Patents

Literature

30results about How to "Save drying energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

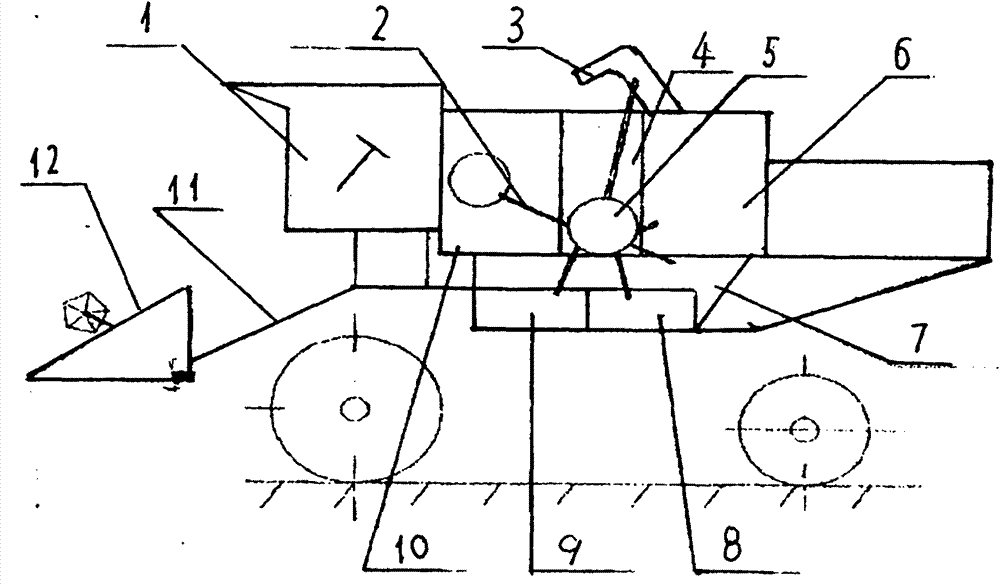

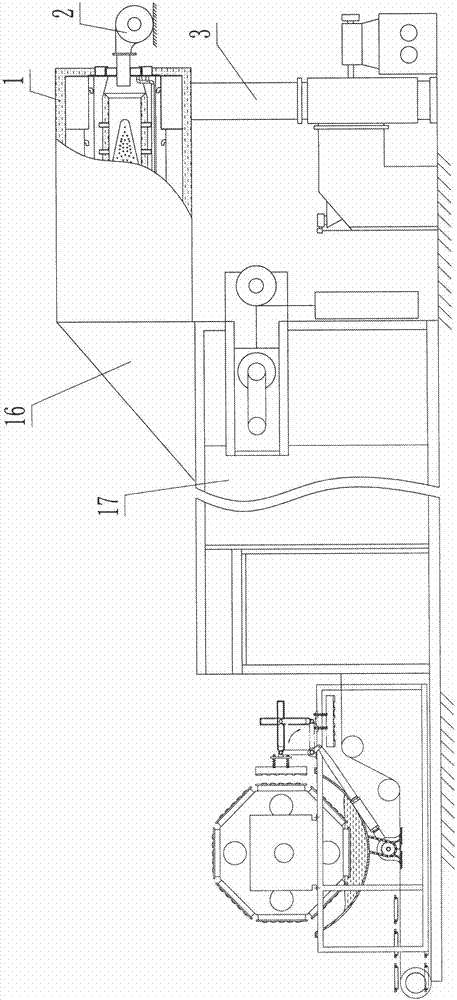

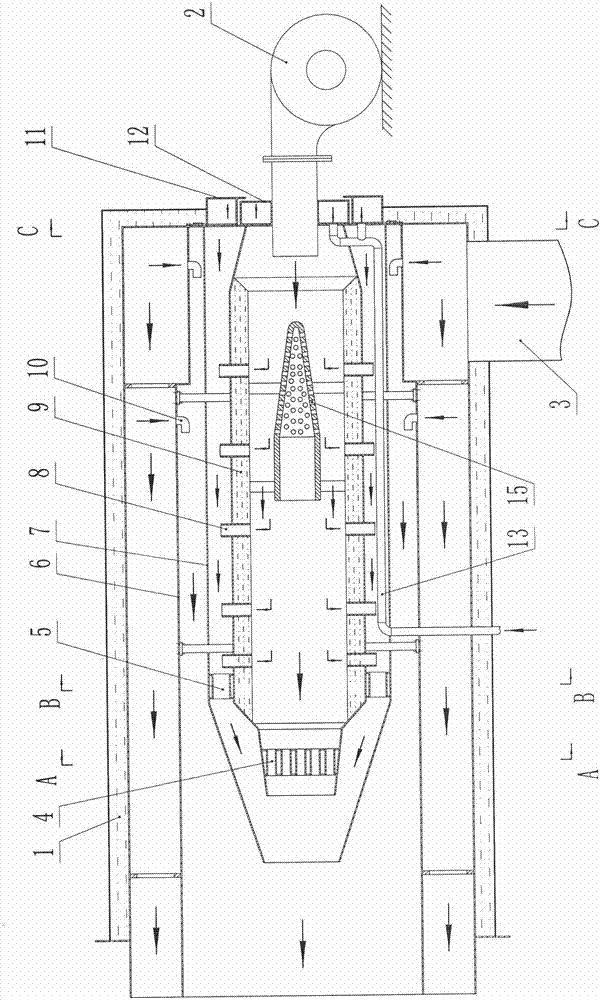

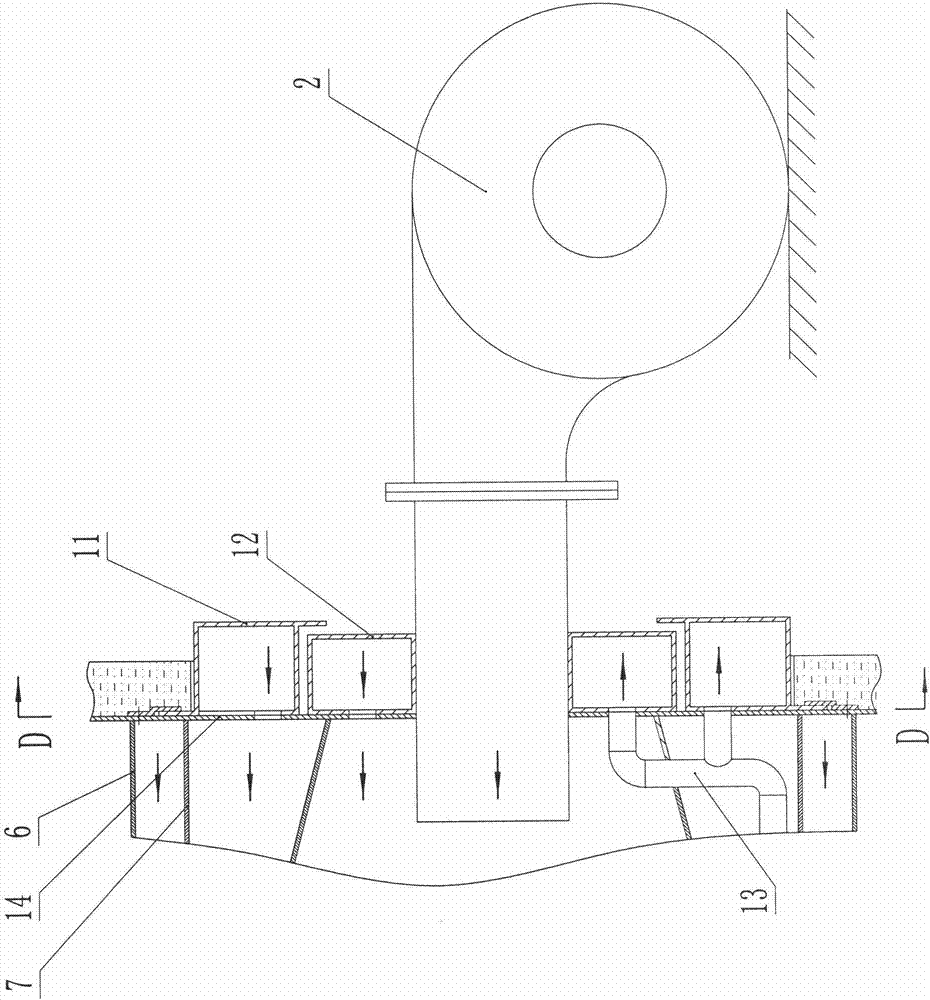

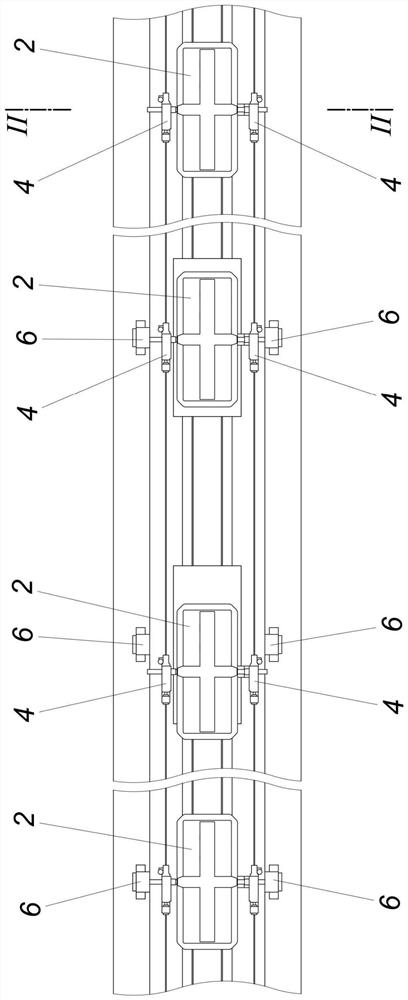

Grain combine harvester with drying function

The invention provides a grain combine harvester with a drying function, and belongs to agricultural machinery. A hot smoke acquiring and distributing device is fitted on a grain harvester combine body and is communicated with a hot smoke exhausting pipe of engine. Hot gas delivering pipes communicate the hot smoke acquiring and distributing device to a threshing device, a separating device, a selecting device, a grain delivering device, a grain bin and a grain discharging device. The heat of hot waste gas exhausted by the engine of the grain harvester combine is utilized, heat is added in each mechanical device for the grains in the grain combine harvester to pass by, accordingly the grains can be dried, parts of free water and combined water in the grains are allowed to evaporate, beneficial conditions are created for post-operation of a drier, and the grain combine harvester has the advantages that novel and reasonable design, fine operating effect, reliability of usage, efficient drying energy and low drying cost.

