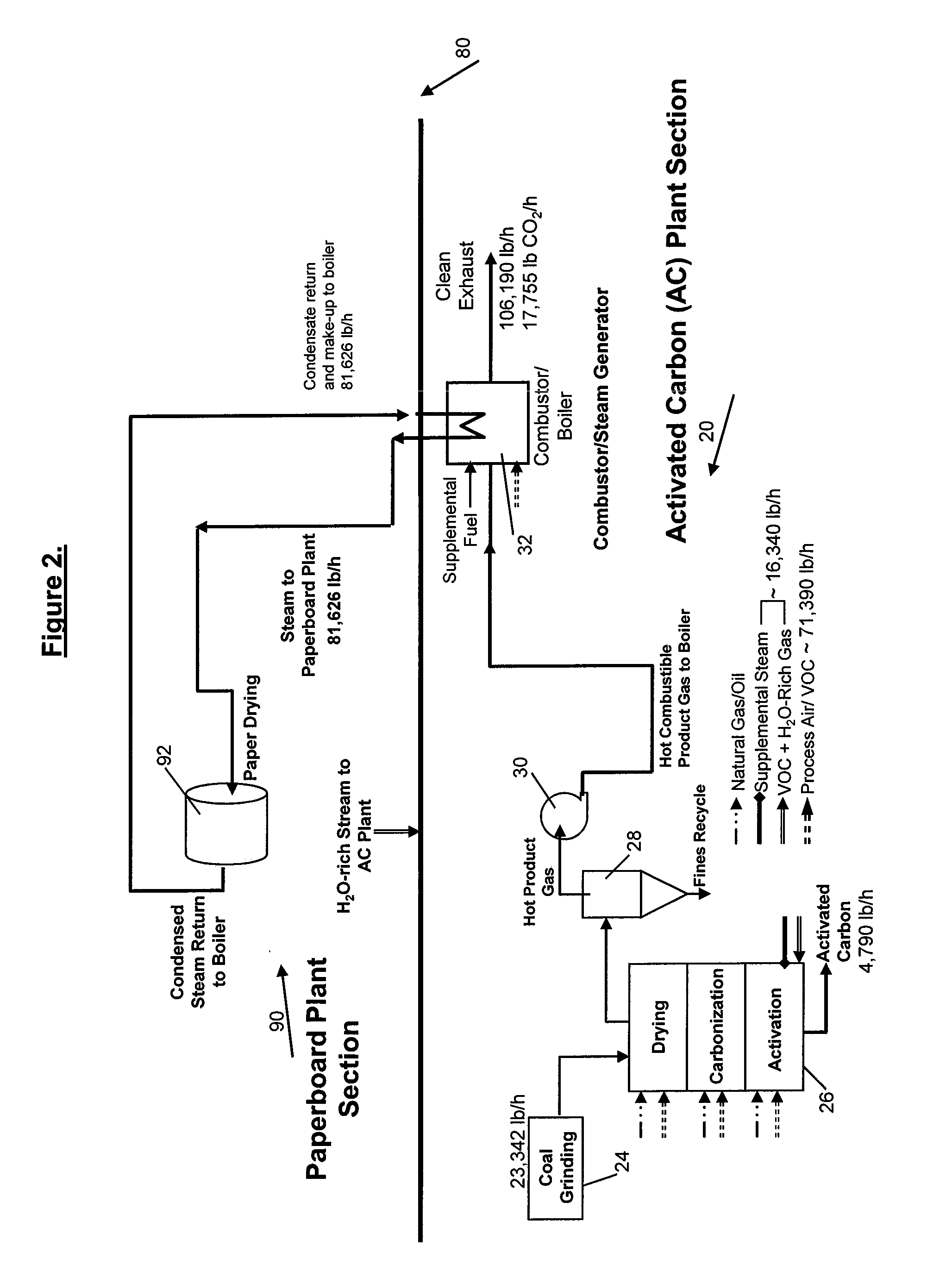

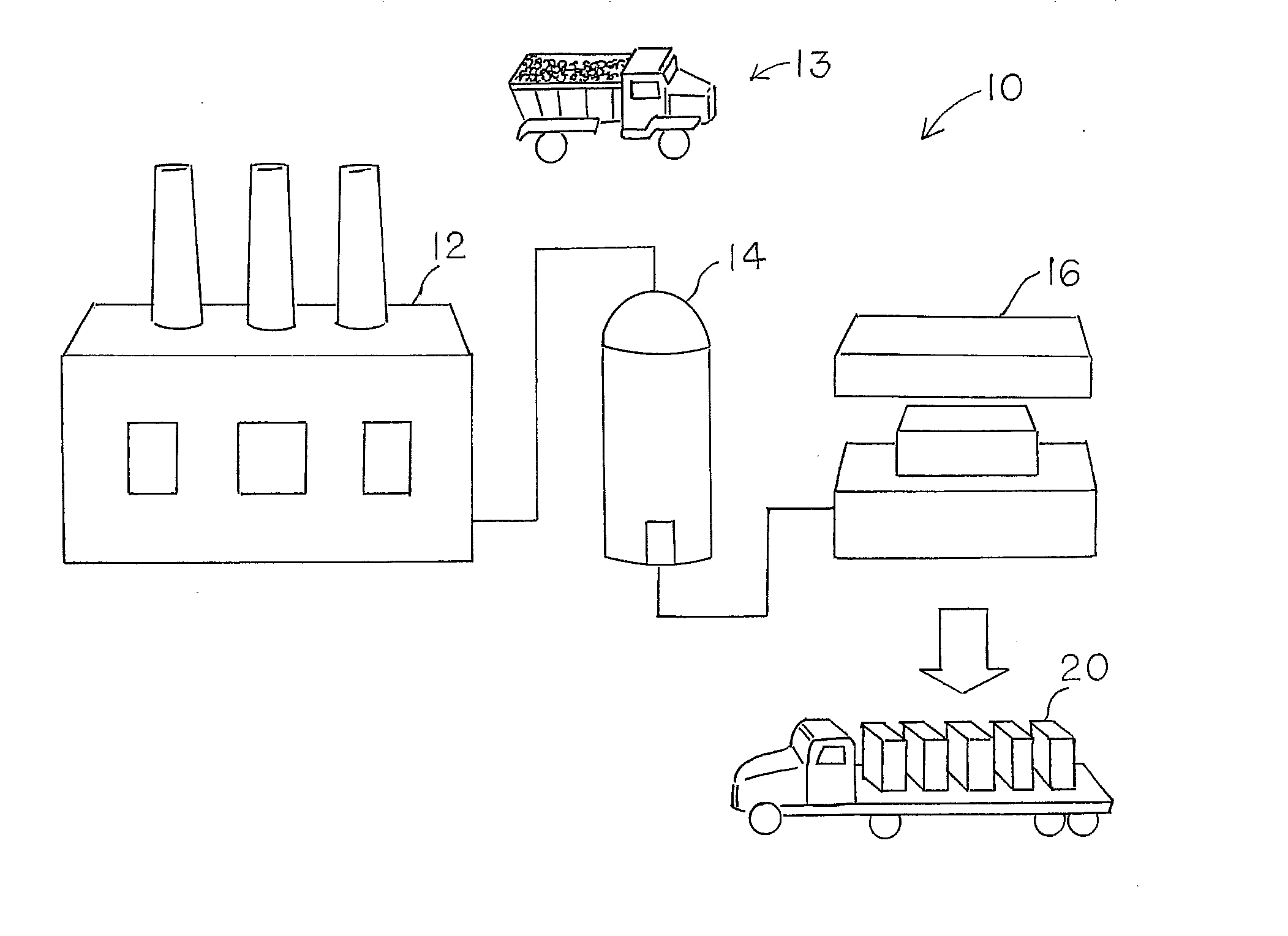

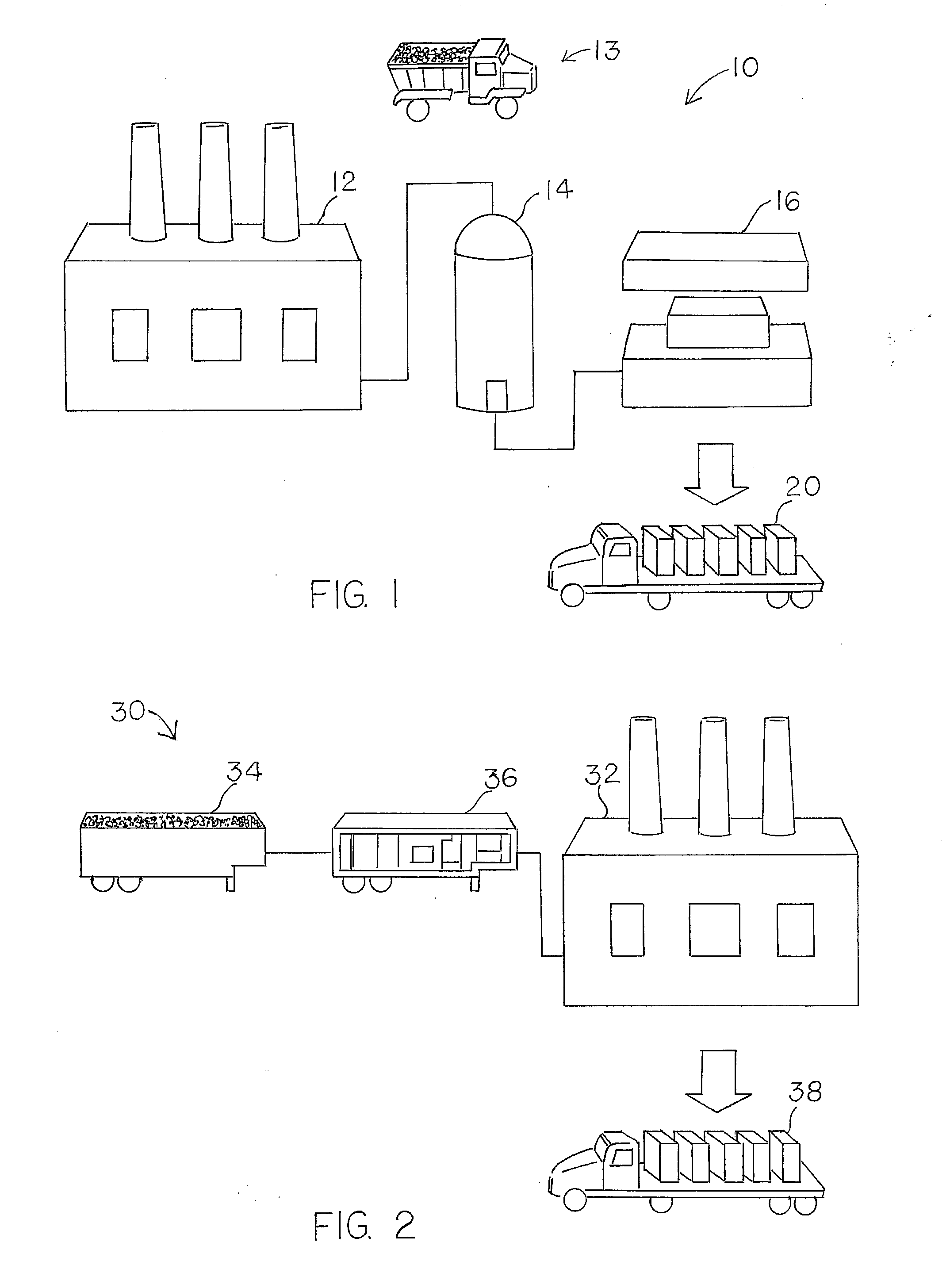

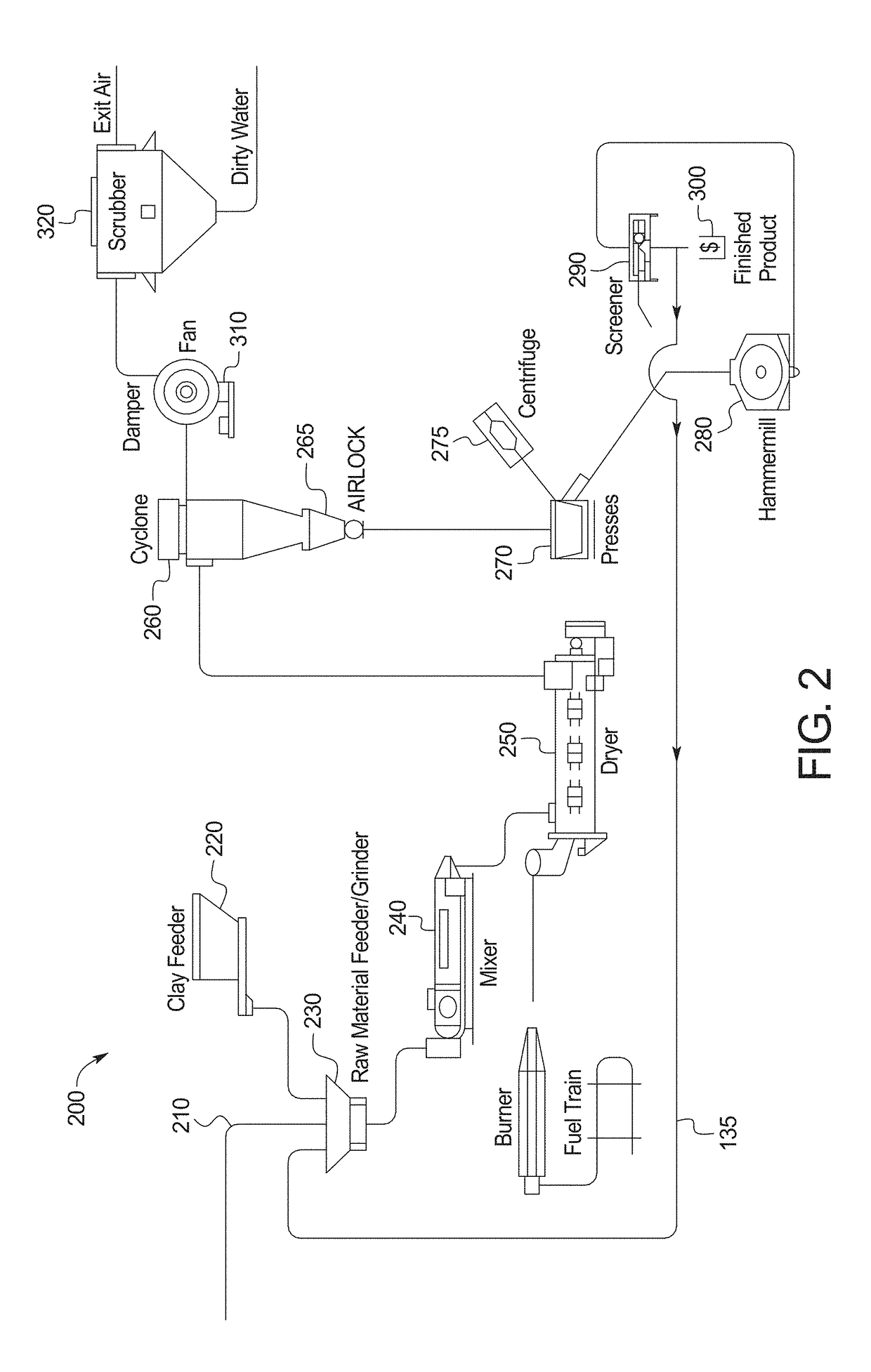

Method of Manufacturing Carbon-Rich Product and Co-Products

ActiveUS20100178624A1Simple and cost-effectiveImprove efficiencyBioreactor/fermenter combinationsGaseous fuel feeder/distributionWater vaporHigh carbon

A method in which a parent hydrocarbon-rich material is processed so as to produce both a carbon-rich solid material that has a higher carbon to hydrogen ratio than that of the parent material and a carbon-deficient combustible gas that has a lower carbon to hydrogen ratio than the parent material. In the process, the material is activated by exposing it to a hot gas stream having elevated levels of one or both of carbon dioxide and water vapor. The combustible gas is combusted to produce heat. At least about 80% of the heat is used in one or more endothermic steps that include drying coal or biomass.

Owner:SRINIVASACHAR SRIVATS

Methods of formulating a cement composition

A method of cementing a wellbore in a subterranean formation, comprising formulating a cement composition that may be suitable for long-term zonal isolation of the subterranean formation by evaluating a subterranean formation, preparing a base cement composition, determining the compressive strength of the base cement composition, determining the tensile strength of the base cement composition, and adjusting the ratio of compressive strength to tensile strength as need to within a first optimizing range to form a first optimized cement composition, and placing the optimized cement composition in the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

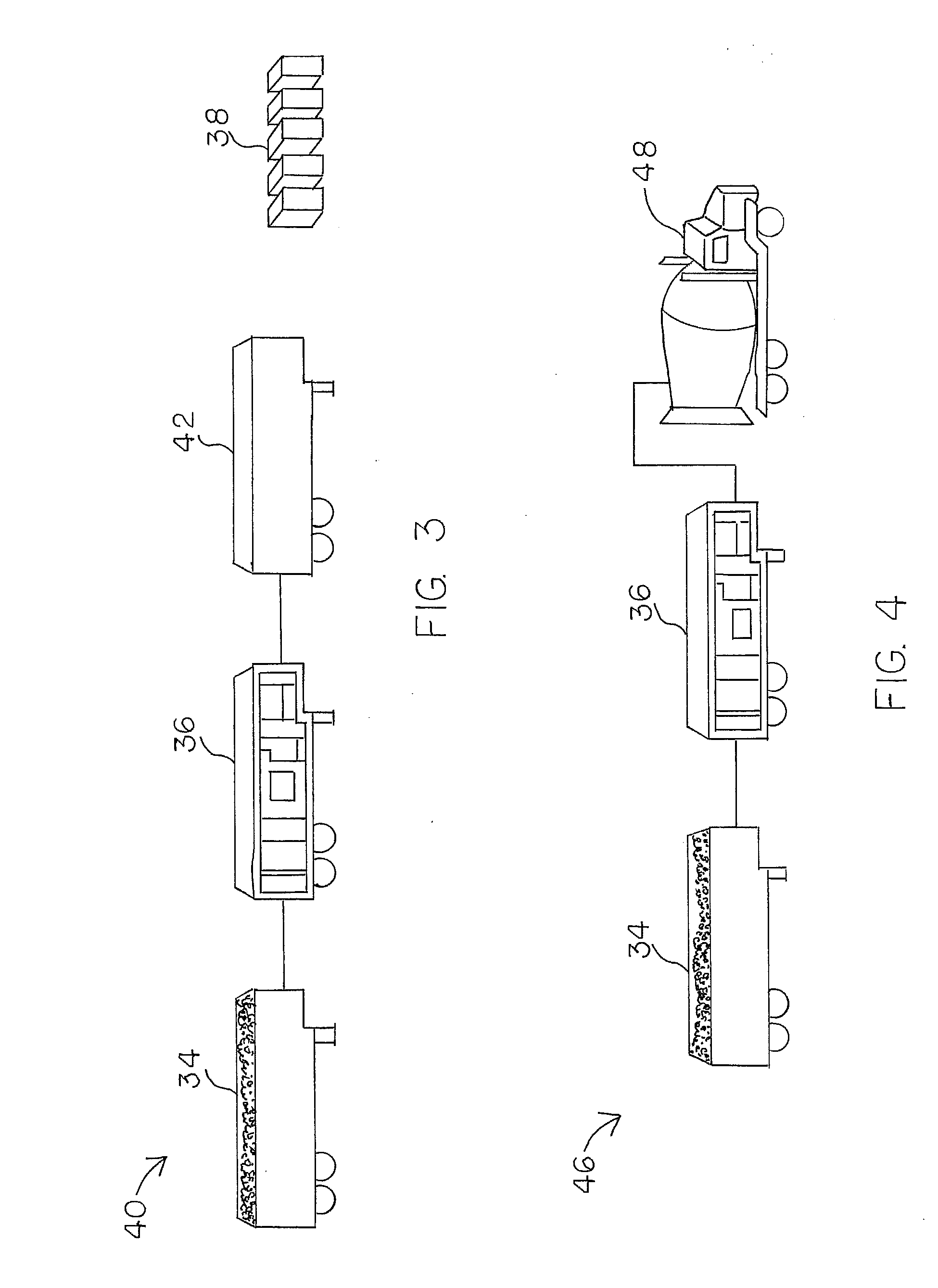

Mobile expanded polymer processing systems and methods

A mobile polymer system. The system includes a mobile platform and a heat generating device mounted to the mobile platform. The system also includes a polymer expansion unit mounted to the mobile platform, wherein the polymer expansion unit is adapted to expand a polymer, using heat generated by the heat generating device, at a location of the mobile polymer expansion system to create an expanded polymer that can be used to create an expanded polymeric product that is comprised of the expanded polymer.

