Patents

Literature

38results about How to "Limited shelf life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

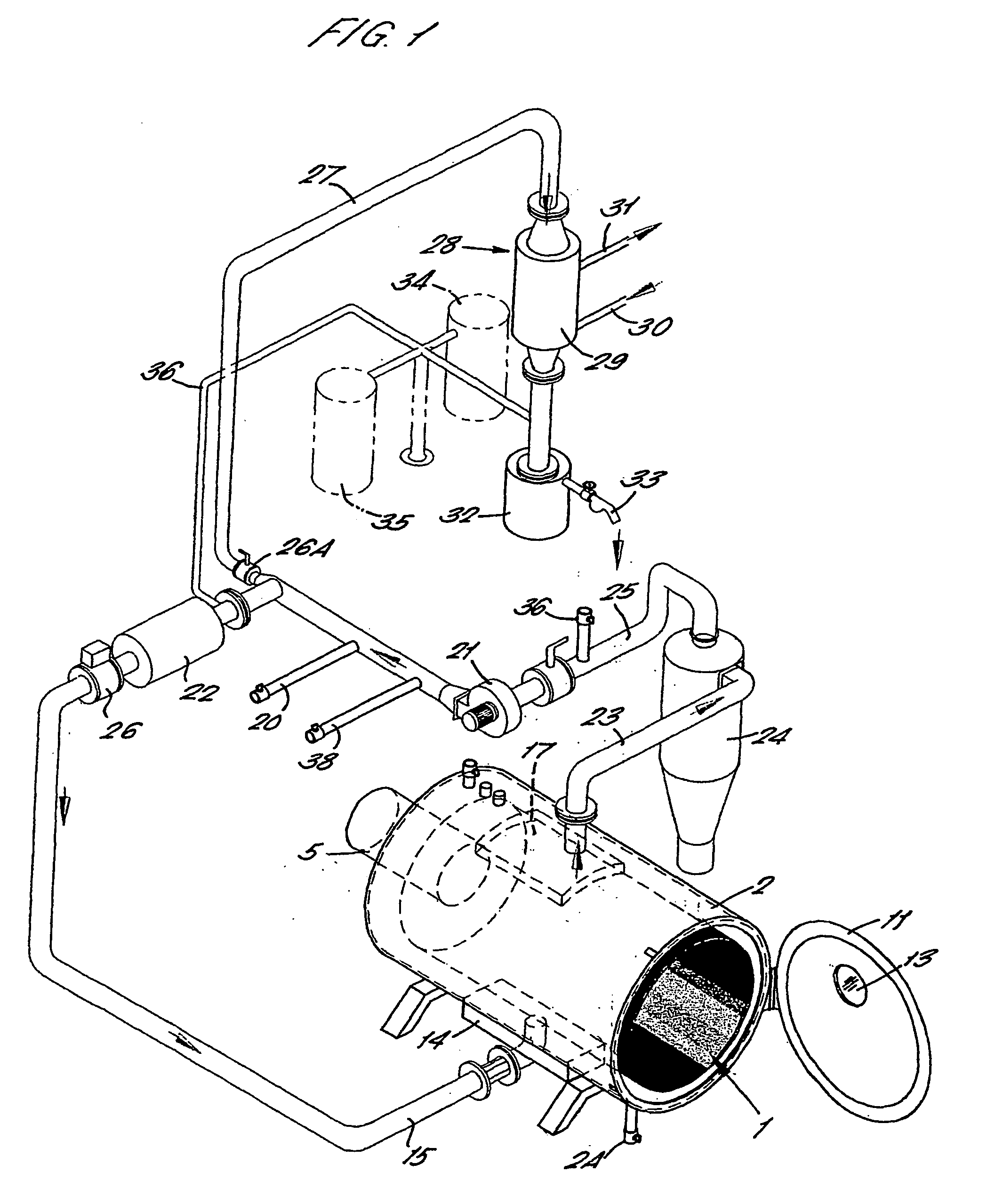

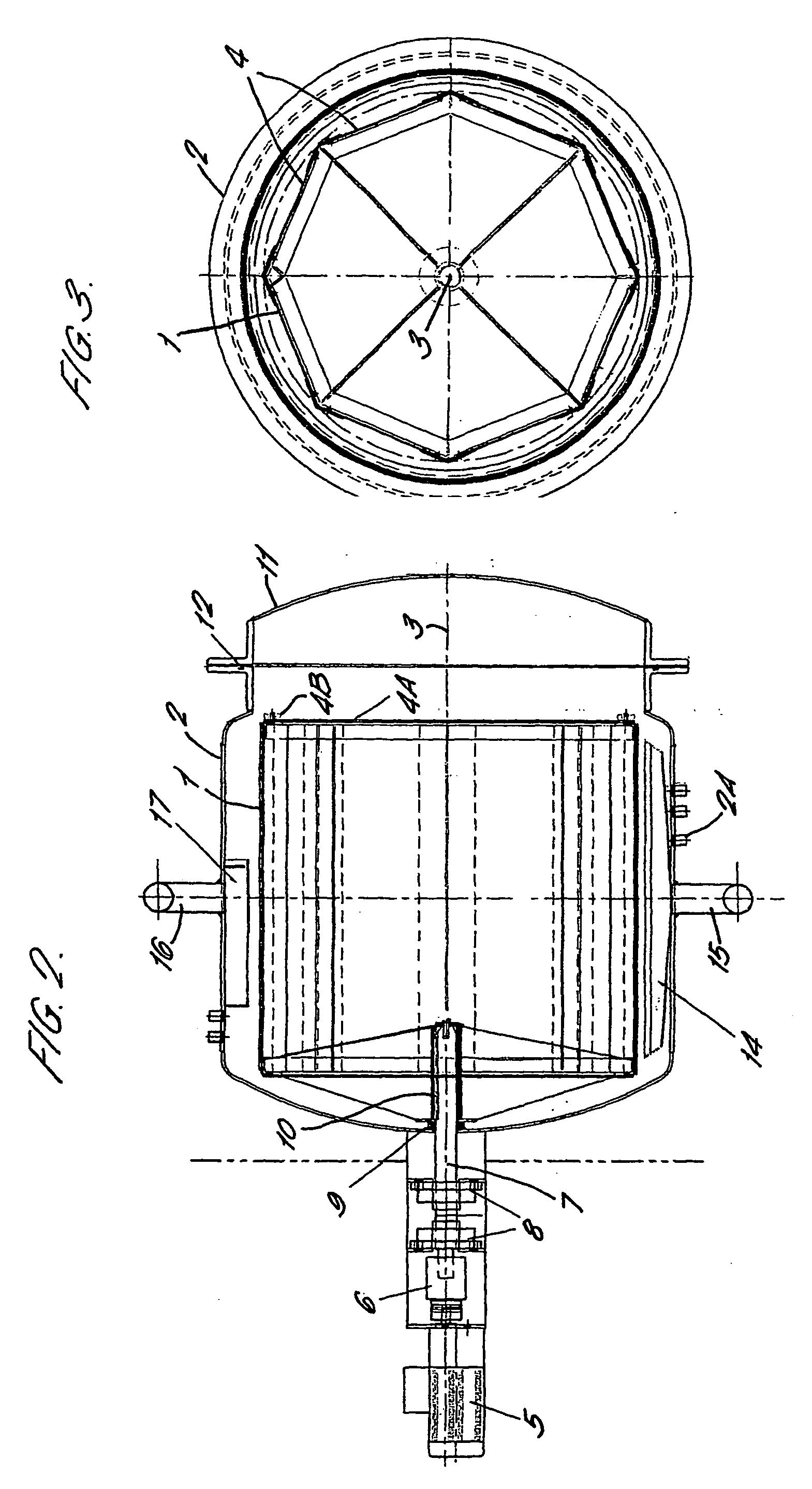

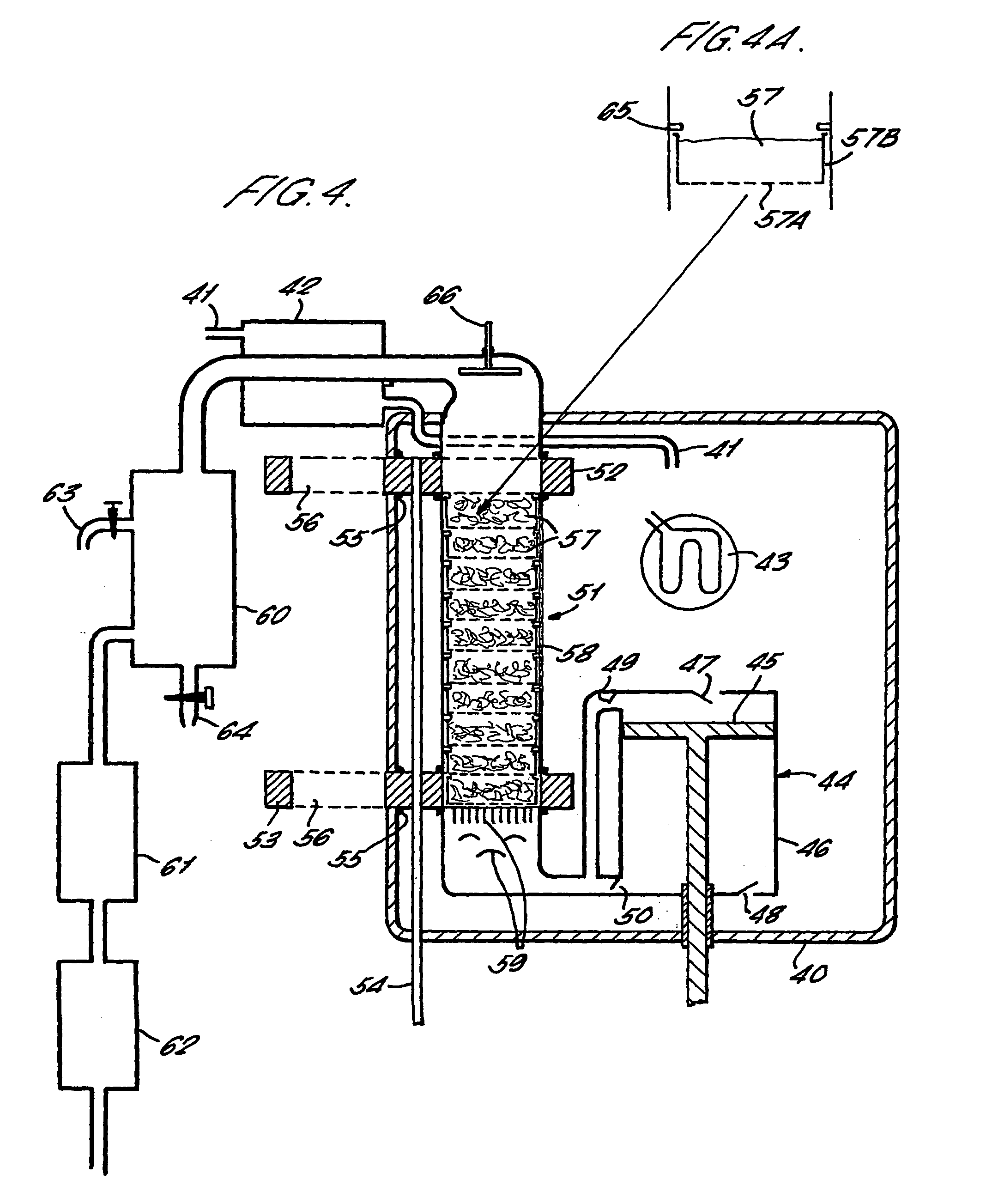

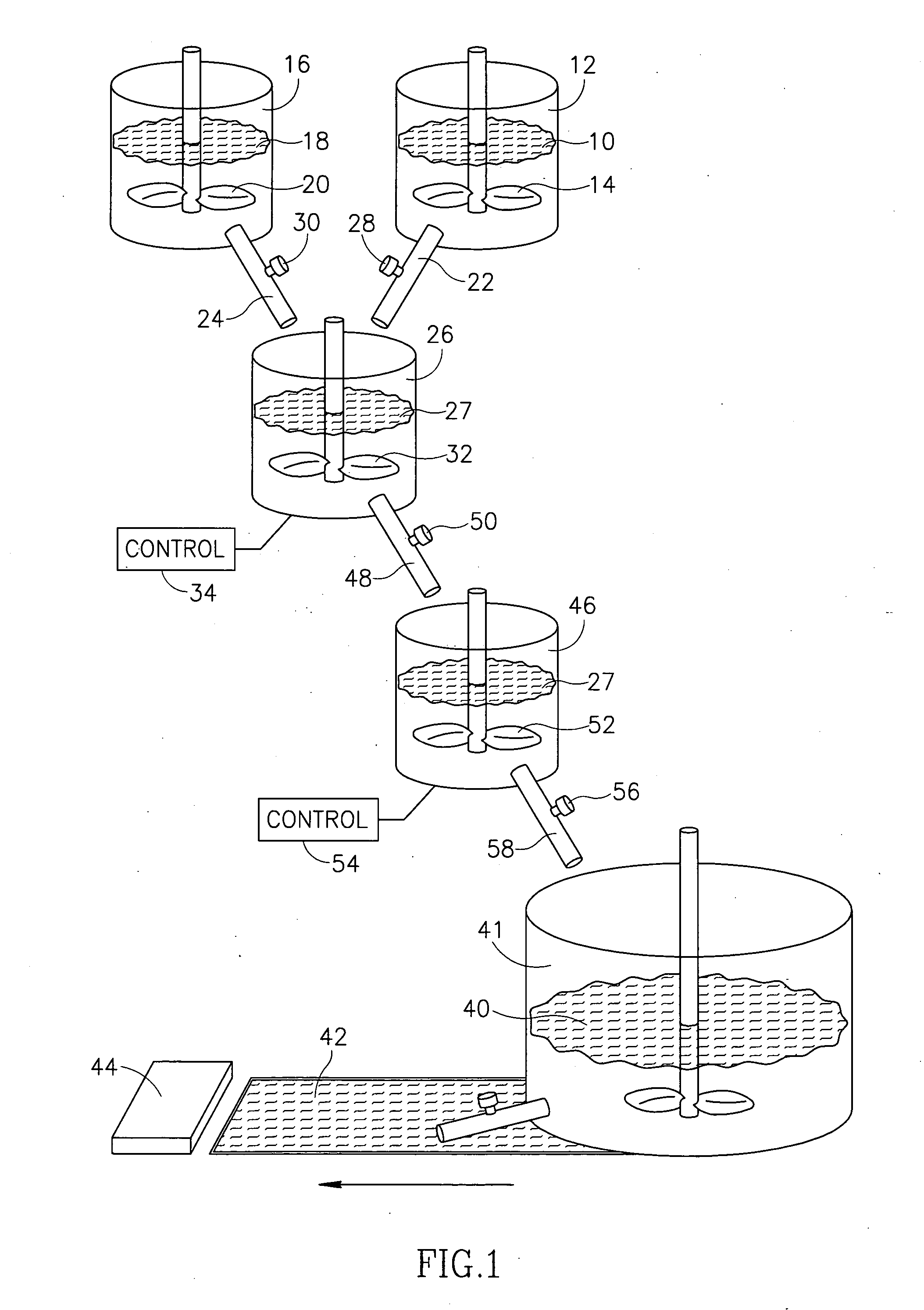

Processes and apparatus for extraction of active substances and enriched extracts from natural products

InactiveUS20040147767A1Reduce the temperatureAvoid expensive laggingBiocideOrganic chemistryNatural productChemistry