Owner:侯林山

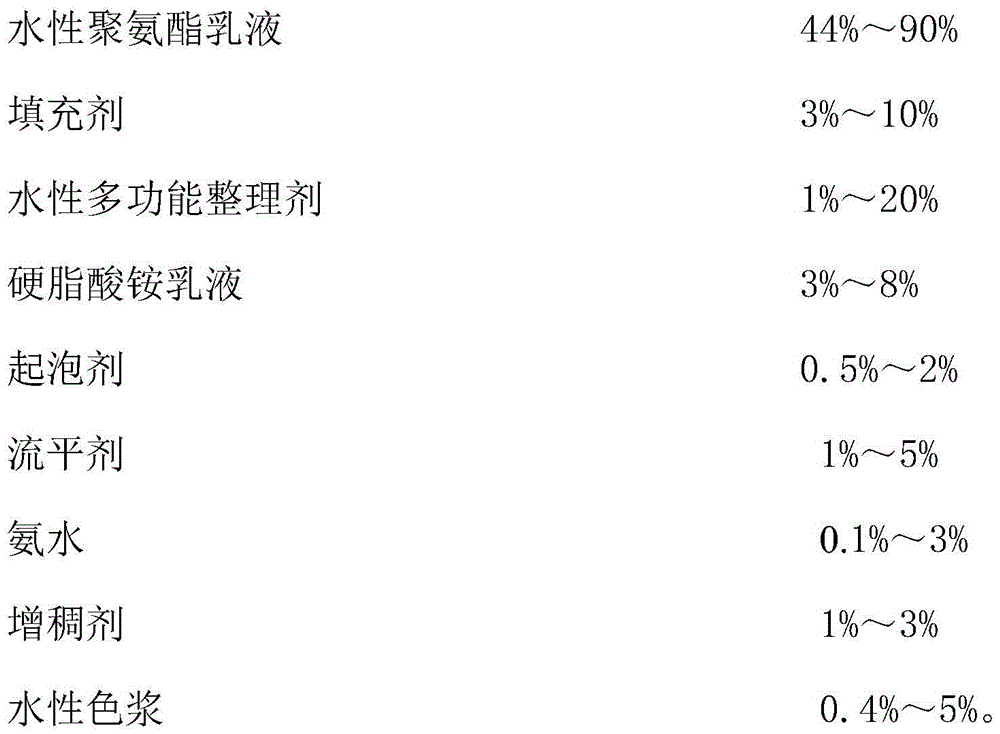

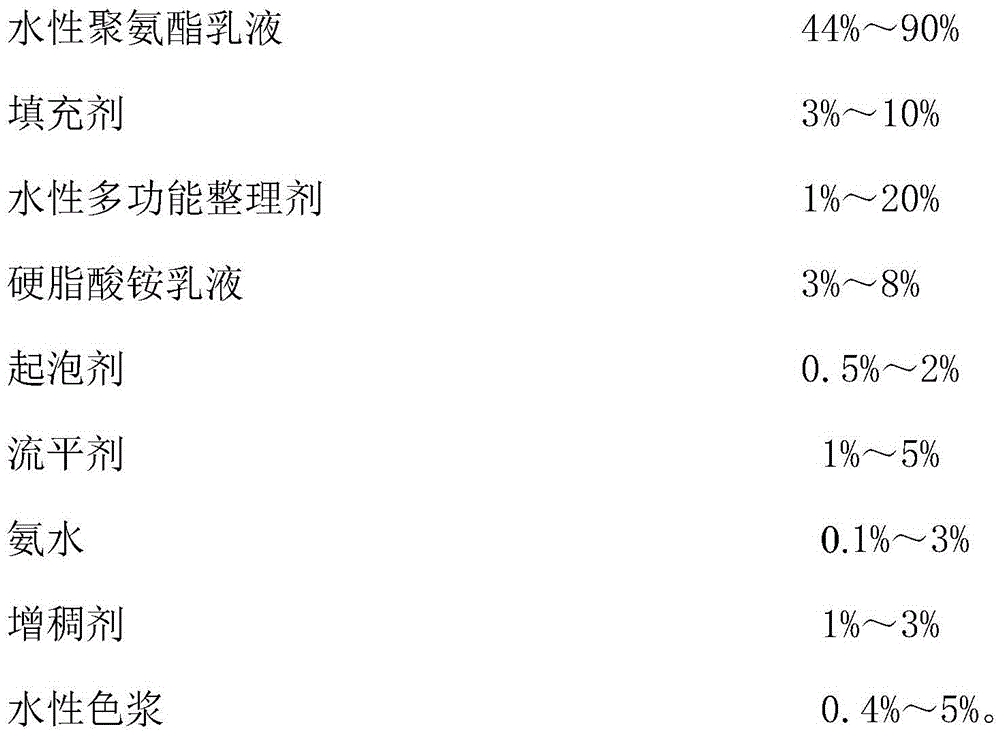

Formula and process for producing multifunctional synthetic leather from waterborne polyurethane intumescent coating

The invention discloses a formula for producing a multifunctional synthetic leather from a waterborne polyurethane intumescent coating. The formula includes a coating liquid; the coating liquid comprises the following components: 44%-90% of waterborne polyurethane emulsion, 3%-10% of a filler, 1%-20% of an aqueous multifunctional finishing agent, 3%-8% of ammonium stearate emulsion, 0.5%-2% of a foaming agent, 1%-5% of a leveling agent, 0.1%-3% of aqueous ammonia, 1%-3% of a thickener and 0.4%-5% of an aqueous color paste. A process is as below: preparing a coating solution; preparing a coating foam, and then applying the coating foam to a leather fabric through precise control of the coating amount by the computer; drying in an oven; and conducting post-treatment to obtain the multifunctional synthetic leather. The product has strong skin feel, soft handle and good peeling resistance and fastness; the coating solution has low water content, and significantly reduces drying energy and water resource; and the entire production process does not produce any sewage or exhaust emission, and is in line with environmental requirements.