Owner:NOVA CHEM INC

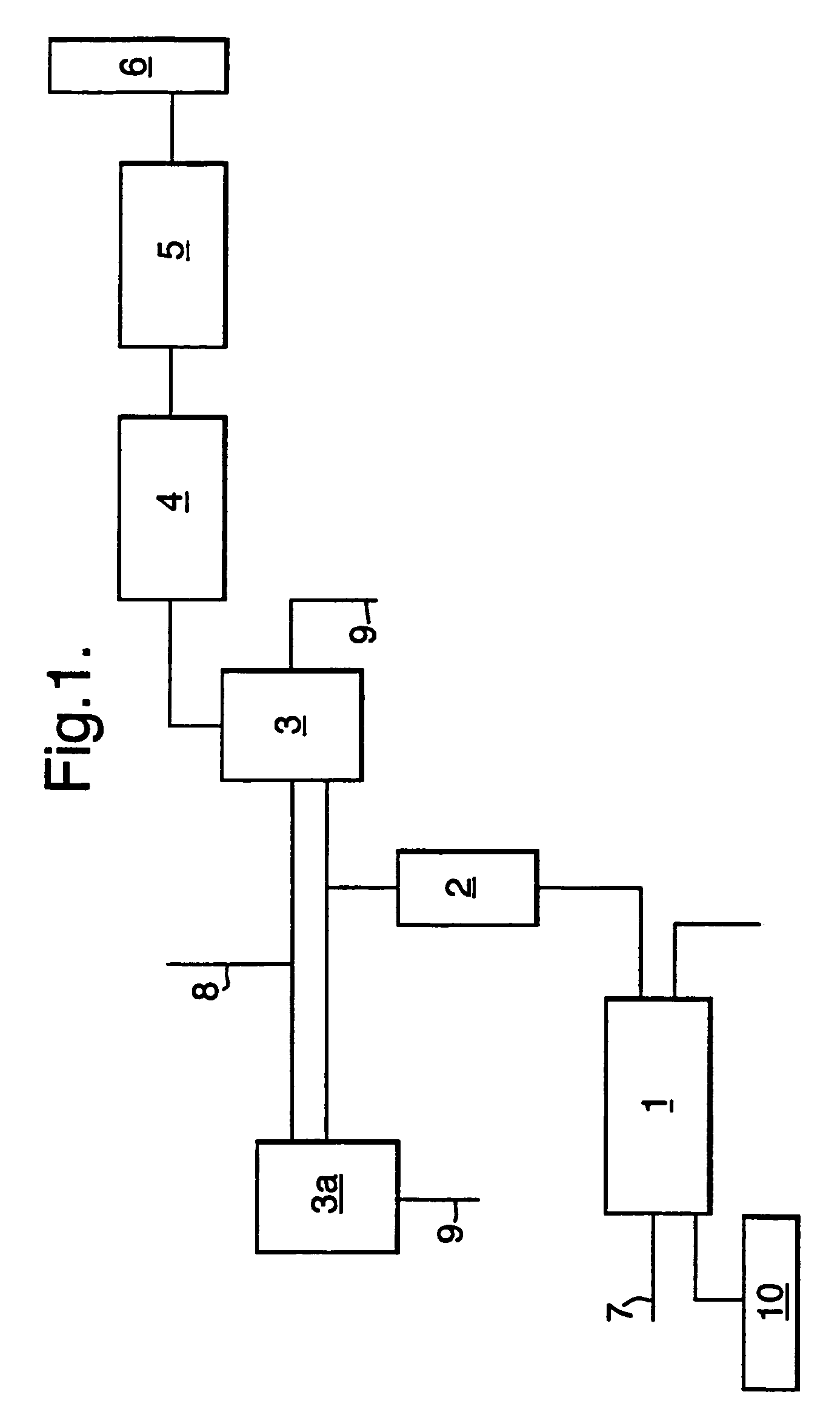

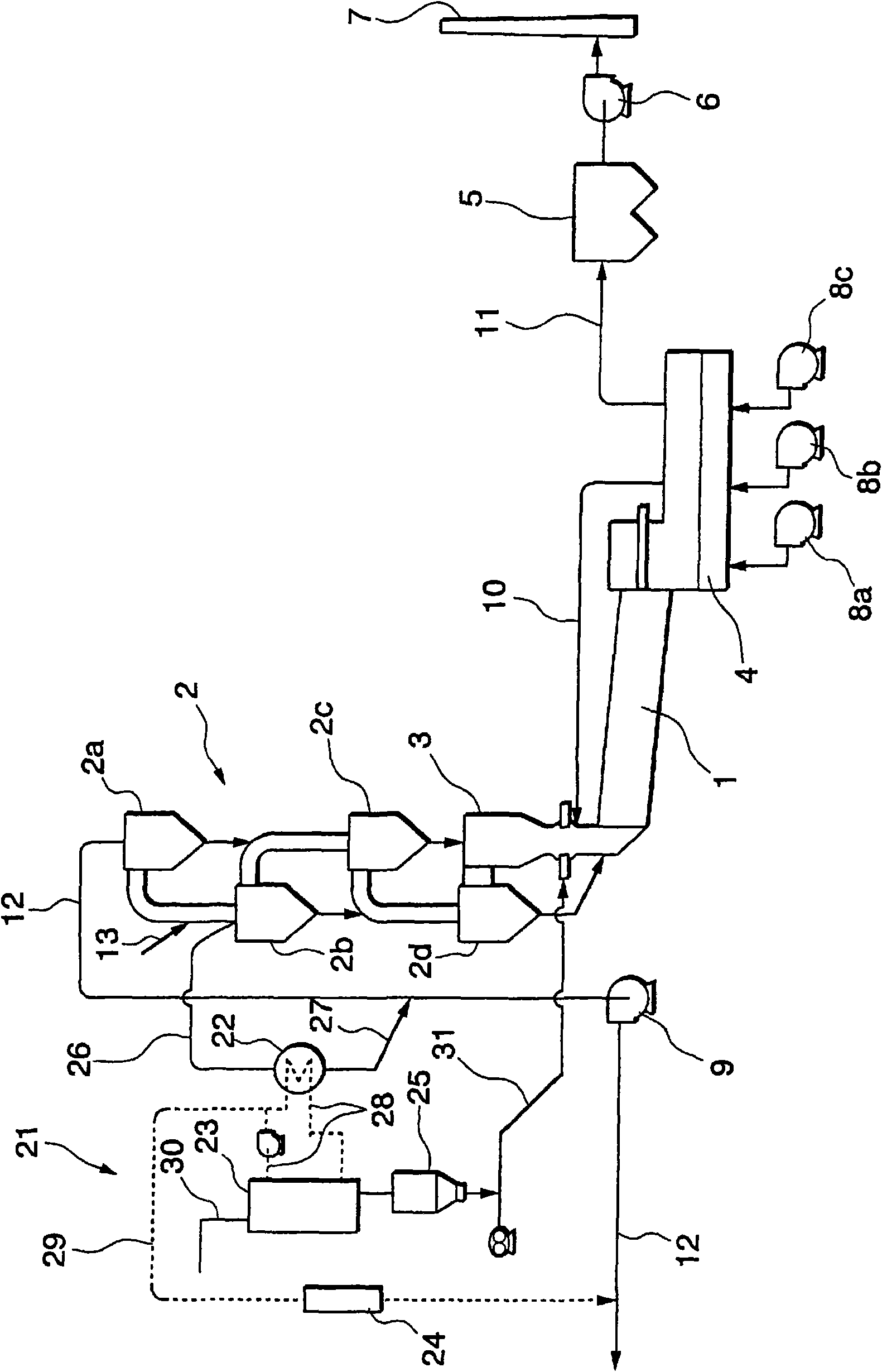

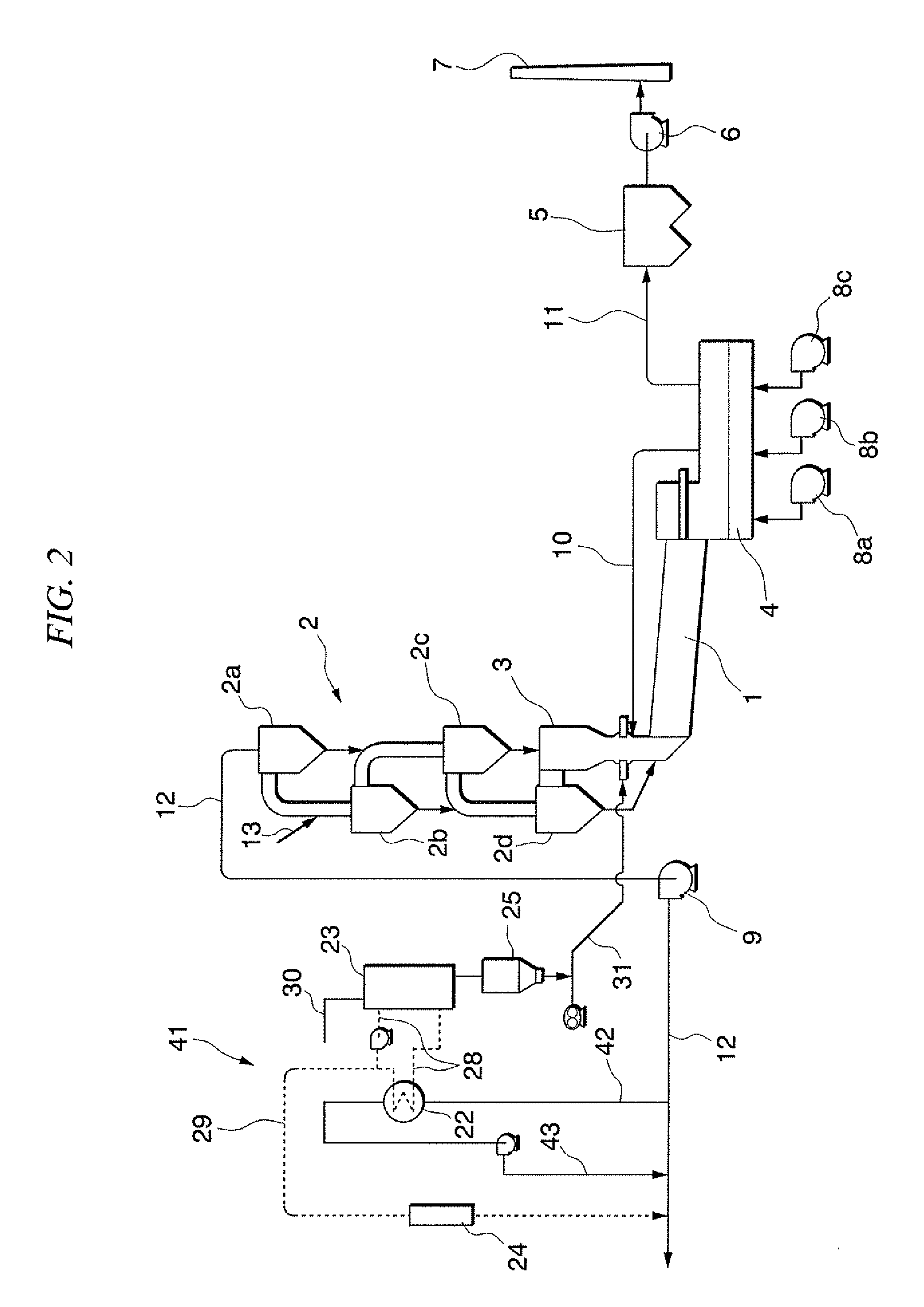

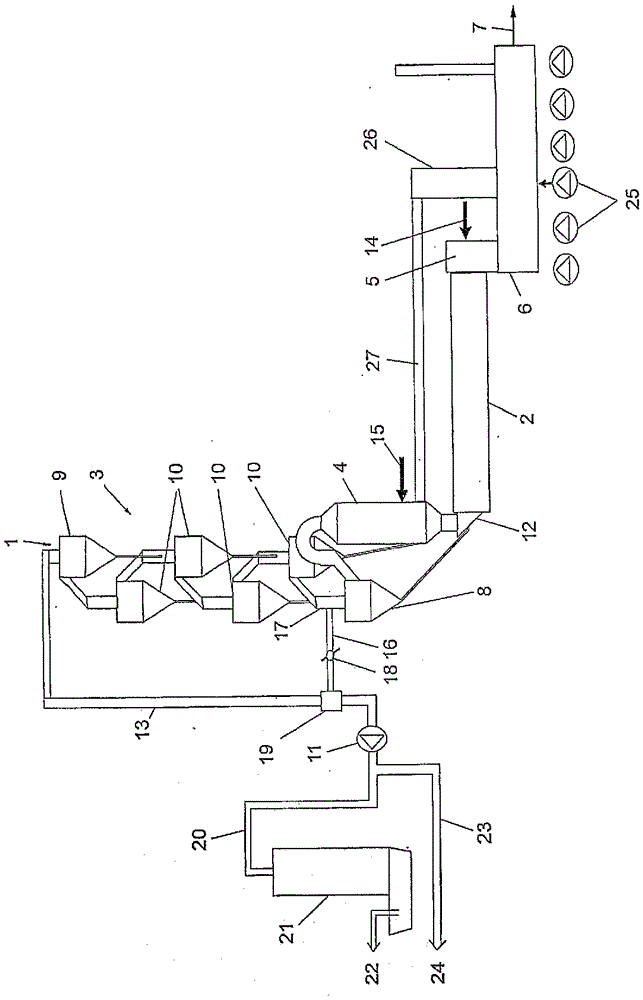

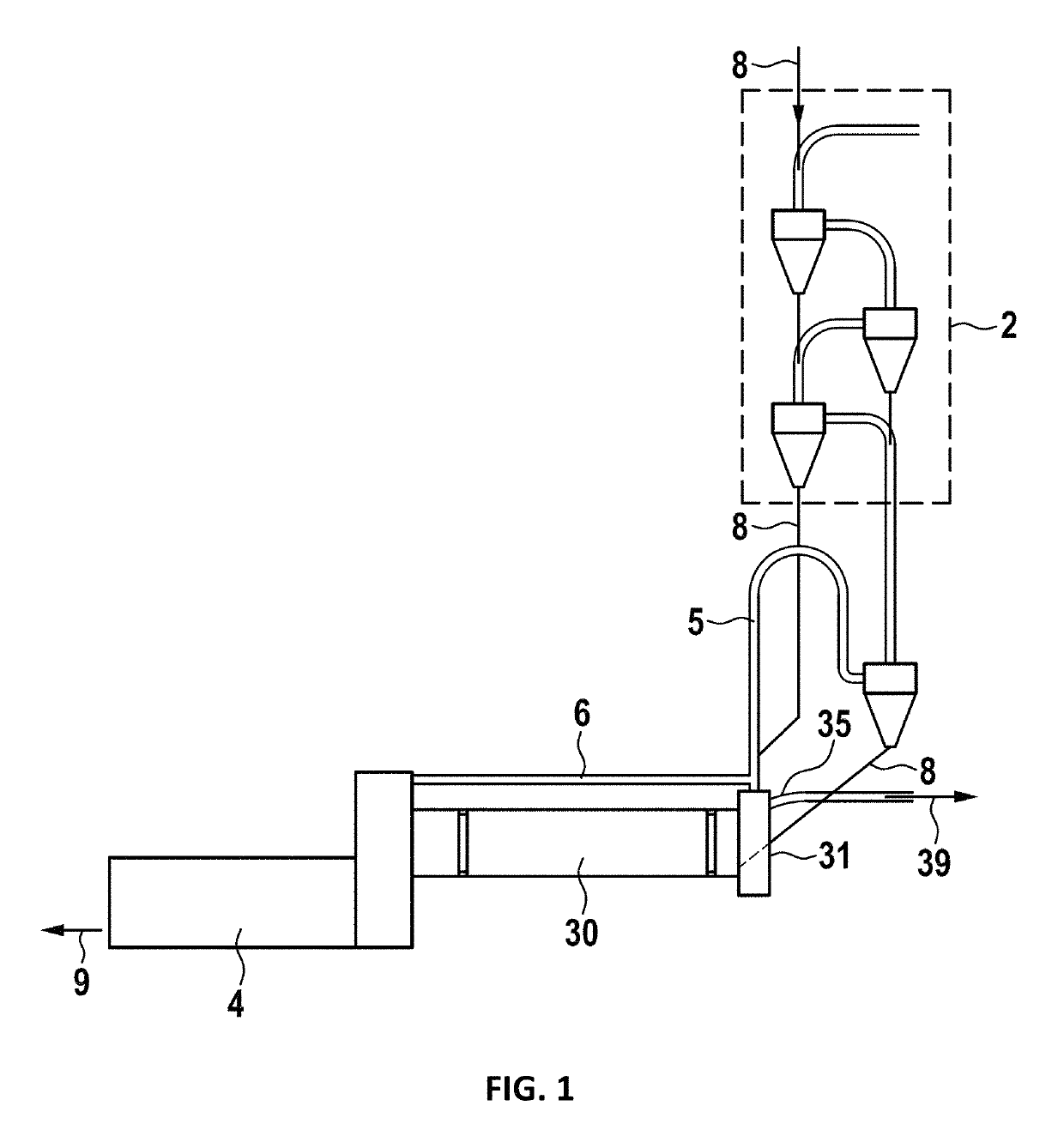

Method and process for co-combustion in a waste to-energy facility

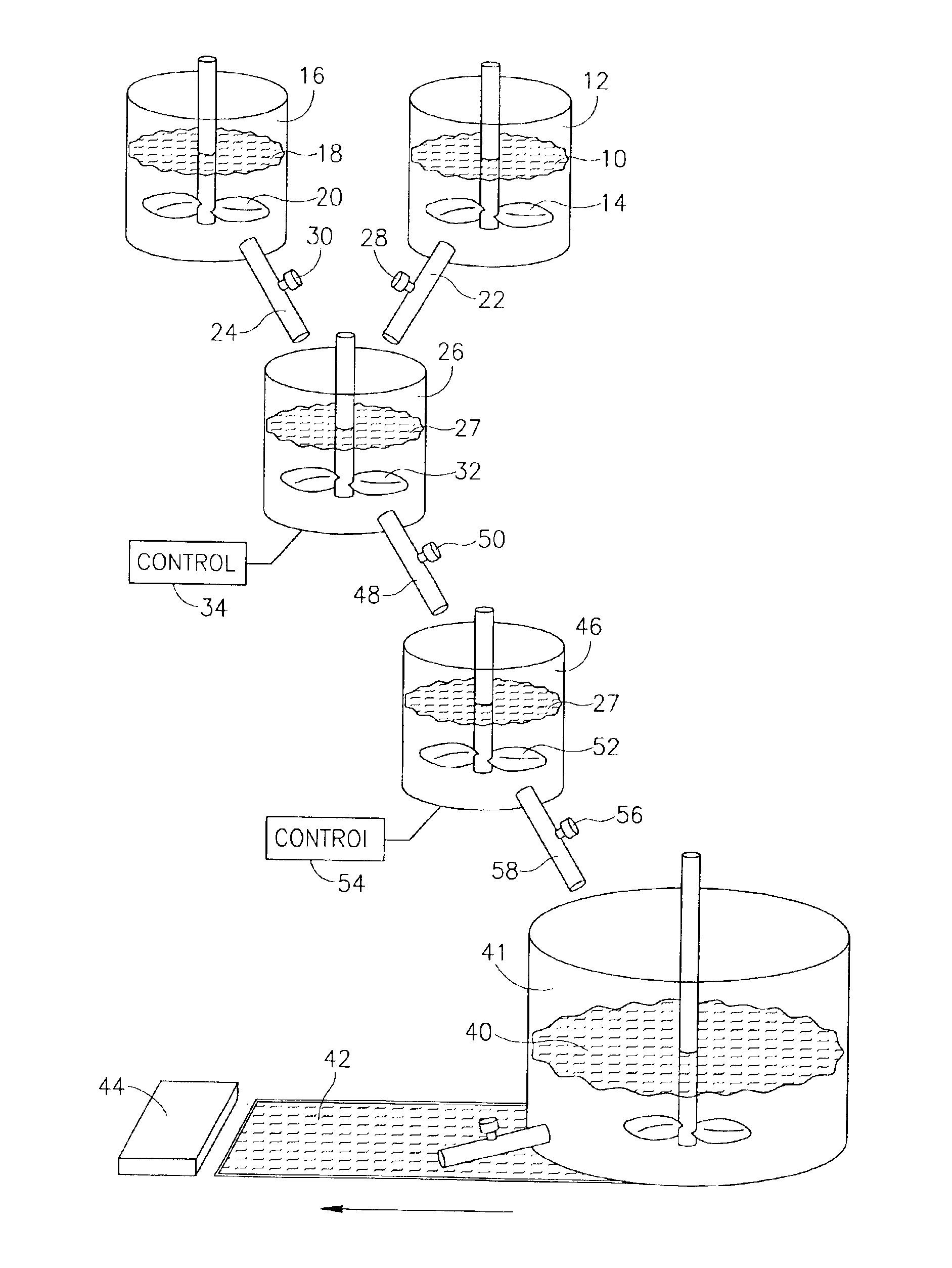

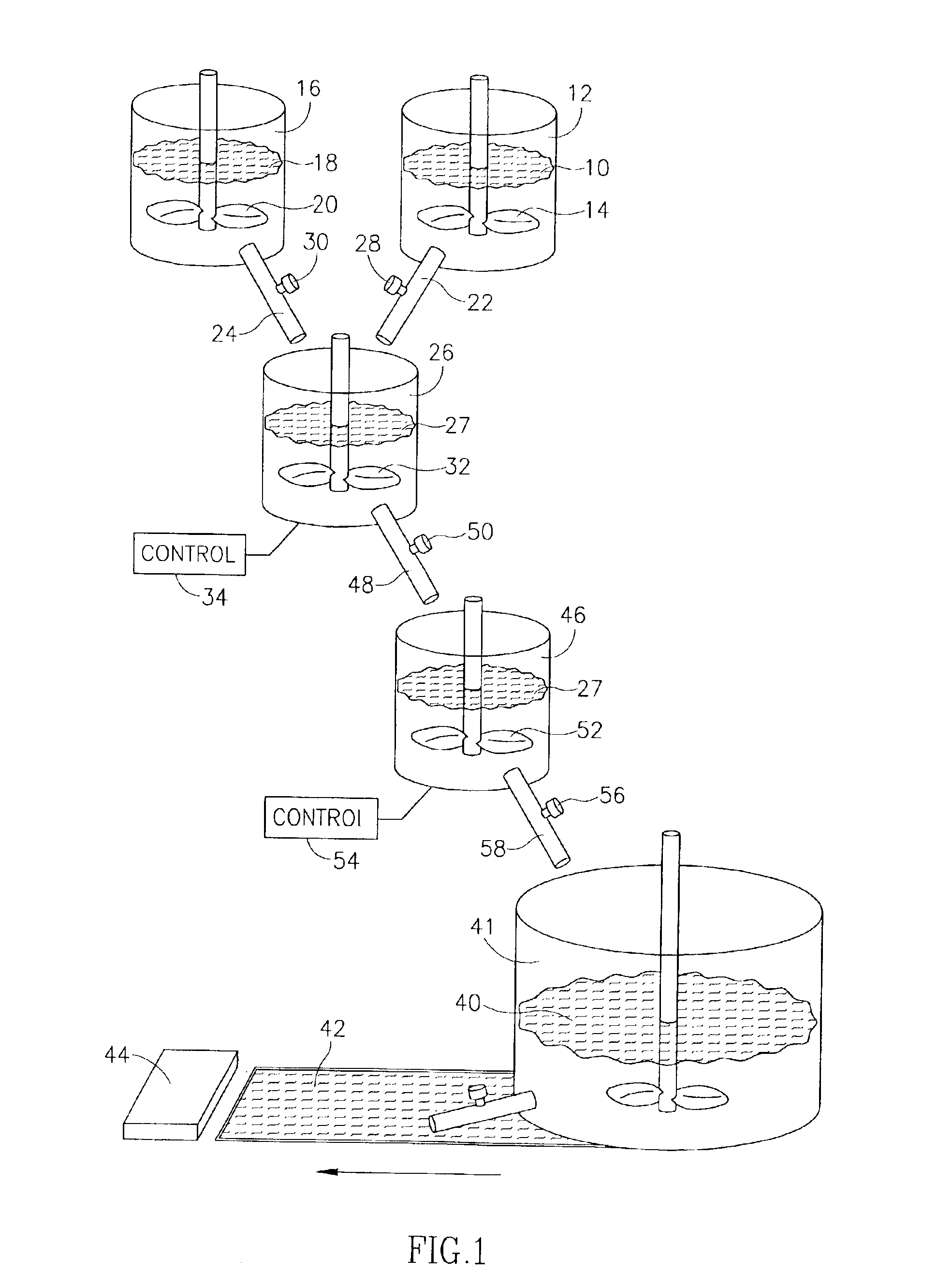

InactiveUS7189074B2Reduce chanceImprove usabilityRotary drum furnacesCeramic production plantsCombustion chamberSlag

The co-combustion process may comprise the following unit operations: routing of hot gas (10) generated in the clinker cooling process to a rotary kiln (1); use of part of the rotary kiln exhaust gas to dry solid wastes in rotary dryers; leading the gases from both the dryer and the combustion kiln to the secondary combustion chamber (2); use of additional fuel to boost up the secondary combustion chamber reaction temperature to as high as 1200° C.; primary dry gas scrubbing in a precalciner or precalciners (3, 3a); heat recovery (4) and power generation; secondary gas scrubbing (5) in a semi-dry scrubber; bag filtering after activated carbon injection and returning of all the collected ash and used carbon into the waste kiln and / or a cement kiln. Detrimental materials for cement processing generated by waste combustion can be by-passed to a scrubbing system and a cement kiln. Residue slag from waste kilns can be treated and reused.