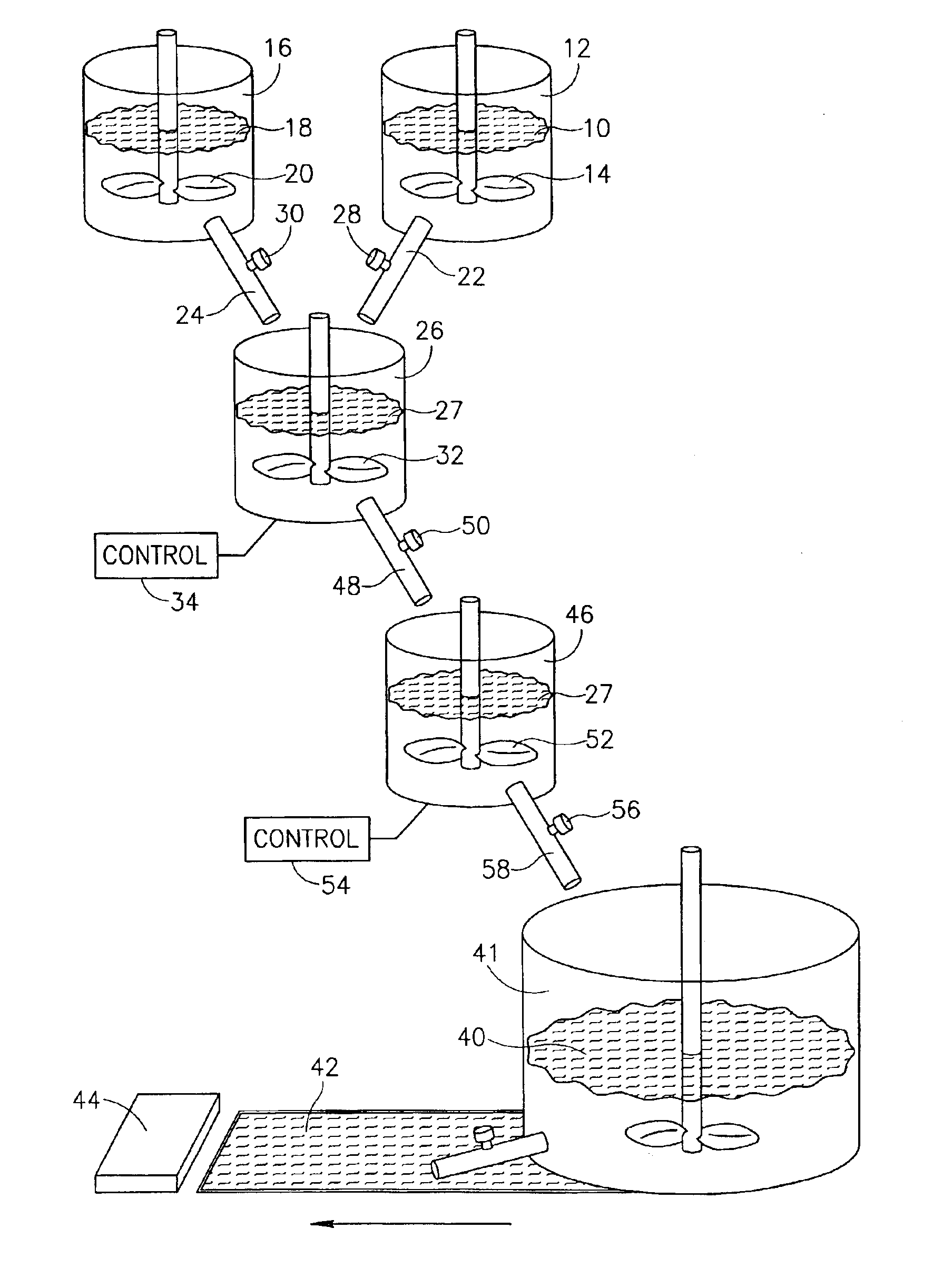

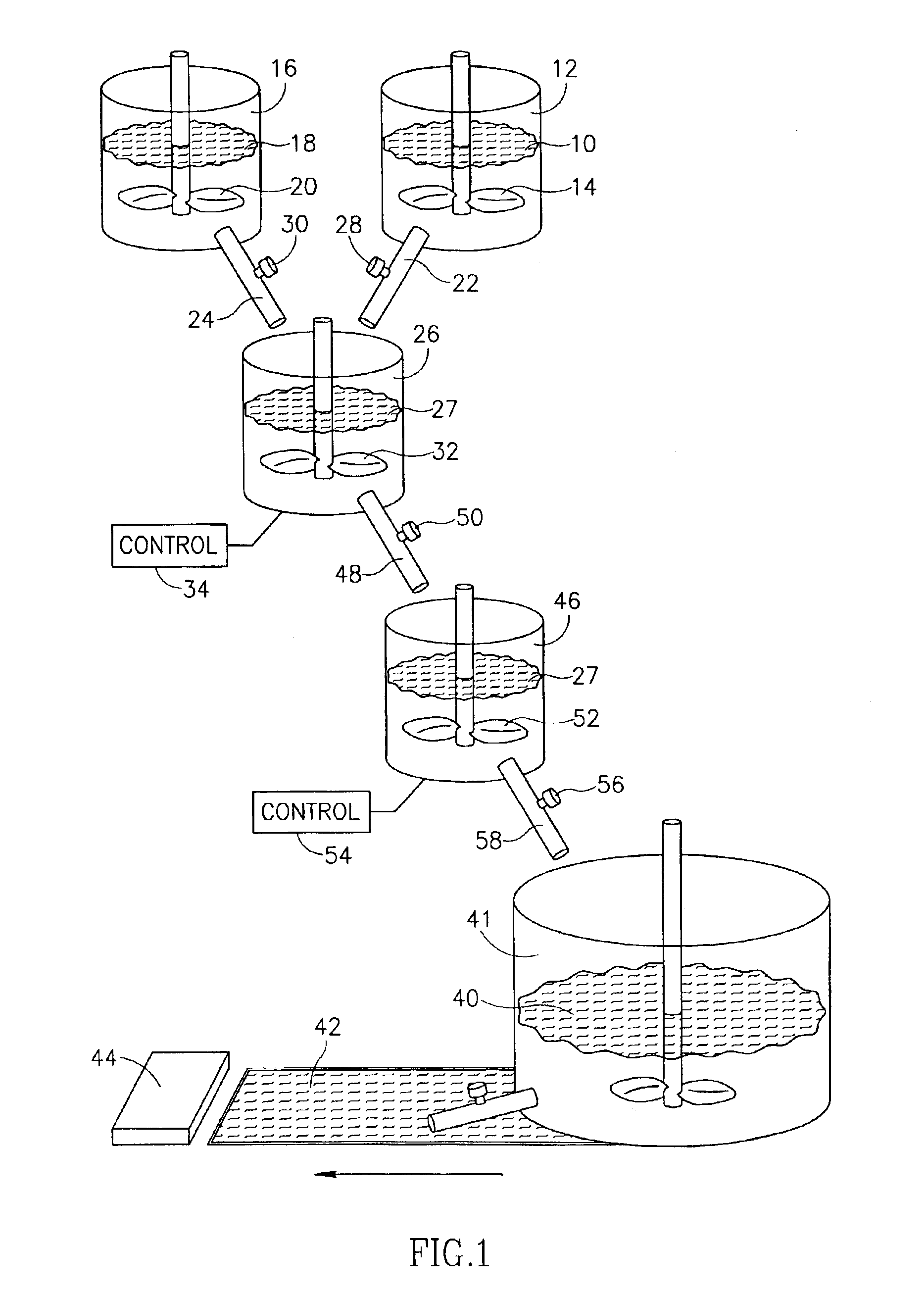

Processes for preparing extracts of natural products such as plant material, and for preparing purified extracts from crude extracts of natural products, by extraction with hot gas. Apparatus suitable for use in preparing extracts of natural products are also described.

Owner:GW PHARMA LTD

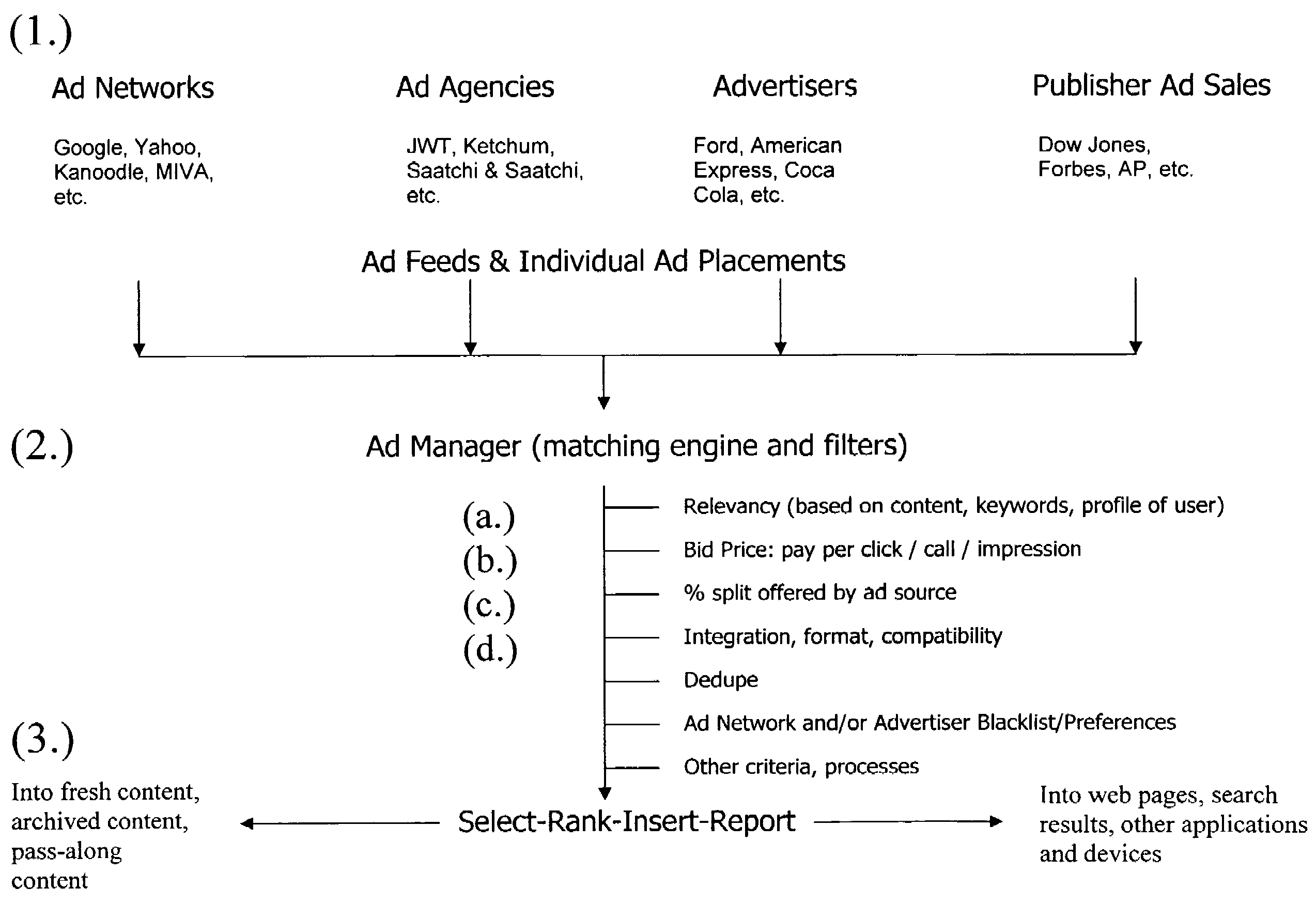

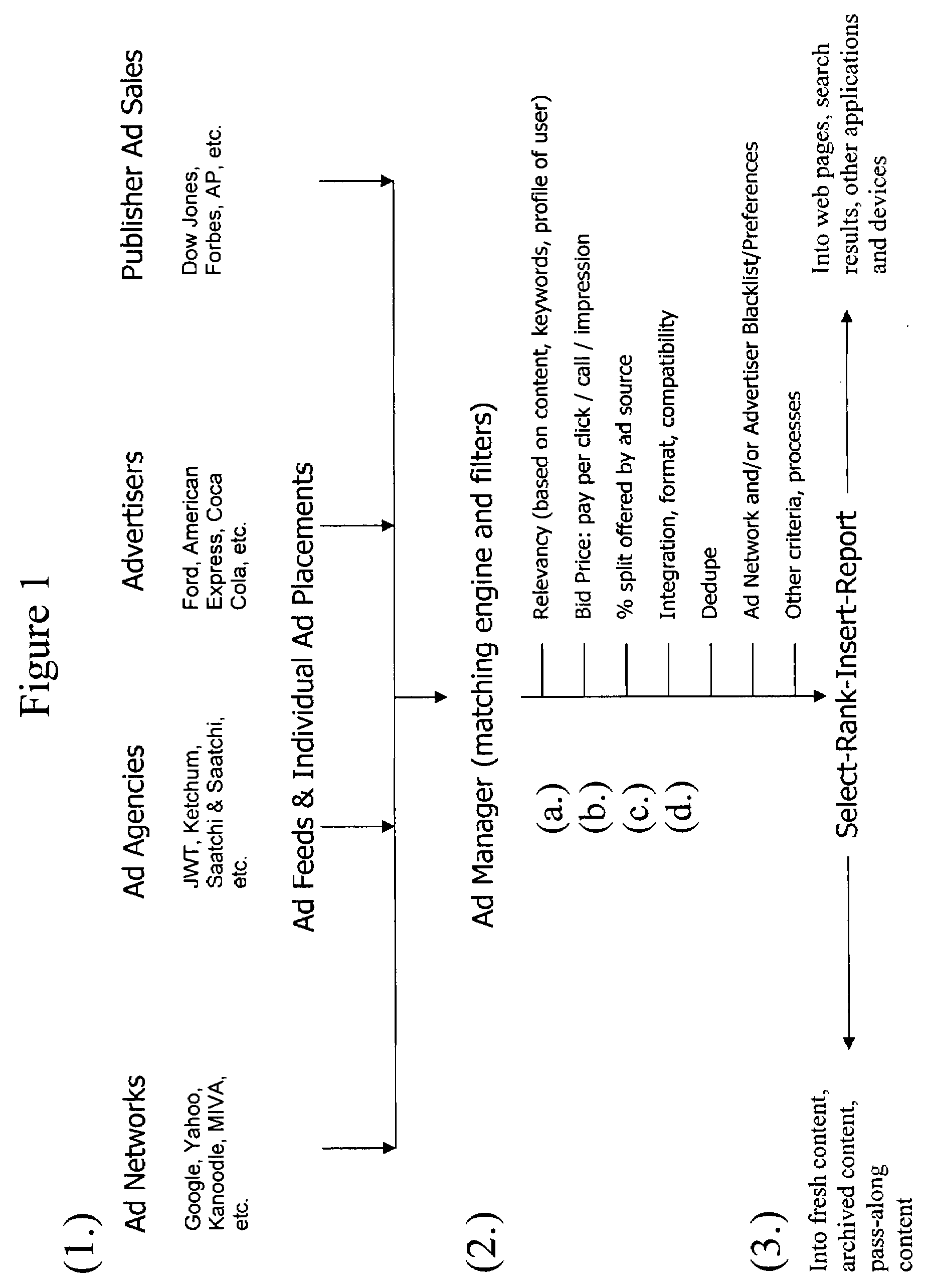

Metalevel electronic marketplace for advertising

A method using an intermediary electronic marketplace for sourcing advertisements from multiple advertisement suppliers that use an electronic marketplace to acquire, select, and place electronic advertisements and providing the advertisements to publishers. By operating as an intermediary, the method can automatically compare prices of advertisements from multiple sources, allowing effective price competition, and the method can provide a third party check to verify that proper payment is made to each publisher.

Owner:ICOPYRIGHT

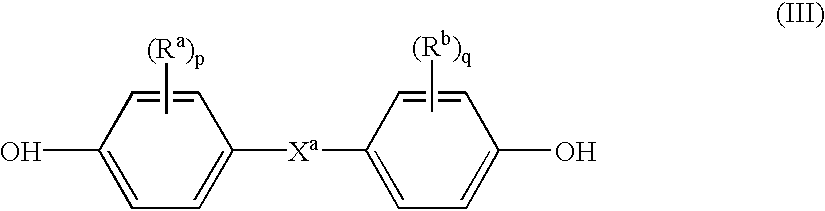

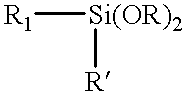

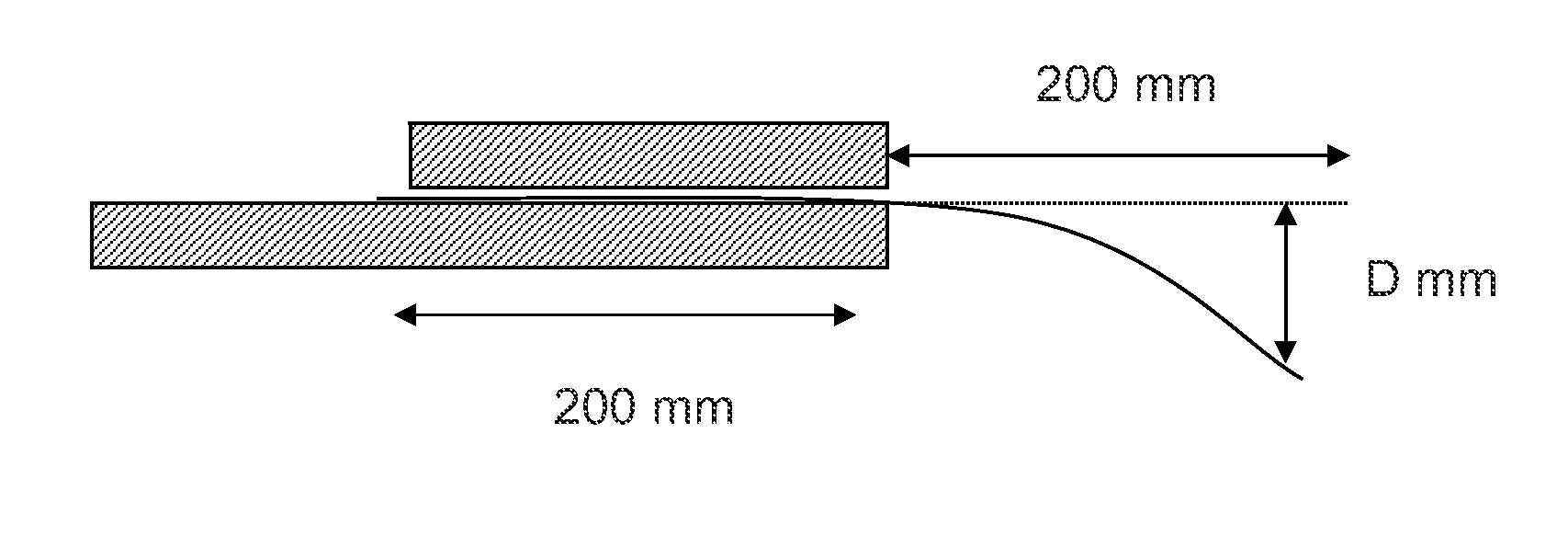

Composition for promoting adhesion between rubber and textiles

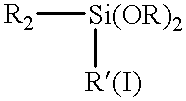

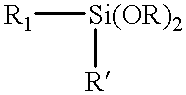

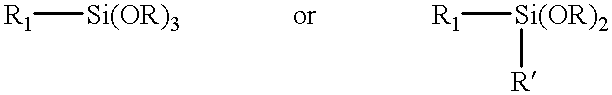

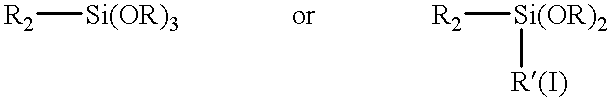

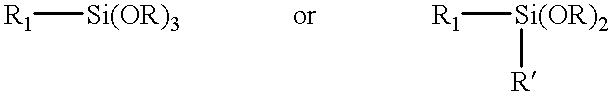

InactiveUS6046262ALimited shelf lifeStable aqueous dispersion/solutionAdhesive processesImpression capsSilane compoundsPolyester

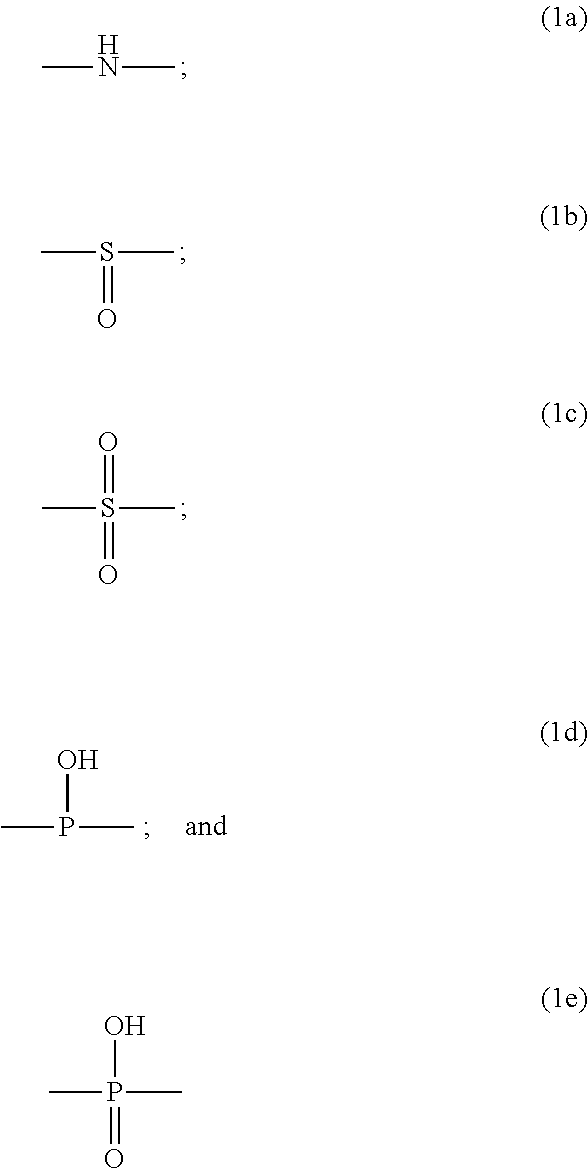

A composition for the promotion of adhesion between a rubber formulation and a textile substrate is provided. The inventive composition comprises either a mixture of specific amine functional silanes and organo-functional silanes having reactive groups or groups with an affinity for rubber. The inventive method entails the use of the inventive composition or a silane compound having both an amine moiety and a reactive group having an affinity for rubber formulations, particularly an unsaturated carbon-carbon bond. The composition may be utilized to adhere any standard reinforcement-type textile, such as polyester or polyamide, to a standard rubber composition, such as SBR, NBR, or EPDM. A method for adhering textiles to rubber formulations is also provided involving a pre-dip, -spray, -coat, and the like, of the inventive composition on a reinforcement-type textile surface followed by the contacting of the rubber formulation. Optionally, and preferably, the process involves the extra utilization of resorcinol-formaldehyde latex as an effective bonding agent to improve the adhesion between the two layers. The resulting textile-reinforced rubber product may be utilized as an automobile fan or timing belt, an automobile tire component, and any other rubber article which requires long-lasting, durable textile reinforcement.

