Method and plant for the simultaneous production of electricity and cement clinker

A technology of cement clinker and cement raw meal, which is applied in lighting and heating equipment, cement production, clinker production, etc., and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

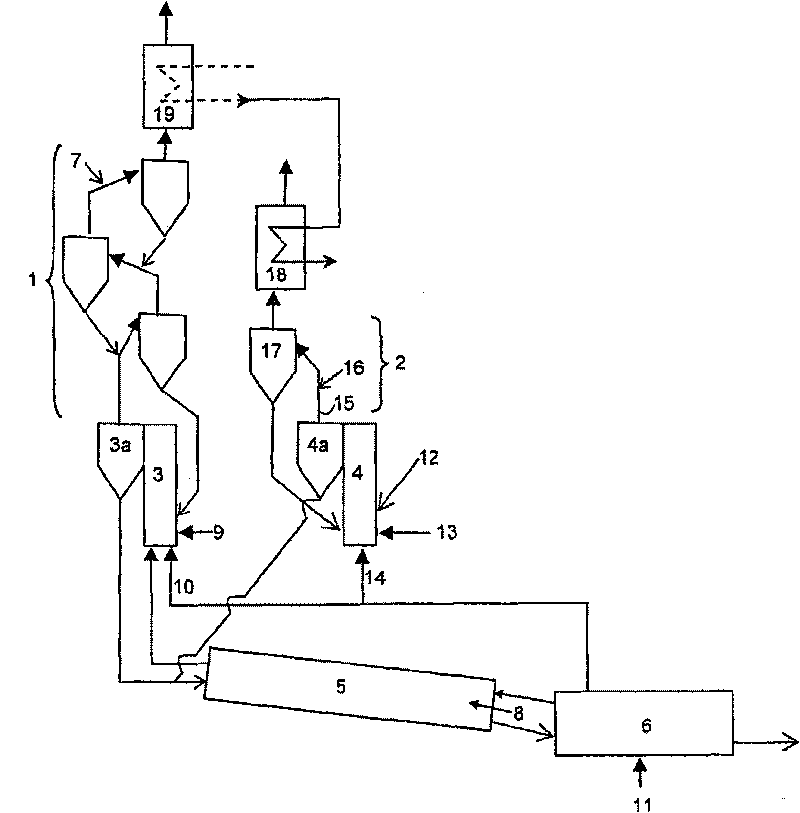

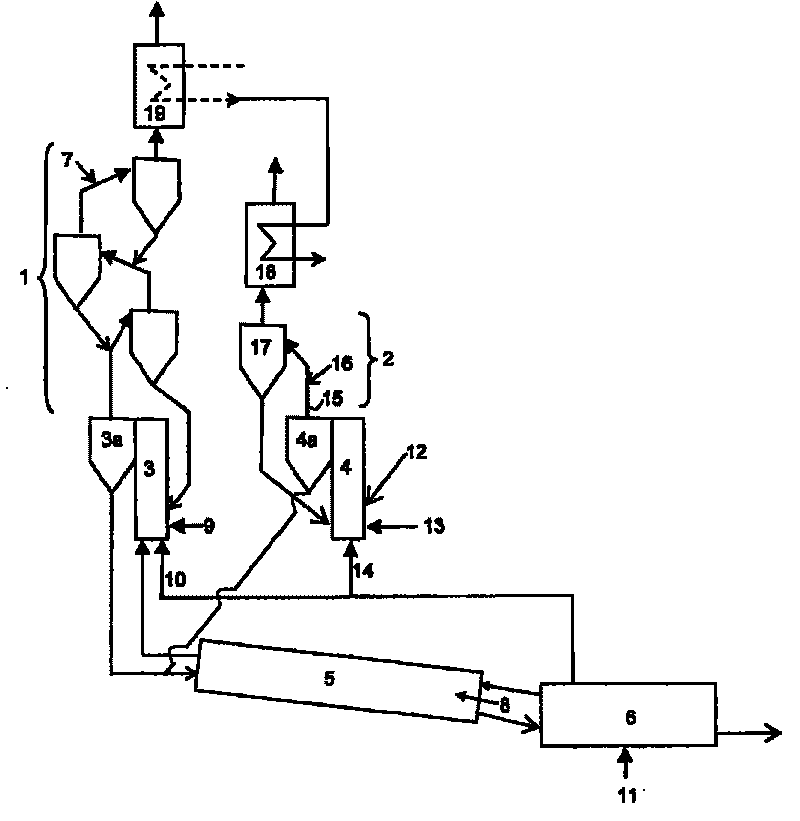

[0015] In the accompanying drawings a cement manufacturing plant can be seen comprising two preheater strings 1 and 2, a rotary kiln 5 and a clinker cooler 6, each of said preheater strings 1 and 2 comprising respectively Calciners 3 and 4, each of which is equipped with a separation cyclone 3a and 4a respectively. The preheater train 1 is designed as a conventional multi-cyclone preheater and in the embodiment shown it comprises three cyclone stages, but may also comprise fewer and additional cyclone stages. The preheater string 1 functions in a conventional manner, wherein cement raw meal is conveyed through the inlet 7 into the inlet pipe for the uppermost cyclone stage of the cyclone preheater, as a first step with heat Exhaust gases and combustion air are heated, calcined and clinkered as they pass in countercurrent relationship through the preheater 1, the calciner 3 and then through the rotary kiln 5, wherein the hot exhaust gases are respectively heated in the The bur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com