Owner:GREEN ISLAND ENVIRONMENTAL +1

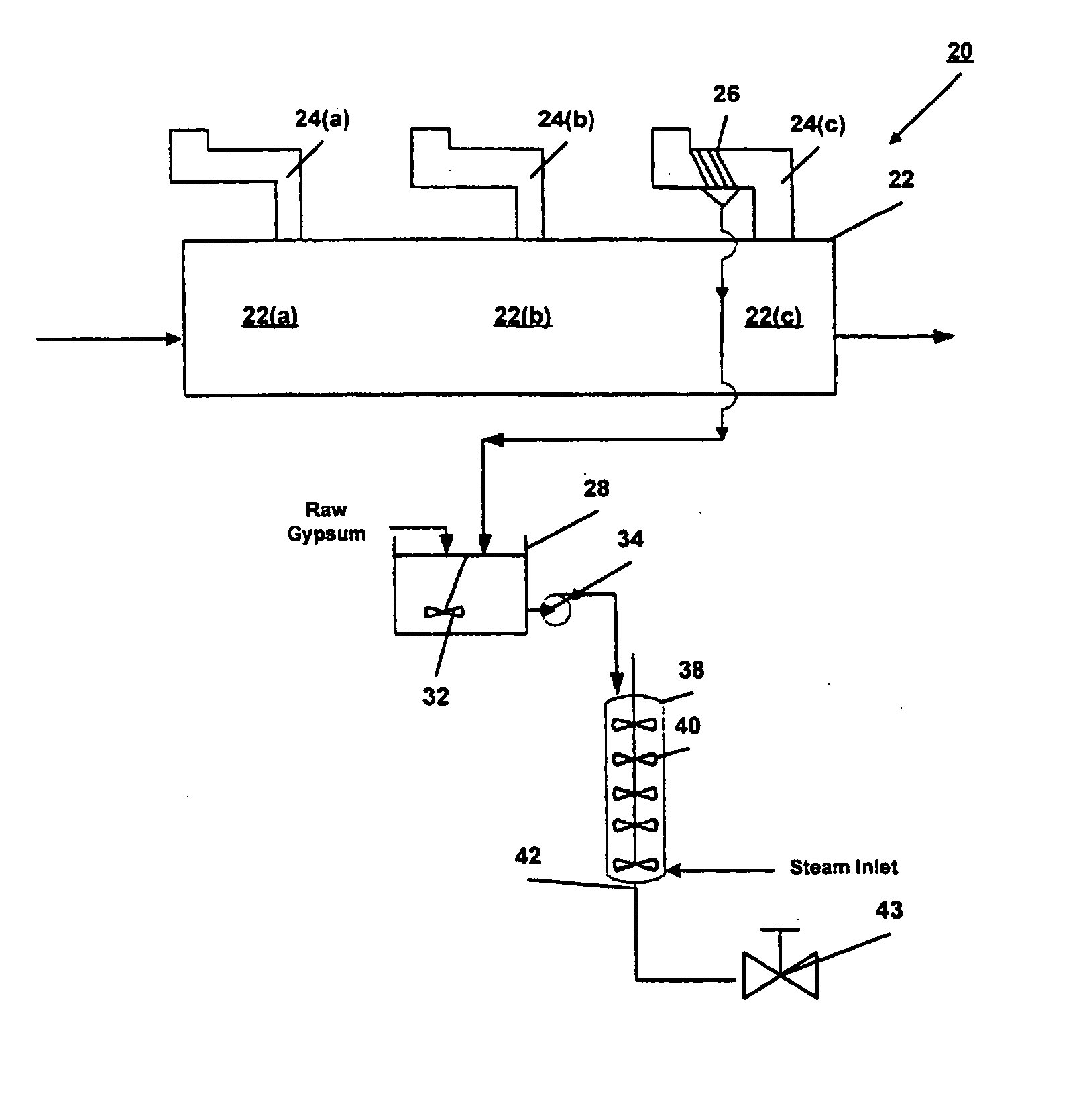

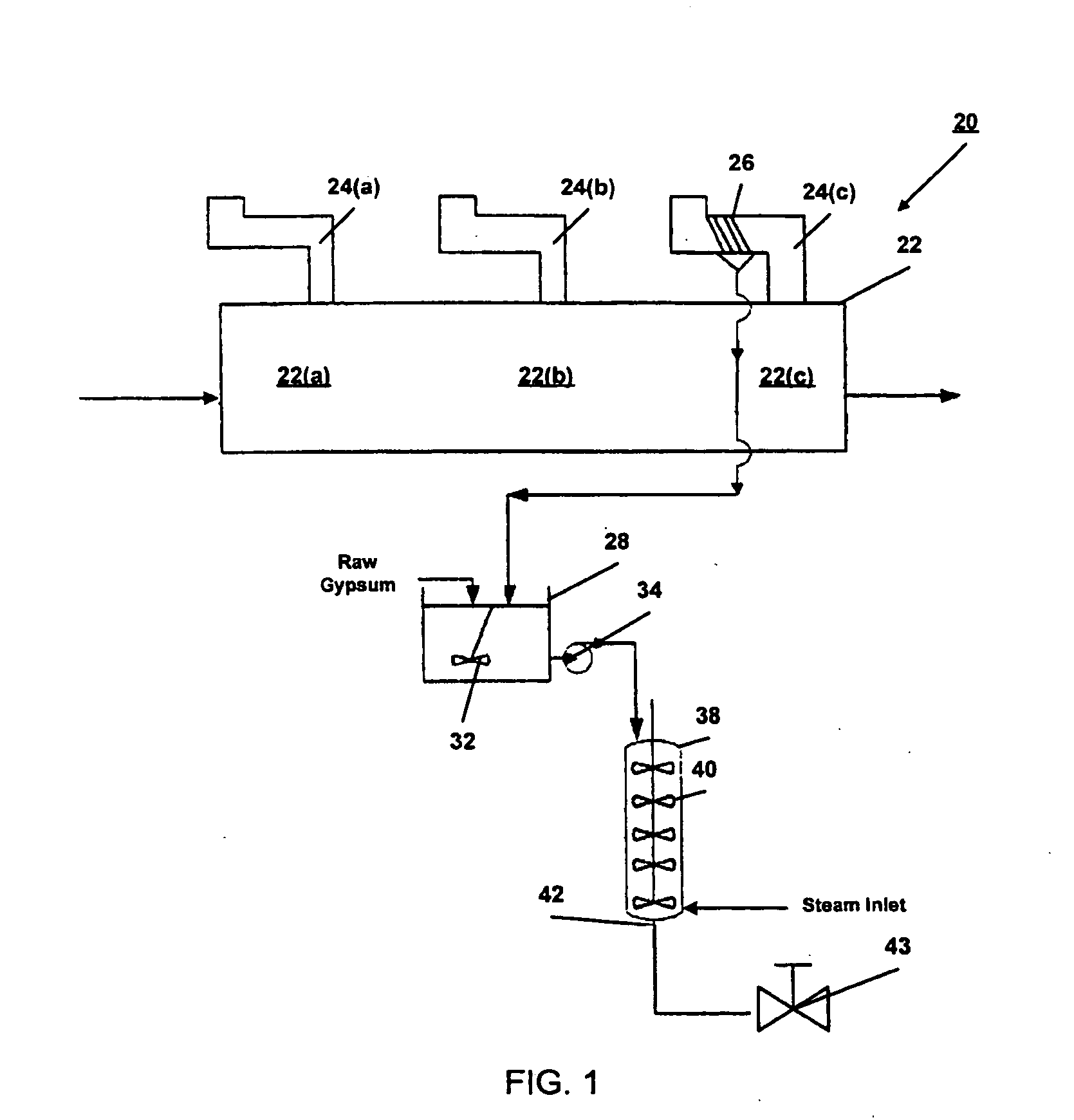

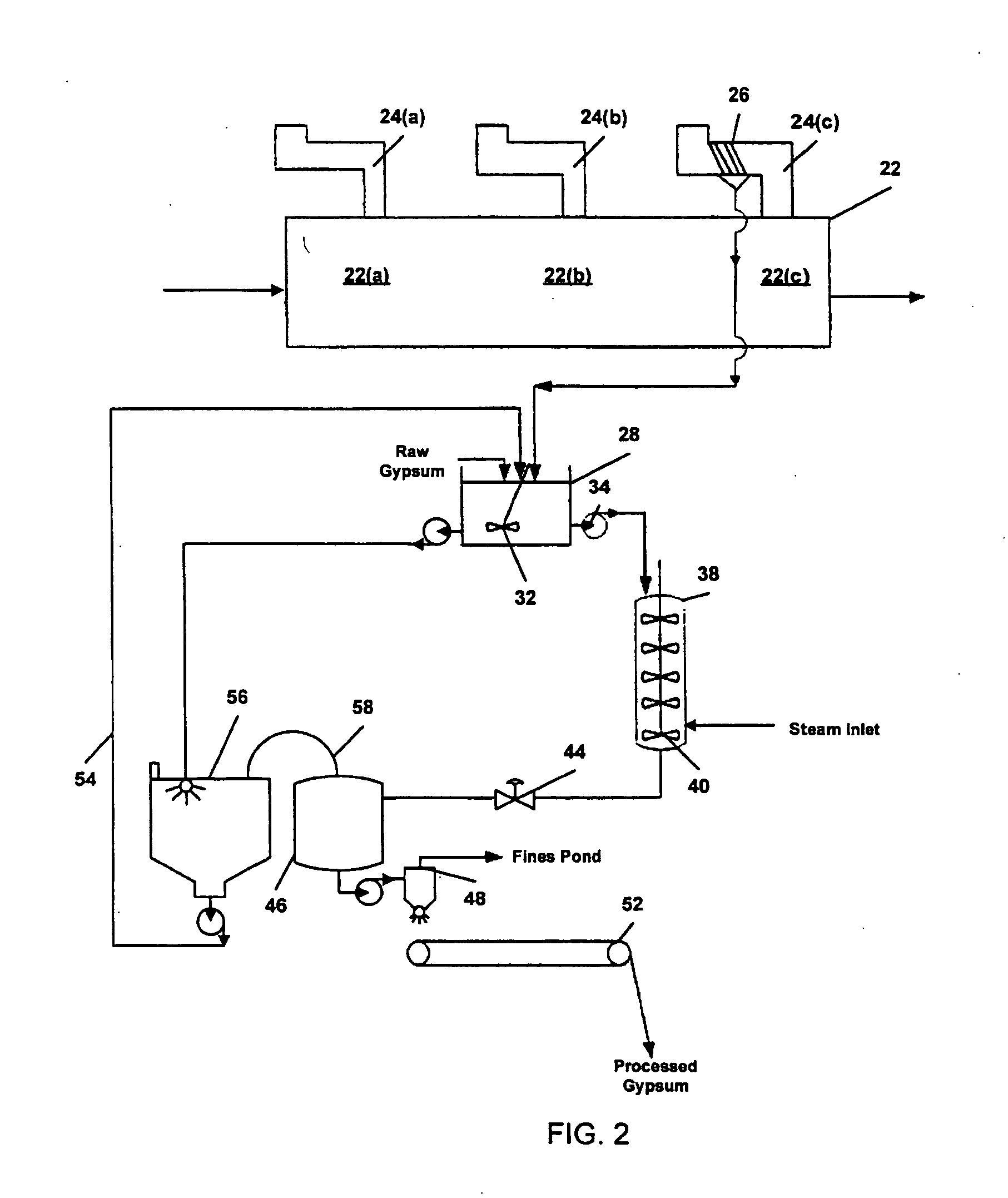

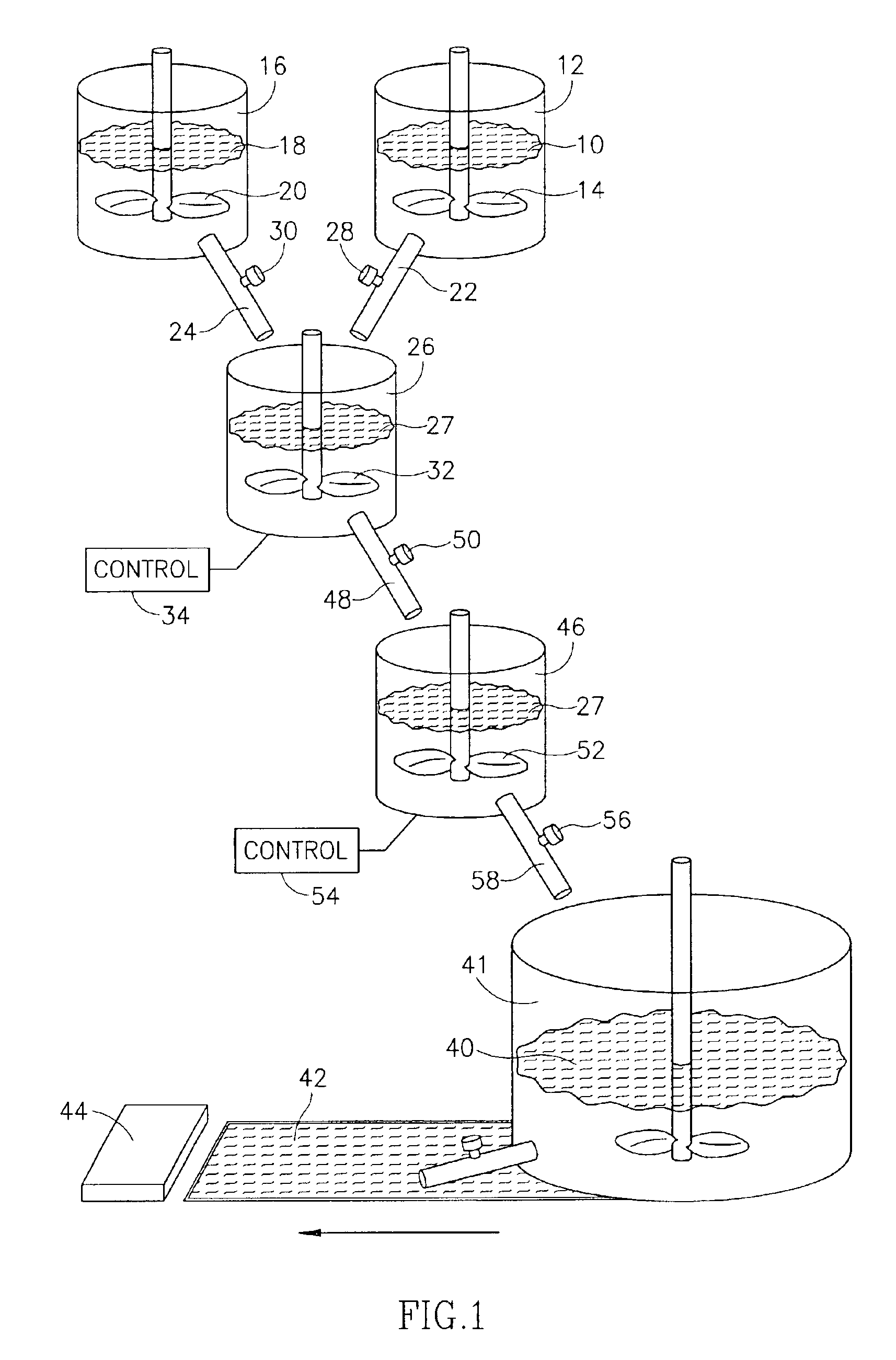

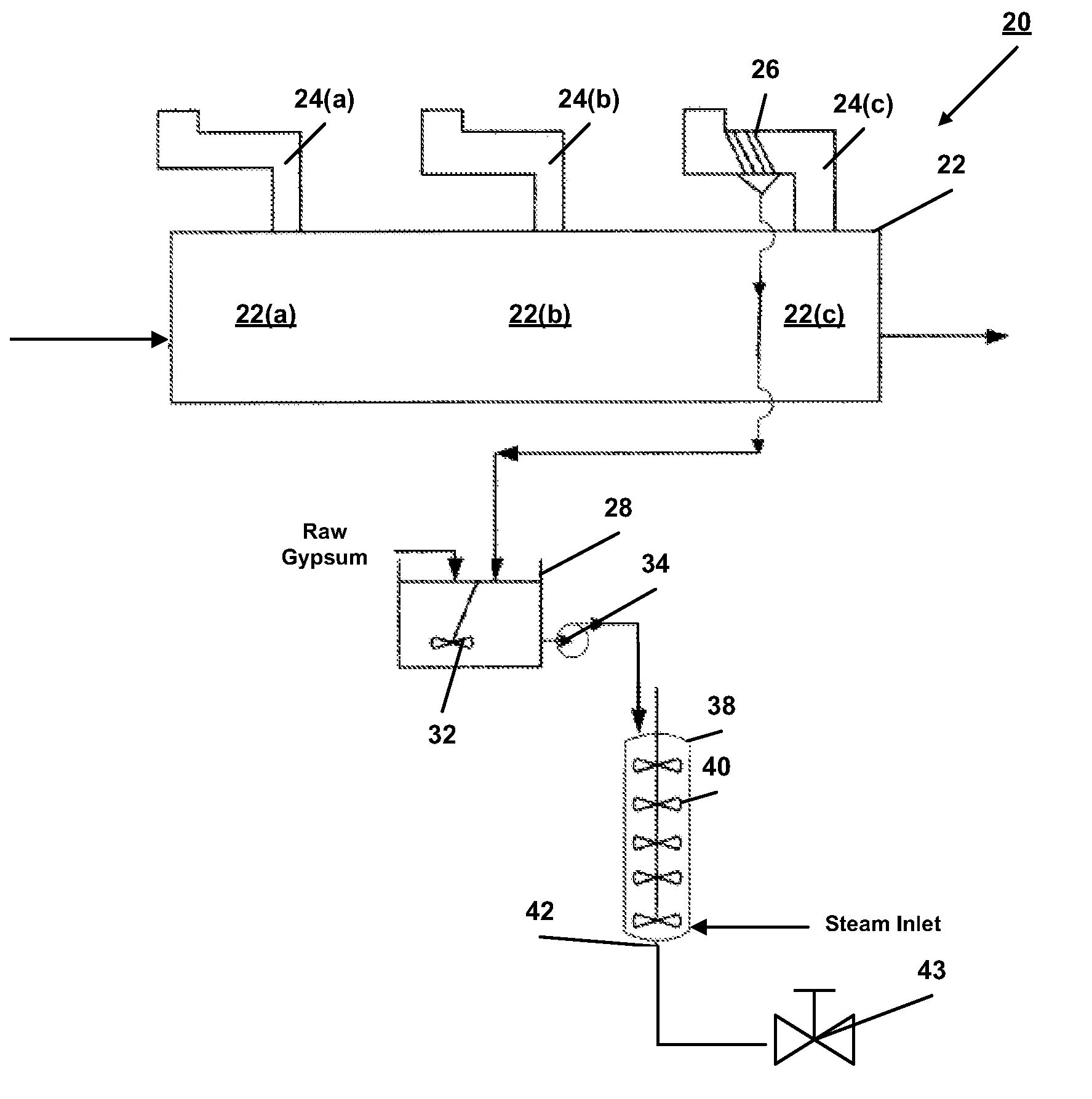

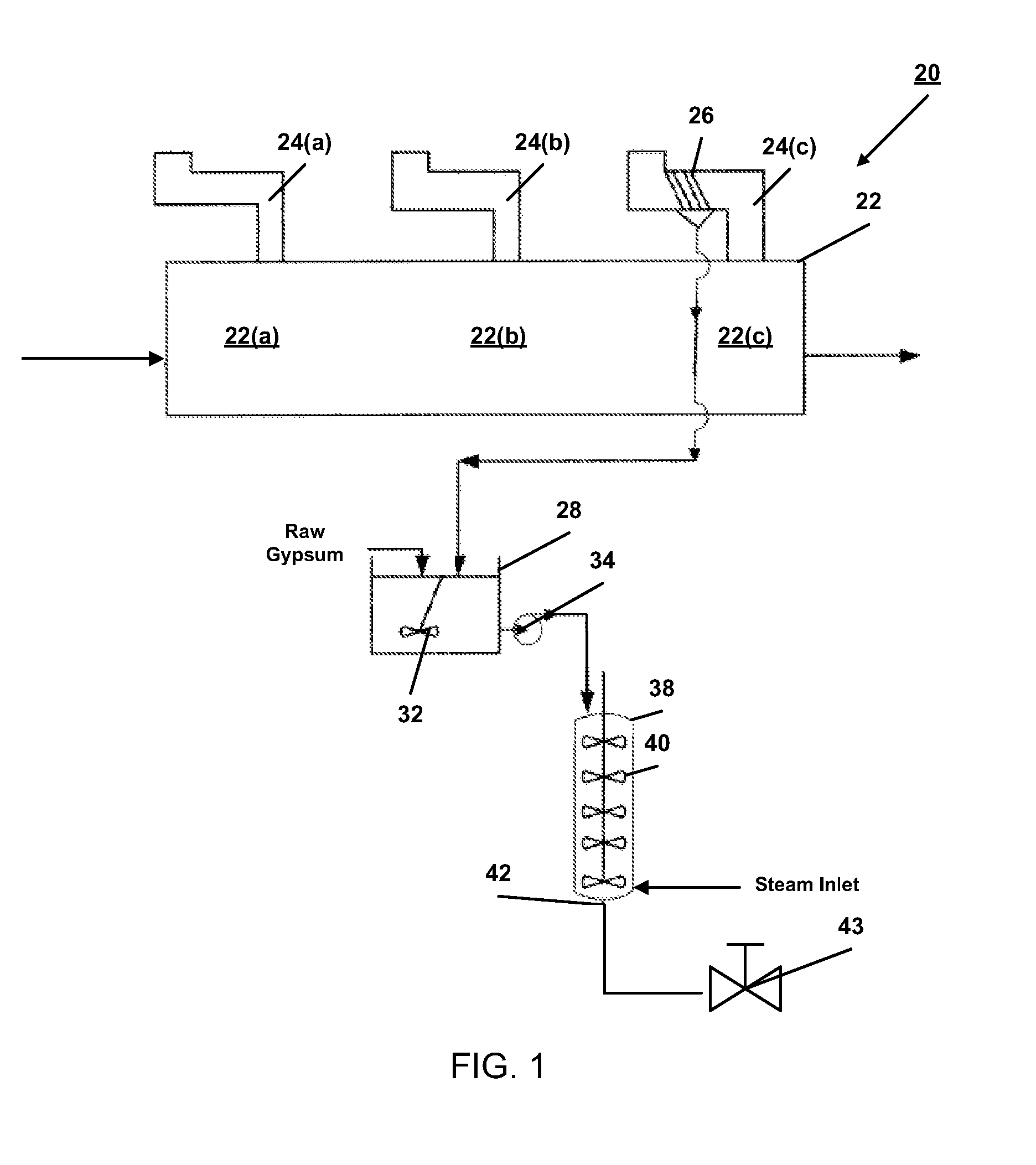

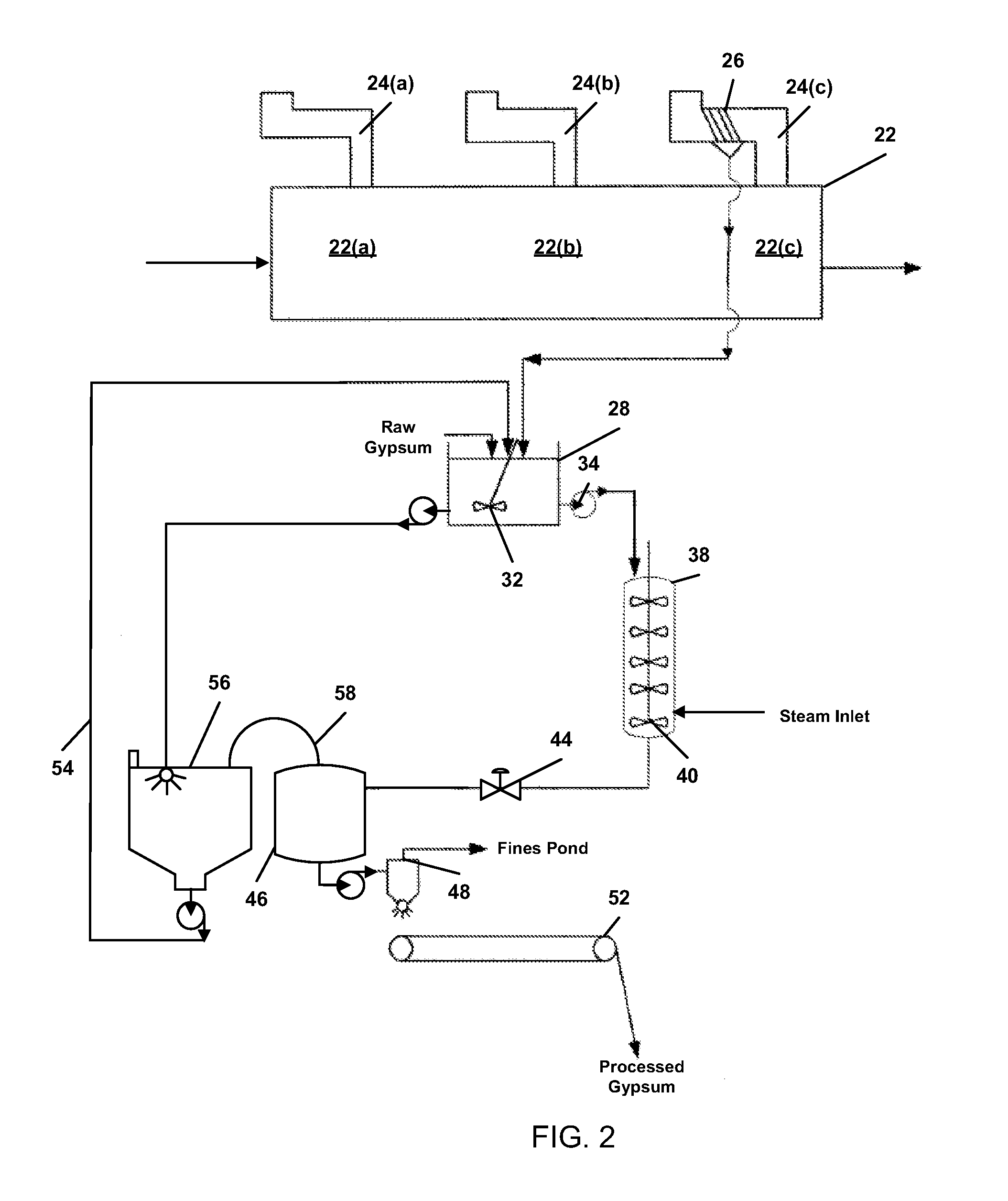

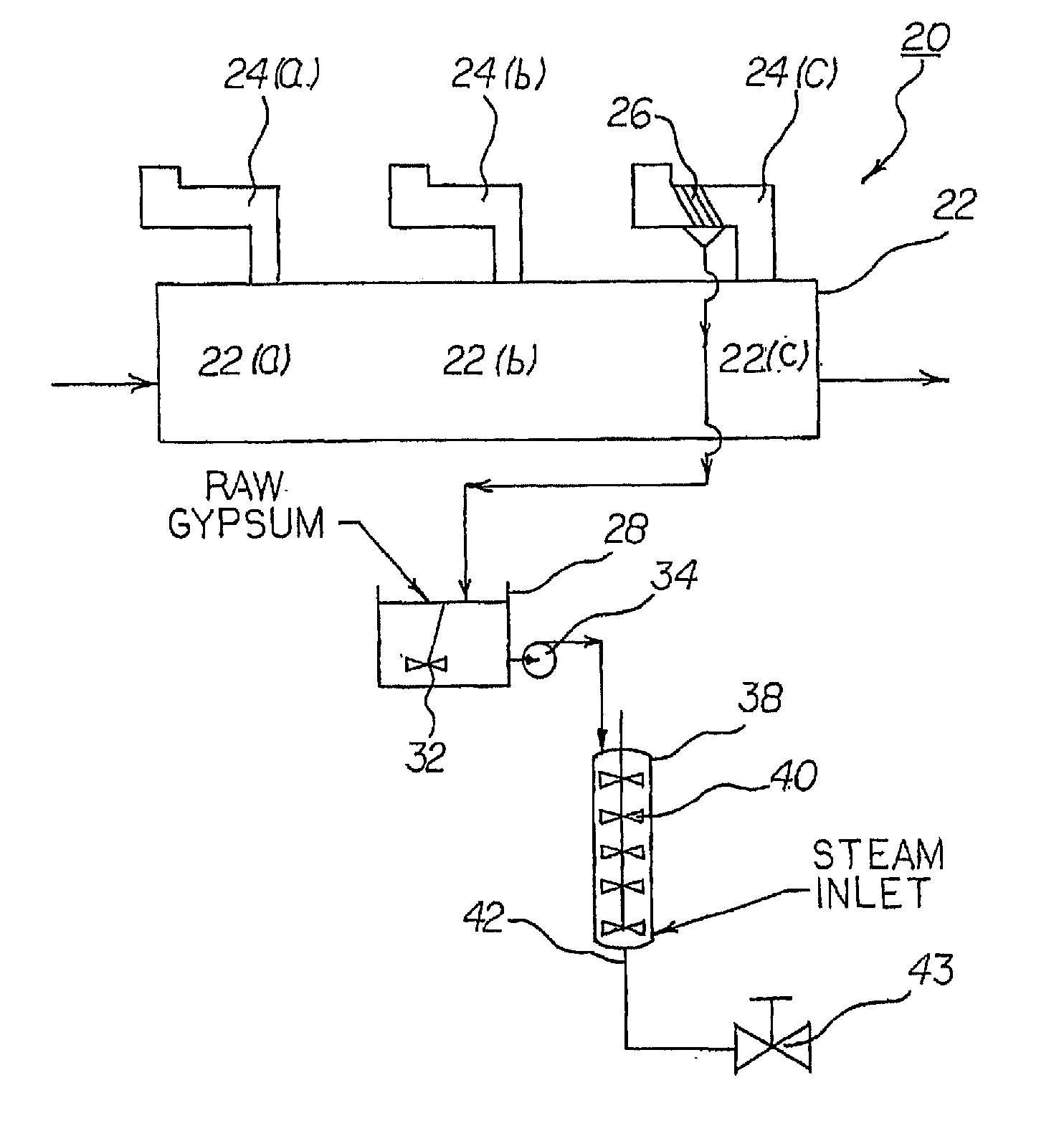

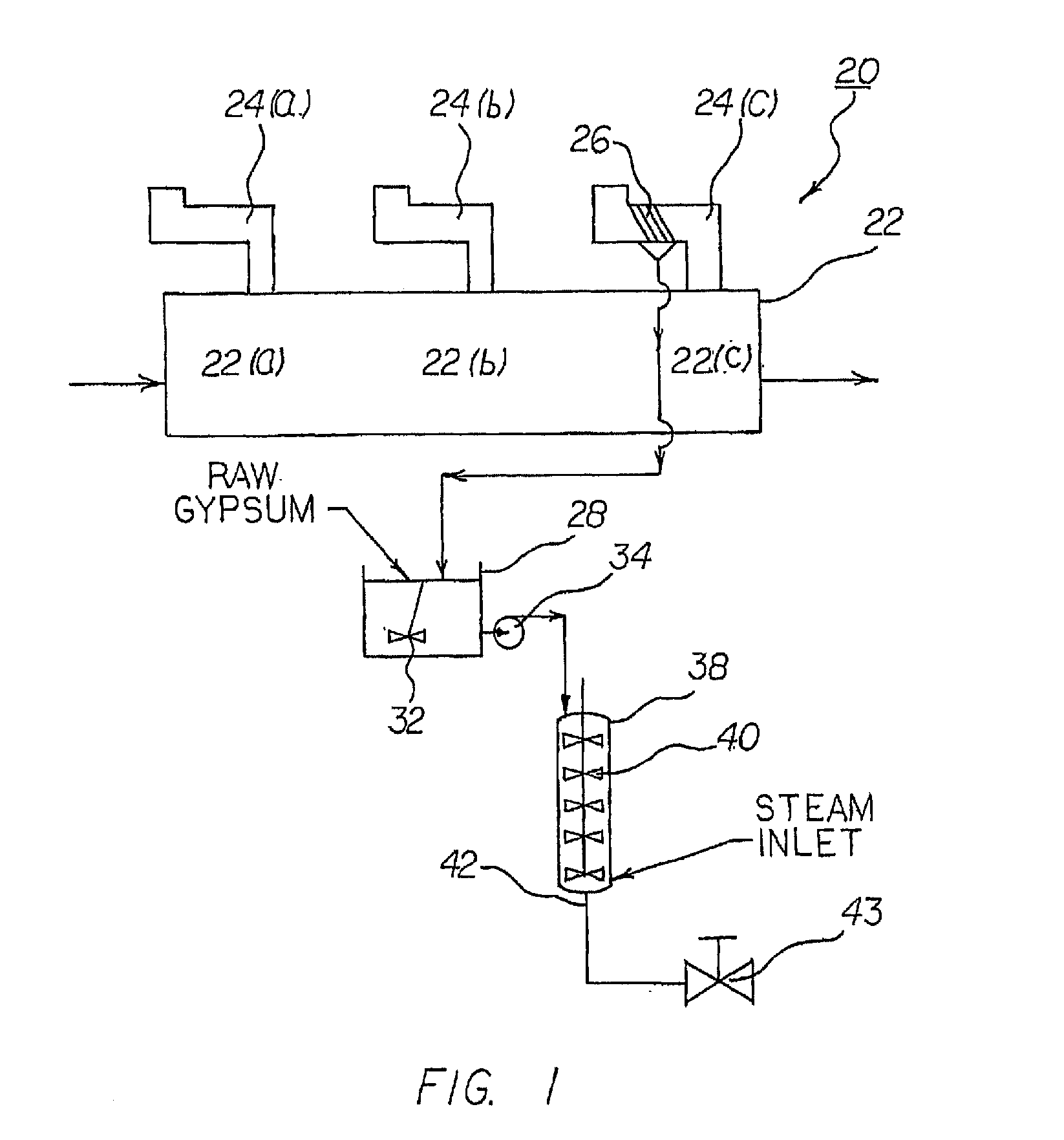

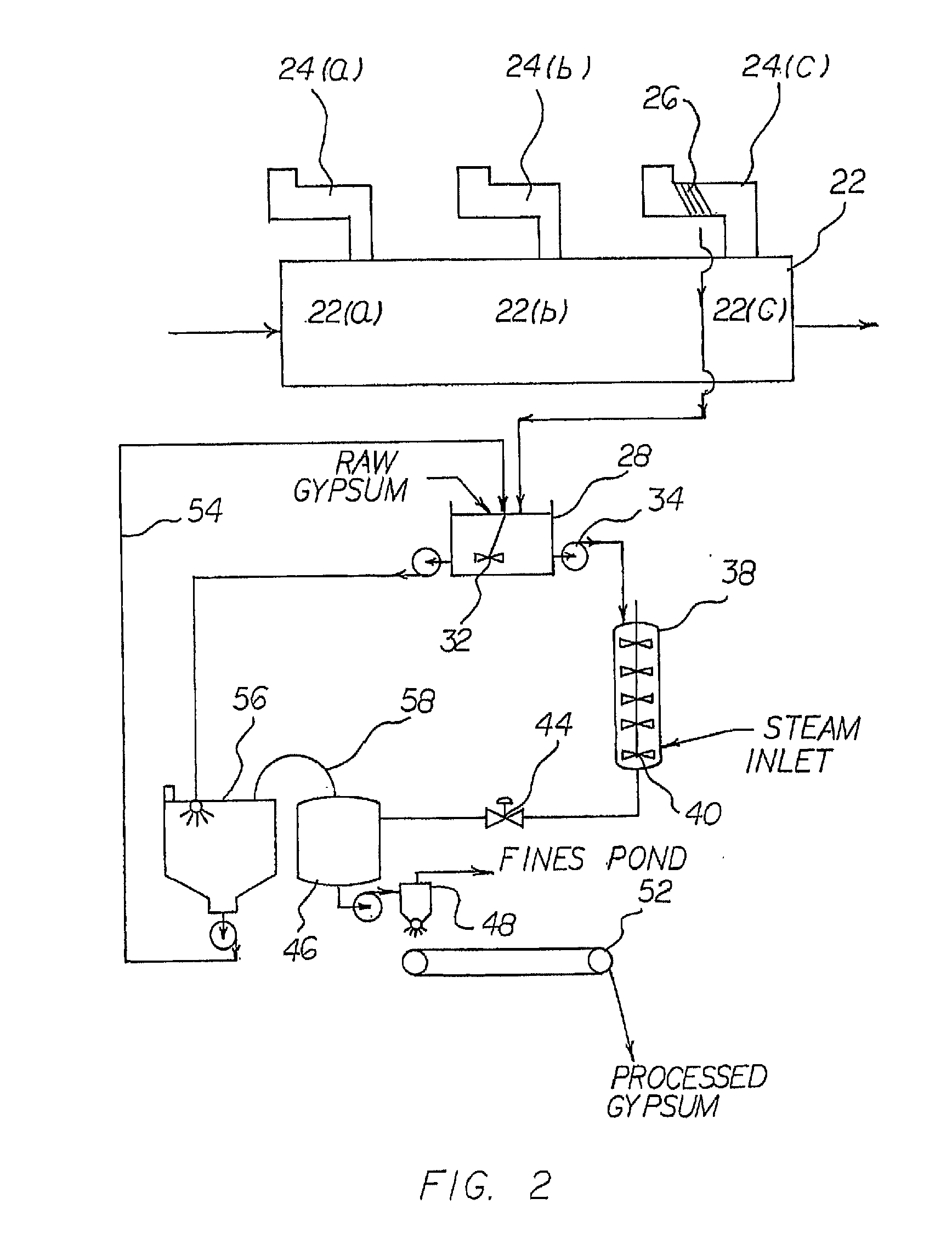

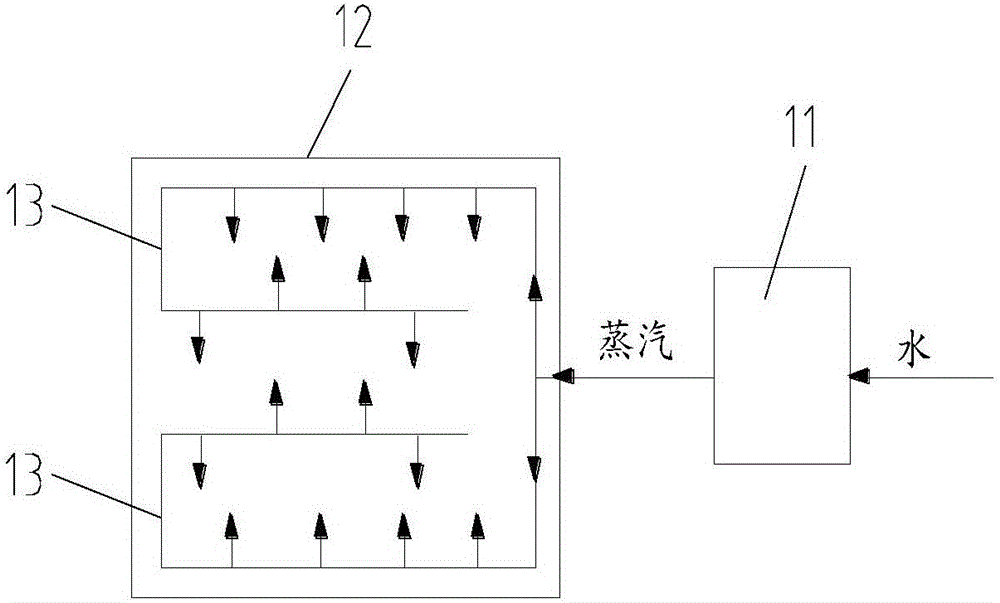

System and method for the production of alpha type gypsum using heat recovery

The present invention relates to a system and associated method for the production of gypsum in manufacturing plant. More specifically, the invention relates to the production of alpha-type gypsum in a gypsum board manufacturing plant. The system yields increased efficiencies by capturing heat given off during processing steps and using that heat to reduce the energy needed for calcination. The invention finds particular application in the production alpha-type gypsum. The present invention is described in greater detail hereinafter in conjunction with the following specific embodiments.