Owner:MILLIKEN & CO

Phenol-formaldehyde resin having low concentration of tetradimer

InactiveUS20080064284A1Improve stabilityLimited shelf lifeSynthetic resin layered productsAldehyde/ketone condensation polymer adhesivesGlass fiberFiber

A phenol-formaldehyde resin, having a low concentration of tetradimer, making the resin suitable for preparing a binder composition for making non-woven fiber products, such as fiberglass insulation, prepared by reacting phenol and formaldehyde in the presence of a sulfite source.

Owner:GEORGIA PACIFIC CHEM LLC

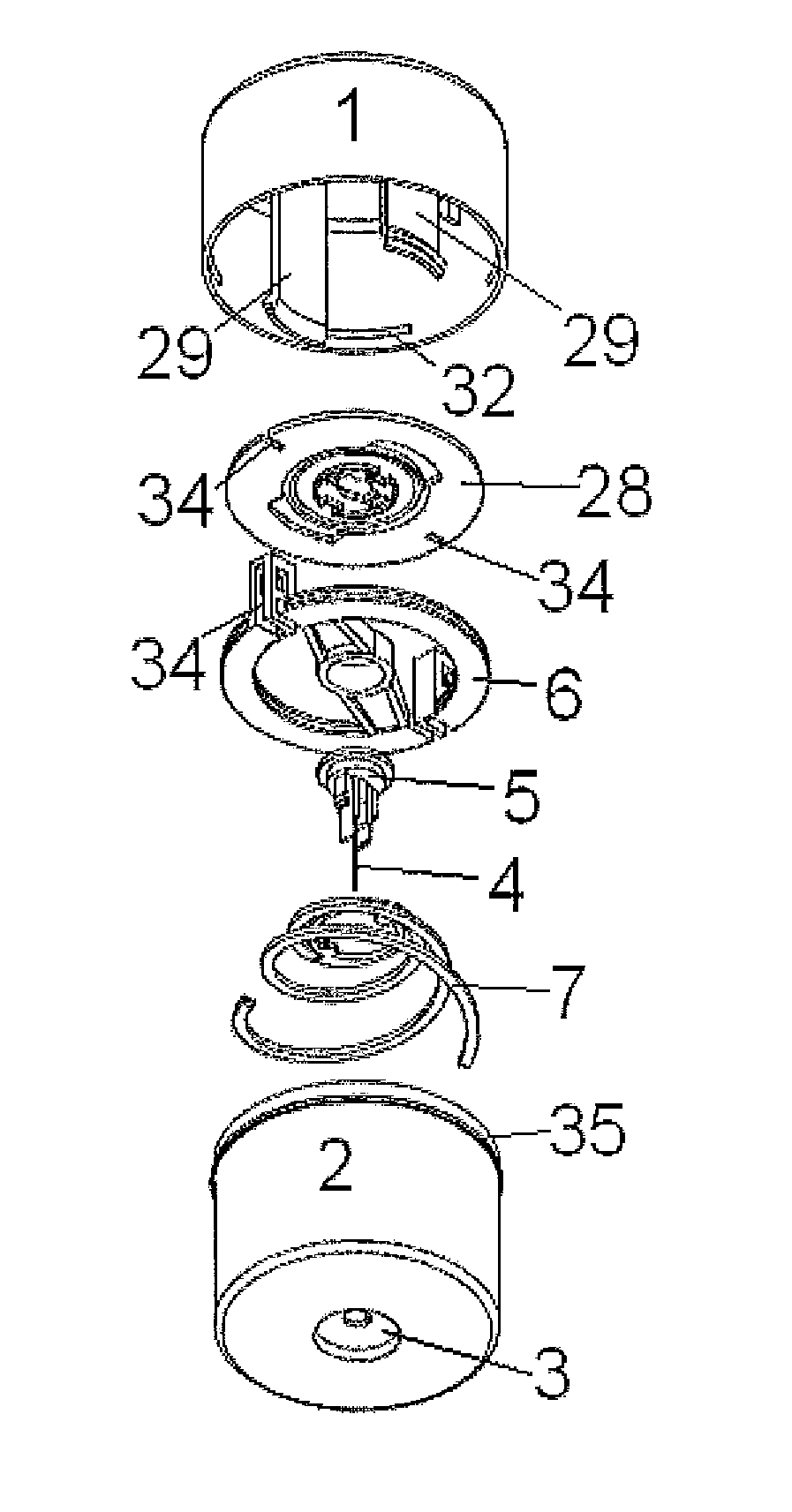

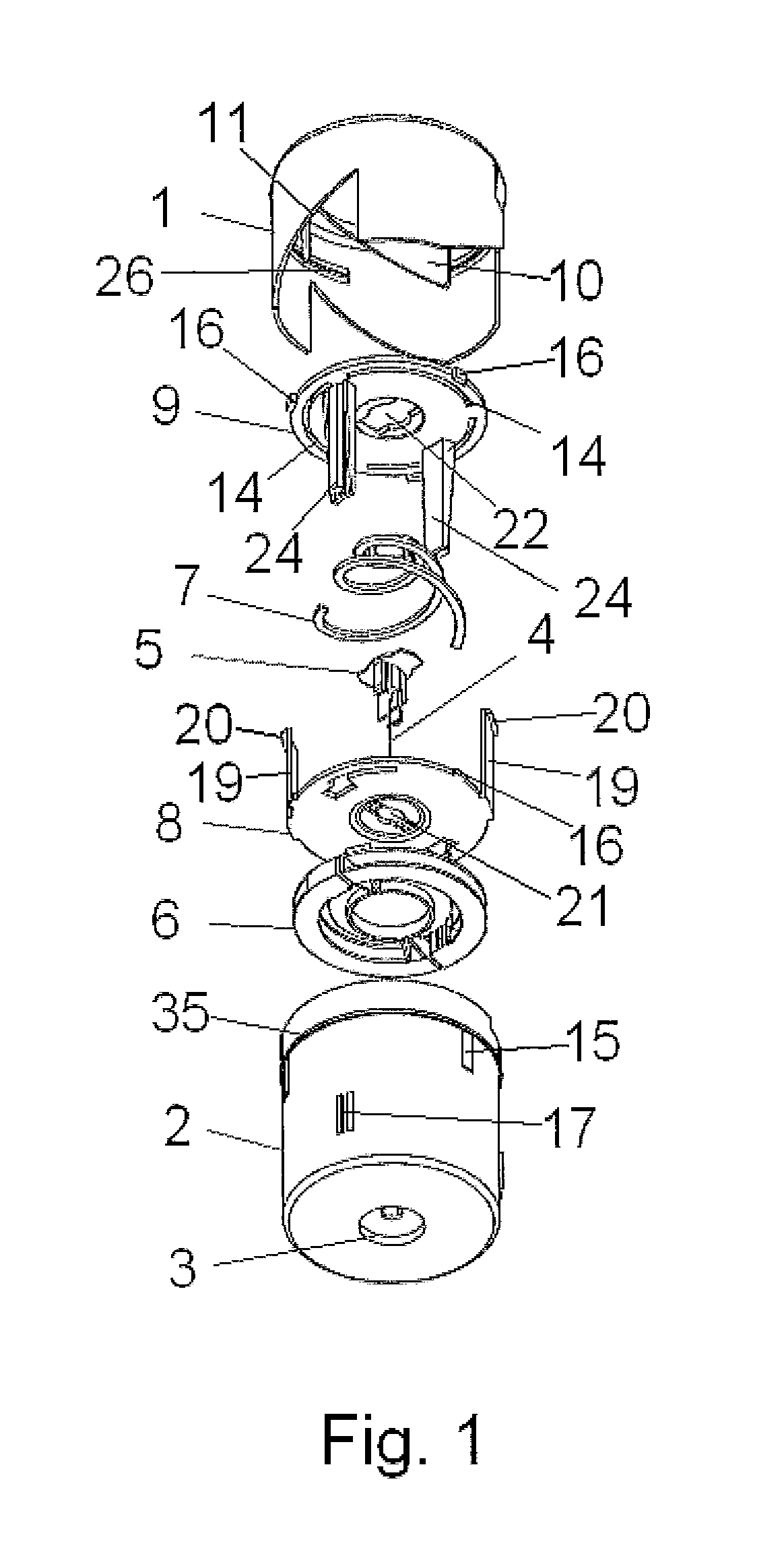

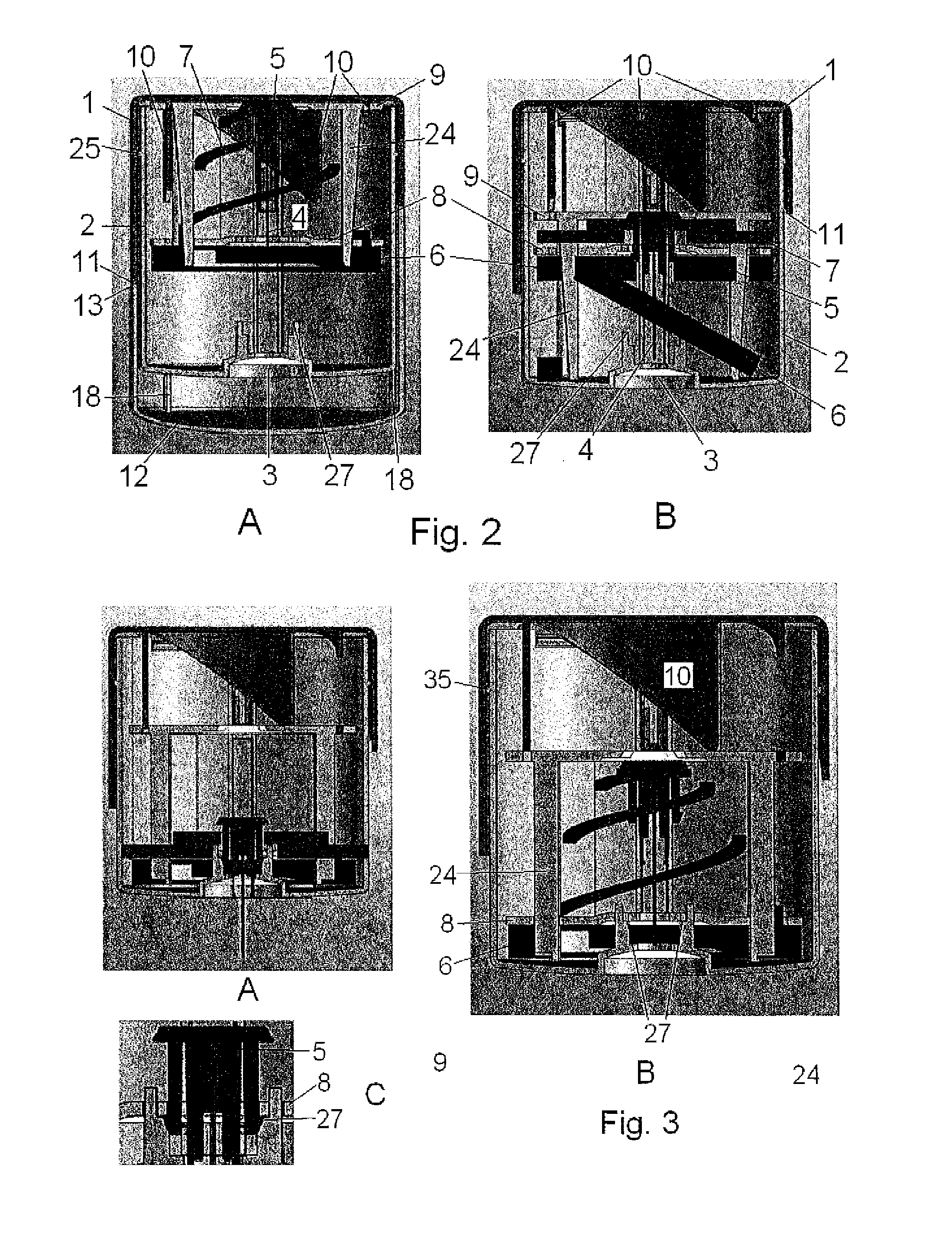

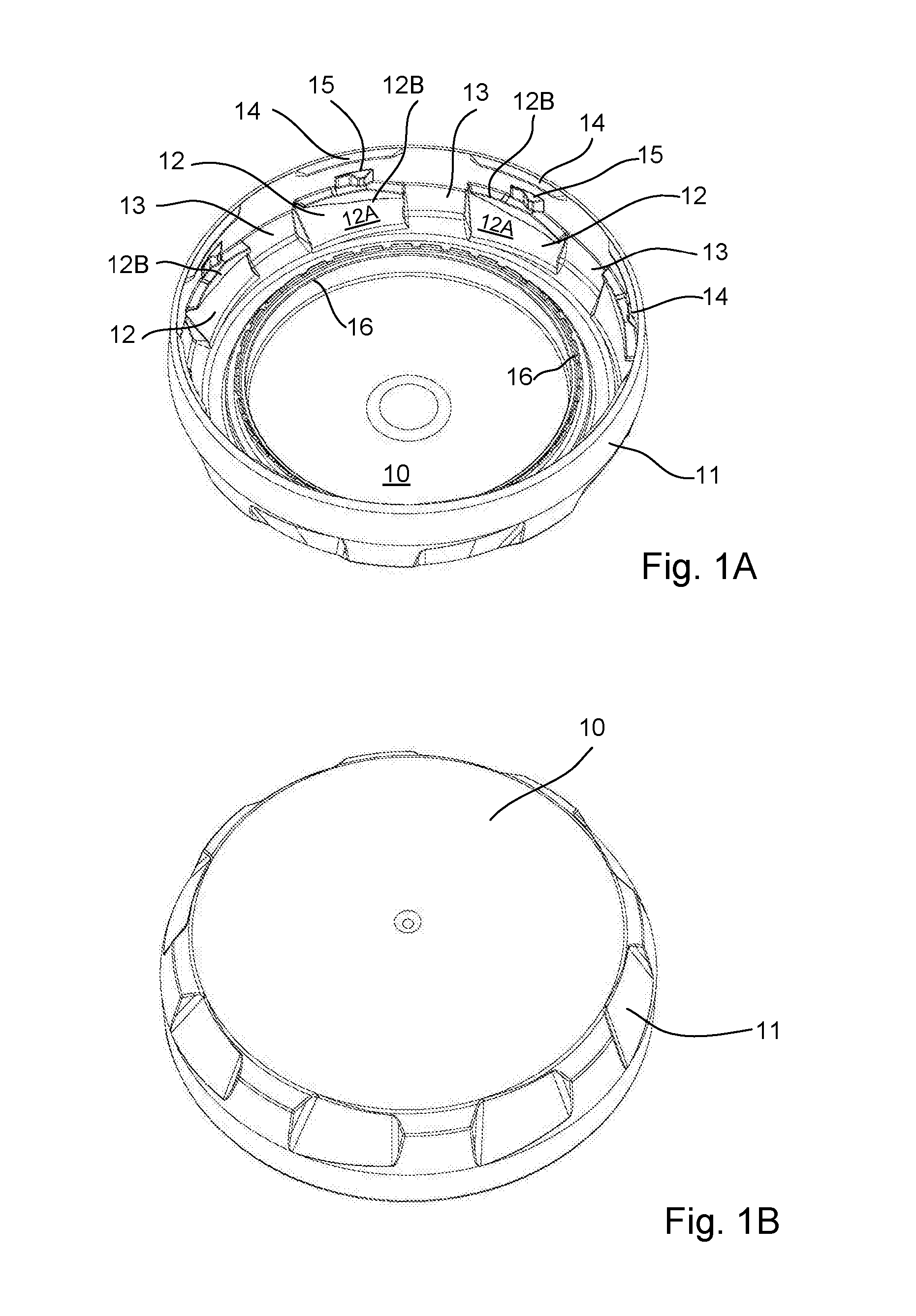

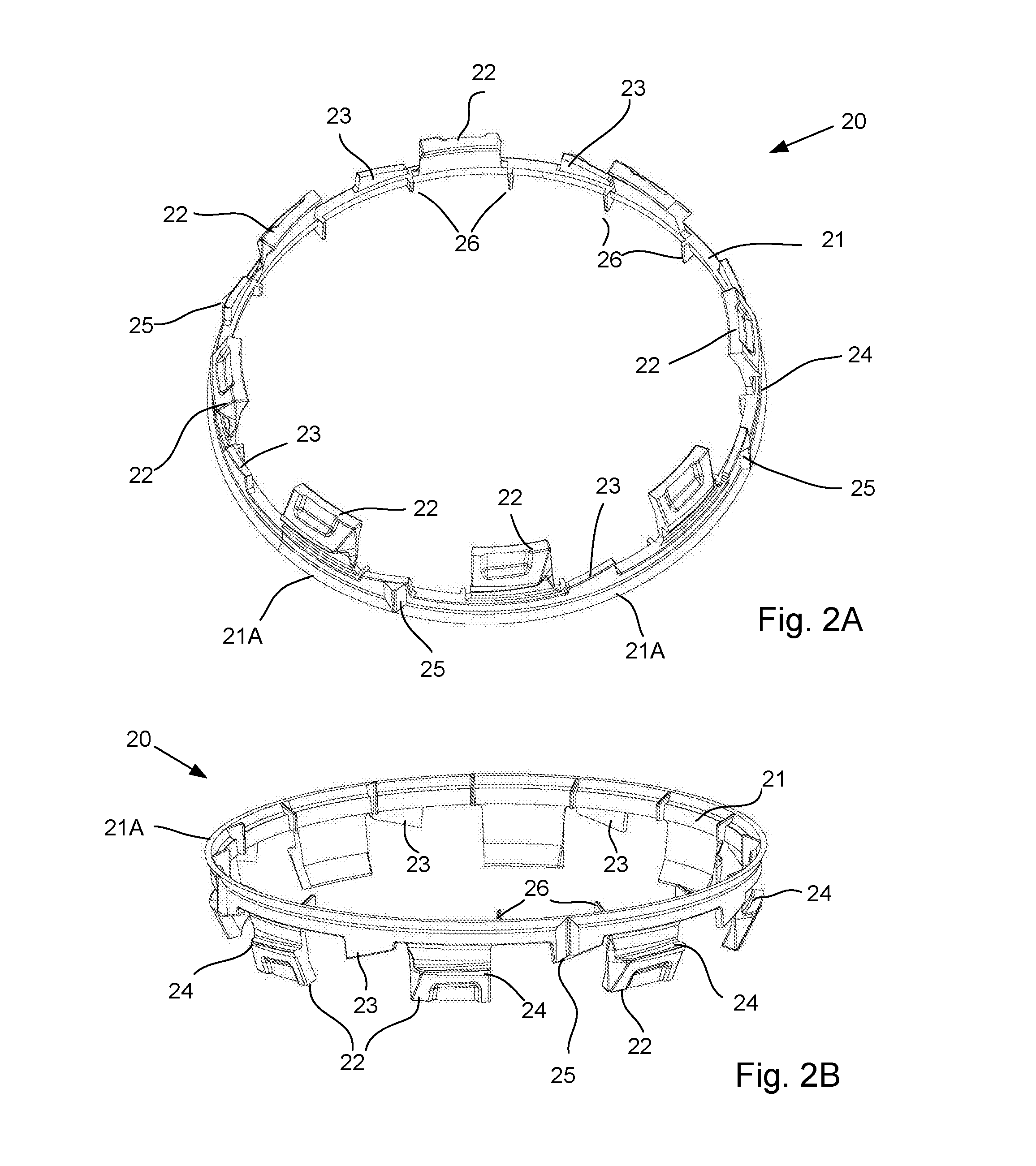

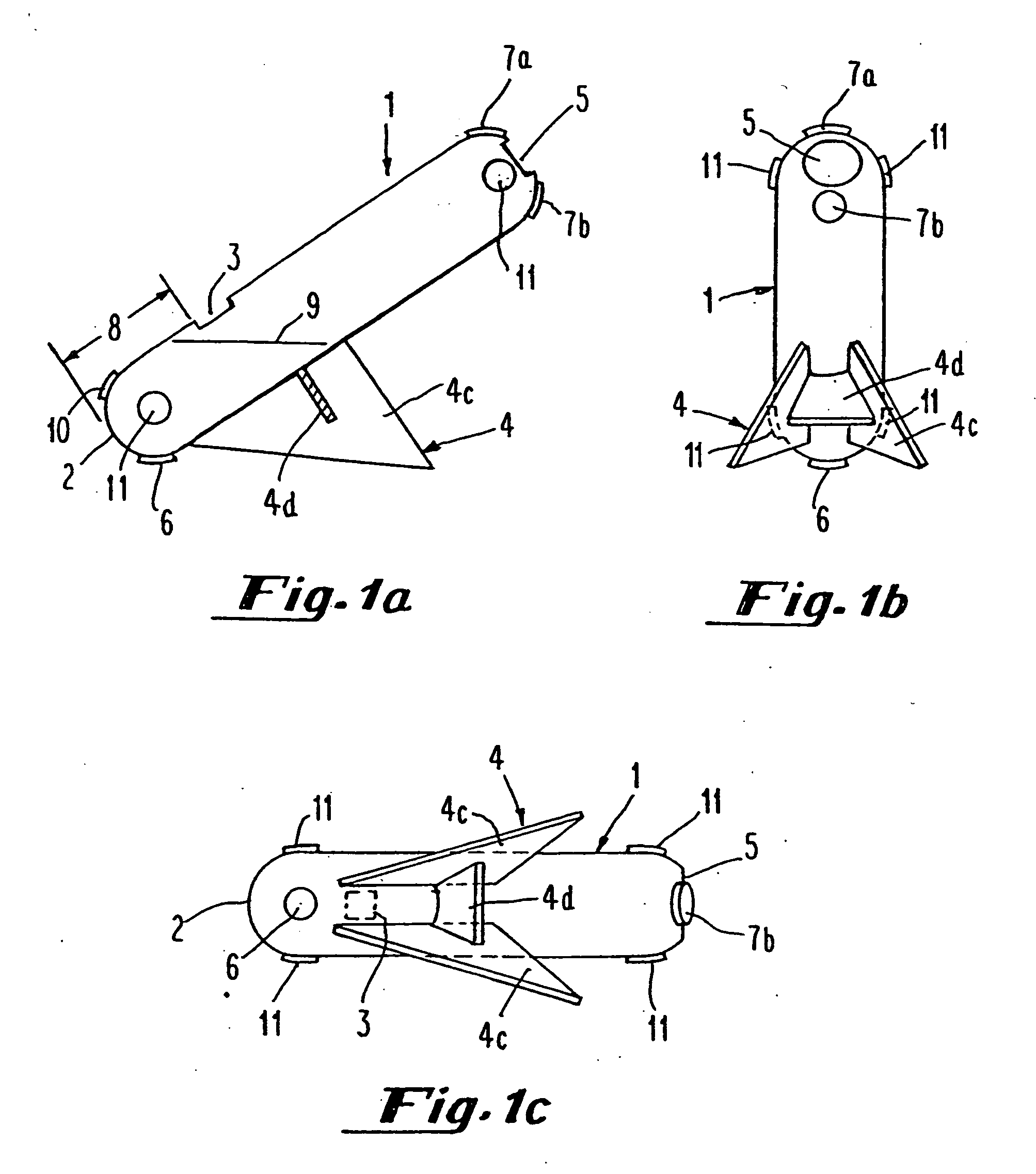

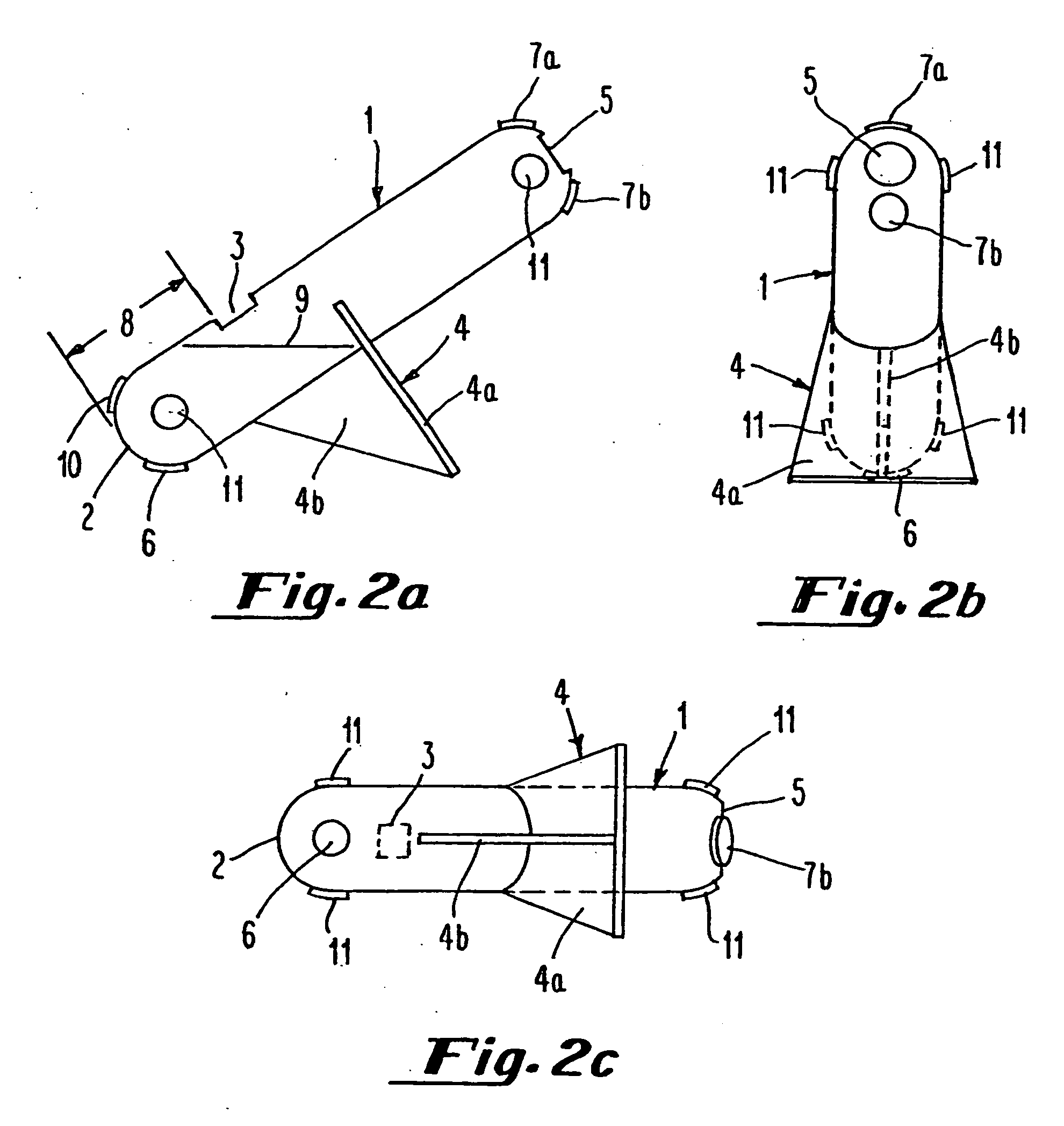

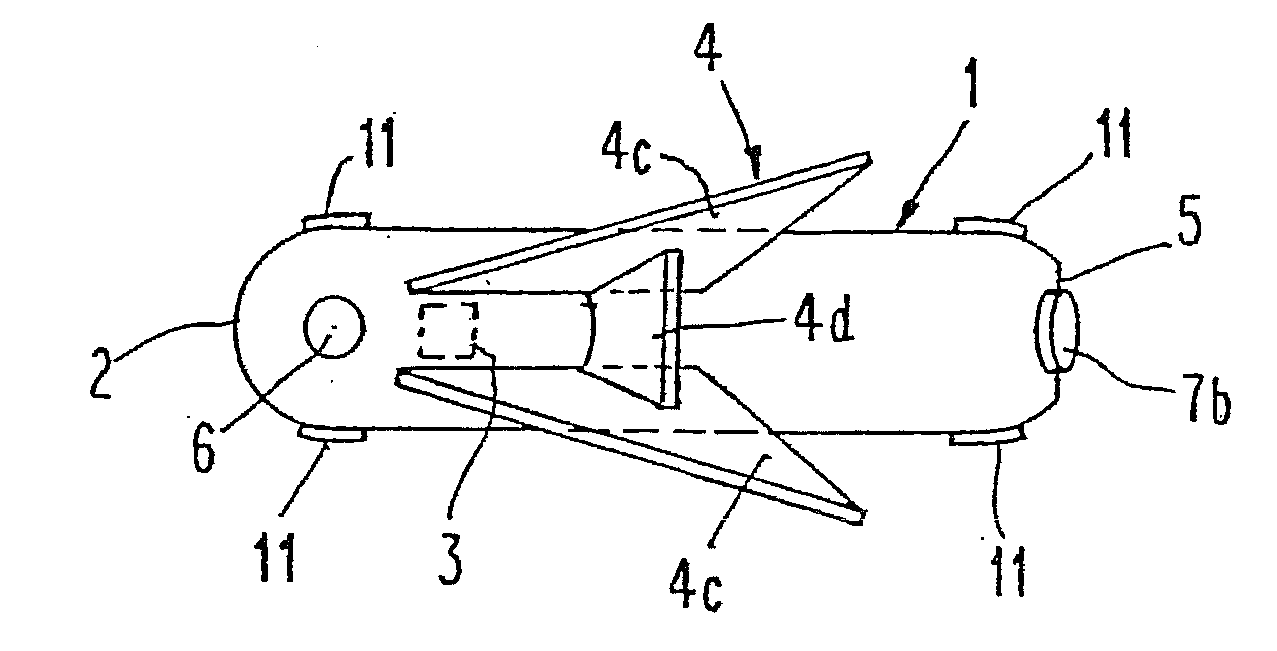

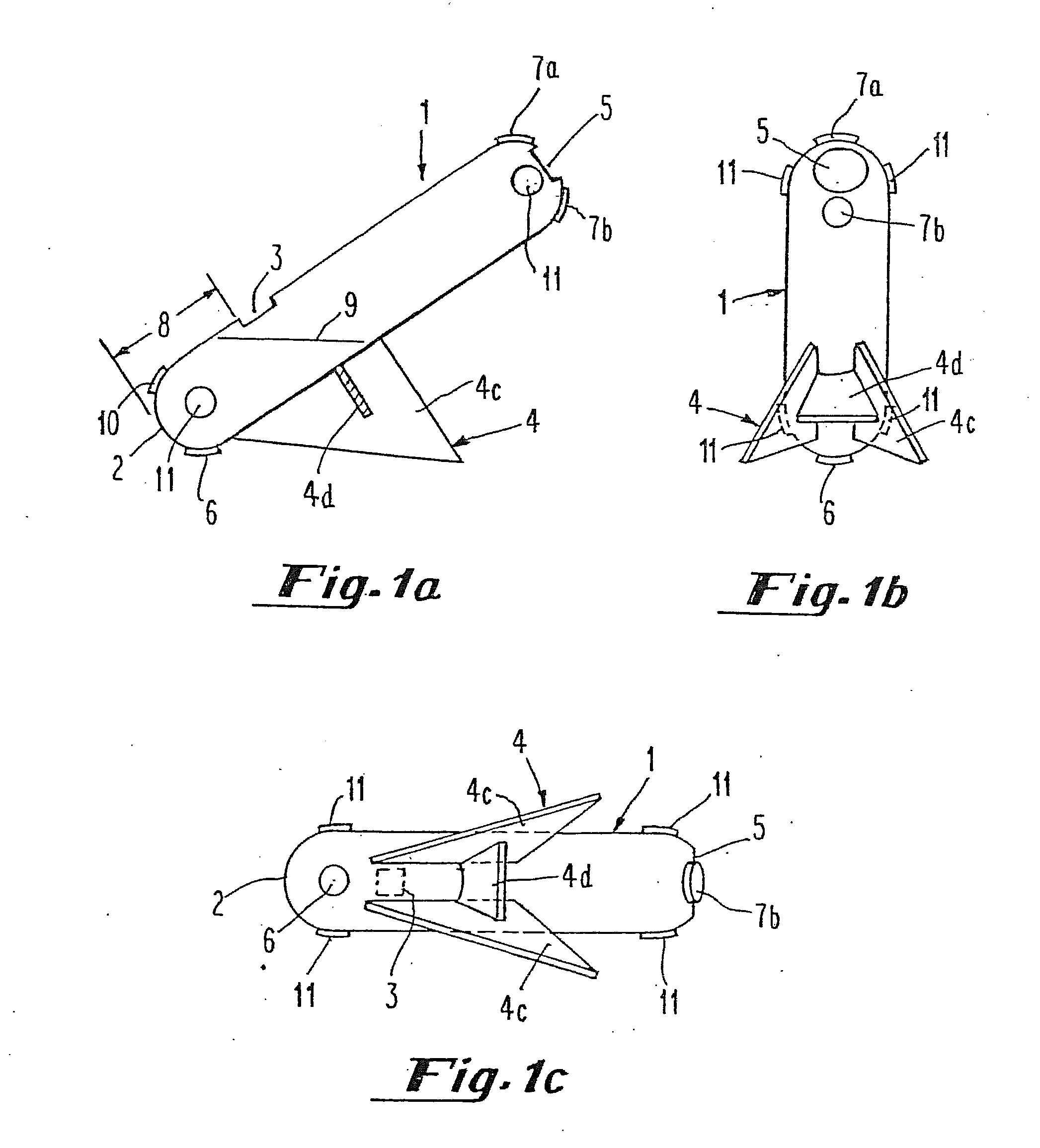

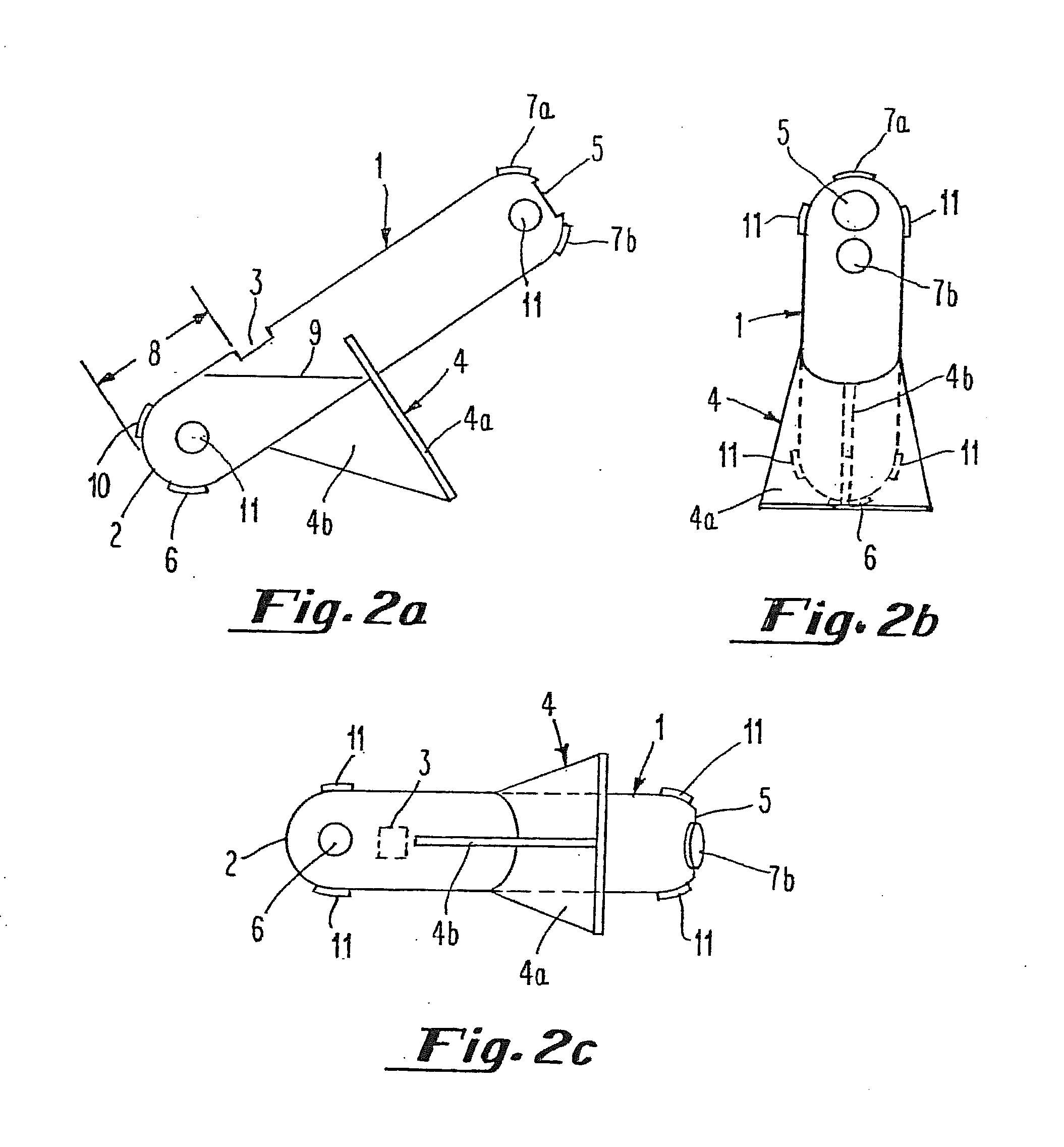

Inserter Device

InactiveUS20120095406A1Limited shelf lifePrevent insertionInfusion syringesSurgical needlesMedical deviceBiomedical engineering

