Gasification with separate calcination

A technology of calcination and calciner, which is applied in ceramic production workshops, cement production, lighting and heating equipment, etc., and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

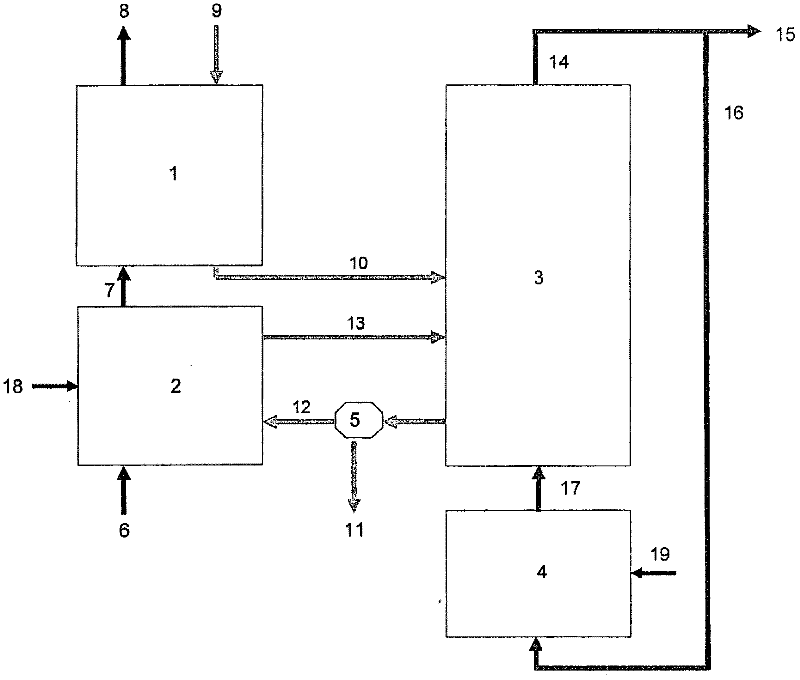

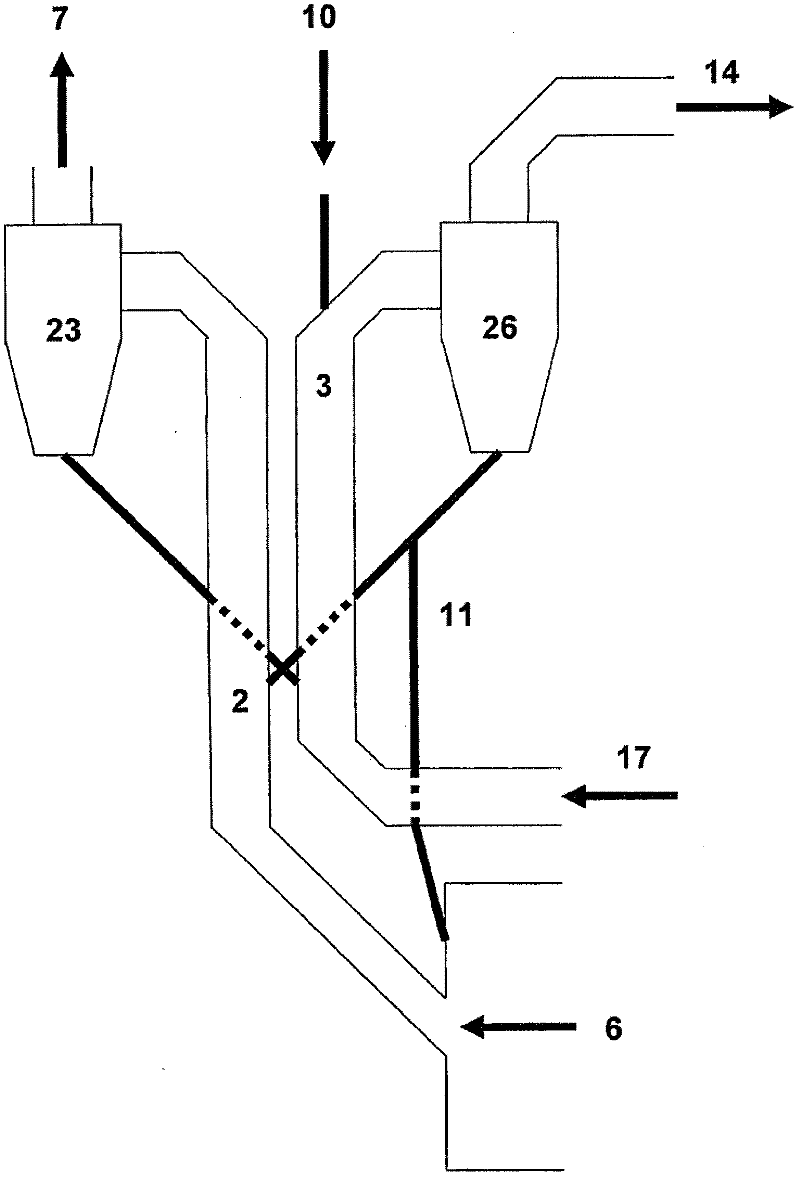

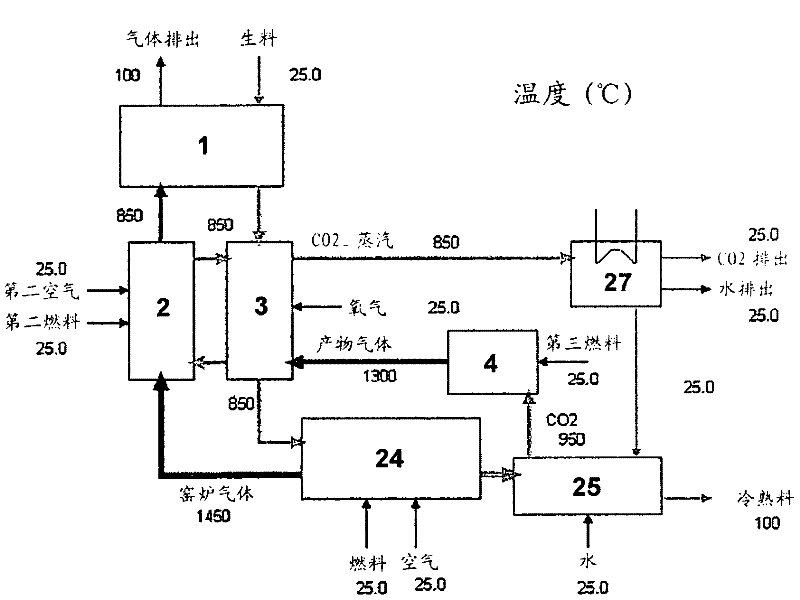

[0023] Depend on figure 1 It can be seen how the hot gas 7 is used to heat the raw cement meal 9 in the preheater 1 . The preheated cement raw meal 10 is introduced into the calciner 3, where the cement raw meal is calcined. A part 15 of the gas 14 from the calciner 3 is withdrawn, while a second part 16 is directed to the gasifier 4 , which is fed with fuel and, if relevant, oxygen 19 . Gas 17 from gasifier 4 is recycled to calciner 3 . Depend on figure 1It can also be seen how the calcined raw cement meal from the calciner 3 is directed to a splitter gate or similar device from which a portion 11 of the calcined raw cement meal is directed to a kiln (not shown) and otherwise A portion 12 is directed to the lift duct 2 . The riser duct 2 receives exhaust gas 6 from a kiln (not shown) as well as secondary fuel and, if relevant, air 19 . The calcined cement raw meal 13 is separated from the exhaust gas 6 by means of a cyclone or similar and recycled to the calciner 3 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com