Owner:CERTAINTEED GYPSUM INC

Gypsum product and method therefor

InactiveUS6902615B2Large energyLimited shelf lifeOther chemical processesSolid waste managementVolumetric Mass DensityReducer

A method comprising adding a suspension of a hydrophobic substance to a gypsum slurry. The hydrophobic substance may impart water repellent characteristics to the gypsum, may be used as a foaming aid, density reducer, dimension stabilizer, and others, and may increase the mechanical strength and durability of the gypsum product. In another embodiment of the present invention, suspensions of other substances may be used in addition to or in place of the hydrophobic substance to impart these characteristics.

Owner:TIP - THE IND PIVOT

Method and process for co-combustion in a waste to-energy facility

InactiveUS20050039638A1High degreeReduce chanceRotary drum furnacesCeramic production plantsCombustion chamberSlag

The co-combustion process may comprise the following unit operations: routing of hot gas (10) generated in the clinker cooling process to a rotary kiln (1); use of part of the rotary kiln exhaust gas to dry solid wastes in rotary dryers; leading the gases from both the dryer and the combustion kiln to the secondary combustion chamber (2); use of additional fuel to boost up the secondary combustion chamber reaction temperature to as high as 1200° C.; primary dry gas scrubbing in a precalciner or precalciners (3, 3a); heat recovery (4) and power generation; secondary gas scrubbing (5) in a semi-dry scrubber, bag filtering after activated carbon injection and returning of all the collected ash and used carbon into the waste kiln and / or a cement kiln. Detrimental materials for cement processing generated by waste combustion can be by-passed to a scrubbing system and a cement kiln. Residue slag from waste kilns can be treated and reused.

Owner:GREEN ISLAND ENVIRONMENTAL +1

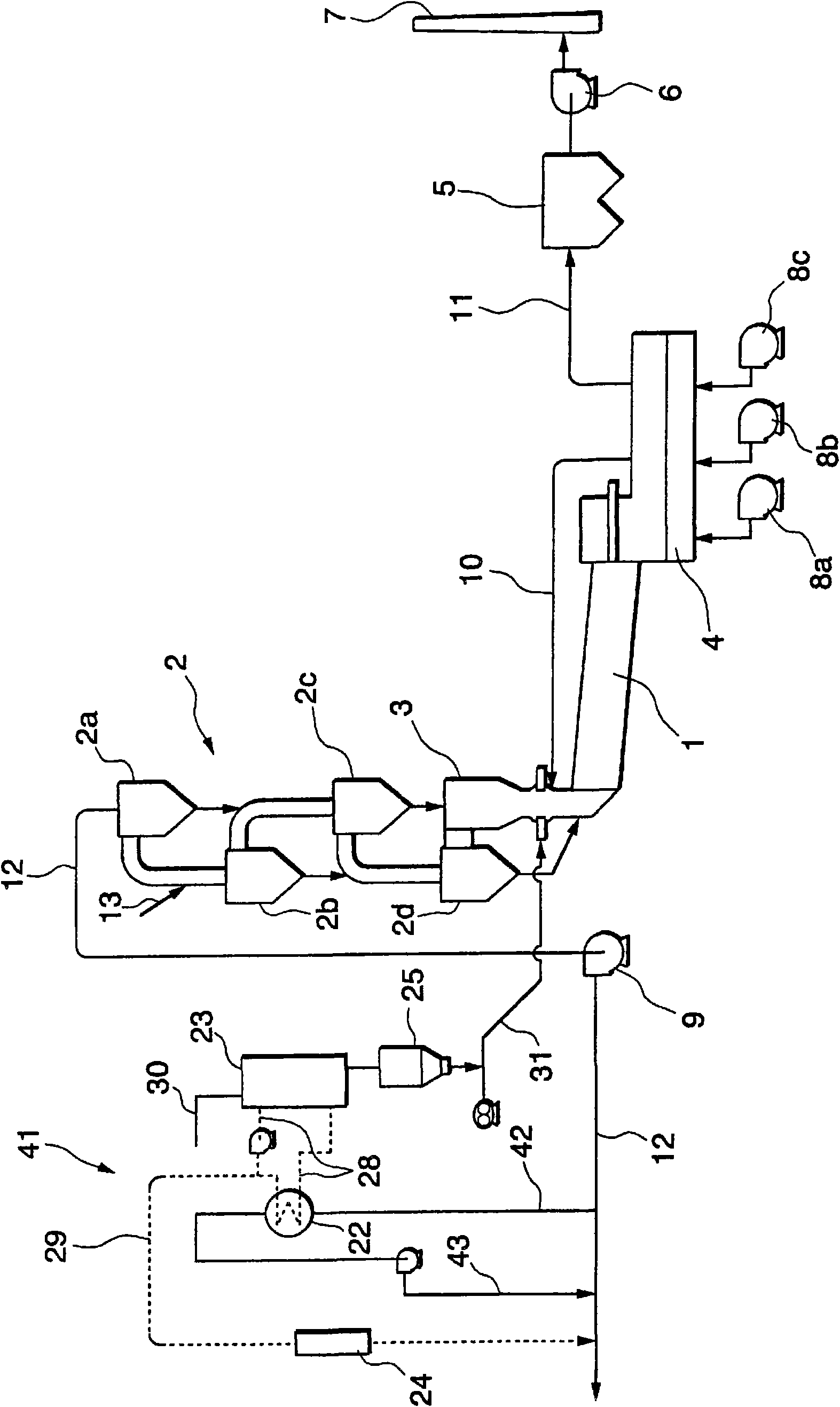

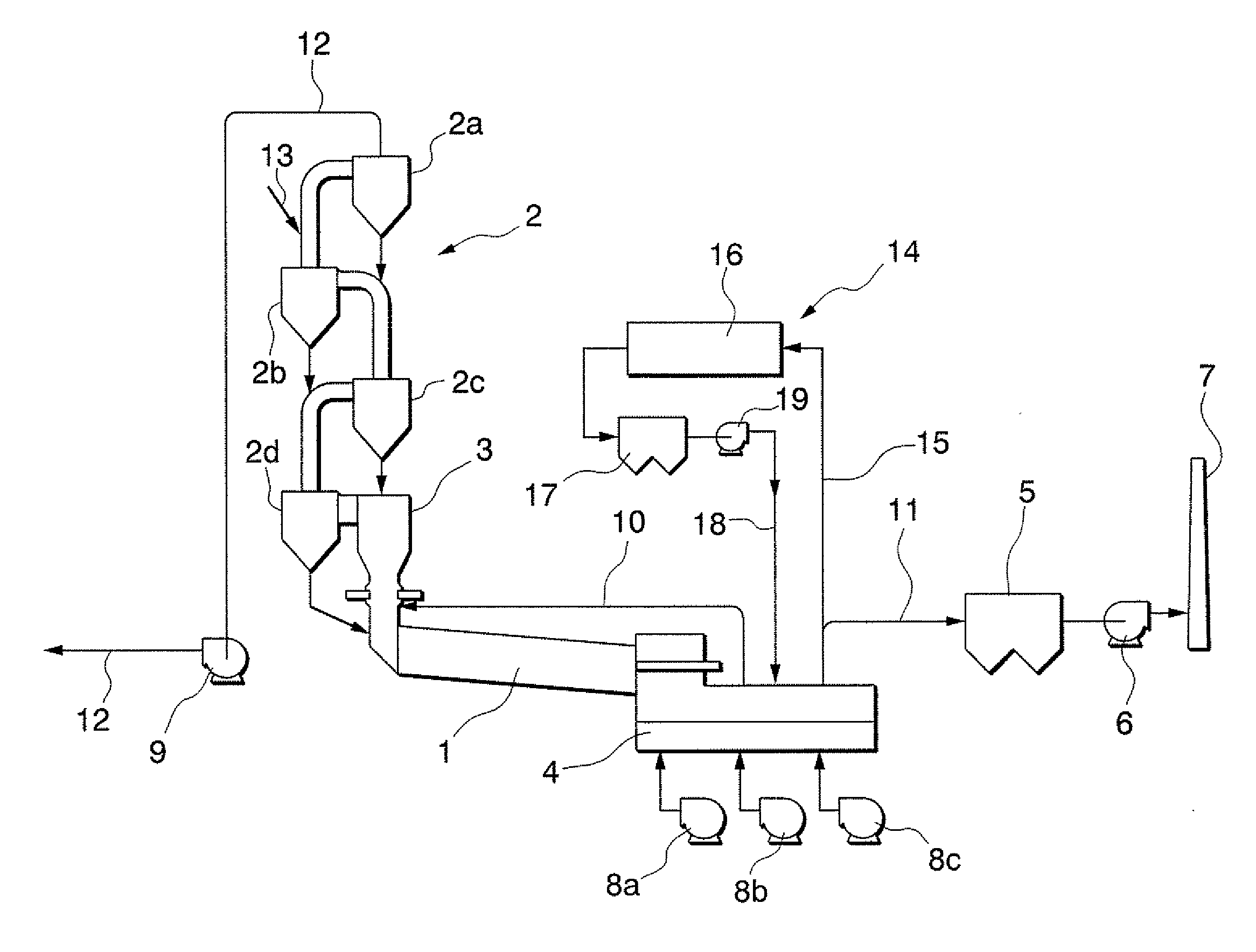

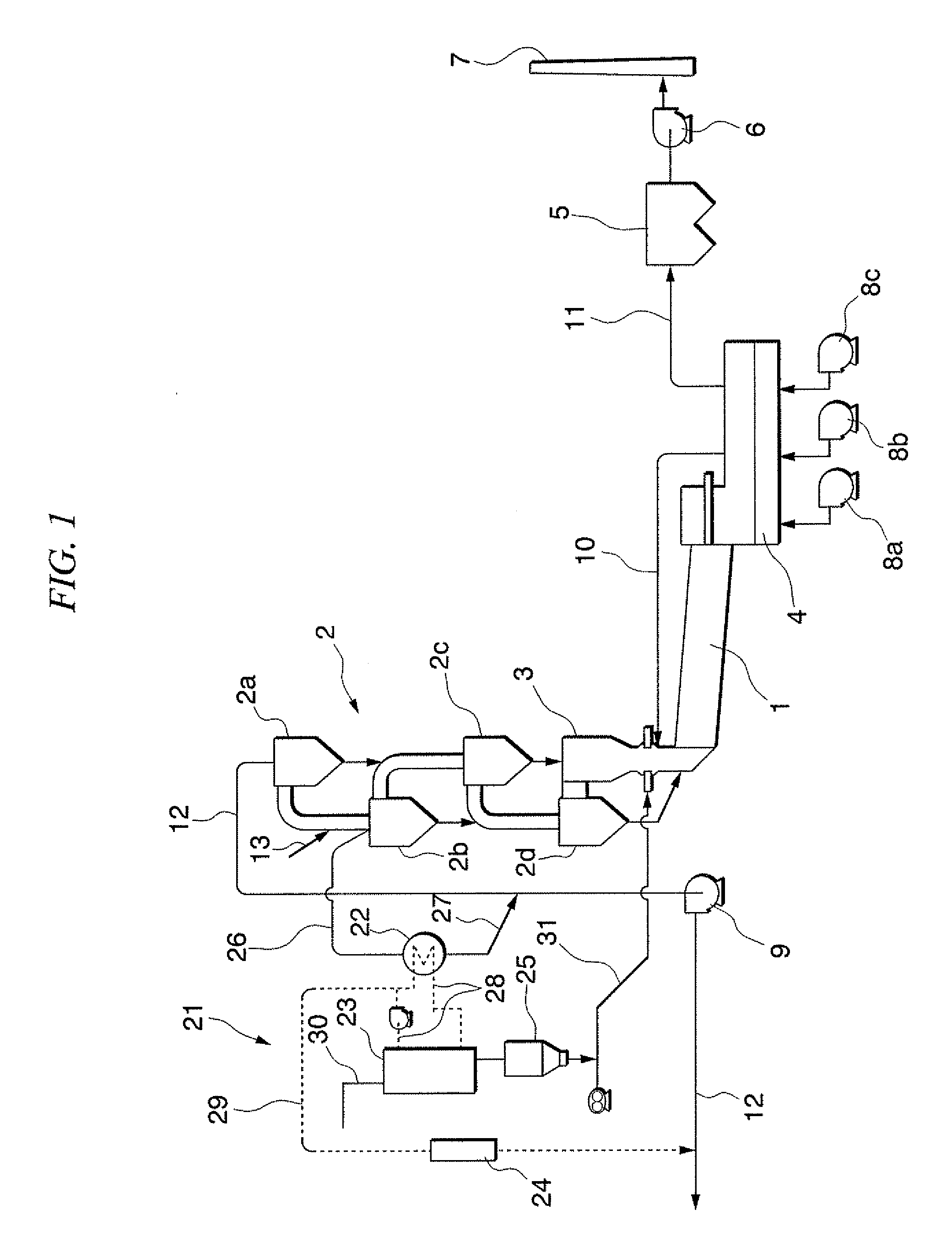

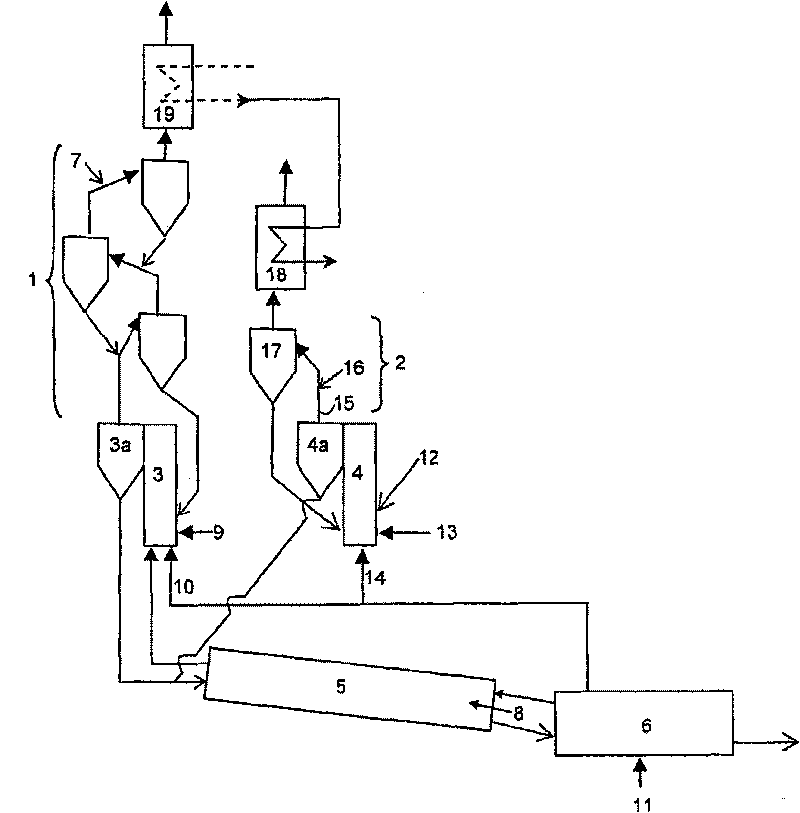

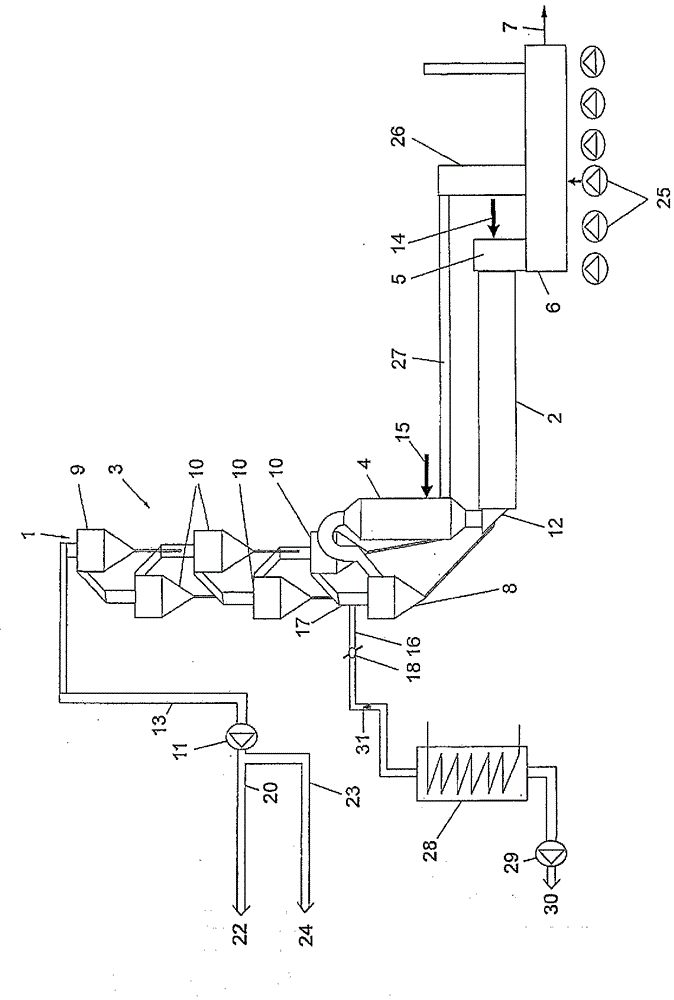

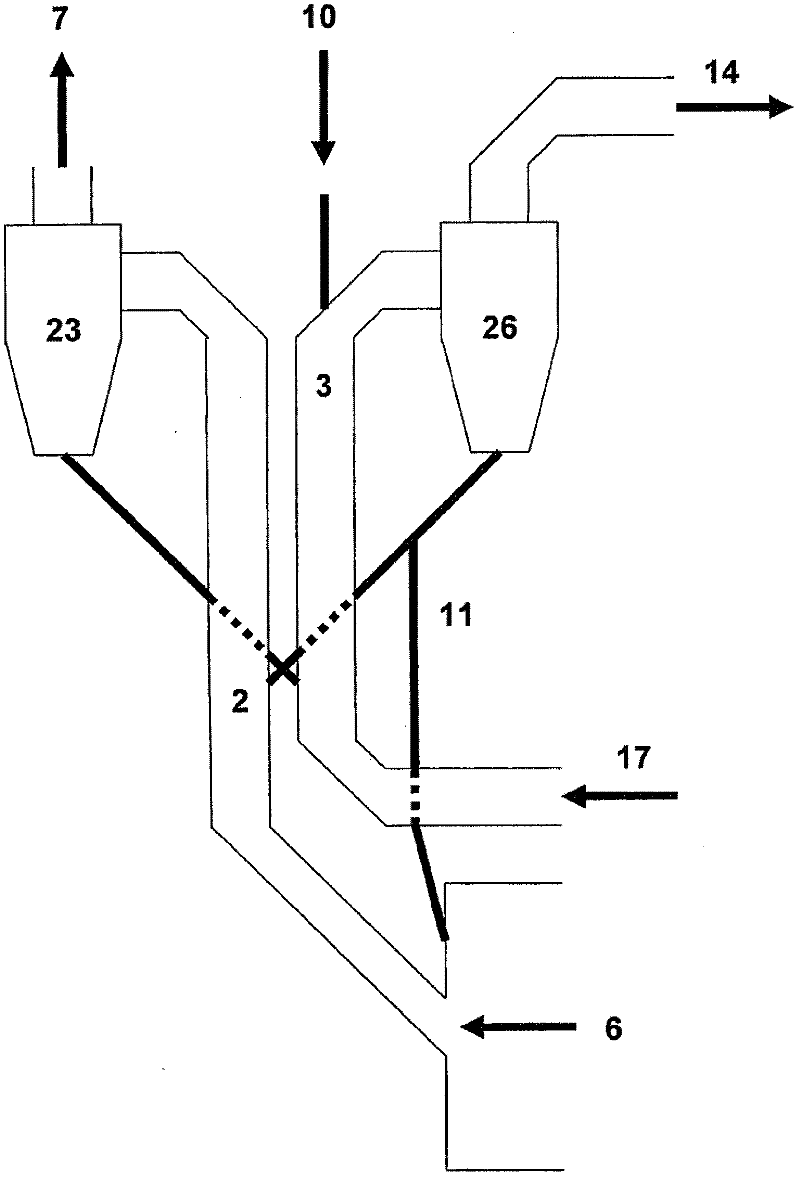

Method of disposing of organic waste of high water content and disposal apparatus therefor

ActiveCN101528614ADoes not affect operationEfficient use ofSludge treatment by de-watering/drying/thickeningDrying solid materials with heatSludgeHigh water content

The present invention discloses a method of disposing of an organic waste of high water content, and disposal apparatus therefor, with which effective utilization of the organic waste of high water content as fuel can be attained by drying the same with the use of cement calcination equipment, and with which the operation efficiency of cement calcination equipment can be enhanced without the danger of influences on the operation of the cement calcination equipment. The method of disposing of an organic waste of high water content comprises the steps of carrying out by means of heat exchanger (22) a heat exchange between superheated steam and exhaust gas separated by cyclone (2b) of suspension preheater (2) and not only introducing the superheated steam of high temperature after the heat exchange in dryer (23) to thereby dry any organic sludge into a dried organic waste but also carrying out once more by means of the heat exchanger (22) a heat exchange of the superheated steam after the drying to thereby attain circulatory use thereof in the drying of organic sludge; and feeding the resultant dried organic sludge to calciner (3) as fuel and combusting the same.

Owner:SUMITOMO OSAKA CEMENT CO LTD

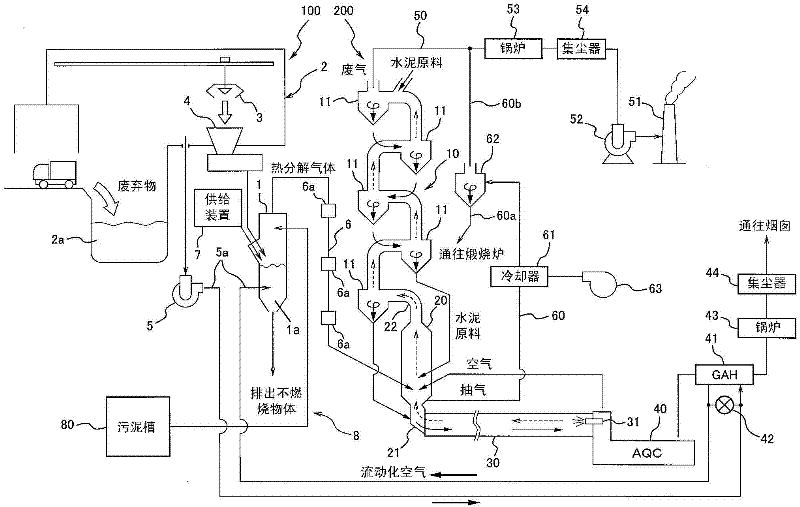

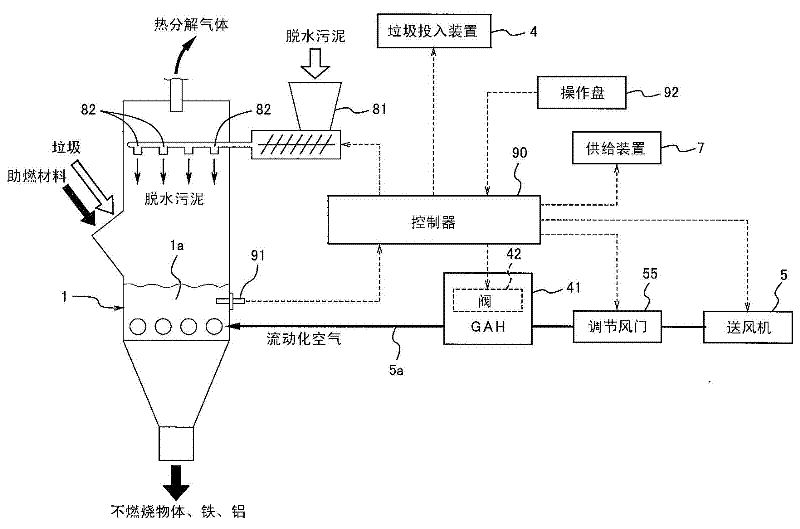

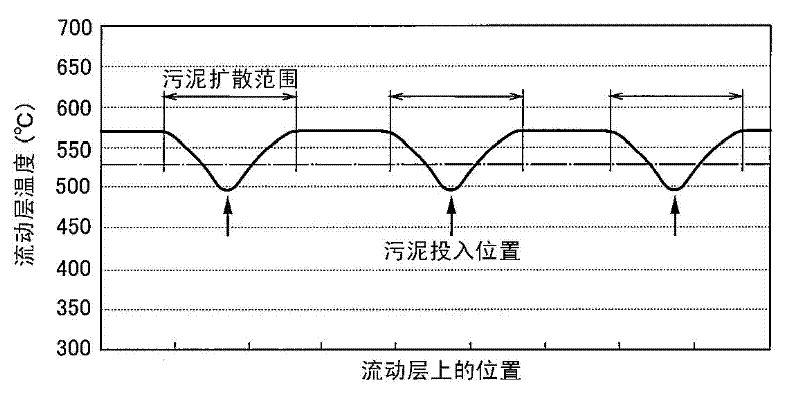

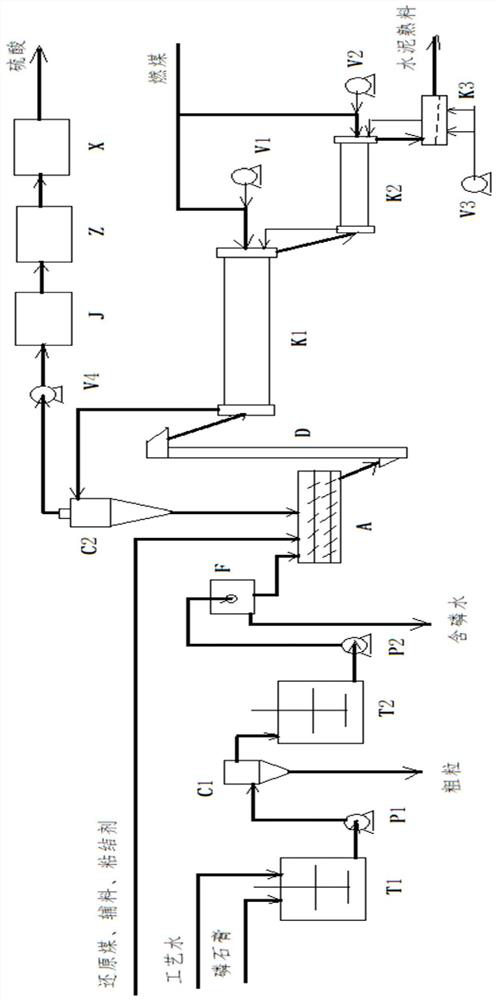

Treating equipment for waste containing sludge

ActiveCN102452802AEfficient use ofHigh calorific valueWater treatment parameter controlWaste water treatment from ceramic industriesSludgeProduct gas

The invention provides treating equipment for waste containing sludge. The objective of the invention is that the temperature of a fluid bed (1a) in a fluid bed gasification furnace (1) used for thermal decomposition of waste can be maintained in a proper range even when considerable waste containing high water content dehydrated sludge is treated. To realize the objective, treating equipment (100) for waste containing sludge is constructed beside cement manufacturing equipment (200). The treating equipment for waste comprises the fluid bed gasification furnace (1) which enables waste to be gasified for production of thermal decomposition gas, a gas delivery line (6) which delivers the produced thermal decomposition gas together with charcoal and ash to between a cement preheater (10) anda decomposing furnace (20), and heating devices like a waste gas air heater (41) which enables the temperature of fluidized air supplied to the gasification furnace (1) to rise by using waste heat ofthe cement manufacturing equipment (200).