The present application relates to an inserter device for inserting a medical device subcutaneous Iy which inserter device comprises a housing (1); a cover (2) which is slidably connected to the housing (1); a hub (5) for an insertion needle (4) which can be moved linearly relative to the housing (1) and relative to the cover (2); a primary spring (6) which moves the hub (5) for the insertion needle (4) relative to the cover (2) and which primary spring (6) is configured to pull the hub (5) for the insertion needle (4) either to a forward or to a retracted position wherein the inserter device further comprises means for biasing the primary spring (6) before insertion.

Owner:UNOMEDICAL AS

Limited-play optical media with improved shelf-life and playability

InactiveUS20040022986A1Complicated to manufactureIncrease costPhotosensitive materialsLayered productsMetal alloyReflective layer

Limited-play optical medium with improved shelf stability are formed from a plurality of layers, including in sequence: (a) a first substrate layer; (b) a data layer; (c) a reflective layer; (d) a reactive layer comprising a dye having a reduced state and an oxidized state and further comprising an oxidized form of a reducing agent effective to convert the dye from the oxidized state to the reduced state, and (e) a second substrate layer. The dye in the reduced state is substantially transparent to light of wavelengths used to read the optical medium, and the dye in the oxidized state absorbs light of wavelengths used to read the optical medium. The reflective metal layer is formed from a metal or metal alloy that is not significantly oxidized by the oxidized form of the reducing agent. For example, the reflective metal layer is suitably formed from silver or gold.

Owner:GENERAL ELECTRIC CO

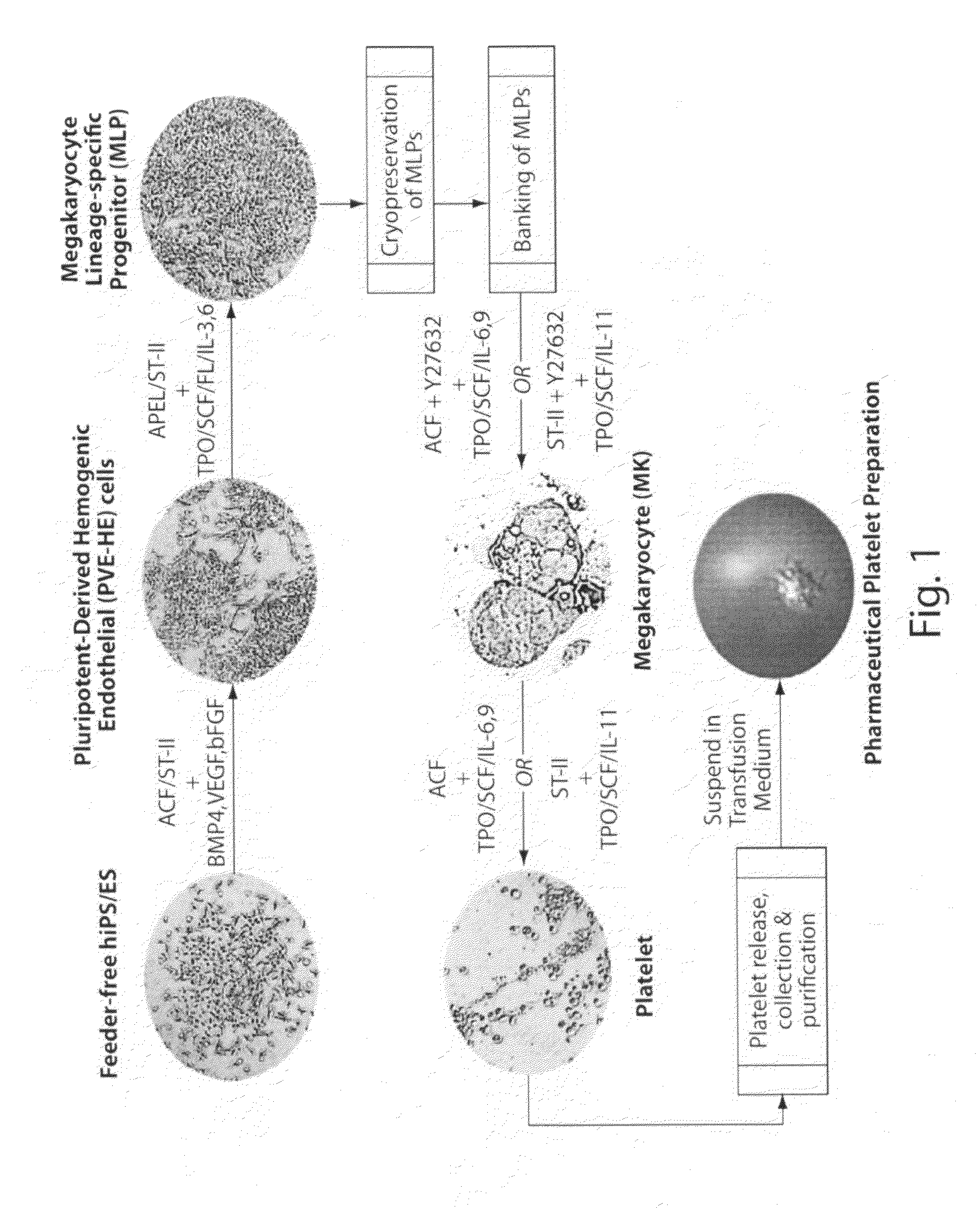

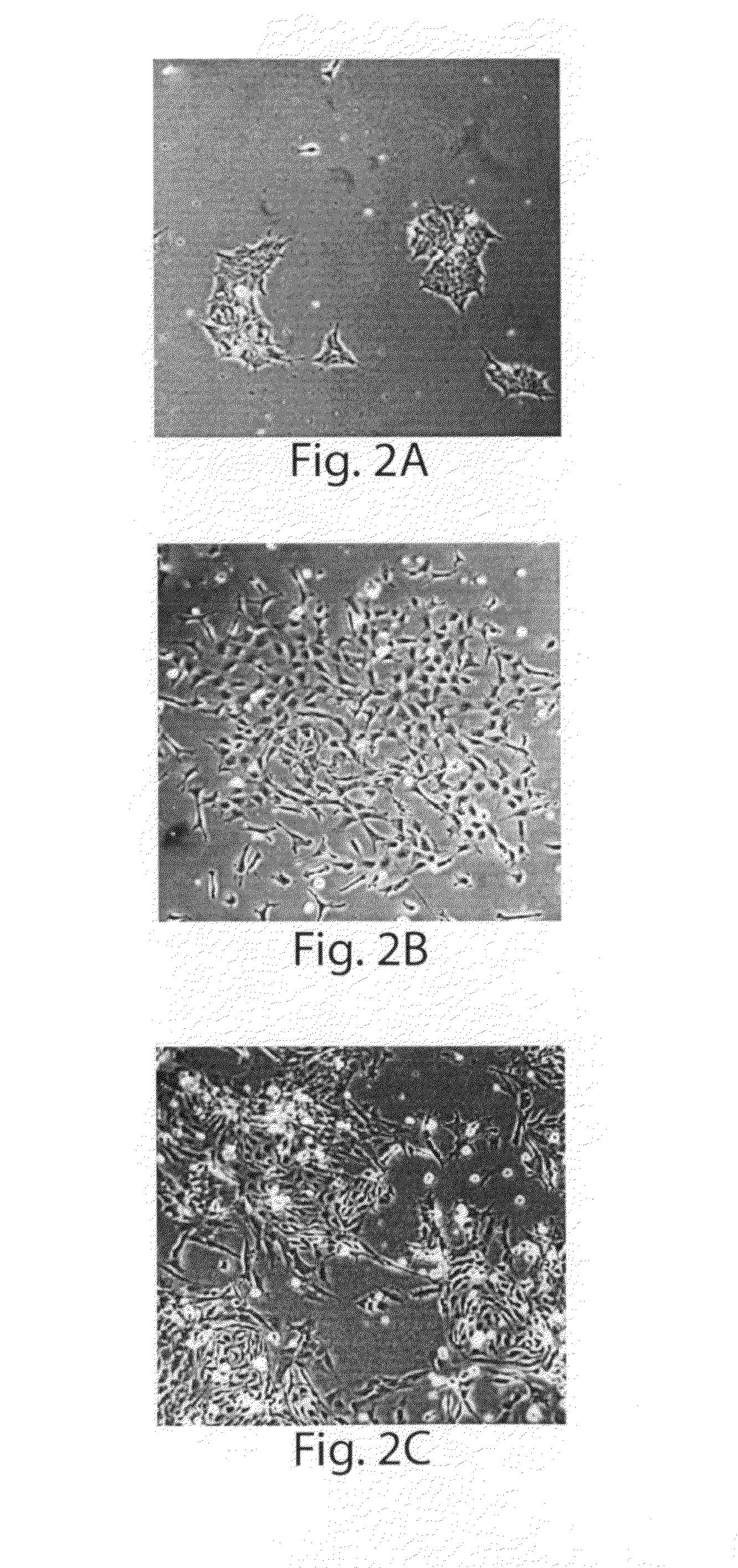

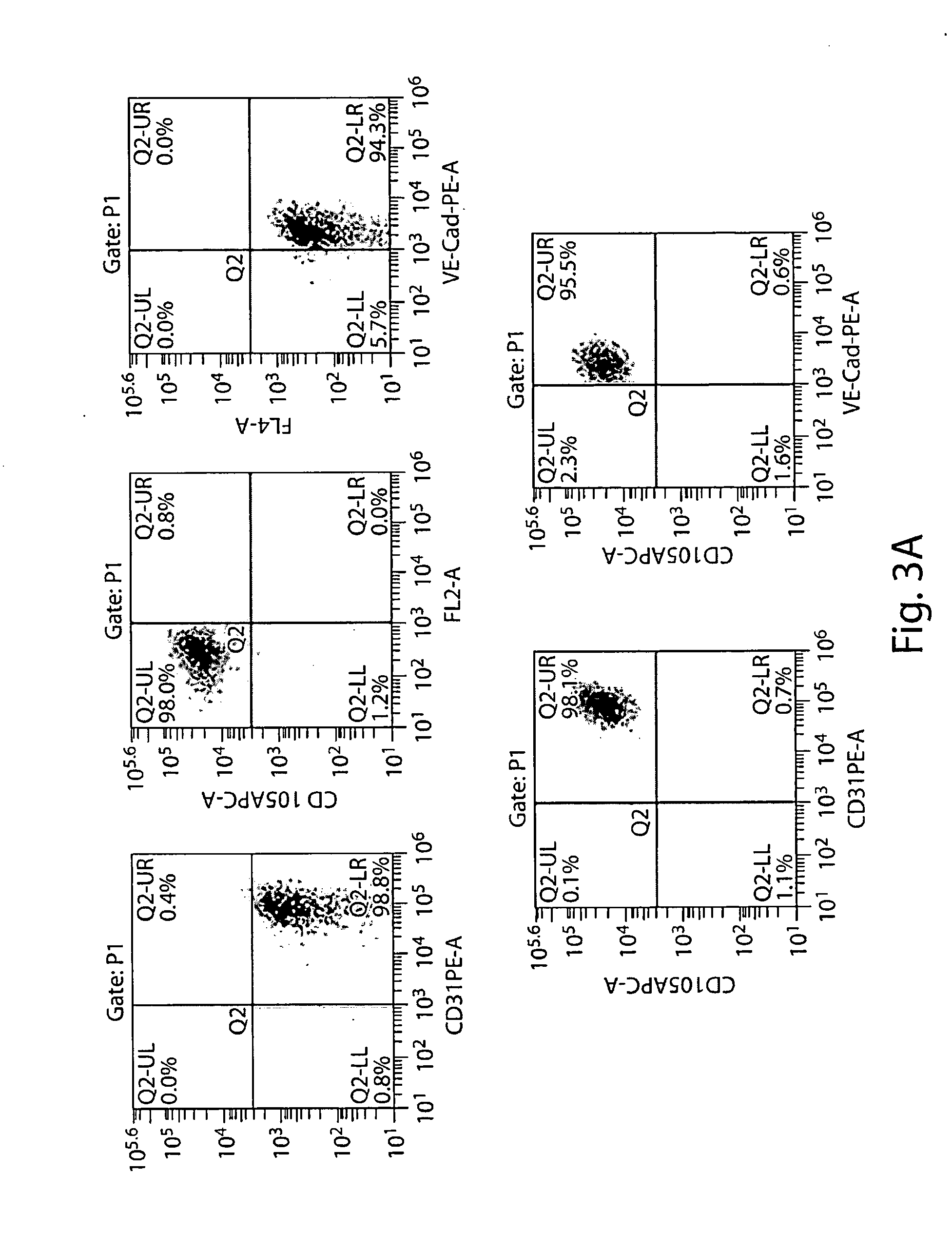

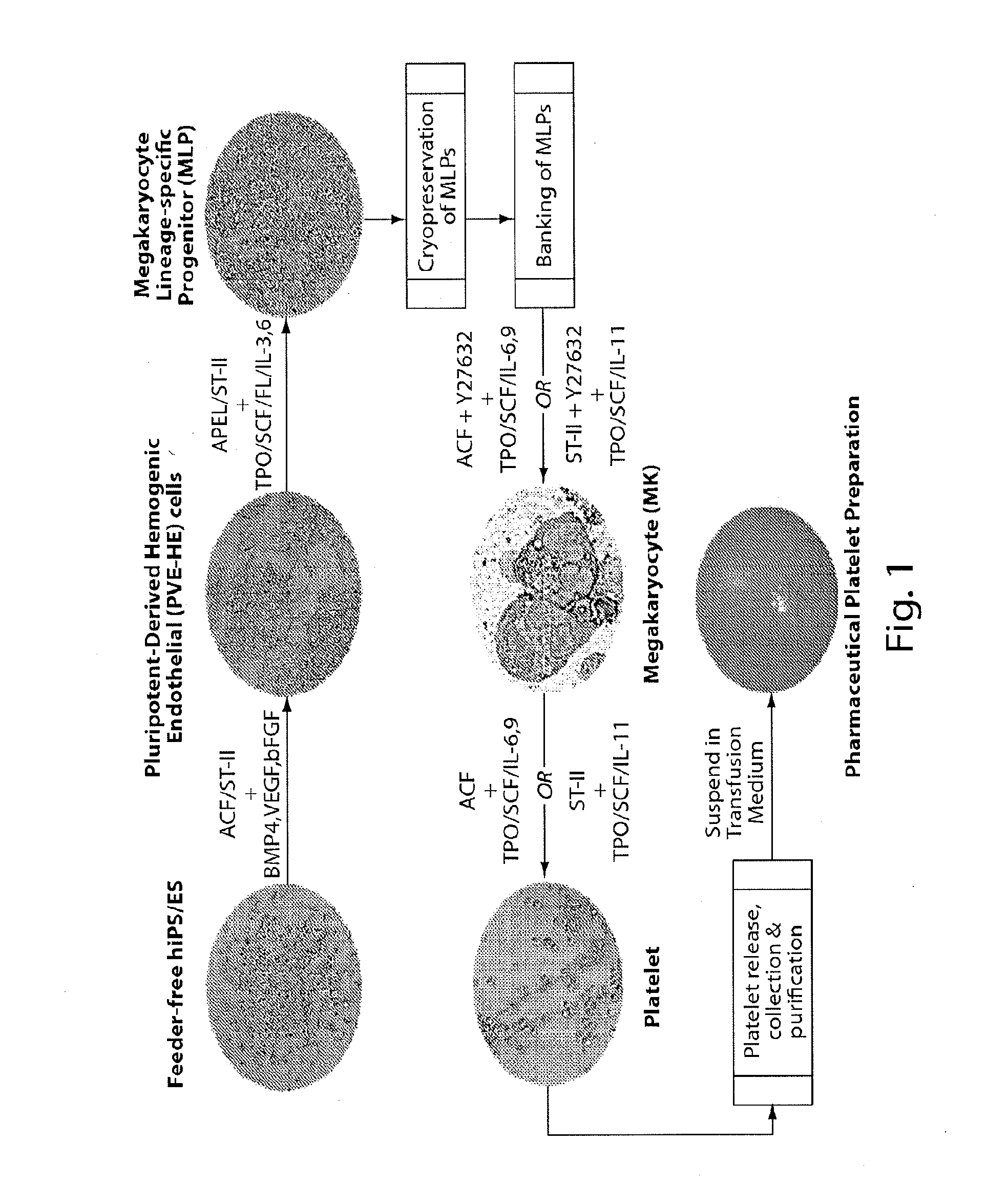

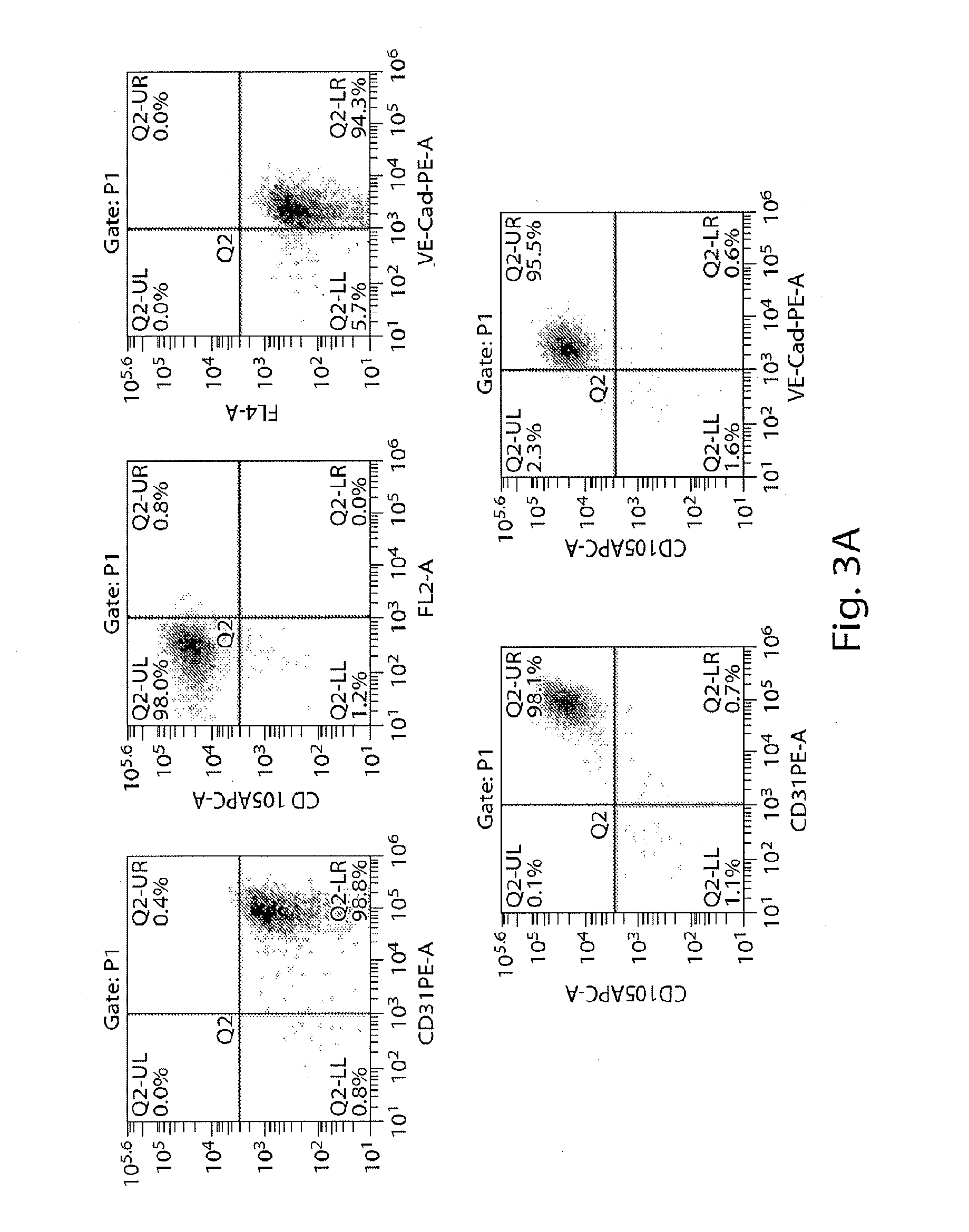

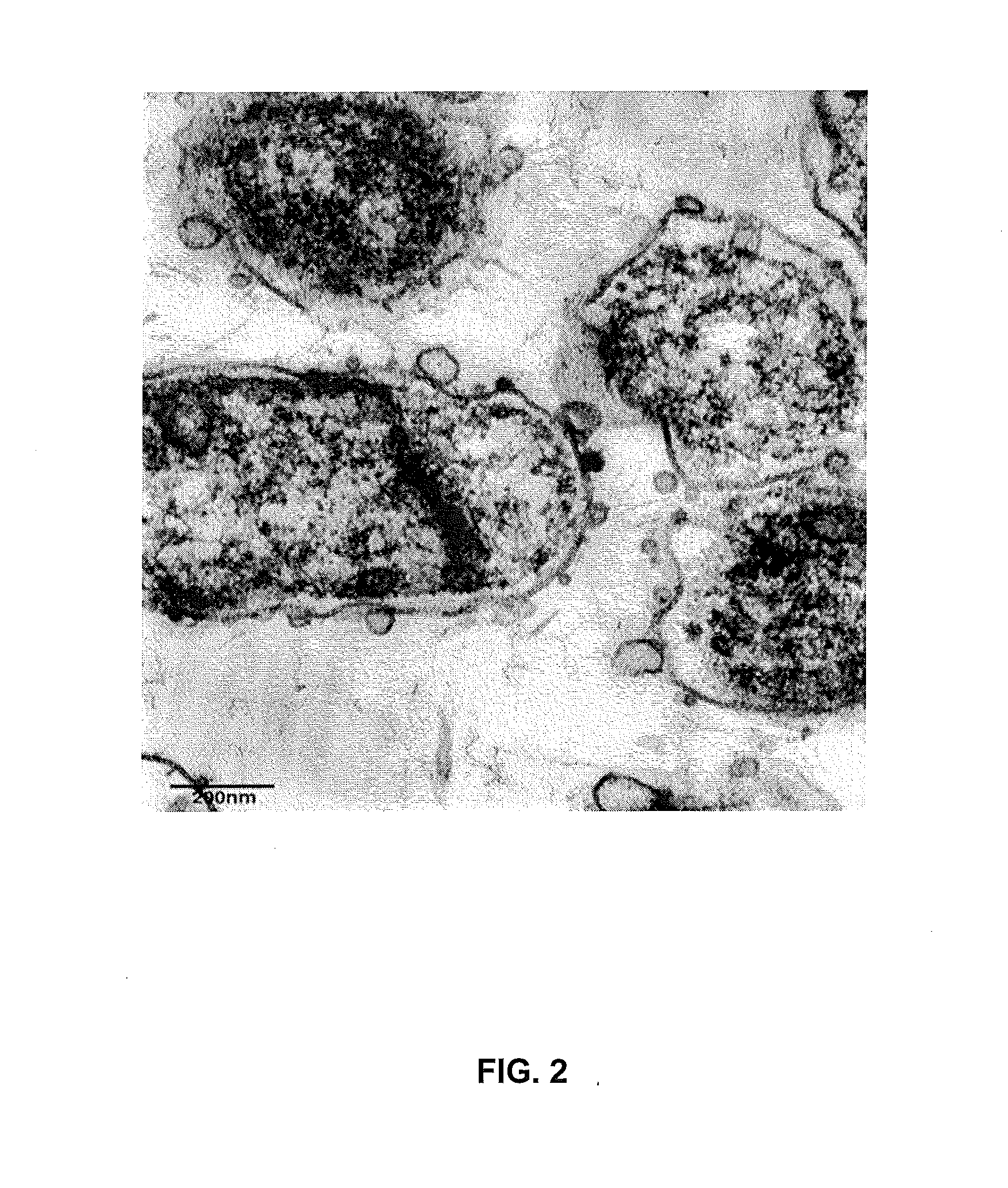

Methods for production of platelets from pluripotent stem cells and compositions thereof

ActiveUS20140271590A1Low immunogenicityEliminate pollutionBiocideMammal material medical ingredientsPlateletInducer Cells

Methods for production of platelets from pluripotent stem cells, such as human embryonic stem cells (hESCs) and induced pluripotent stem cells (iPSCs) are provided. These methods may be performed without forming embryoid bodies or clusters of pluripotent stem cells, and may be performed without the use of stromal inducer cells. Additionally, the yield and / or purity can be greater than has been reported for prior methods of producing platelets from pluripotent stem cells. Also provided are compositions and pharmaceutical preparations comprising platelets, preferably produced from pluripotent stem cells.

Owner:ADVANCED CELL TECH INC

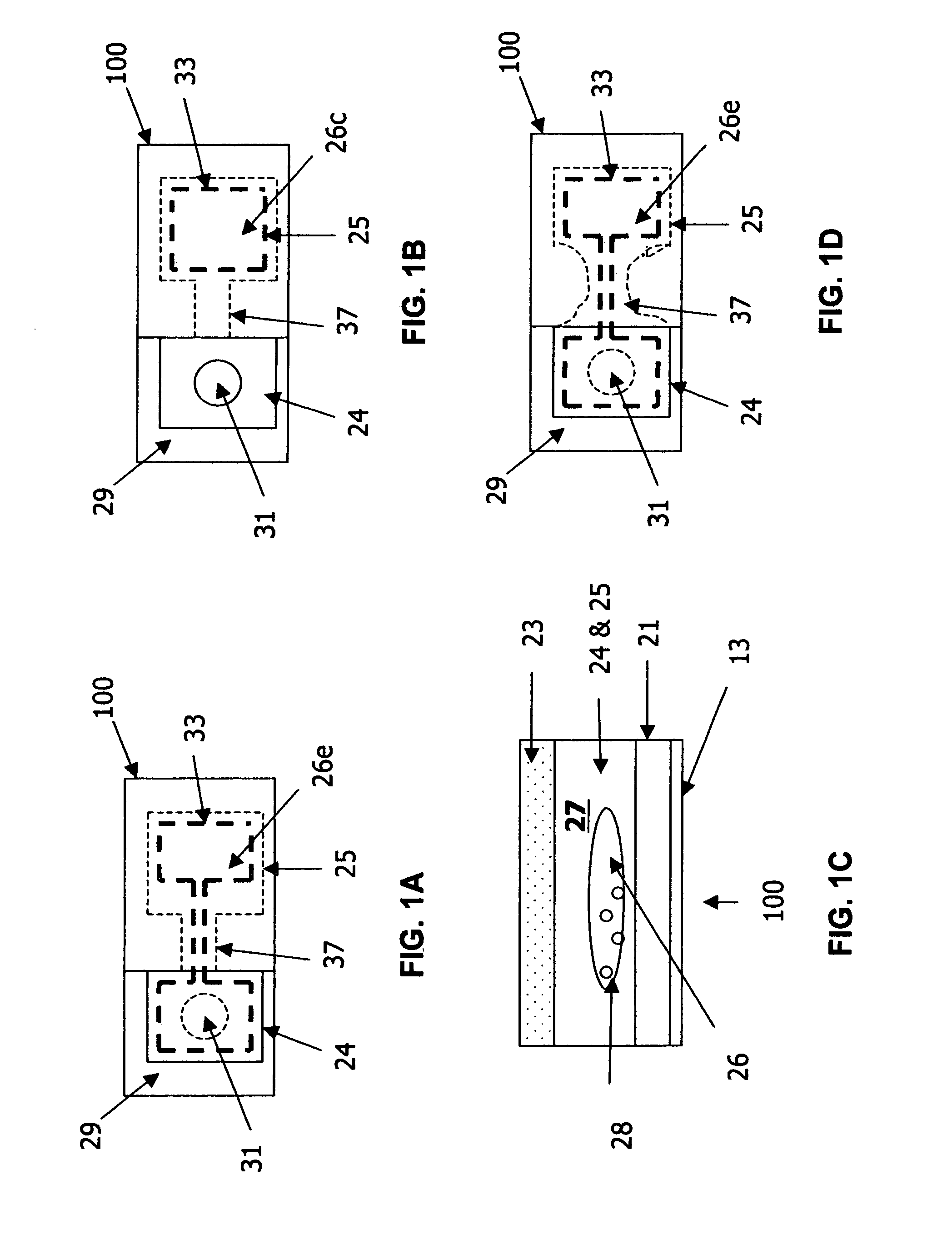

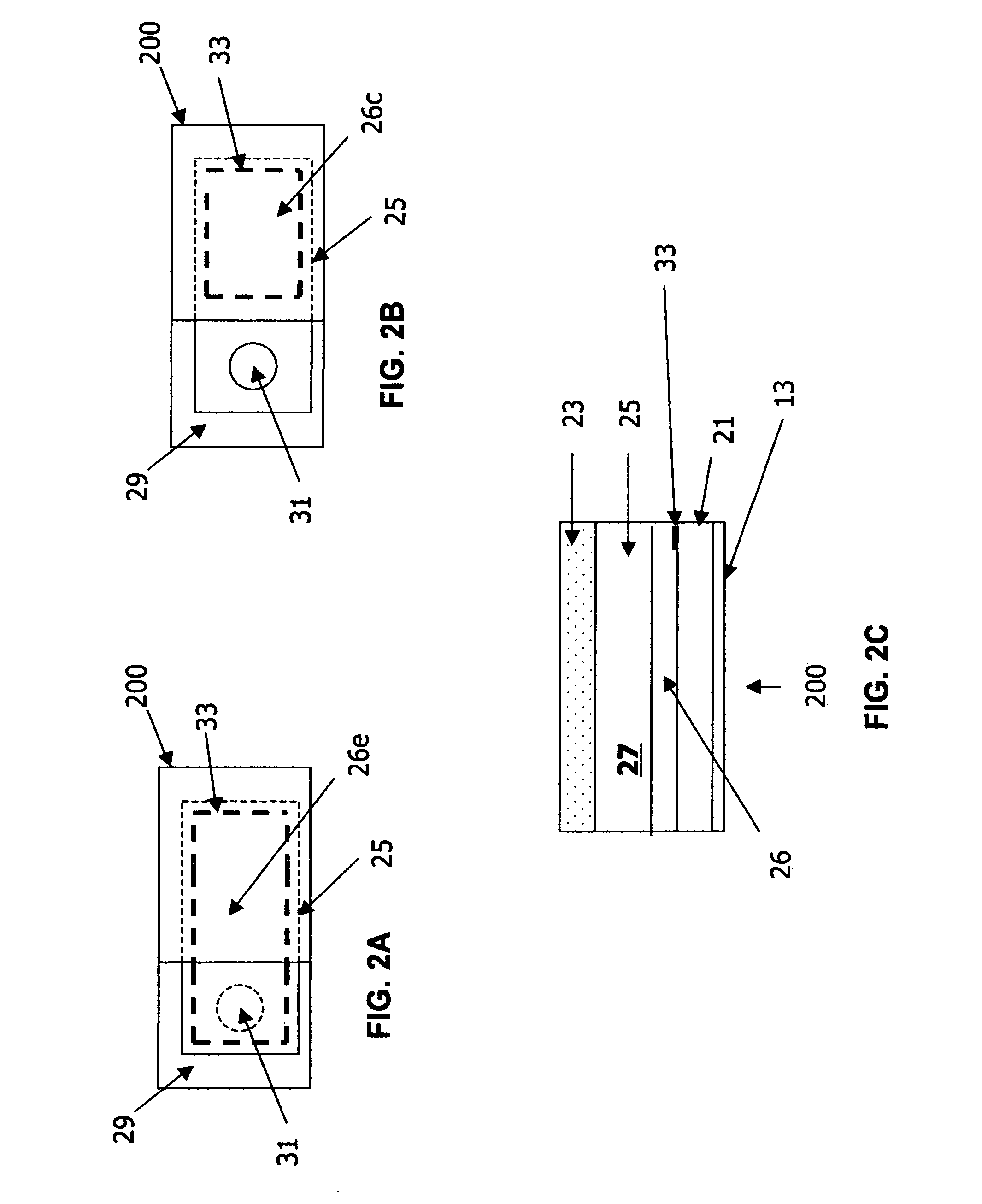

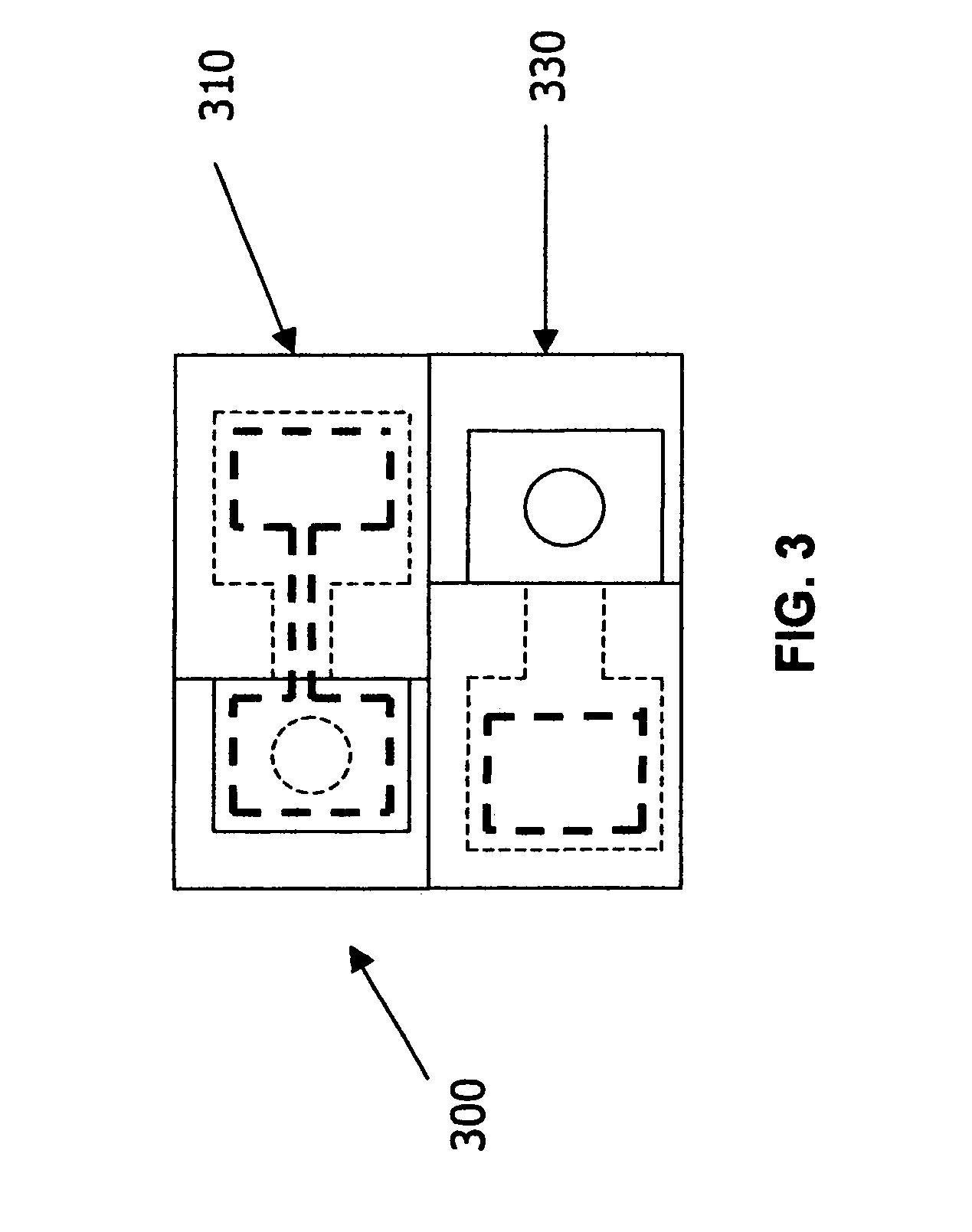

Stimulus indication employing polymer gels

InactiveUS20060262828A1Limited shelf lifeImprove effectivenessThermometers using mean/integrated valuesTemperature measurement in household appliancesMedicineVisual perception

Techniques and devices are presented for communicating exposure to a potentially harmful stimulus. The devices include a stimulus sensitive gel which changes volume in response to exposure to the stimulus and thereby presents a contrast in color that serves as a visual indicator that exposure to the stimulus has occurred.