Owner:KAWASAKI HEAVY IND LTD +4

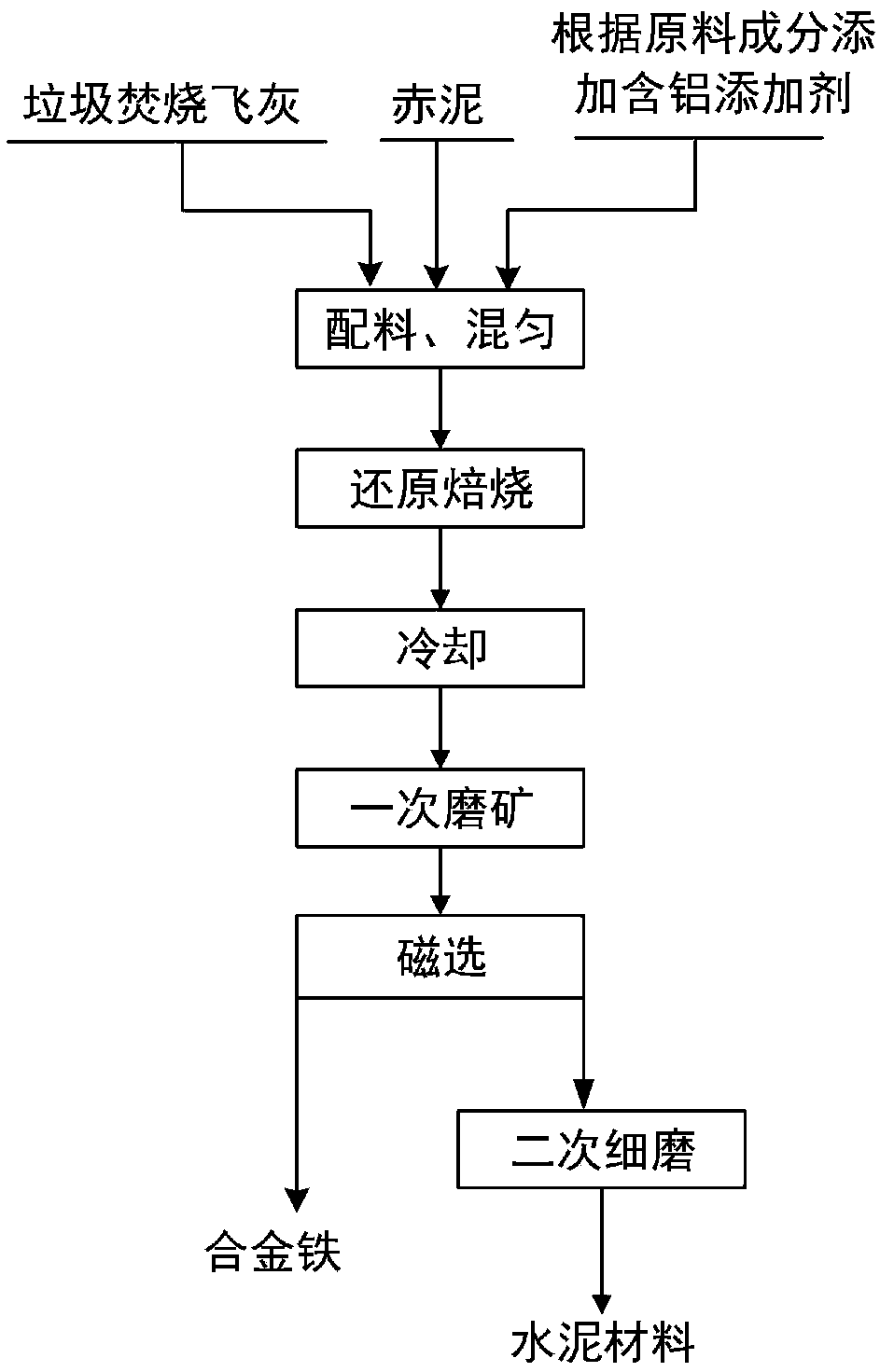

Method for preparing alloy iron and cement material

ActiveCN109265029AIncrease valueSpeed up entrySolid waste disposalTransportation and packagingRed mudAlloy

The invention provides a method for preparing alloy iron and a cement material and belongs to the field of resource recovery of solid wastes. According to the method, carbon, a synergistic effect of calcium and heavy metal components in garbage combustion fly ash and silicon, aluminum and silicon components in red mud is efficiently utilized to finally obtain the alloy iron and the cement materialand wastes are treated by wastes; components of the two wastes are complementary, and the carbon in the garbage combustion fly ash also can provide a reduction agent for reduction, so that iron minerals in the red mud are promoted to be reduced into metal iron; the metal iron is formed and siderophile heavy metal elements in the garbage combustion fly ash are promoted to enter an iron phase; meanwhile, the resource recovery of the solid wastes is realized through the cement material formed by Al2O2 and SiO2 in the red mud and CaO in the garbage combustion fly ash, so that recycling and comprehensive utilization of the two important dangerous wastes, which need to be urgently treated and include the garbage combustion fly ash and the red mud, and a lot of industrial solid wastes can be realized and the comprehensive utilization rate of resources is improved.

Owner:TSINGHUA UNIV

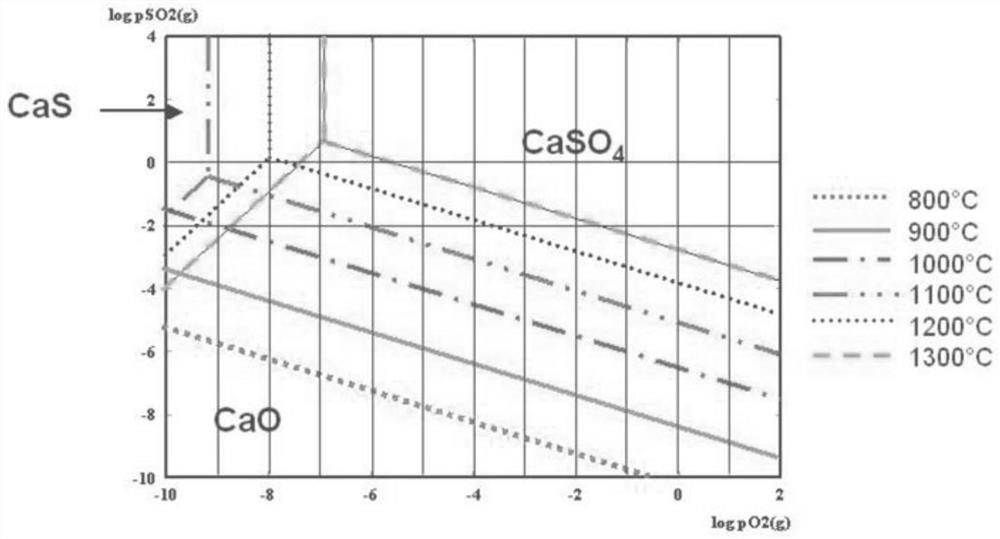

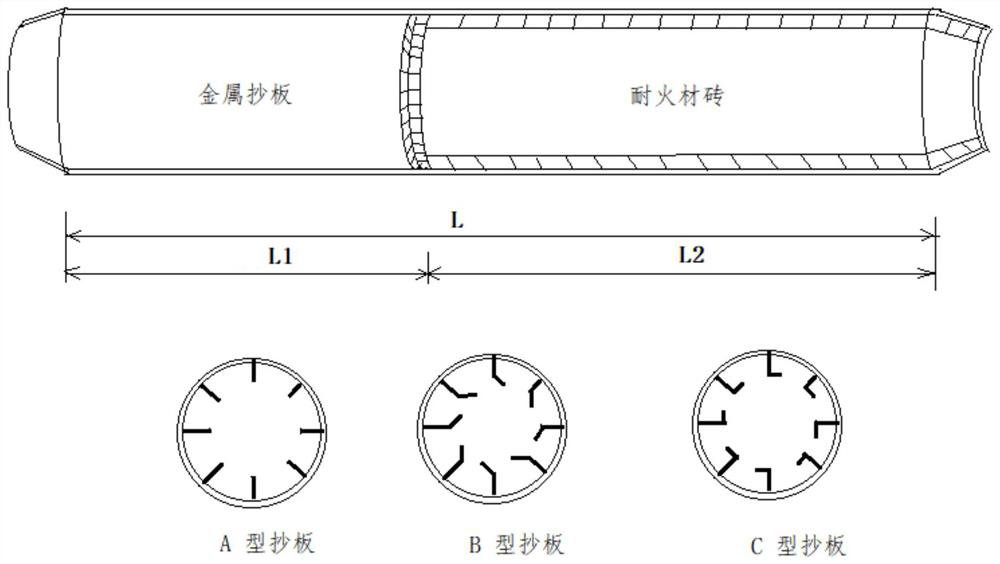

Production method for producing cement and sulfuric acid from phosphogypsum

InactiveCN112694067AImprove product qualityEliminate the environmental problems of stackingSulfur compoundsCeramic production plantsReductive decompositionDust control

The invention discloses a production method for producing cement and sulfuric acid by using phosphogypsum. The method comprises the following steps: carrying out pretreatment purification on phosphogypsum to reduce insoluble phosphorus, water-soluble phosphorus impurities and most free water in the phosphogypsum, kneading with a reducing agent, granulating, and directly feeding the material into a reductive decomposition integrated rotary kiln with fluidization preheating function; controlling a gas phase atmosphere to perform step-by-step heating, drying, dehydration and reductive decomposition under the combustion of the pulverized coal; sulfur dioxide gas generated after reductive decomposition is used for producing sulfuric acid after being subjected to dust removal and purification; and the reduced and decomposed material enters an oxidation calcining kiln for cement clinker sintering, and the gas-phase atmosphere is controlled under the combustion of pulverized coal for heating, mineralizing and sintering to obtain the cement clinker. Compared with the prior art, the production method for producing cement and co-producing sulfuric acid by using phosphogypsum has the advantages that the coal consumption for reduction and firing is reduced, the production efficiency and the product quality are improved, the device investment is saved, the economic benefit of producers is increased, and the environmental protection problem of phosphogypsum stacking treatment is eliminated.

Owner:CHENGDU QIANLIJIN TECHCAL INNOVATION CO LTD

Method for disposing of organic waste of high water content and disposal apparatus therefor

InactiveUS20100058963A1Easy to useReused efficiently and effectivelySludge treatment by de-watering/drying/thickeningSludge treatment by oxidationCycloneSludge

A method for disposing of an organic waste of high water content according to the present invention, includes: a step in which by means of a heat exchanger (22), a heat exchange is carried out between superheated steam and exhaust gas extracted by a cyclone (2b) of a suspension preheater (2), the high temperature superheated steam that was subjected to the heat exchange is introduced to a dryer (23), thereby drying any organic sludge into a dried organic waste, and by means of the heat exchanger (22), the superheated steam used for the drying is subjected to another heat exchange, thereby recycling the superheated steam in the drying of the organic sludge; and a step in which the resulting dried organic sludge is supplied to a precalcining furnace (3) as fuel and combusted.

Owner:SUMITOMO OSAKA CEMENT CO LTD

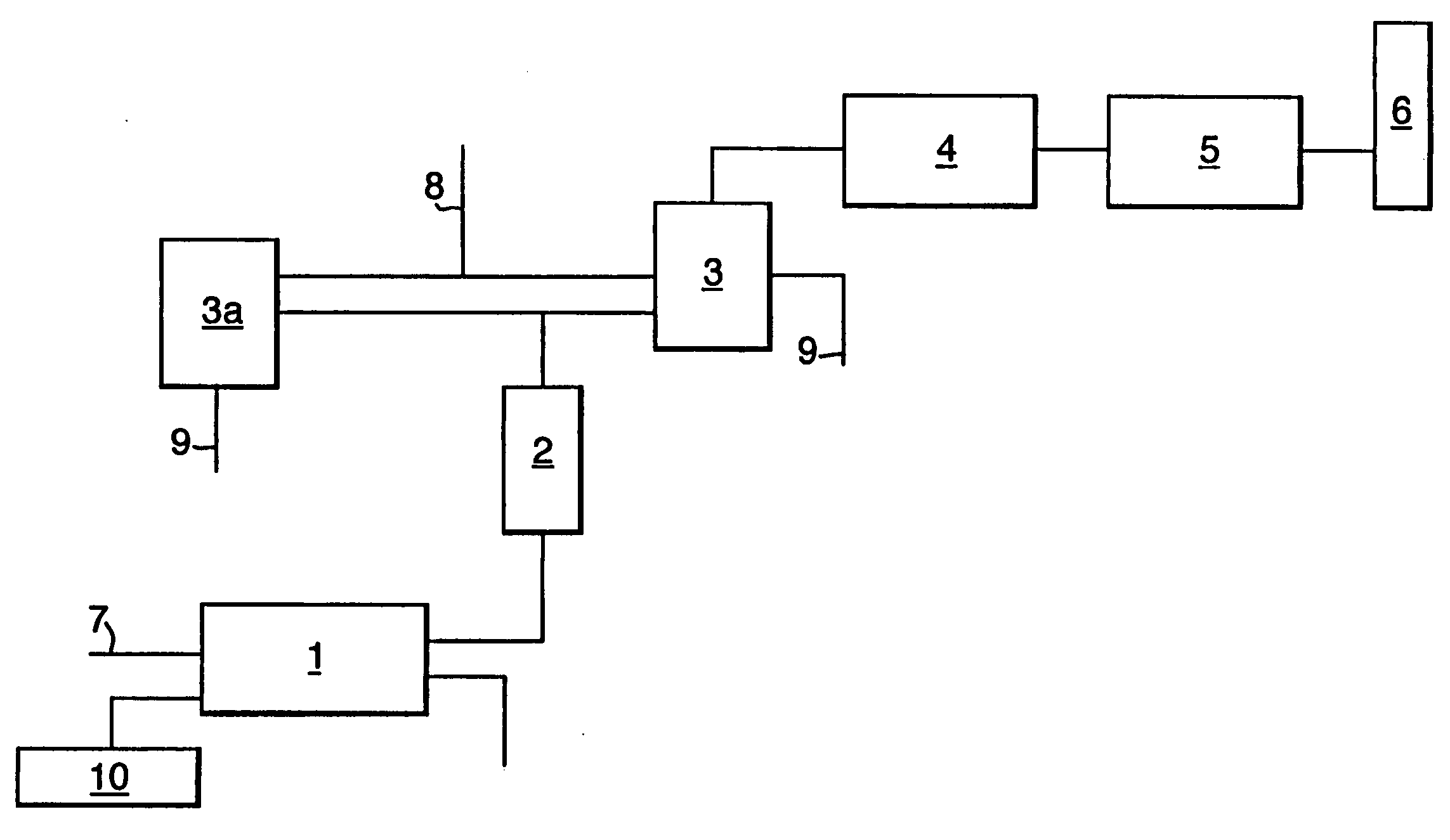

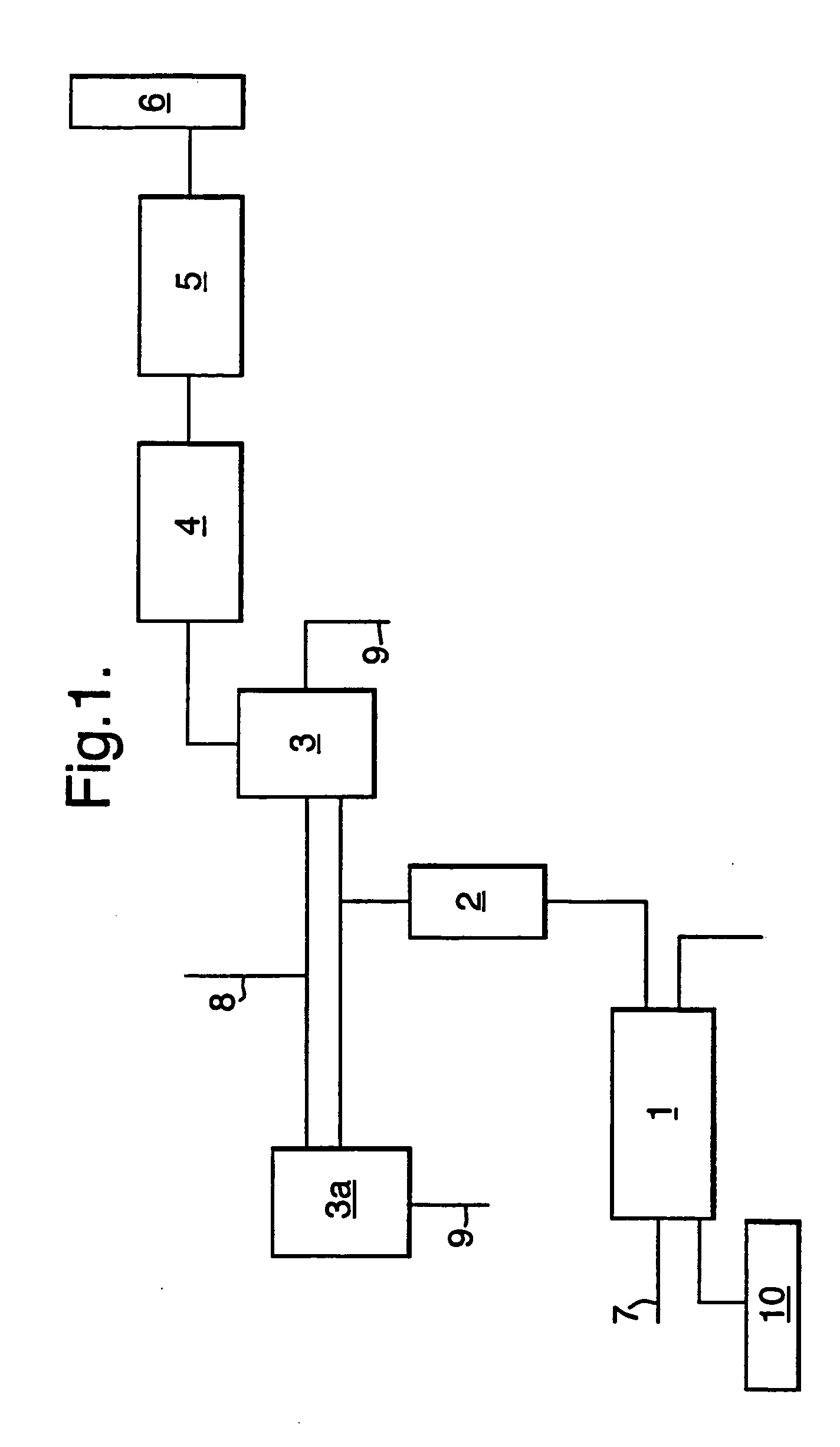

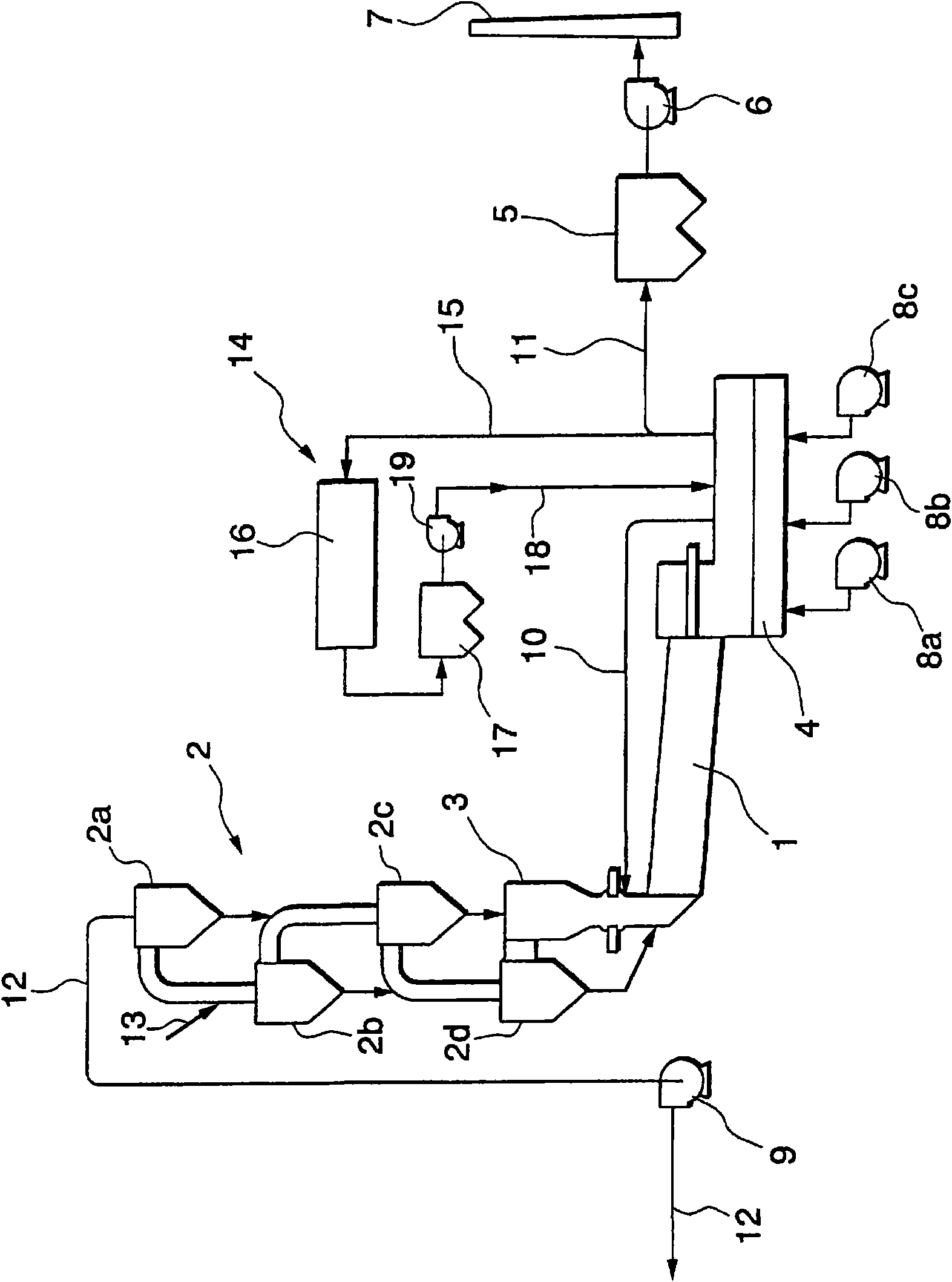

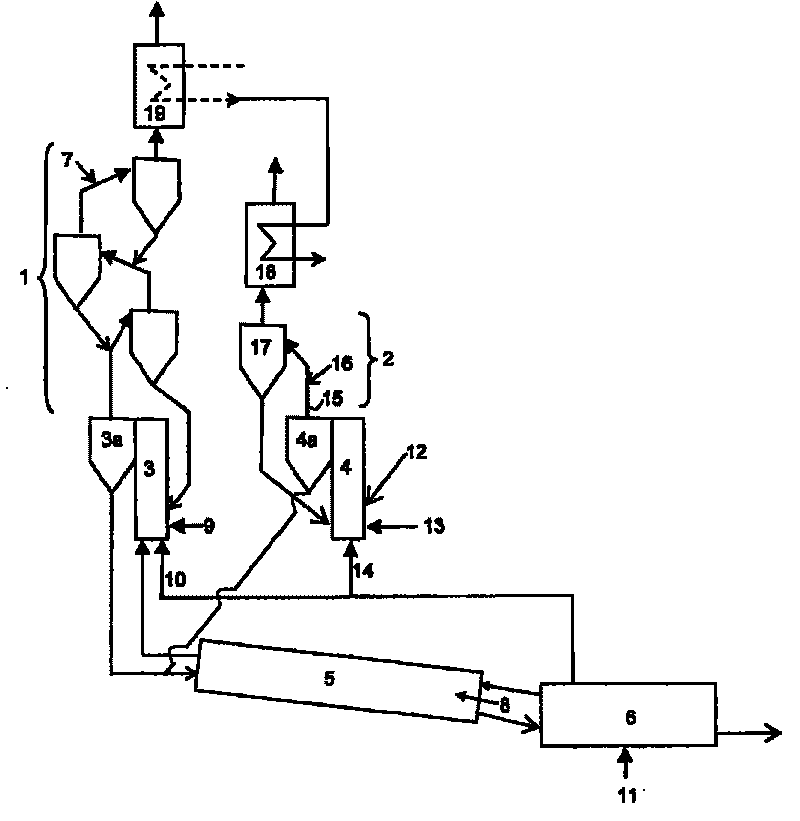

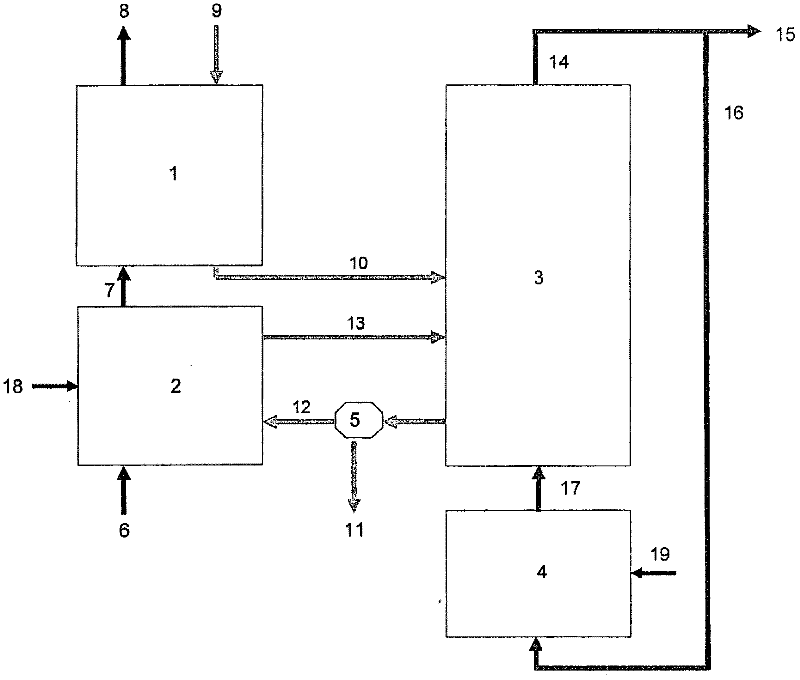

Method and plant for the simultaneous production of electricity and cement clinker

InactiveCN101765752AStructural solutionImprove the efficiency of conversion into electrical energyRotary drum furnacesCeramic production plantsPhysical chemistryProcess engineering

Described is a method as well as a plant for the simultaneous production of electricity and cement clinker by which method cement raw meal is calcined in a calciner (4) subject to simultaneous supply of fuel and combustion air and subsequently burned into cement clinker in a kiln (5), and where some of the heat contained in the exhaust gases from the calciner (4) is utilized to generate electricity by means of a boiler section (18). The method and plant are peculiar in that the combustion air supplied to the calciner (4) does not contain alkali or chloride, and in that the temperature of the exhaust gases used to generate electricity is at least 500 DEG C. Hereby is obtained that coating formations formed on the boiler tubes due to the condensation of alkali and chloride vapours can be avoided, while, at the same time, the efficiency with which thermal energy can be converted into electrical energy can be increased.

Owner:F L SMIDTH & CO AS

Gypsum product and method therefor

InactiveUS6932863B2Large energyLimited shelf lifeOther chemical processesSolid waste managementSlurryWater resistant

A method for making a gypsum product water resistant, the method comprising adding a suspension of a hydrophobic substance to a gypsum slurry.