Owner:PRASIDIUX LLC

Composition for promoting adhesion between rubber and textiles

InactiveUS6333281B1Limited shelf lifeStable aqueous dispersion/solutionAdhesive processesImpression capsSilane compoundsPolyester

A composition for the promotion of adhesion between a rubber formulation and a textile substrate is provided. The inventive composition comprises either a mixture of specific amine functional silanes and organo-functional silanes having reactive groups or groups with an affinity for rubber. The inventive method entails the use of the inventive composition or a silane compound having both an amine moiety and a reactive group having an affinity for rubber formulations, particularly an unsaturated carbon-carbon bond. The composition may be utilized to adhere any standard reinforcement-type textile, such as polyester or polyamide, to a standard rubber composition, such as SBR, NBR, or EPDM. A method for adhering textiles to rubber formulations is also provided involving a pre-dip, -spray, -coat, and the like, of the inventive composition on a reinforcement-type textile surface followed by the contacting of the rubber formulation. Optionally, and preferably, the process involves the extra utilization of resorcinol-formaldehyde latex as an effective bonding agent to improve the adhesion between the two layers. The resulting textile-reinforced rubber product may be utilized as an automobile fan or timing belt, an automobile tire component, and any other rubber article which requires long-lasting, durable textile reinforcement.

Owner:MILLIKEN & CO

Method for promoting adhesion between rubber and textiles

InactiveUS6346563B1Limited shelf lifeStable aqueous dispersion/solutionAdhesive processesImpression capsPolyesterSilane compounds

A composition for the promotion of adhesion between a rubber formulation and a textile substrate is provided. The inventive composition comprises either a mixture of specific amine functional silanes and organo-functional silanes having reactive groups or groups with an affinity for rubber. The inventive method entails the use of the inventive composition or a silane compound having both an amine moiety and a reactive group having an affinity for rubber formulations, particularly an unsaturated carbon-carbon bond. The composition may be utilized to adhere any standard reinforcement-type textile, such as polyester or polyamide, to a standard rubber composition, such as SBR, NBR, or EPDM. A method for adhering textiles to rubber formulations is also provided involving a pre-dip, -spray, -coat, and the like, of the inventive composition on a reinforcement-type textile surface followed by the contacting of the rubber formulation. Optionally, and preferably, the process involves the extra utilization of resorcinol-formaldehyde latex as an effective bonding agent to improve the adhesion between the two layers. The resulting textile-reinforced rubber product may be utilized as an automobile fan or timing belt, an automobile tire component, and any other rubber article which requires long-lasting, durable textile reinforcement.

Owner:MILLIKEN & CO

Methods for production of platelets from pluripotent stem cells and compositions thereof

ActiveUS20150313944A1Eliminate pollutionHigh purityBioreactor/fermenter combinationsBiocidePlateletInducer Cells

Methods for production of platelets from pluripotent stem cells, such as human embryonic stem cells (hESCs) and induced pluripotent stem cells (iPSCs) are provided. These methods may be performed without forming embryoid bodies or clusters of pluripotent stem cells, and may be performed without the use of stromal inducer cells. Additionally, the yield and / or purity can be greater than has been reported for prior methods of producing platelets from pluripotent stem cells. Also provided are compositions and pharmaceutical preparations comprising platelets, preferably produced from pluripotent stem cells.

Owner:ADVANCED CELL TECH INC

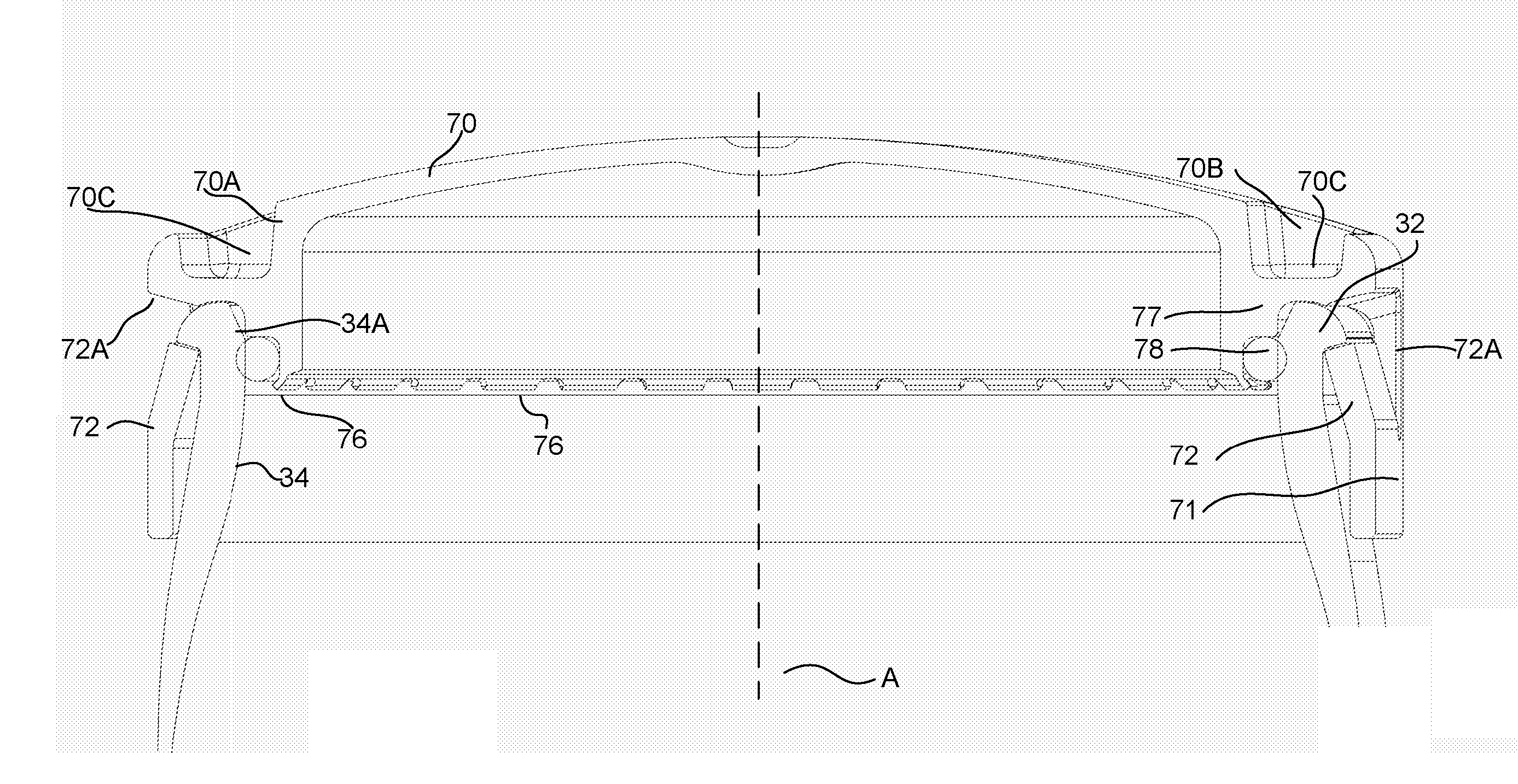

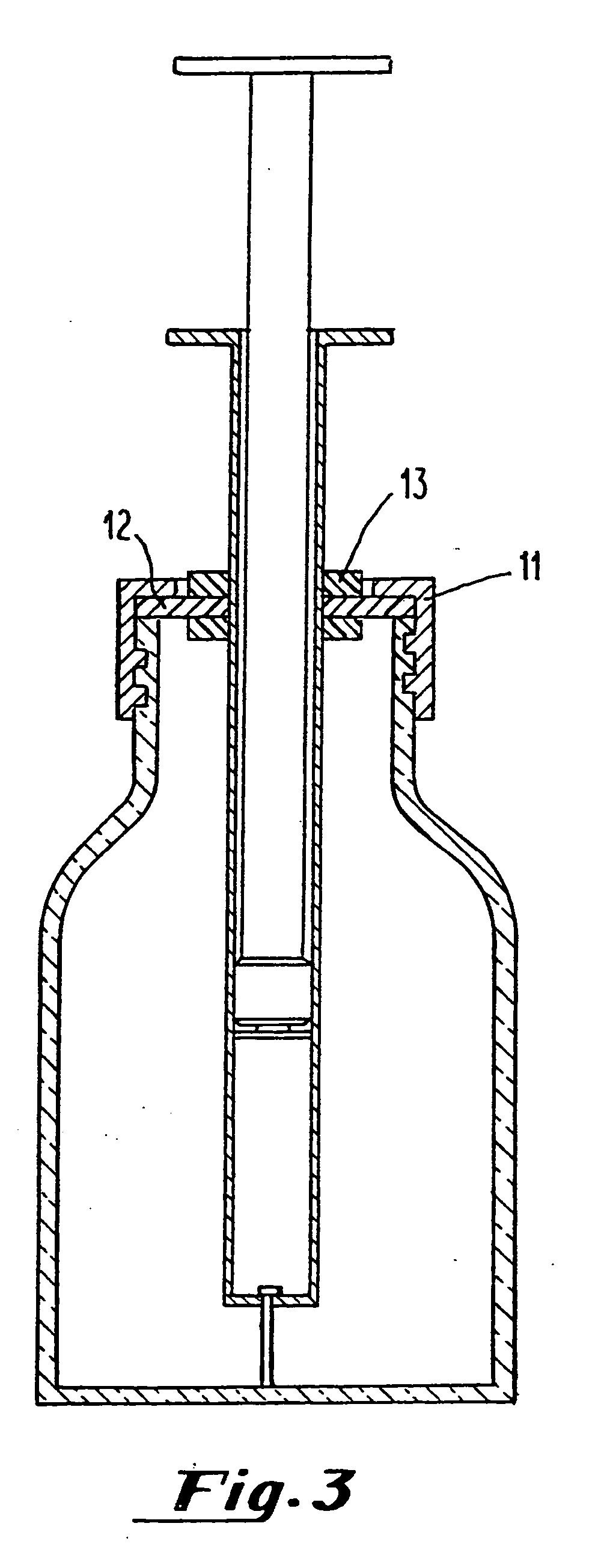

Closure for a container

InactiveUS20160107806A1Excellent gas barrier performanceResists compression setCapsDecorative coversElastomerPolyoxymethylene

A closure for releasably securing to a container adapted for storing foodstuff or a beverage, the closure comprising closing means (14) for closing a mouth of the container and securing means (22,23) for securing it in a closed position, the closing means and the securing means being formed of a plastics material comprising polyoxymethylene so as to provide a substantial gas barrier to the passage of oxygen and / or carbon dioxide therethrough, The closure may have a sealing member (18) formed of resilient material (compared to the rigid material of the remainder of the closure) for providing a seal between the closure and the container. The sealing member may be provided on a bore component which projects into the container so that, in use, it seals against an internal surface of the container. The sealing member may be an o-ring (18) formed of an elastomer, e.g. nitrile butadiene rubber. A foodstuff or beverage container, e.g. in the shape of a wine glass or the shape of a beer glass, having such a closure is also described. The use of a plastics material comprising polyoxymethylene for closing a container provides a barrier to the ingress of oxygen and / or to the egress of carbon dioxide to improve the shelf life of the product is also described.

Owner:KEMIRA OY +1

Enhanced Flexible Lightweight Ballistic, Stab and Spike resistant Materials

InactiveUS20120141720A1Limited shelf lifeUnlimited shelf lifeArmourLayered productsThermoplasticEngineering

The present invention provides a use of a thermoplastic composition for manufacturing a personal protection equipment for personal ballistic, stab and knife protection, wherein the thermoplastic composition comprises at least a first thermoplastic polymer that has a melting point different to the melting point of a second thermoplastic polymer. Further, the present invention provides a personal protection equipment comprising a plurality of ballistic fabric layers, and at least one thermoplastic composition for use in ballistic applications, wherein the thermoplastic composition comprises at least a first thermoplastic polymer as set forth above.

Owner:EI DU PONT DE NEMOURS & CO

Wood product and method therefor

InactiveUS6908677B2Limited shelf lifeLarge energyWood veneer joiningBaby linensProduction linePerformance-Enhancing Substances

A method comprising adding a suspension of a wood-property-enhancing substance to a wood product precursor. The suspension may be added to the wood product precursor in a production line prior to making a finished wood product. The suspension may be manufactured at a site where the wood product precursor is produced. A finished wood product may be made from the wood product precursor. An article is also described comprising a finished wood product made by adding a suspension of a wood-property-enhancing substance to a wood product precursor.

Owner:TIP - THE IND PIVOT

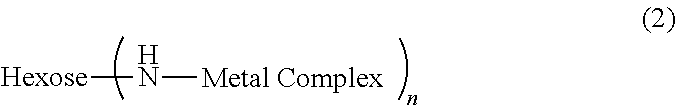

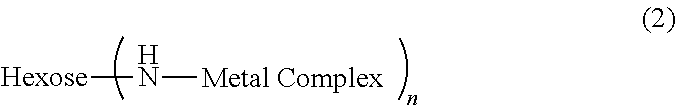

Metal chelate linked to a hexose carrier for use as a metallopharmaceutical diagnostic or therapeutic agent

ActiveUS8858916B2Affecting responseEasy to useOptical radiation measurementGeneral/multifunctional contrast agentsMetal chelateX-ray

A compound comprising a metal chelate linked to a hexose carrier for use as a metallopharmaceutical diagnostic or therapeutic agent is provided. The compound is suitable for imaging by single-photon emission computed tomography, computer assisted tomography, magnetic resonance spectroscopy, magnetic resonance imaging, positron emission tomography, fluorescence imaging or x-ray.

Owner:MALLINCKRODT NUCLEAR MEDICINE LLC

Vinyl acetate/ethylene and ethylene/vinyl chloride blends as binders for nonwoven products

ActiveUS7153791B2Improve performanceEasy curingSynthetic resin layered productsWoven fabricsCelluloseEmulsion

This invention is directed to an improvement in binders particularly suited for use in preparing nonwoven products and to the nonwoven products. The improved binders comprise a blend of emulsion polymerized ethylene-vinyl chloride (EVCl) polymer and an emulsion polymerized self crosslinkable vinyl acetate-ethylene-N-methylolacrylamide (VAE-NMA) polymer. The blends of the EVCl polymer emulsion and the VAE-NMA polymer emulsion can be applied to cellulose and cellulose / synthetic nonwoven substrates and cured in the absence of an acid catalyst to provide a self-sustaining web having excellent wet strength performance. The blends of EVCl and VAE-NMA polymers do not require an acid catalyst to facilitate cure.