Owner:TIP - THE IND PIVOT

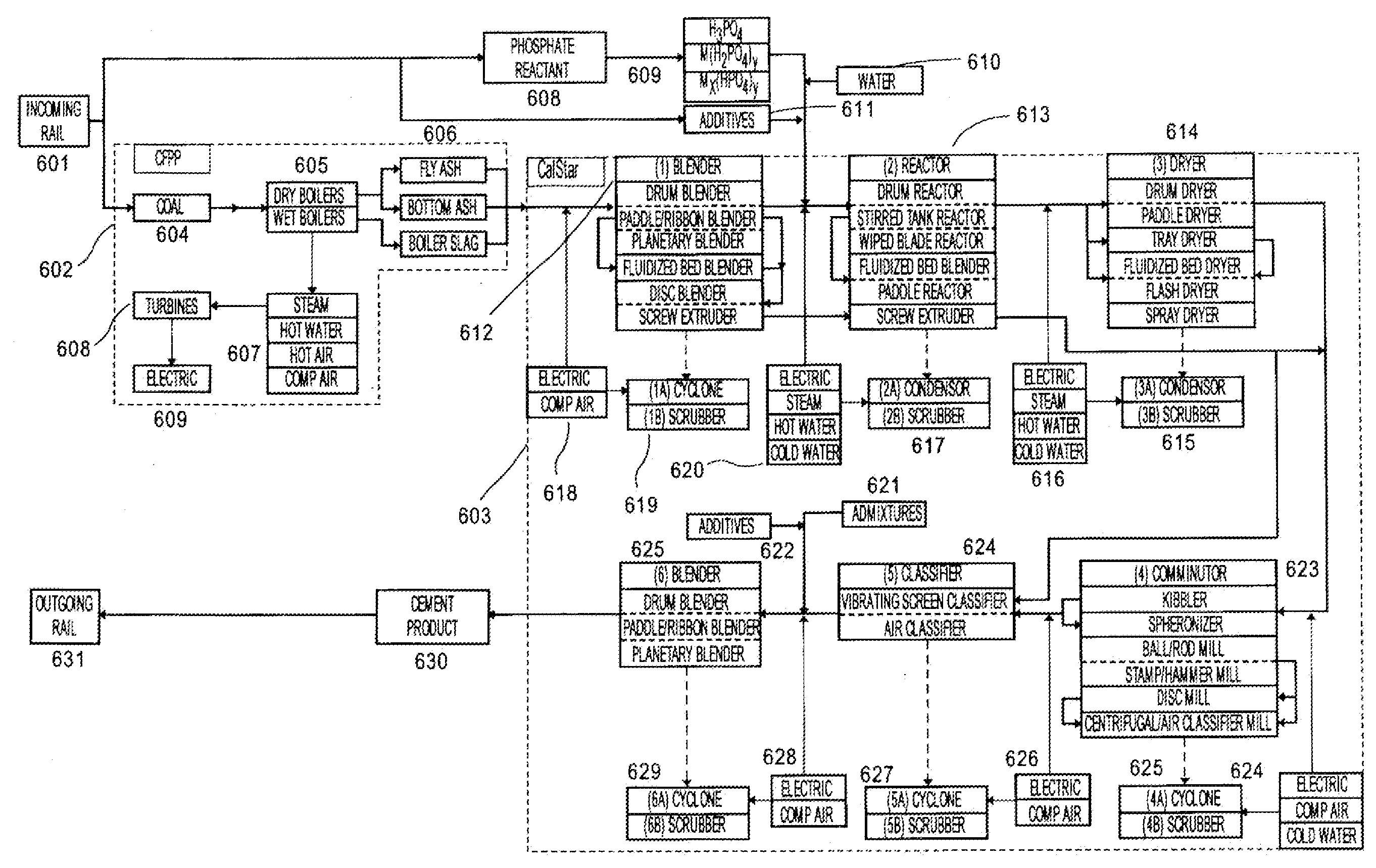

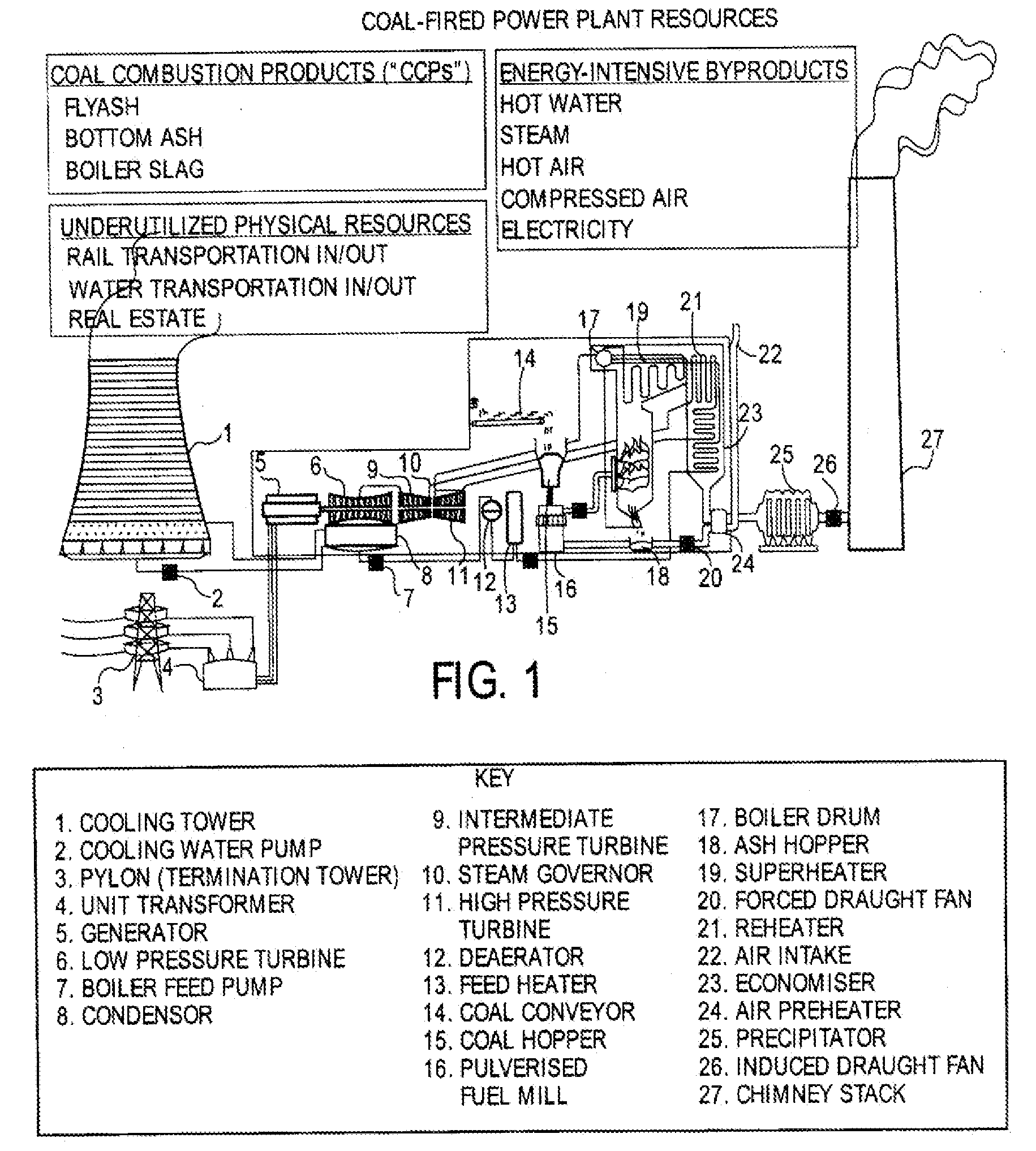

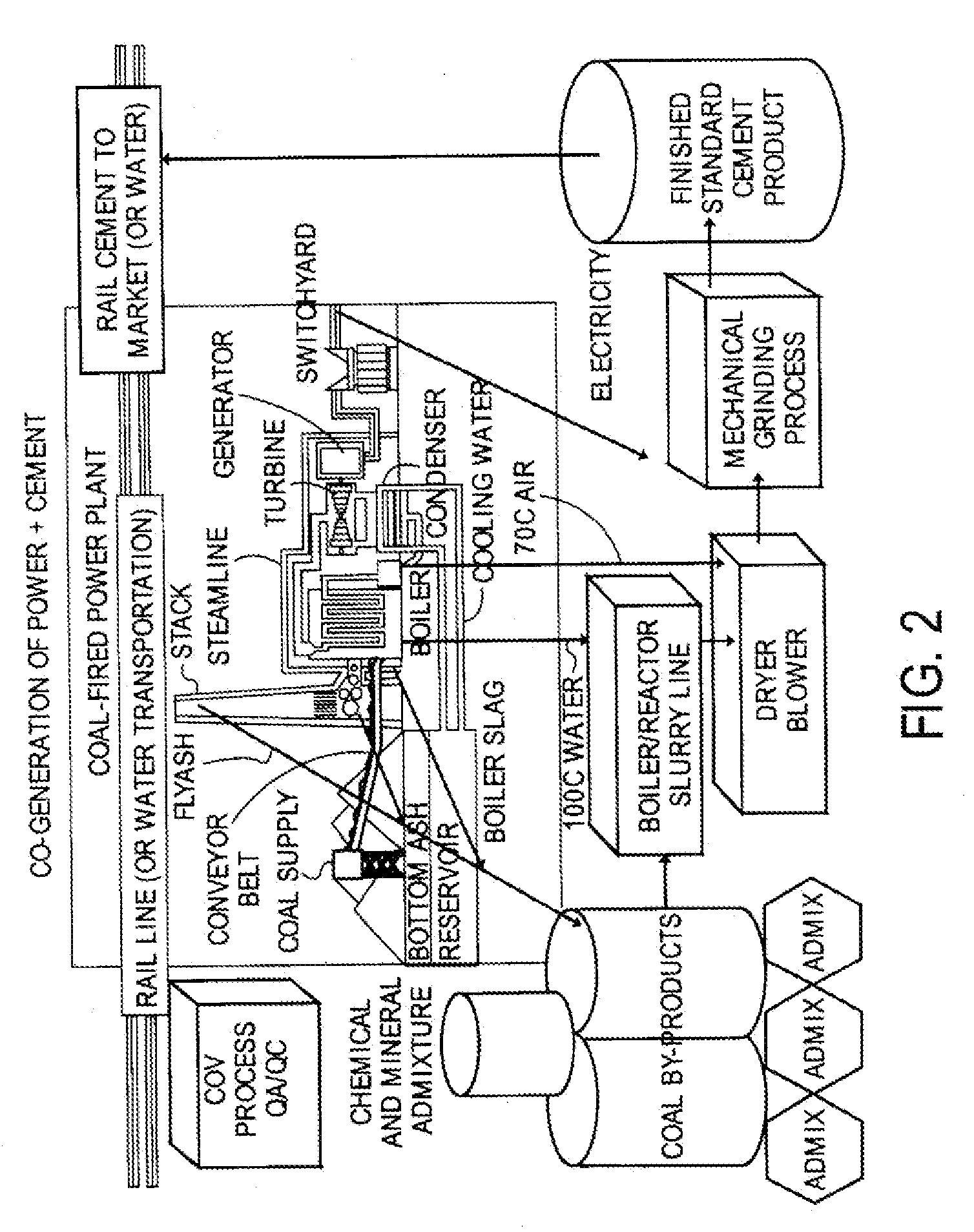

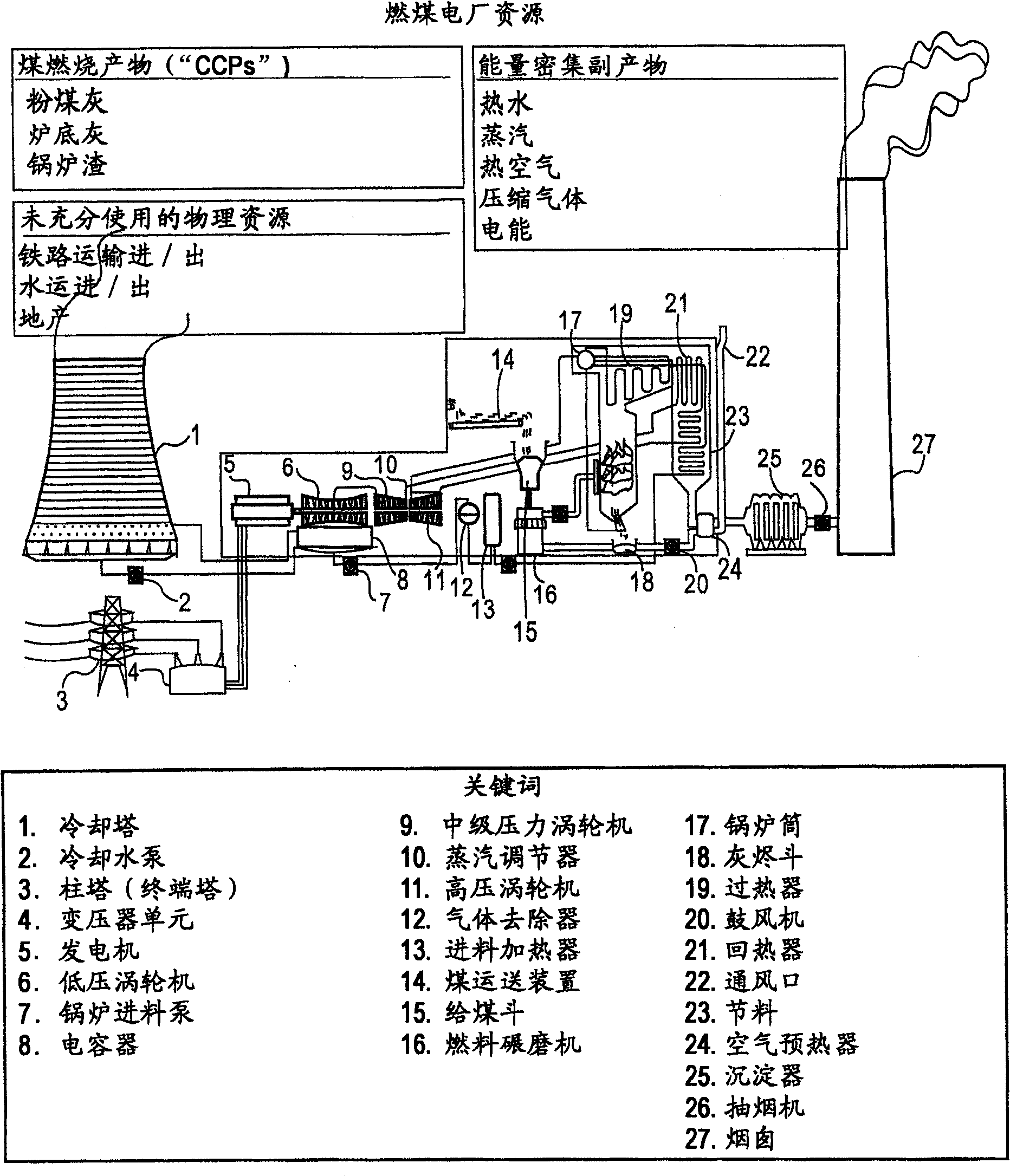

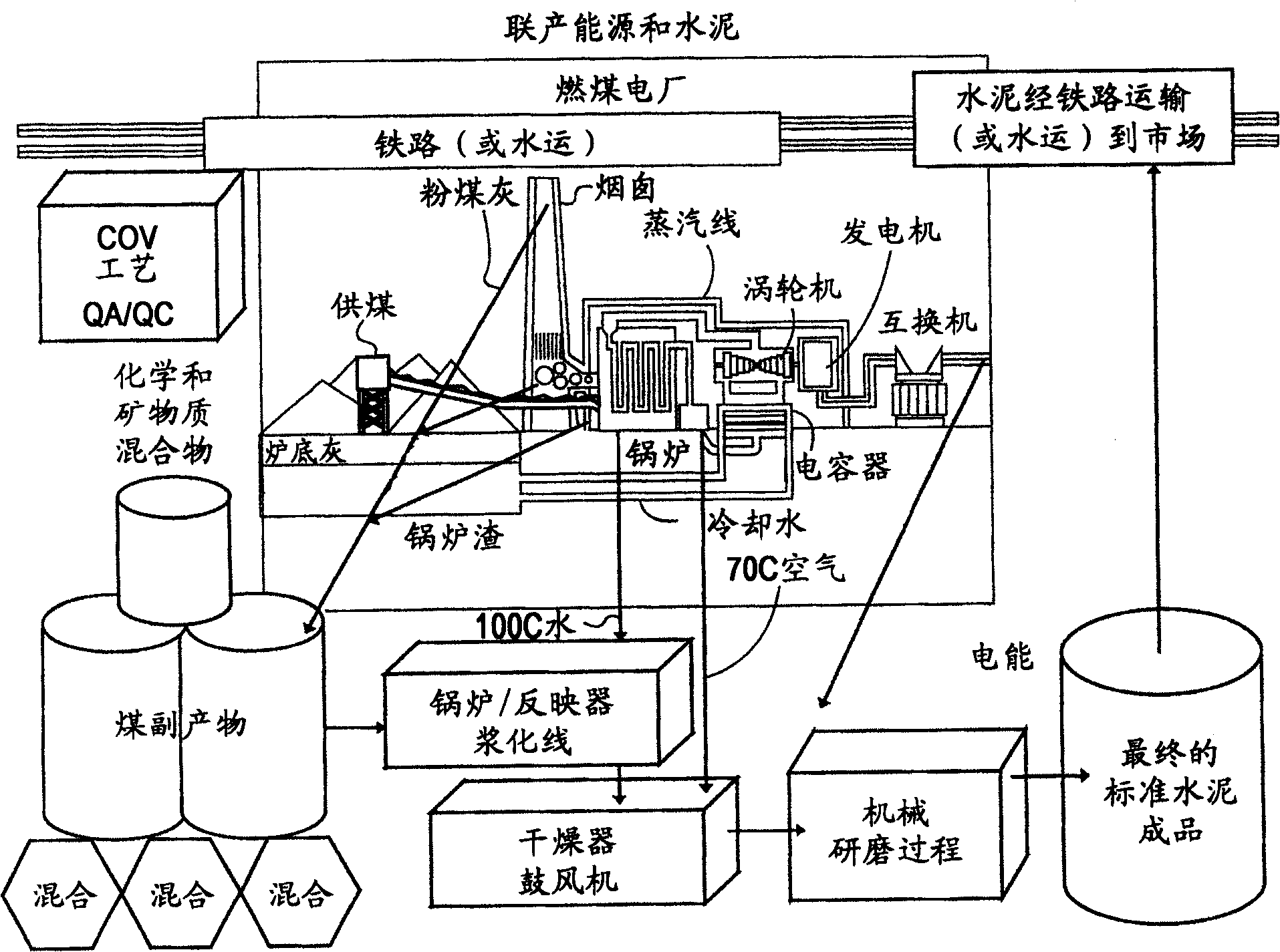

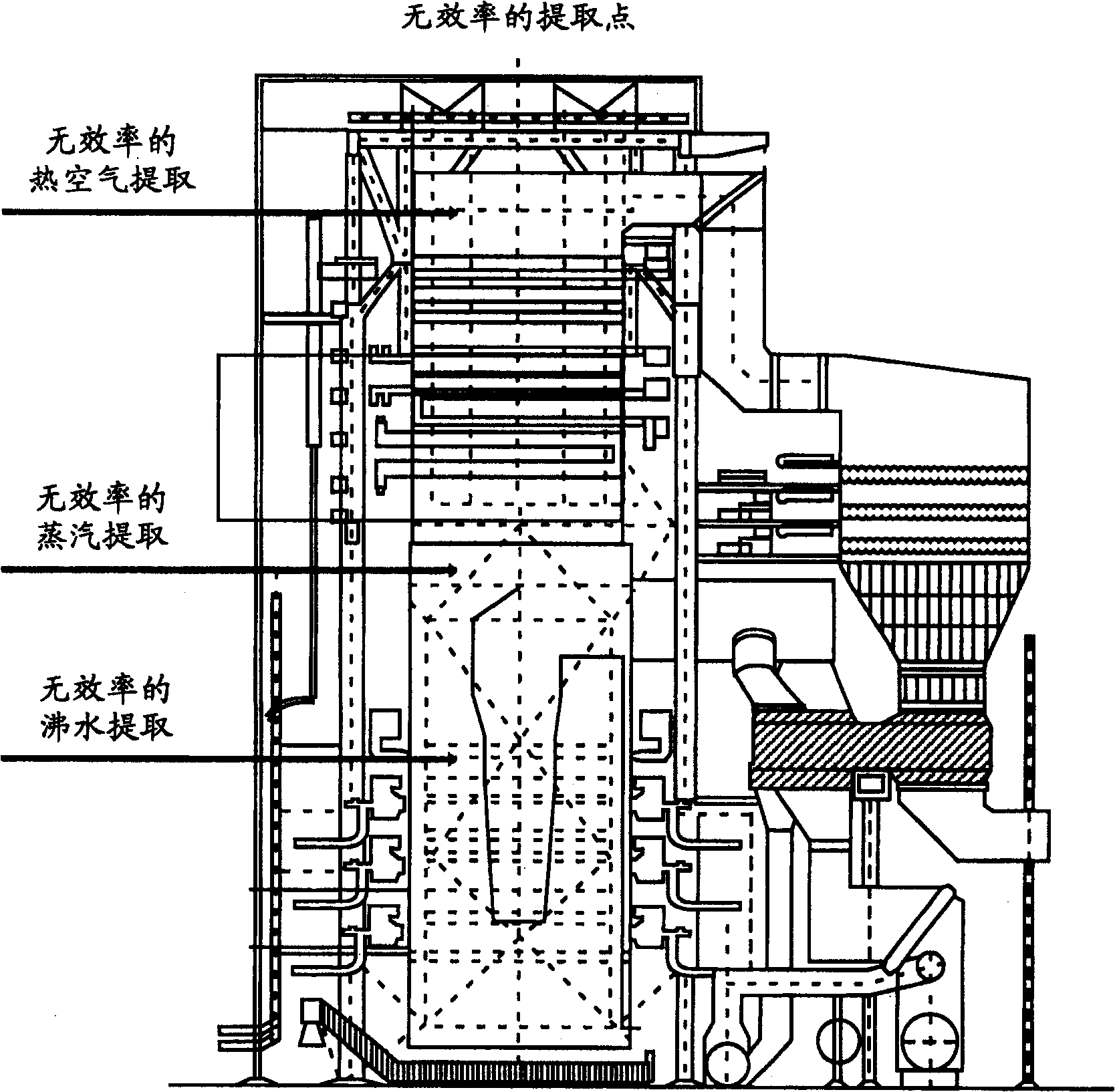

Conversion of coal-fired power plants to cogenerate cement

InactiveUS20080264066A1Promoting efficient use of energy and resourceMitigate global greenhouse gas (GHG) emissionCeramic production plantsEfficient propulsion technologiesClimate changeCogeneration

The invention provides systems, processes and methods for converting heterogeneous coal-fired power plants to cogenerate a sustainable, consistent, and economic cement. Such cogeneration enables a simultaneous production of both electric power and cement and thus provides significant economic and environmental efficiencies and benefits and eliminates a major source of greenhouse gas emissions and thereby mitigates a major contributor to climate change.

Owner:CALSTAR CEMENT

System and method for the production of alpha type gypsum using heat recovery

Owner:CERTAINTEED GYPSUM INC

System and Method for the Production of Gypsum Using Heat Recovery

The present invention relates to a system and associated method for the production of gypsum in manufacturing plant. More specifically, the invention relates to the production of alpha-type gypsum in a gypsum board manufacturing plant. The system yields increased efficiencies by capturing heat given off during processing steps and using that heat to reduce the energy needed for calcination. The invention finds particular application in the production alpha-type gypsum. The present invention is described in greater detail hereinafter in conjunction with the following specific embodiments.

Owner:CERTAINTEED GYPSUM INC

Method and apparatus for combining a foundry with a cementatious block plant

InactiveUS20030047840A1Reduce shipping costsCost for sandSolid waste managementCeramic production plantsFoundryMaterials science

The present invention pertains to a method and apparatus for combining a foundry with a cementations product plant. The spent foundry sand and core butts can be used by the cementatious product plant as aggregate material in manufacturing cementatious products, such a blocks and pavers. This has the advantages of reducing the cost of the aggregate and reducing or eliminating disposal costs for the spend foundry sand.

Owner:KELLY MICHAEL B

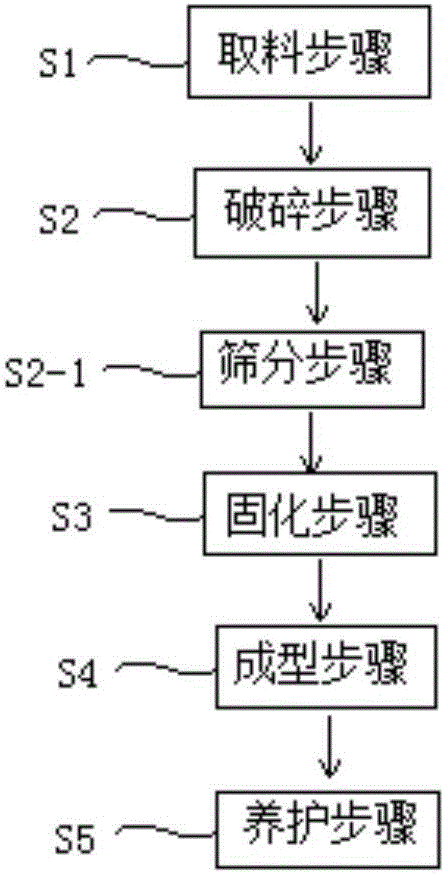

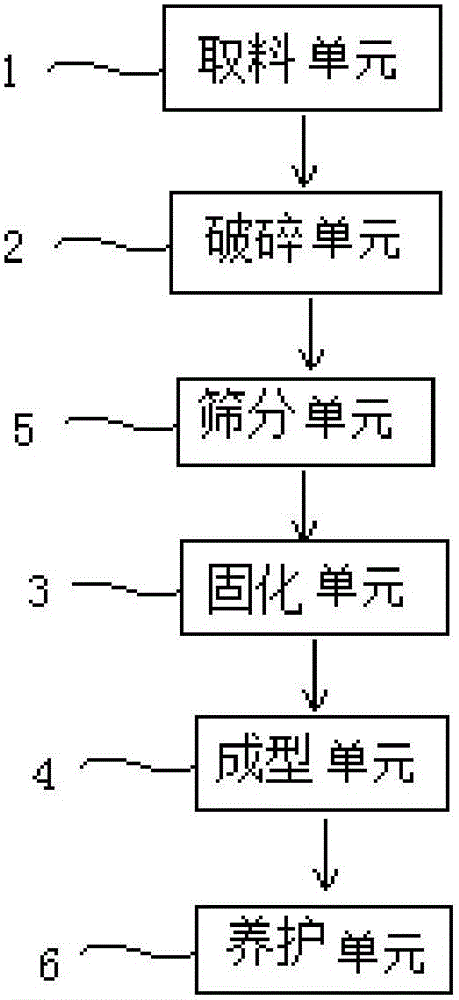

Drilling rock harmless treatment and resource utilization technology and device

PendingCN106431040AImprove curing abilityImprove completenessSolid waste managementCeramic production plantsSolid componentResource utilization

The invention discloses a drilling rock harmless treatment and resource utilization technology and device. The drilling rock harmless treatment and resource utilization technology includes the steps: a taking step: extracting preset-volume to-be-treated rock debris in a rock debris storage pool, and taking the volume of the preset-volume to-be-treated rock debris extracted at each time as a volume unit; a crushing step: crushing the to-be-treated rock debris taken in the taking step into powder particles; a curing step: respectively adding the preset volume parts of a curing agent, cement and stones into the powder to-be-treated rock debris, and blending evenly into a mixture; and a forming step: pressing the mixture formed in the curing step into preset-volume building blocks. In the way, a solid component after solid-liquid separation forms the mixture through the technology and through the action of the preset-proportion curing agent and other raw materials, the mixture is pressed into the building blocks, and the transformation of solid slurry into a building material is achieved; the technology has strong curing treatment ability, and the resource utilization degree and the environmental protection performance are improved.

Owner:北京华飞兴达环保技术有限公司

Conversion of coal-fired power plants to co-generate cement

InactiveCN101293747AReduce shipping costsReduce or eliminate the needCeramic production plantsEfficient propulsion technologiesCogenerationClimate change

The invention provides systems, processes and methods for converting heterogeneous coal-fired power plants to cogenerate a sustainable, consistent, and economic cement. Such cogeneration enables a simultaneous production of both electric power and cement and thus provides significant economic and environmental efficiencies and benefits and eliminates a major source of greenhouse gas emissions and thereby mitigates a major contributor to climate change.