Owner:WACKER CHEM CORP

Antimicrobial compositions and methods of use

ActiveUS20160007594A1Improve solubilityLow polydispersity indexCosmetic preparationsBiocideEmulsionMicrobiology

Owner:PURDUE RES FOUND INC

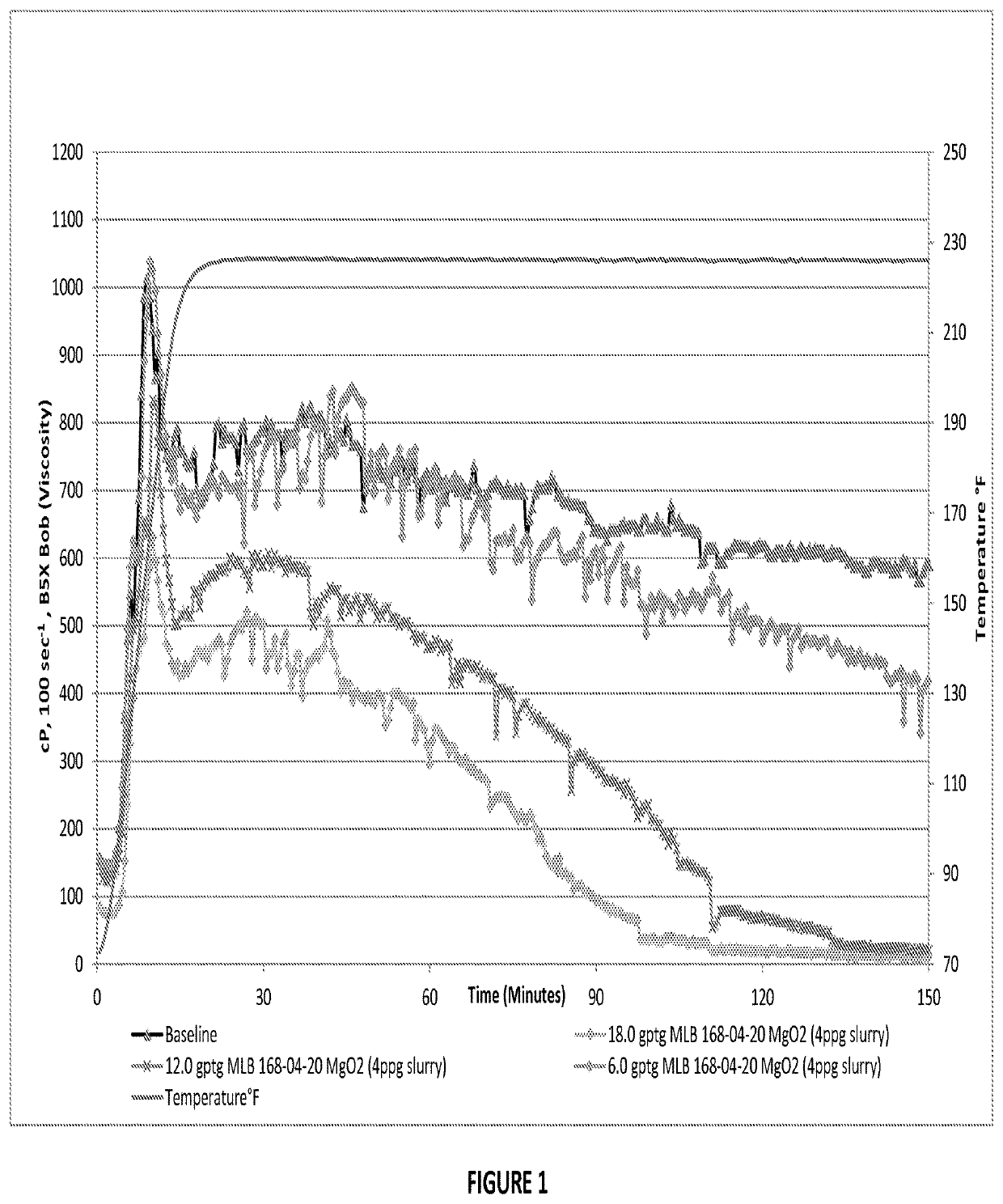

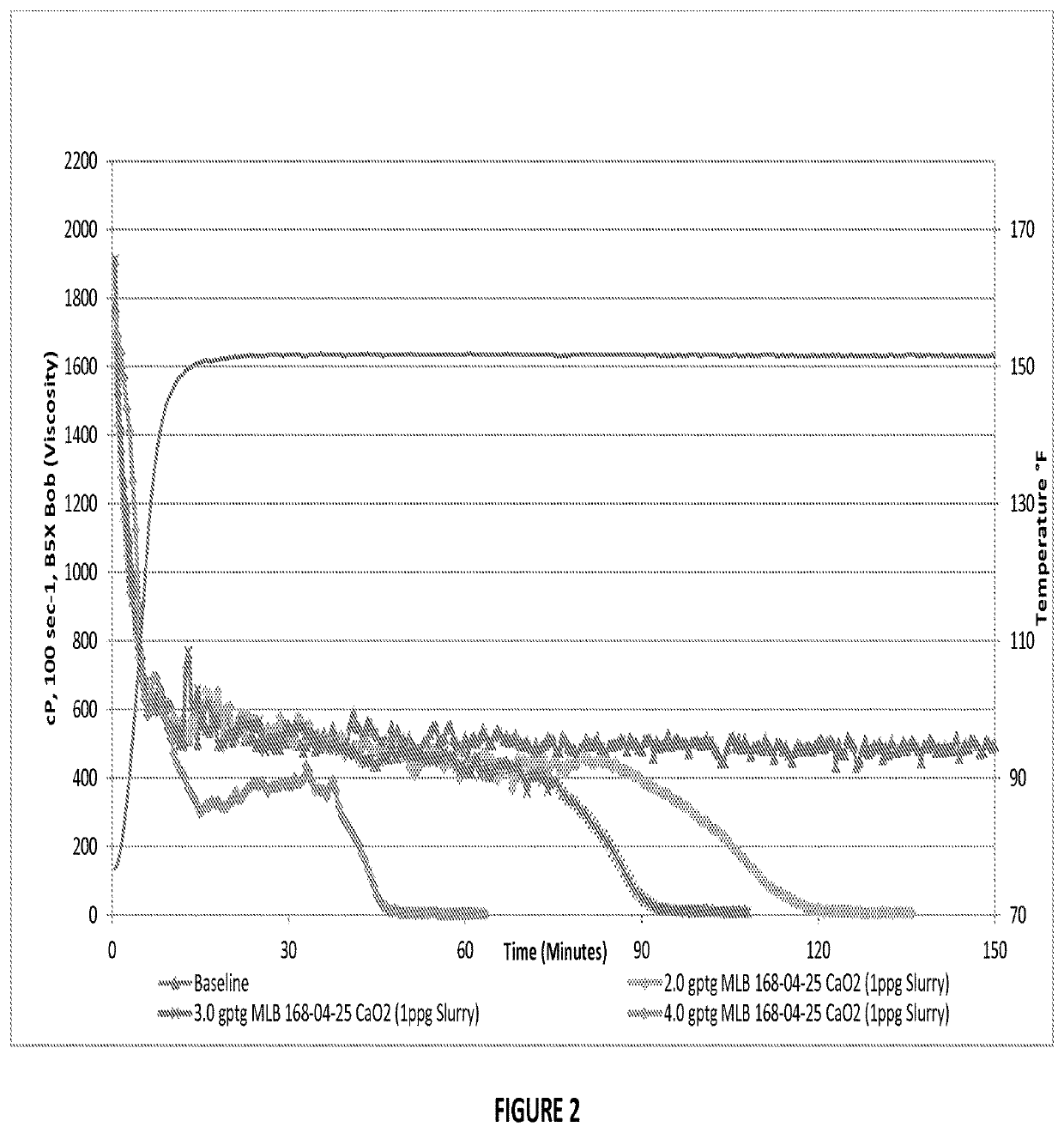

Oxidative breakers in a silicone based suspension

ActiveUS10696887B2Reduce flammabilityExtended shelf lifeDrilling compositionSuspending AgentsSilicon dioxide

An oxidative breaker system for use in reducing the viscosity of a polysaccharide-based or derivatized polysaccharide-based suspension includes a silicone carrier fluid, an oxidizer, and a suspension aid. The suspension aid is preferably fumed silica. The oxidizer may be selected from the group consisting of alkali metal peroxide, transition metal peroxide, persulfate compound, bromide compound, and bromate compound. In highly preferred embodiments, the oxidizer is magnesium peroxide or calcium peroxide. Alternative carrier fluids and suspension agents are also included in the art. Also disclosed is a method for breaking a polysaccharide-based suspension with the inventive oxidative breaker system.

Owner:FLOTEK CHEM LLC

Decorative material midbody with split-packaged chemical additive

InactiveCN102674757AFlexible and convenient quality control measuresSave drying energyChemical additionMaterials science

The invention discloses a decorative material midbody with split-packaged chemical additives and relates to a novel material, in particular to the production and the application of a novel decorative material. The decorative material midbody with split-packaged chemical additives is packaged by classification according to the length of quality guarantee periods of component materials, wherein a component A consists of chemical additives, fillers and pigments with the quality guarantee period being above six months, and a component B consists of hydraulic inorganic solidifying materials with the quality guarantee period being only three months. The decorative material midbody with split-packaged chemical additives has the advantages that the advantage that the quality guarantee period of the component A is long is exerted, the difficulty in storage and transportation is reduced and the wastage of fillers, pigments and additives is reduced; and the emphasized safekeeping and storage of the component B with the short quality guarantee period are facilitated, the component B can be taken out from the unused midbody for timely use or be replaced by new component B when the deadline of the quality guarantee period approaches, and the situations of potential engineering hazards and energy wastage are avoided.

Owner:上海绿特丹保温工程有限公司

Paper product and method therefor using molten wax suspension

InactiveUS7255776B2Good dispersionMaintain stabilityNatural cellulose pulp/paperSpecial paperProduction lineWax

A method including improving a property of a paper product precursor by adding a molten wax suspension to paper product precursor, the molten wax suspension including a suspension of liquid wax particles in a liquid solvent, the liquid wax particles being at a temperature higher than the melting point of the wax. The molten wax suspension may be added to the paper product precursor in a production line prior to making a finished paper product. A finished paper product may be made from the paper product precursor.

Owner:TIP - THE IND PIVOT

Vinyl acetate/ethylene and ethylene/vinyl chloride blends as binders for nonwoven products

ActiveUS20060052017A1Stable shelf life viscosityHigh viscositySynthetic resin layered productsWoven fabricsCelluloseEmulsion

This invention is directed to an improvement in binders particularly suited for use in preparing nonwoven products and to the nonwoven products. The improved binders comprise a blend of emulsion polymerized ethylene-vinyl chloride (EVCl) polymer and an emulsion polymerized self crosslinkable vinyl acetate-ethylene-N-methylolacrylamide (VAE-NMA) polymer. The blends of the EVCl polymer emulsion and the VAE-NMA polymer emulsion can be applied to cellulose and cellulose / synthetic nonwoven substrates and cured in the absence of an acid catalyst to provide a self-sustaining web having excellent wet strength performance. The blends of EVCl and VAE-NMA polymers do not require an acid catalyst to facilitate cure.

Owner:WACKER CHEM CORP

Paper product and method therefor using molten wax suspension

InactiveUS20050230074A1Avoid dustPrevent lintNatural cellulose pulp/paperSpecial paperWaxProduction line

A method including improving a property of a paper product precursor by adding a molten wax suspension to paper product precursor, the molten wax suspension including a suspension of liquid wax particles in a liquid solvent, the liquid wax particles being at a temperature higher than the melting point of the wax. The molten wax suspension may be added to the paper product precursor in a production line prior to making a finished paper product. A finished paper product may be made from the paper product precursor.

Owner:TIP - THE IND PIVOT

Methods and formulations for the efficient delivery of drugs by nebulizer

InactiveUS20060171897A1Reduced stabilityLimited shelf lifeDispersion deliveryAerosol deliveryNebulizerWater insoluble

Formulations, methods and devices for producing formulations and methods for nebulizer delivery of formulations of water-insoluble drugs and drugs requiring storage in aqueous or other water-miscible pharmaceutically unacceptable vehicles for stability are provided. Also provided are methods for minimizing wastage of drugs administered by nebulizer, and for the achievement of quantitative dosing with diluent from a mass marketed formulations, which because of the mass market is much less costly per dose than formulations manufactured specifically for much lower volume medical use.

Owner:COIFMAN ROBERT E

Phenol-formaldehyde resin having low concentration of tetradimer

InactiveUS7807748B2Improve stabilityLimited shelf lifeSynthetic resin layered productsAldehyde/ketone condensation polymer adhesivesFiberGlass fiber

A phenol-formaldehyde resin, having a low concentration of tetradimer, making the resin suitable for preparing a binder composition for making non-woven fiber products, such as fiberglass insulation, prepared by reacting phenol and formaldehyde in the presence of a sulfite source.

Owner:GEORGIA PACIFIC CHEM LLC

Methods and Formulations for the Efficient Delivery of Drugs by Nebulizer

InactiveUS20090007906A1Reduced stabilityLimited shelf lifeRespiratorsDispersion deliveryNebulizerWater insoluble

Formulations, methods and devices for producing formulations and methods for nebulizer delivery of formulations of water-insoluble drugs and drugs requiring storage in aqueous or other water-miscible pharmaceutically unacceptable vehicles for stability are provided. Also provided are methods for minimizing wastage of drugs administered by nebulizer, and for the achievement of quantitative dosing with diluent from a mass marketed formulations, which because of the mass market is much less costly per dose than formulations manufactured specifically for much lower volume medical use.

Owner:COIFMAN ROBERT E

Version of FDG Detectable by Single-Photon Emission Computed Tomography

ActiveUS20110177004A1Limited shelf lifeEasy to useOptical radiation measurementPeptide/protein ingredientsPhoton emissionMetal chelate

A compound comprising a metal chelate linked to a hexose carrier for use as a metallopharmaceutical diagnostic or therapeutic agent is provided. The compound is suitable for imaging by single-photon emission computed tomography, computer assisted tomography, magnetic resonance spectroscopy, magnetic resonance imaging, positron emission tomography, fluorescence imaging or x-ray.

Owner:MALLINCKRODT NUCLEAR MEDICINE LLC

Antimicrobial food package

InactiveUS20150175336A1Quality improvementLimited shelf lifeBiocideInorganic active ingredientsAntimicrobial surfaceThin membrane

A package comprising packaging material defining an enclosed space suitable for containing an item susceptible to microbial growth or spoilage is described. An interior of the package comprises at least one antimicrobial surface bearing an ordered nanoarray of metal or metal oxide nanostructures. A packaging material in the form of a sheet or film having a first face and a second face, in which at least a portion of one of the first or second faces of the film comprises a surface bearing a nanoarray of metal or metal oxide nanostructures, is also described.

Owner:UNIV COLLEGE CORK NAT UNIV OF IRELAND CORK

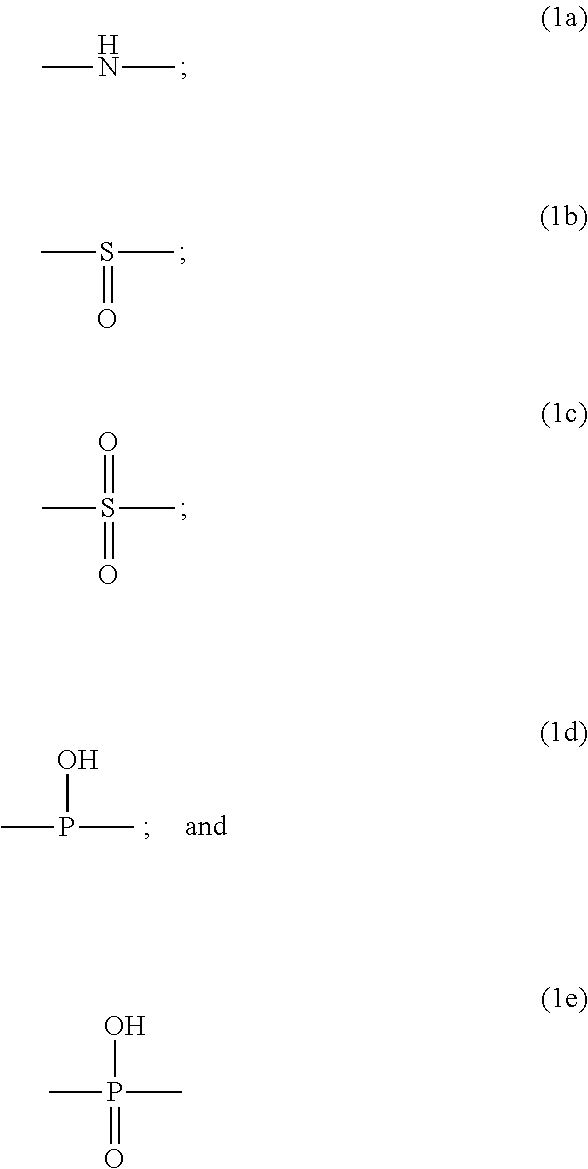

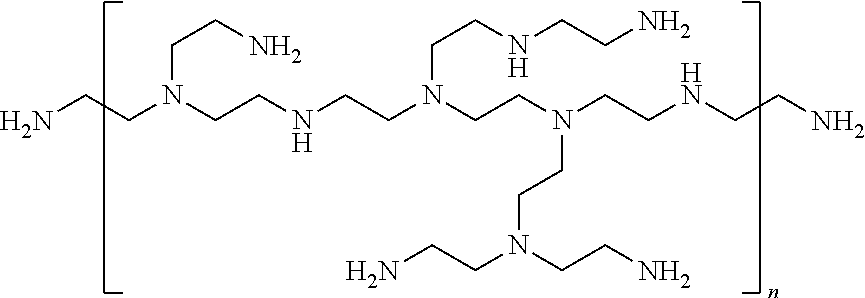

Carboxylated polyamine derivatives as transfection reagents

ActiveUS20150275220A1Improve signal-to-noise ratioEfficient transfectionOrganic active ingredientsInksPerylene derivativesTransfection

The invention provides polyamine derivatives, a use of the polyamine derivatives for the transfection of polyanions into cells, and a method of transfecting cells with a polyanion, comprising mixing said polyanion with a polyamine derivative e.g. in a buffer and treating said cells with the mixture obtained in the previous step.

Owner:BIONTECH DELIVERY TECH GMBH

Condom

InactiveUS20160015668A1Limited shelf lifeImprove stabilityBiocidePowder deliveryDusting powdersActive agent

There is provided a condom having a coating or deposit of a composition which includes a physiologically-active agent such as glyceryl trinitrate, wherein the condom has been treated with a neutralising or acidic material such that the condom, when immersed in water, results in the water having a pH of 7 or less. The condom may be treated with an acidic slurry of dusting powder. Also provided is a process for the manufacture of condoms, in which the process includes the steps of: 1) treating the formed condoms with a neutralising or acidic material; and 2) thereafter applying to the condoms a composition including a physiologically-active agent such as glyceryl trinitrate, wherein the condoms, when immersed in water, results in the water having a pH of 7 or less.

Owner:FUTURA MEDICAL DEV LTD

Buffered compositions and methods for their use in surface treatments

PendingUS20190209471A1Reduce skin irritationLow toxicityHydroxy compound active ingredientsTetracycline active ingredientsSurface finishingAnatomic Surface

The present invention comprises buffered compositions and methods for antiseptically treating or pretreating anatomic surfaces for invasive surgical or treatment procedures. The compositions and methods according to the present invention find use in treating skin, gums and ocular surfaces for injections and other procedures. The buffered compositions of the present invention comprise antiseptic agents, optionally within an aqueous gel or semi-gel formulation, to provide enhanced methods of treating anatomic surfaces such as the gums or eye prior to surgical or other invasive procedures. Buffered compositions provide additional benefits to standard non-buffered preparations including decreased toxicity to the anatomic surfaces, which improves post-procedural discomfort and vision in the case of ocular surfaces.

Owner:PANASEEA LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com