Owner:CALSTAR CEMENT

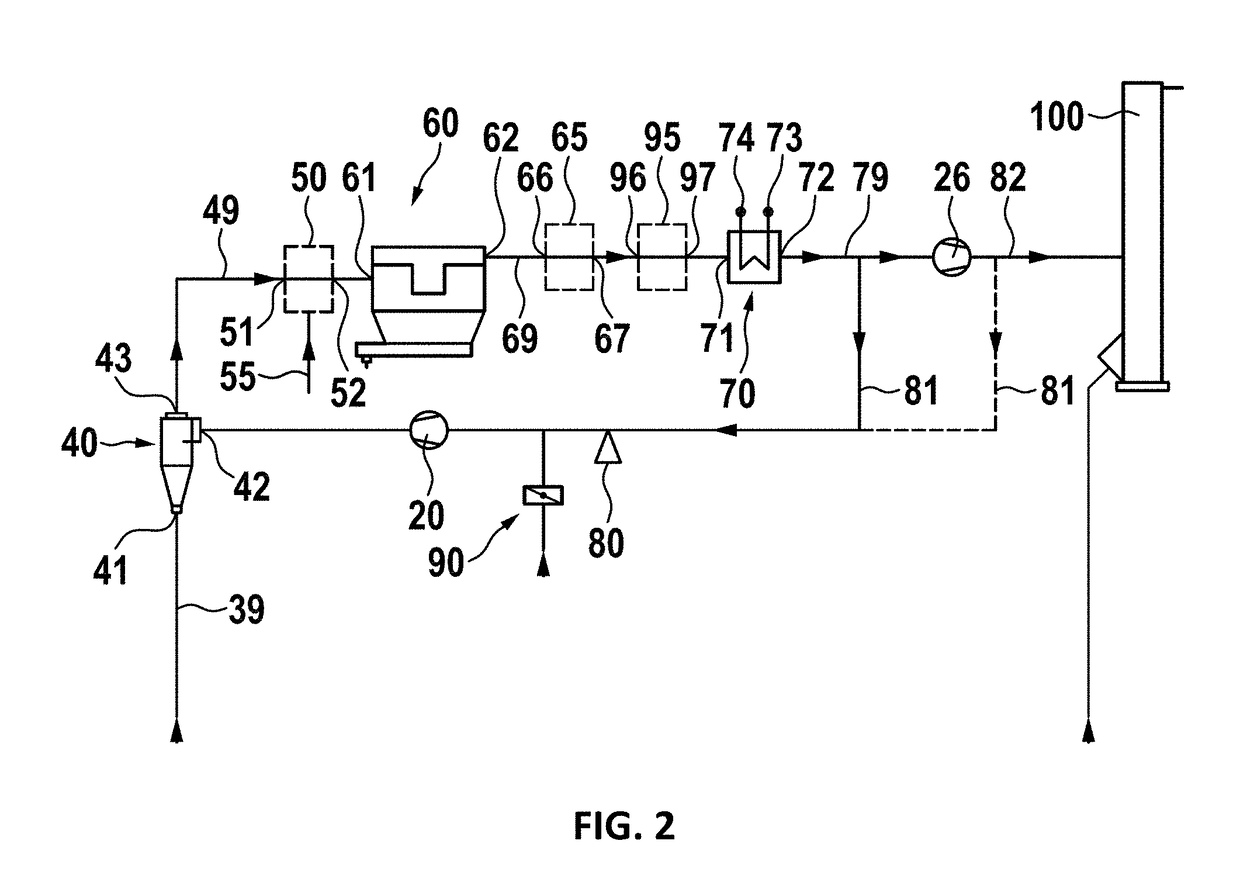

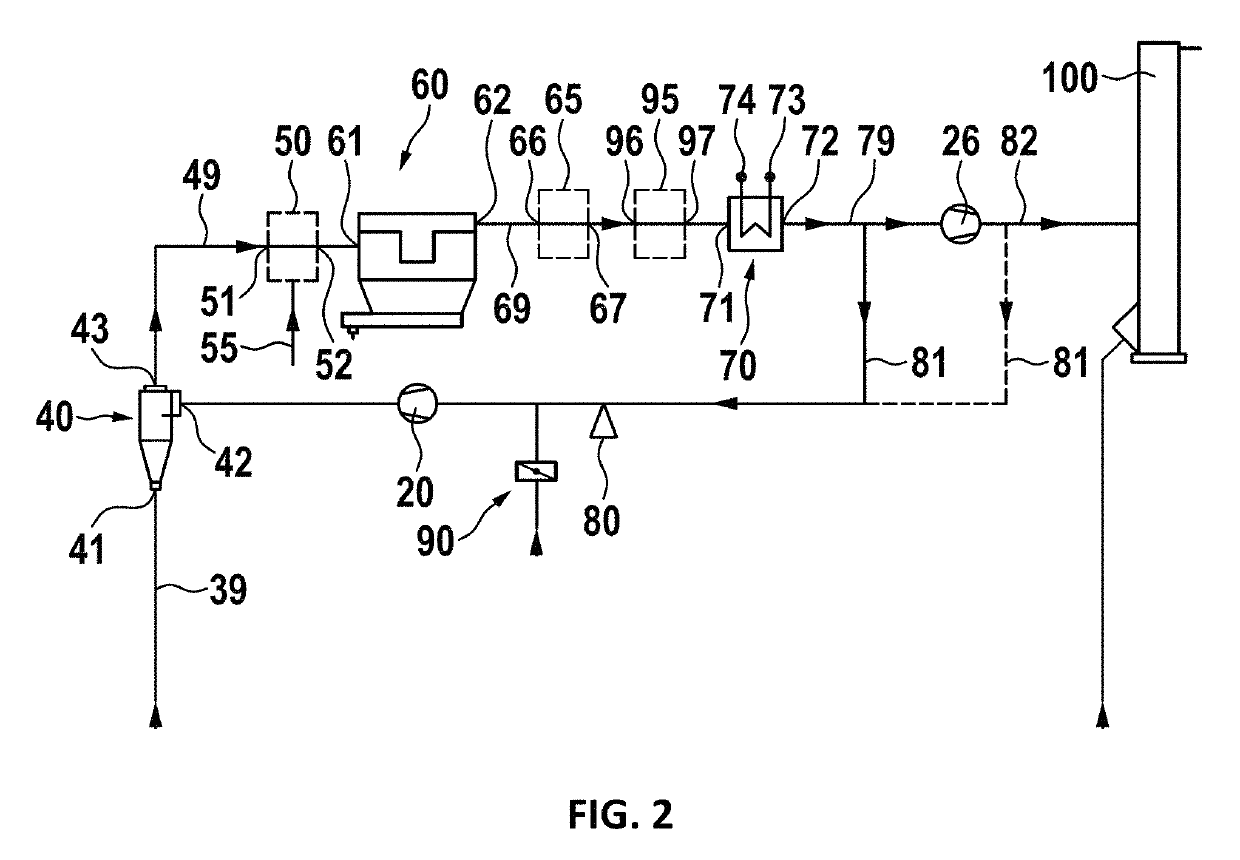

Method and Apparatus for Producing Cement Clinker

In methods of and / or plants for manufacturing cement clinker, the amount of chloride bypass exhaust gas 79 can be substantially decreased, when using previously cooled chloride bypass exhaust gas 81 and / or cooled kiln exhaust gas as coolant for the chloride bypass exhaust gas 39 prior to deducting the chloride bypass exhaust gas 39.

Owner:SUDBAYERISCHES PORTLAND ZEMENTWERK GEBR WIESBOCK & CO

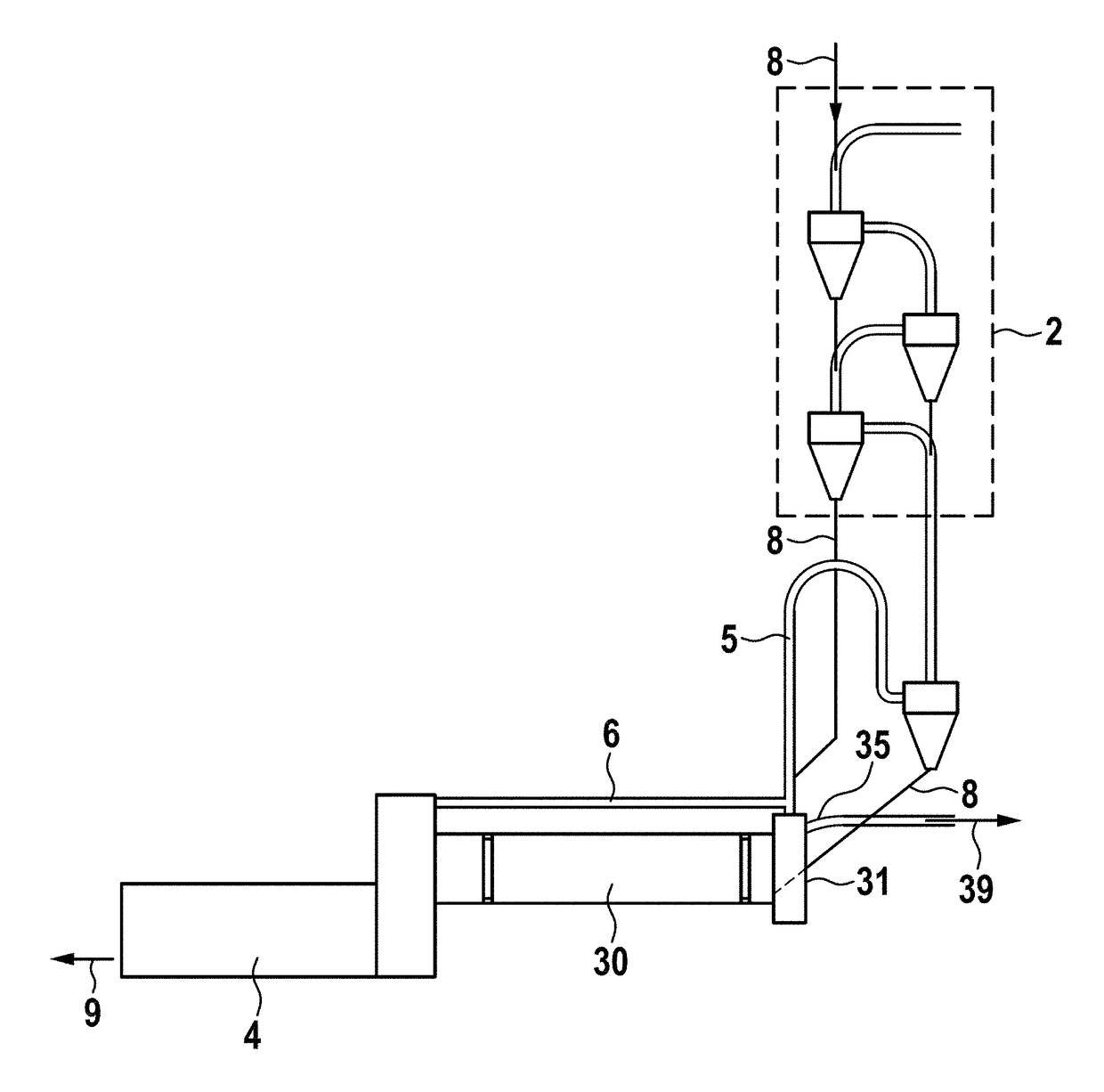

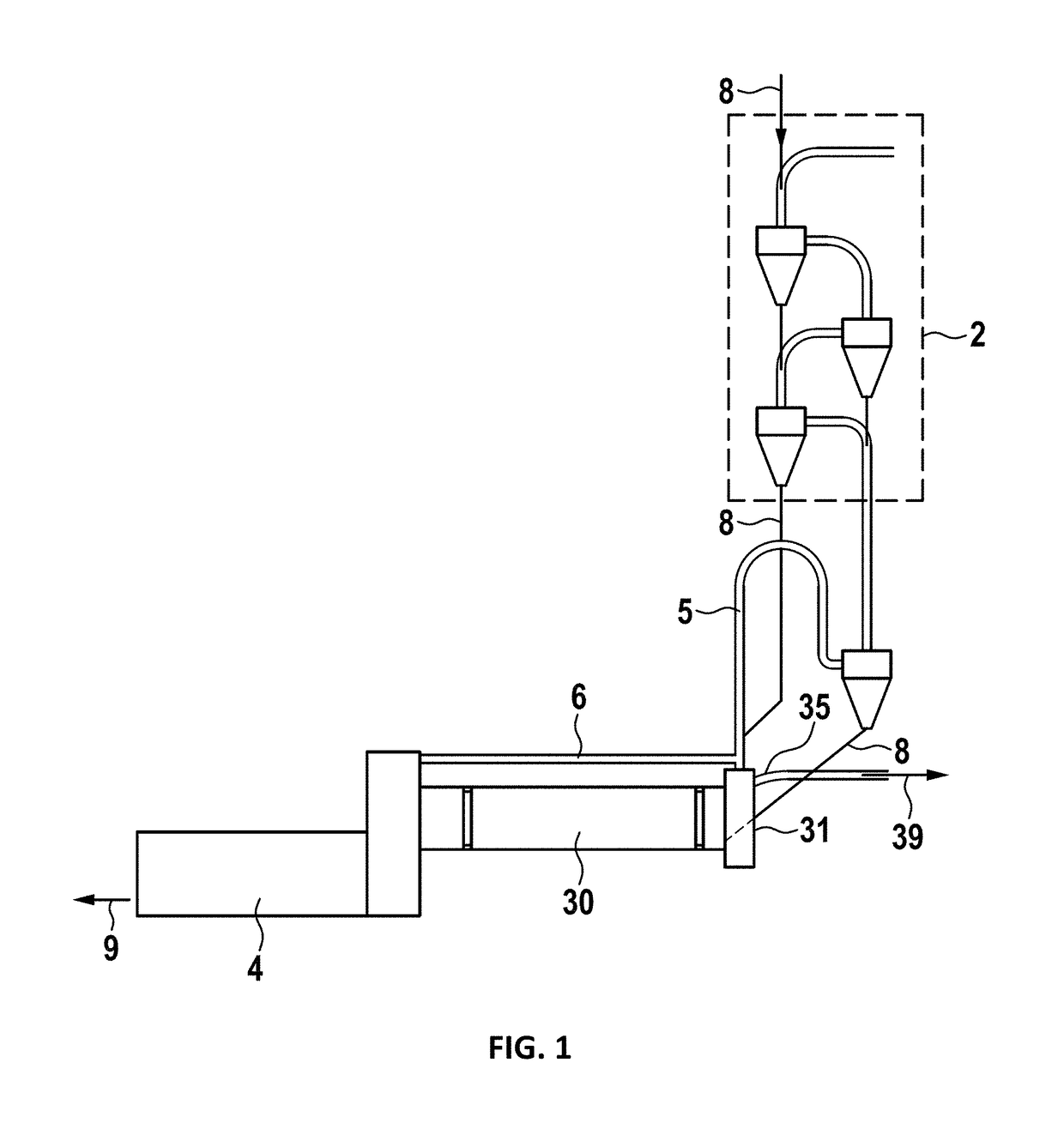

Process and device for cement clinker production

InactiveCN105283428AIncrease production capacityIncrease costRotary drum furnacesCeramic production plantsPhysicsExhaust gas

In a cement clinker production process in which raw mix is preheated with use of the hot exhaust gases from a clinker furnace in a preheater (3) and the preheated raw mix, optionally calcined in a calciner (4), is fired in the clinker furnace (2) to give clinker, wherein the preheater (3) comprises at least one train from a plurality of cyclone flotation gas heat exchangers (8, 9, 10) through which the furnace exhaust gas passes in succession and in which the raw mix is preheated in stages, a substream of the furnace exhaust gas is diverted in such a way that only a residual stream of the furnace exhaust gas is utilized for preheating the raw mix.

Owner:HOLCIM

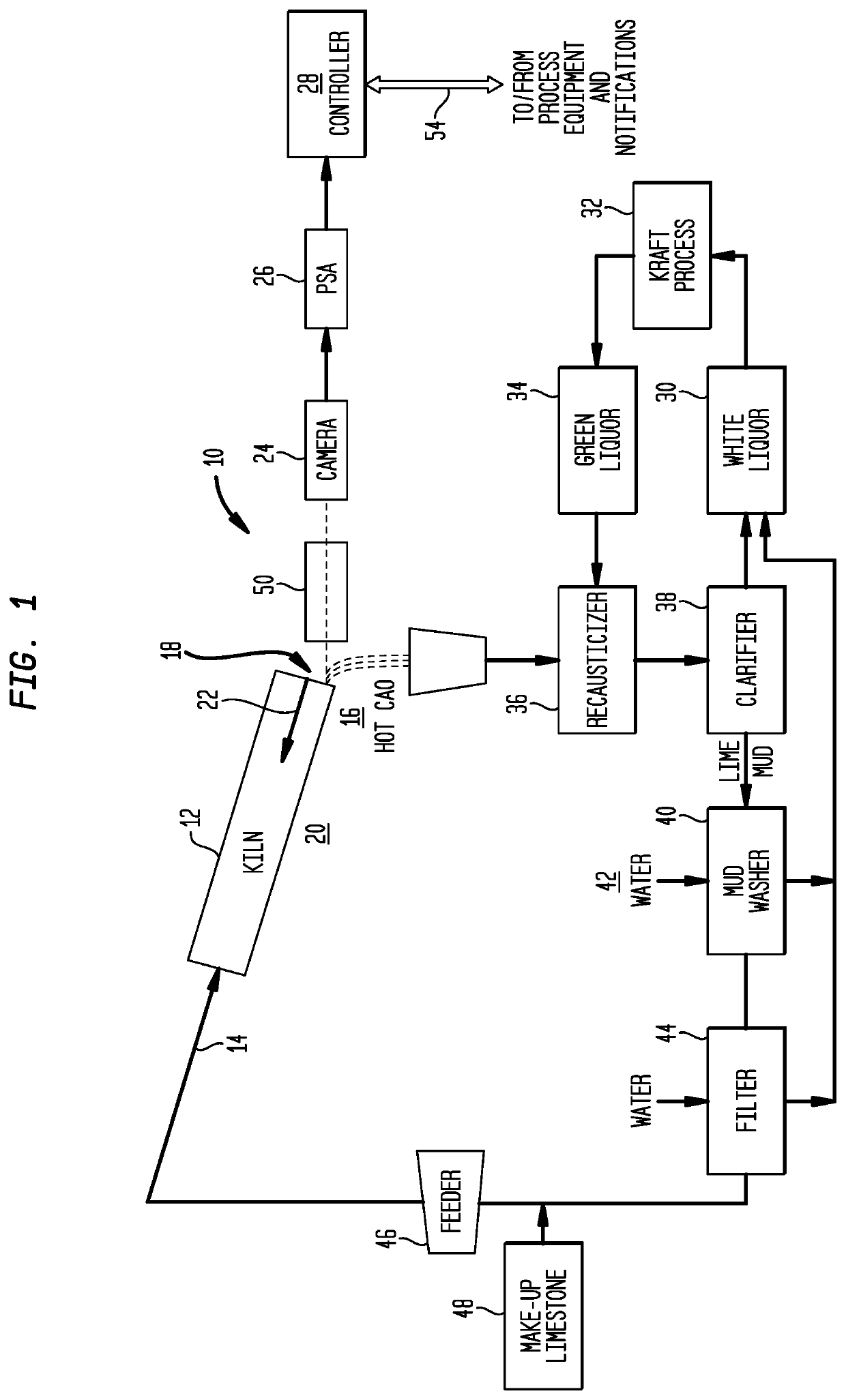

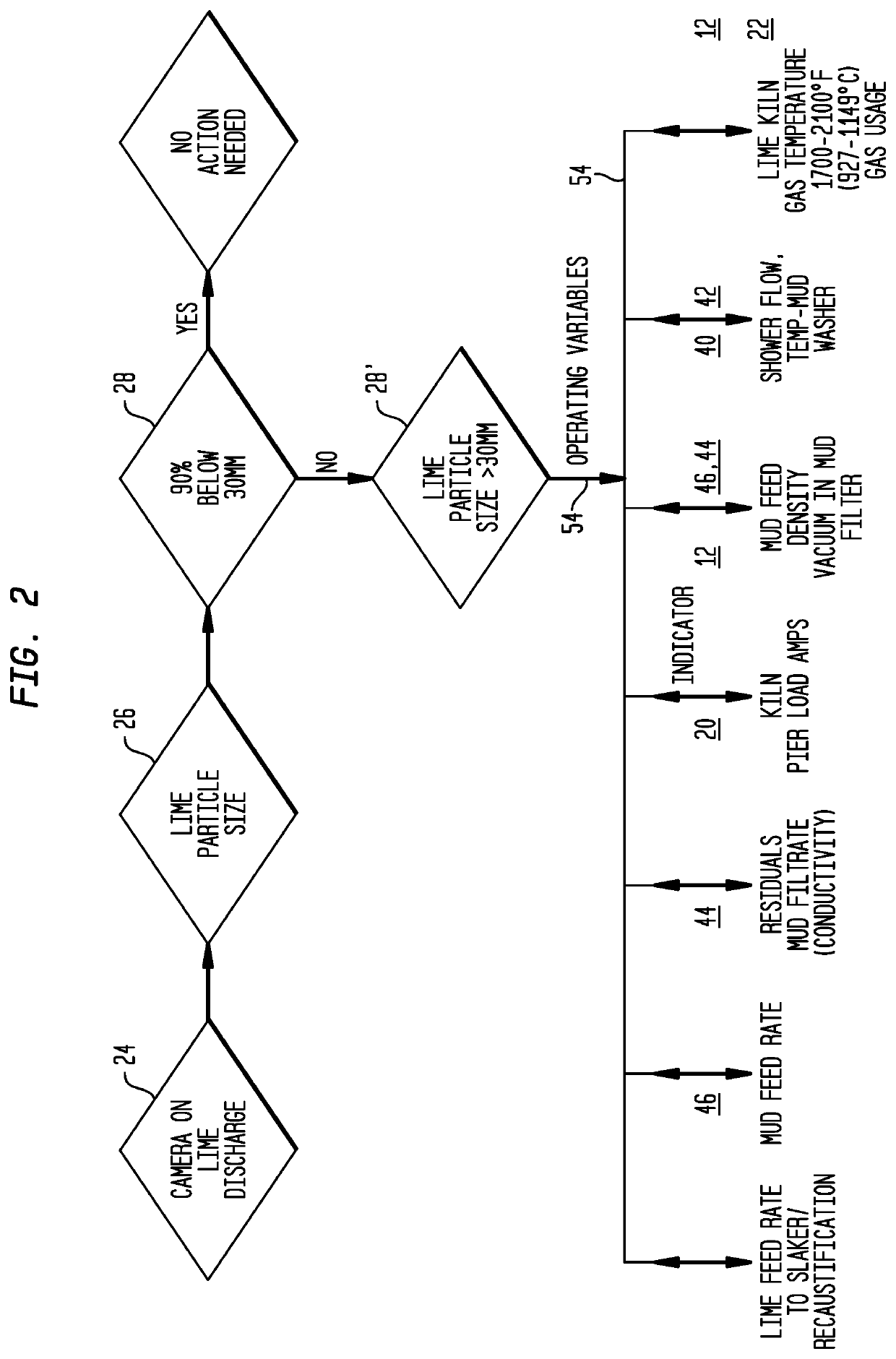

CLOSED LOOP CONTROL WITH CAMERA DETECTION OF PEBBLE SIZE OF LIME PARTICLES TO AMELIORATE LIME KILN RINGING and IMPROVE UPTIME and OPERATING EFFICIENCY

An improved lime mud recycling system including a camera proximate the kiln outlet imaging the granular lime and providing outlet images of the granular lime exiting the kiln, a processor analyzing the outlet images of the granular lime and providing pebble size distributions for the granular lime exiting the kiln, as well as a controller communicating with the processor comparing the pebble size distribution of the granular lime exiting the kiln with predetermined prescribed operating parameters for pebble size distributions for the granular lime exiting the kiln and issuing (I) a notification and / or (II) a control signal prompting remedial action when the pebble size distributions for the granular lime exiting the kiln are outside of the predetermined prescribed operating parameters.

Owner:GPCP IP HLDG LLC

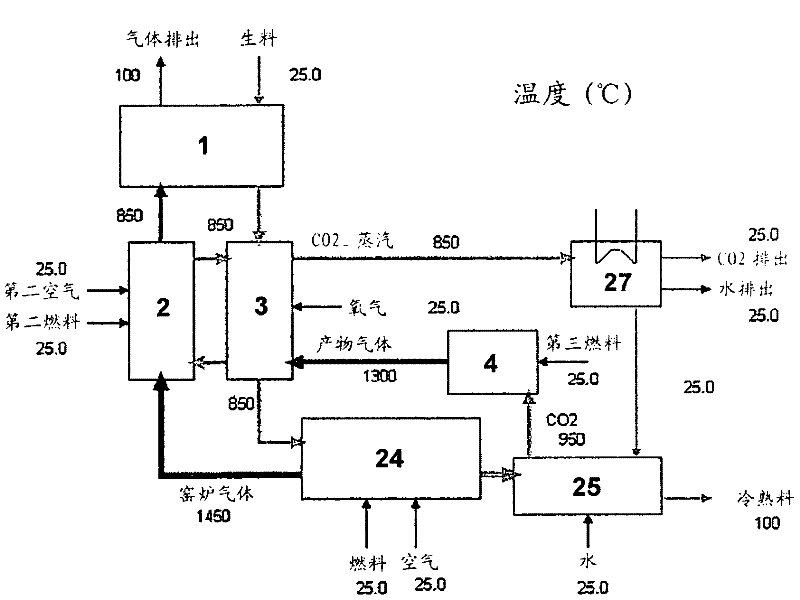

Gasification with separate calcination

InactiveCN102057240ASavings by purchasing emissions permitsRotary drum furnacesCeramic production plantsCalcinationMaterials science

A description is provided of a method and an apparatus for manufacturing of cement whereby cement raw meal is preheated in a preheater, calcined in a calciner by contact with hot gases which are introduced into the calciner via a gas inlet and being diverted from the calciner via a gas outlet, and where calcined cement raw meal is diverted from the calciner, burned into cement clinker in a kiln and subsequently cooled in a clinker cooler. The method and the apparatus are peculiar in that at least a portion of the calcined cement raw meal diverted from the calciner is heated further in a separate system to a temperature which exceeds the calcination temperature, and being subsequently recirculated to the calciner, and in that at least a portion of the gases which are diverted via the gas outlet of the calciner is removed from the plant with a view to storage in the underground or other additional treatment.

Owner:F L SMIDTH & CO AS

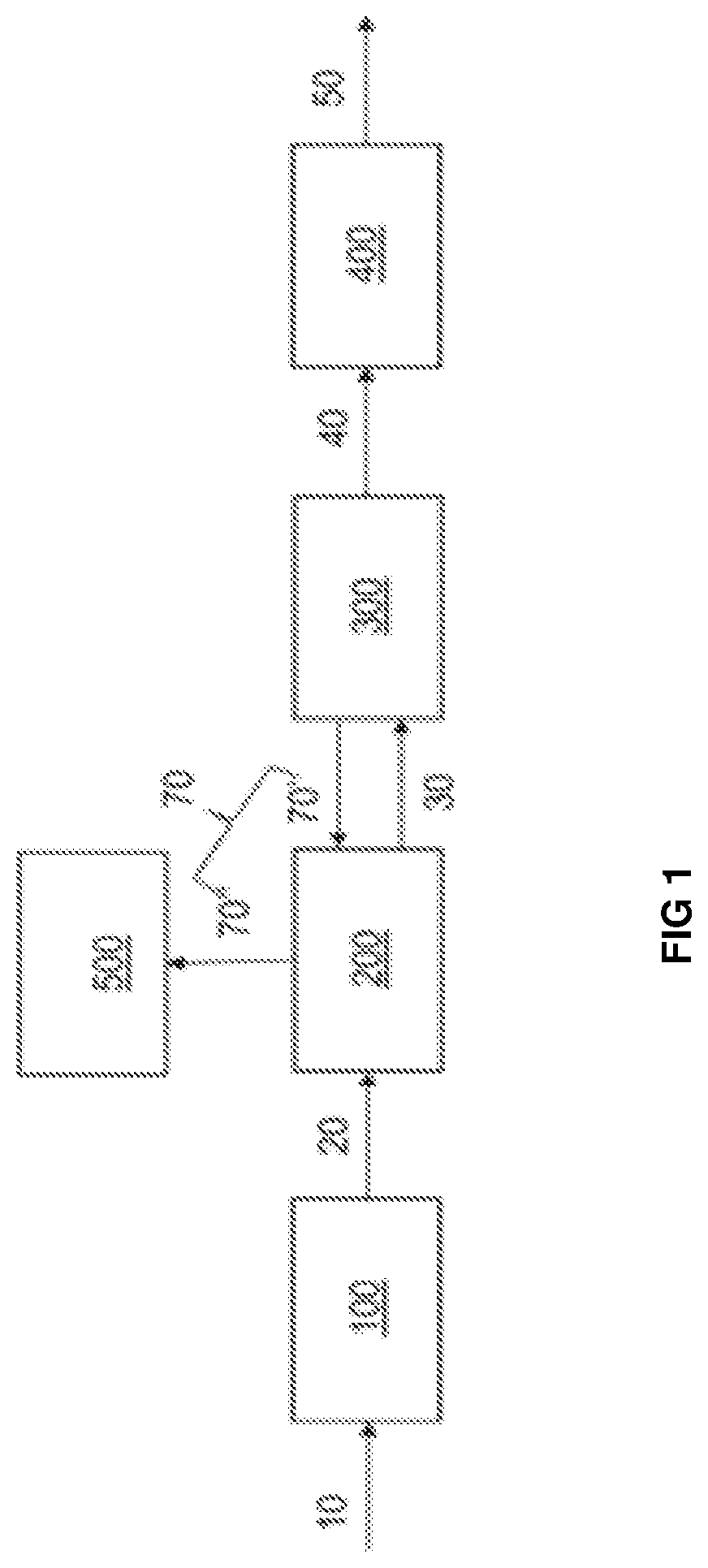

Method for the production of a syngas from a stream of light hydrocarbons and from combustion fumes from a cement clinker production unit

A process for producing a syngas containing CO and H2 from a stream of light hydrocarbons and from combustion flue gases from a cement clinker production unit comprising at least one calcining kiln (300), and a means for discharging the combustion flue gases (500) from the calcining kiln to the outside of said unit, said process comprising the following steps:at least some of the combustion flue gases (70) obtained in said clinker production unit are collected upstream of said means for discharging the combustion flue gases (500);a reaction stream (113) comprising a stream of light hydrocarbons (110) containing methane and the combustion flue gases (70) is prepared;said reaction stream (113) is sent to a tri-reforming reactor (1009) to obtain a syngas (114).

Owner:INST FR DU PETROLE +1

Method and apparatus for producing cement clinker

ActiveUS10457599B2Reduces exergyLow oxygenGas treatmentDispersed particle separationChlorideEngineering

In methods of and / or plants for manufacturing cement clinker, the amount of chloride bypass exhaust gas 79 can be substantially decreased, when using previously cooled chloride bypass exhaust gas 81 and / or cooled kiln exhaust gas as coolant for the chloride bypass exhaust gas 39 prior to deducting the chloride bypass exhaust gas 39.

Owner:SUDBAYERISCHES PORTLAND ZEMENTWERK GEBR WIESBOCK & CO

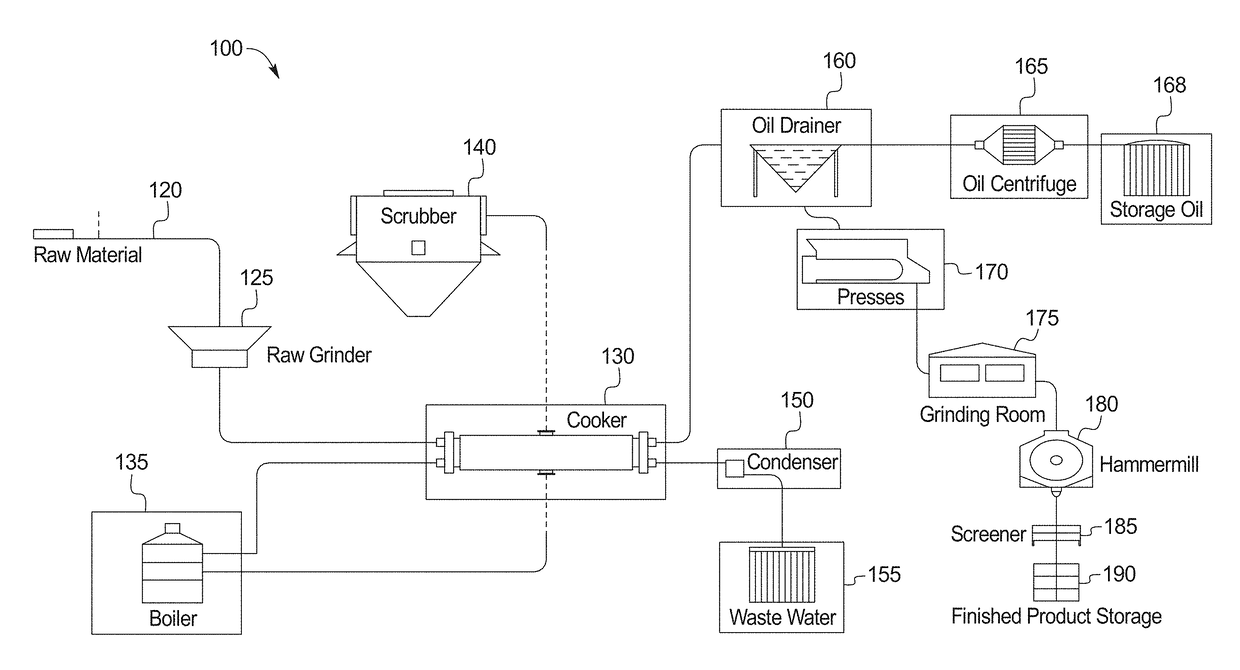

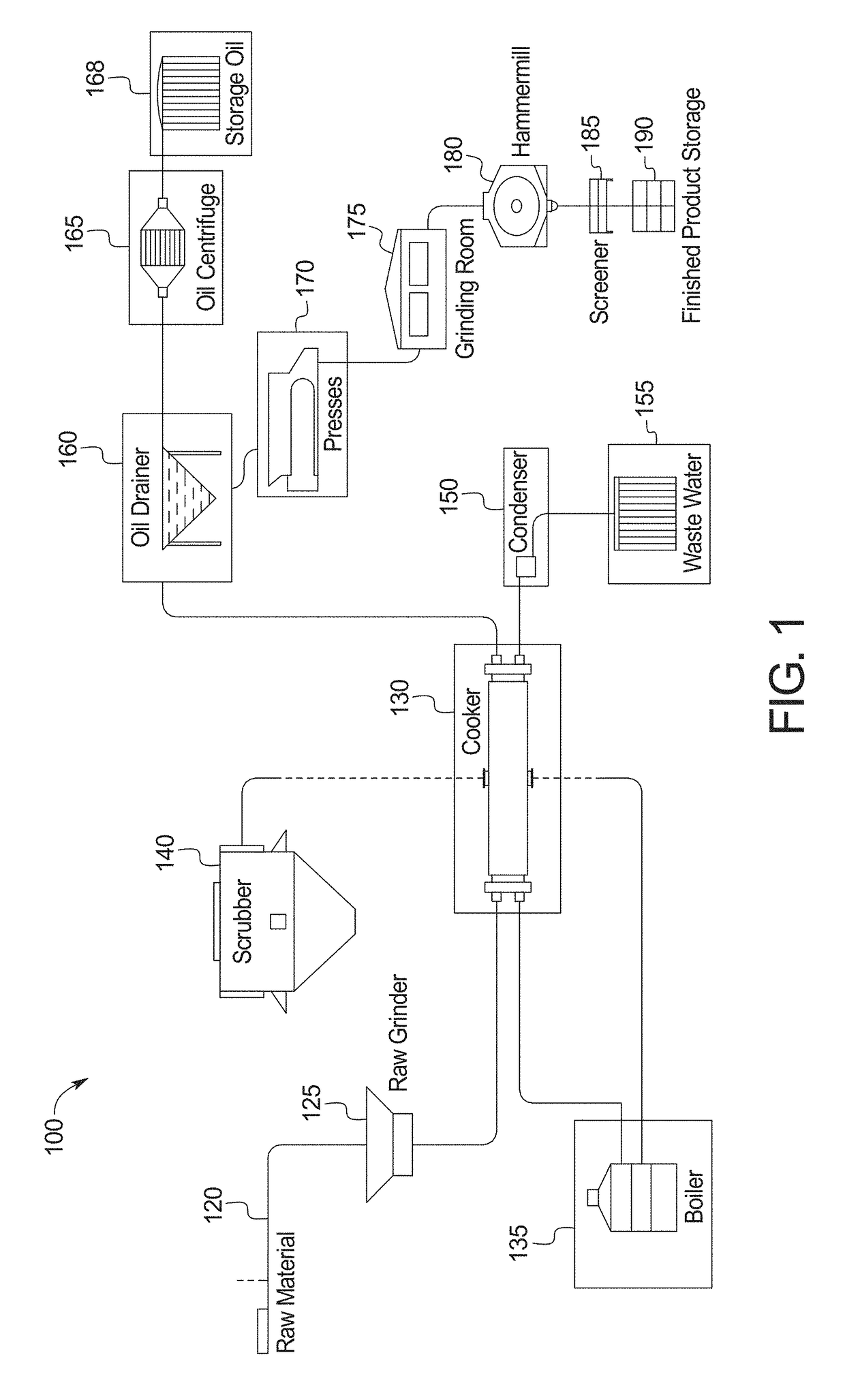

Concrete compositions and methods for making thereof

ActiveUS20180141861A1Increase demandReduce the populationSolid waste managementCeramic production plantsCarpWaste product

The present concrete composition uses Asian carp fishmeal (the burned remains of the carp) as an admixture. The core principle behind the development of present concrete composition stems from attempting to find a beneficial use for a waste product in a civil engineering application. The incorporation of the fishmeal improves the cementitious properties when added to a concrete mix. Thus, the fishmeal concrete composition incentivizes the harvesting of Asian carp and the production of fishmeal.

Owner:ABOVE GRADE ENVIRONMENTAL

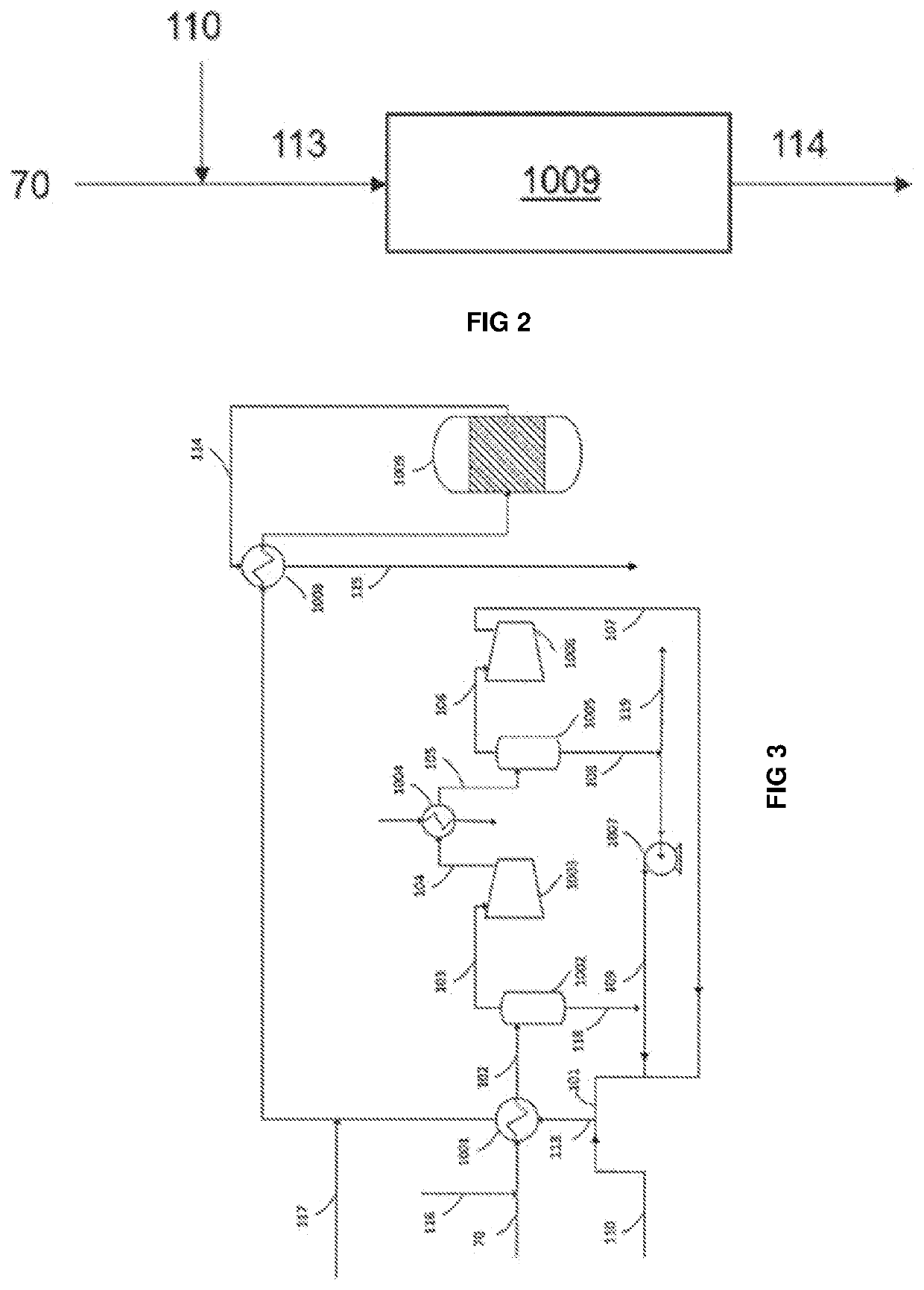

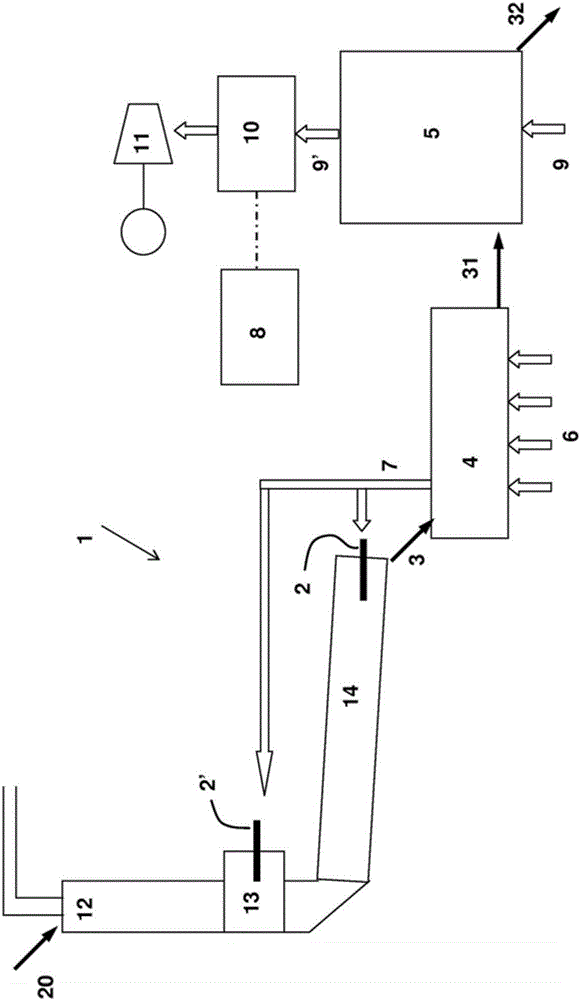

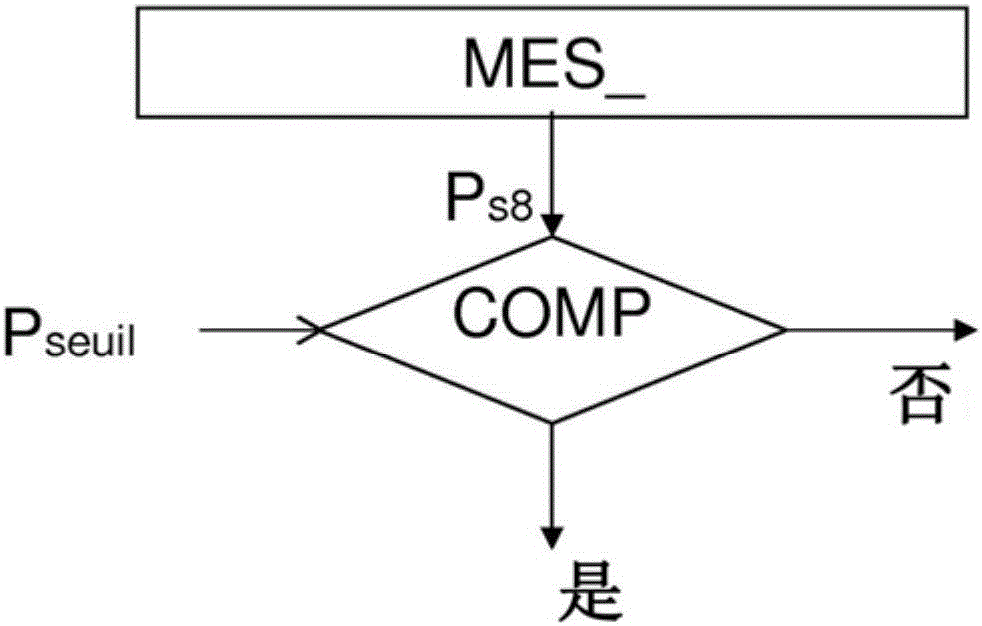

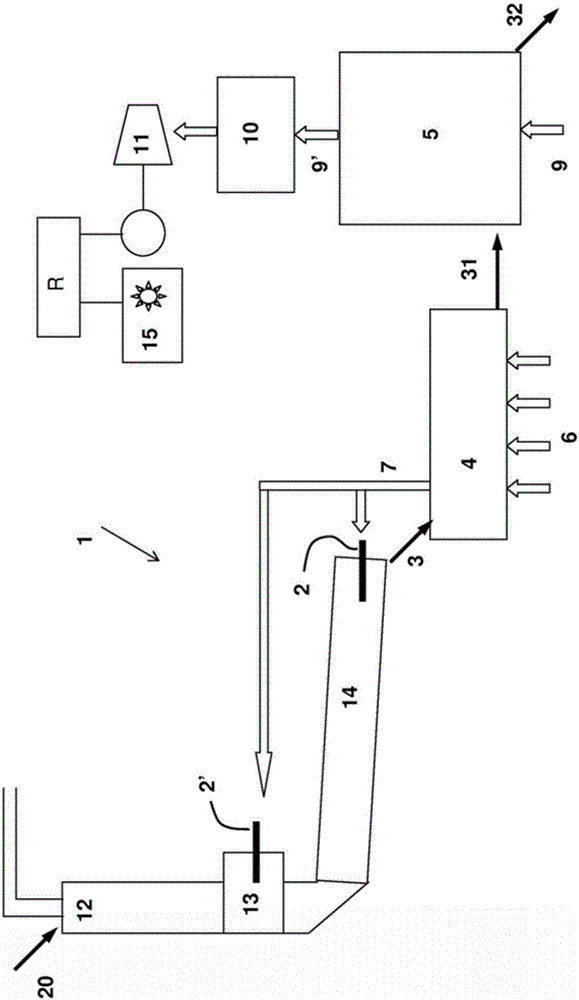

Recovery of intermittent lost heat

The invention relates to a cement clinker manufacturing method implemented in a continuous production facility (1) having at least one area (2, 2') for fuel combustion for firing an inorganic raw material. In said method, the raw material is converted into clinker by firing, thus obtaining hot clinker (3), then the hot clinker (3) is cooled in two consecutive steps: a first cooling step, implemented in a first cooler (4); and a second cooling step, implemented in a second cooler (5). According to the invention, the first cooling step is continually carried out by blowing an oxygen gas (6) on the hot clinker to obtain partially cooled clinker, and all the heated oxygen gas (7), created by the first cooler (4), is sent to said at least one combustion area (2, 2') of said facility to be used as a combustion gas by adjusting the amount of oxygen gas, blown in the first cooler, such as to cover the combustion gas needs of said facility without any excess; and the partially cooled clinker (31) is stored in a storage chamber of the second cooler (5) or even a storage chamber associated with said second cooler, and the second cooling step is intermittently carried out on the partially cooled clinker.

Owner:FIVES FCB

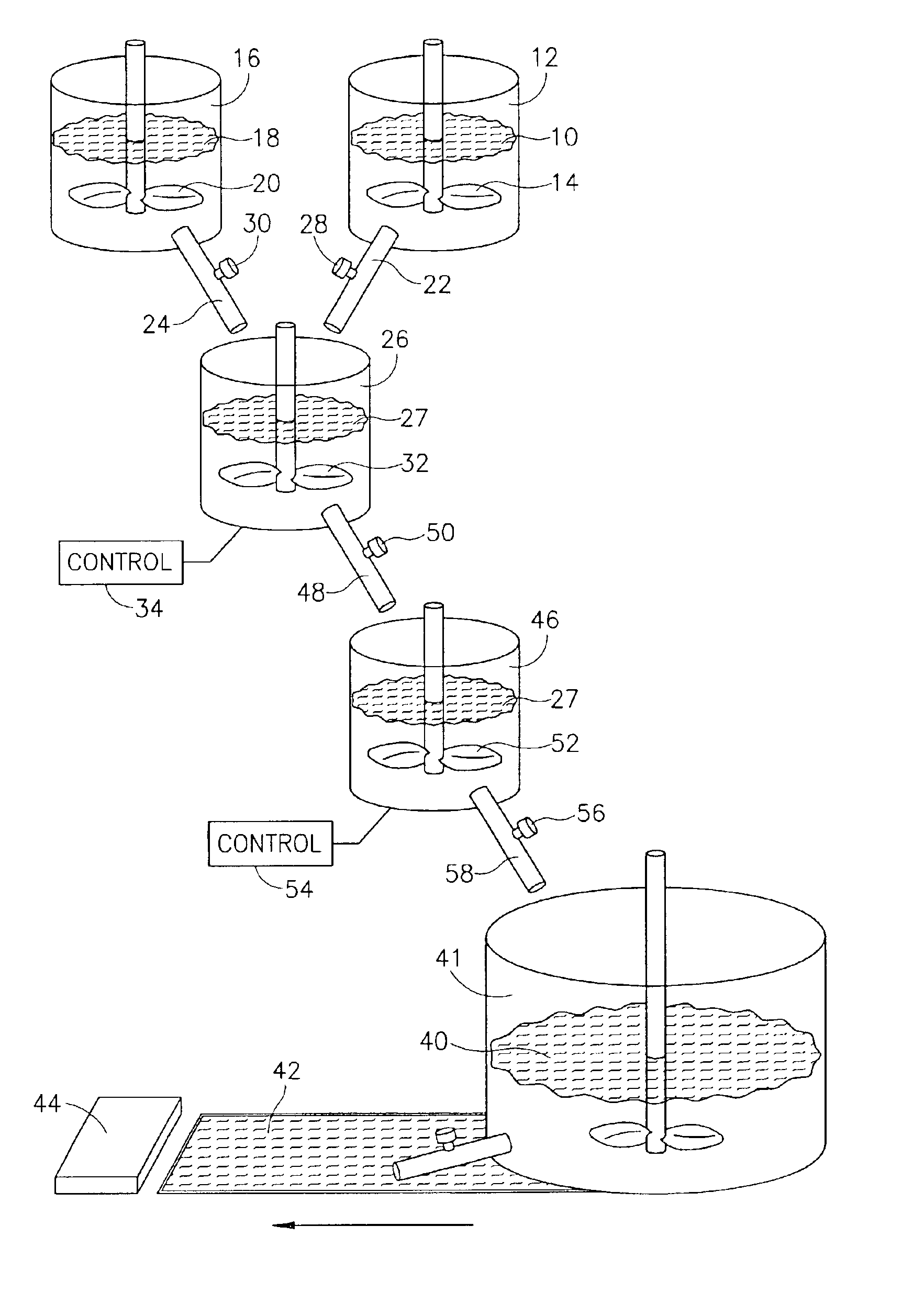

Organic sludge treatment device and treatment method

ActiveUS20210009455A1Easy to operateHigh viscosityWaste water treatment from ceramic industriesByproduct vaporizationSludgeExhaust fumes

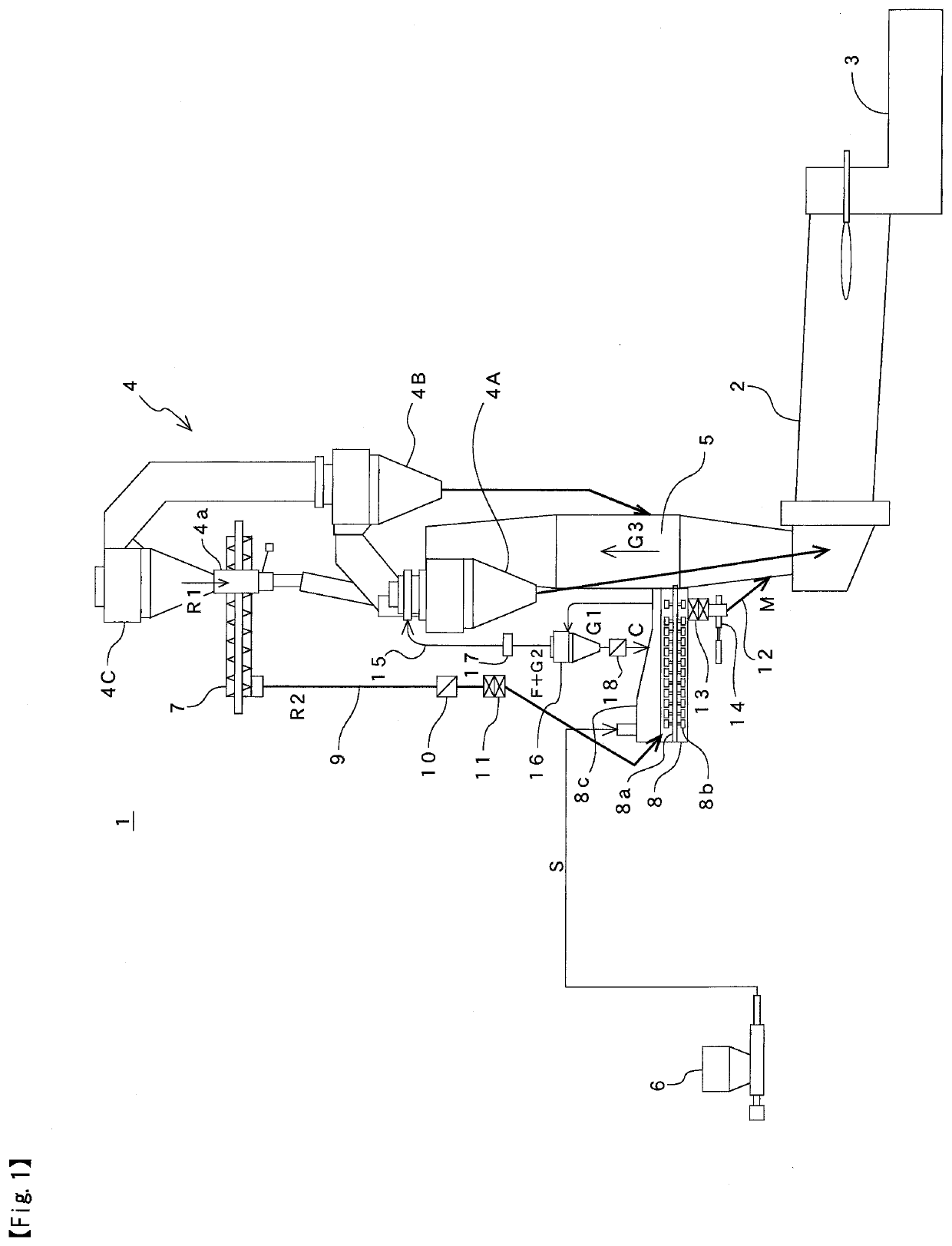

To treat organic sludge while keeping facility costs, cement production efficiency, and a reduction in clinker production amount to a minimum. An organic sludge treatment device includes: a fractionation device 7 that fractionates a preheated raw material R2 from a preheater cyclone 4C excluding a bottommost cyclone of a cement burning device 1; a mixing device 8 that mixes an organic sludge S with the fractionated preheated raw material, and that dries the organic sludge using sensible heat of the preheated raw material; and a supply device (mixture chute 12, double-flap damper 13, shut damper 14) that supplies a mixture M from the mixing device to a calciner furnace 5 of the cement burning device or to a duct disposed between a kiln inlet portion of a cement kiln 2 and the calciner furnace. The treatment device may be provided with an introduction device for introducing an exhaust gas G2 including dust, odor and water vapor from the mixing device to a gas outlet of a bottommost cyclone 4A of the cement burning device.

Owner:TAIHEIYO ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com