Owner:宋婷婷

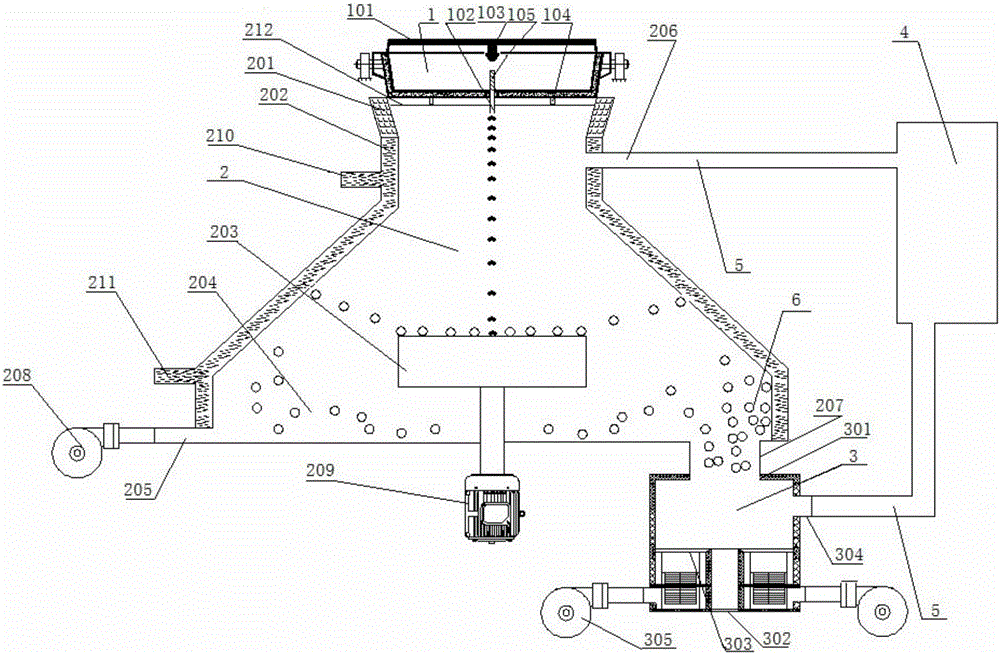

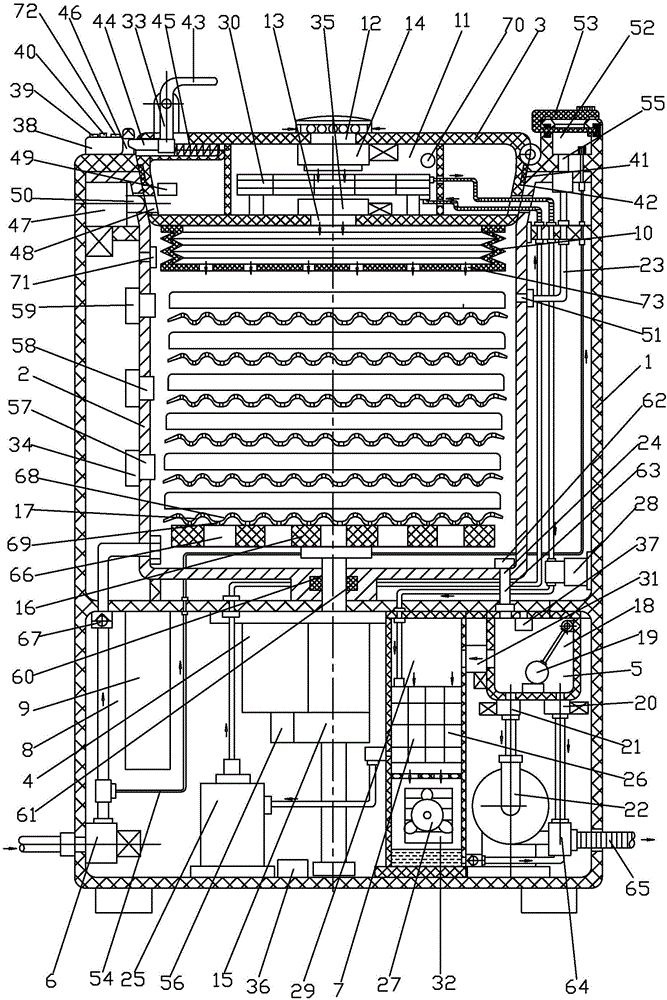

Blast furnace slag thermal fracture centrifugal drying method granulation device and method

InactiveCN105779673AEmission reductionSave drying energyRecycling and recovery technologiesProcess efficiency improvementSlagWater content

The invention aims at the problem existing in the prior art for blast furnace slag treatment, provides a blast furnace slag thermal fracture centrifugal drying method granulation device and method and belongs to the technical field of treating devices for blast furnace metal smelting waste. The device comprises an intermediate tank, a granulation chamber, a filling type countercurrent heat exchanger and a high-temperature air collecting purifier. The intermediate tank is located on the upper portion of the granulation chamber. The granulation chamber is located on the upper portion of the filling type countercurrent heat exchanger. The intermediate tank, the granulation chamber and the filling type countercurrent heat exchanger are sequentially connected. The high-temperature air collecting purifier is located outside and is connected with the granulation chamber and the filling type countercurrent heat exchanger through pipelines. According to the device and the method, a drying method is adopted for treating blast furnace slag, high-temperature sensible heat of the blast furnace slag can be utilized for generating power, precious water resources can be saved, emission of harmful gas is reduced, and energy consumption is reduced. Moreover, for the treated blast furnace slag, due to the extremely low water content of the dried slag, the vitrification rate can be kept 95% or above.

Owner:于良富 +2

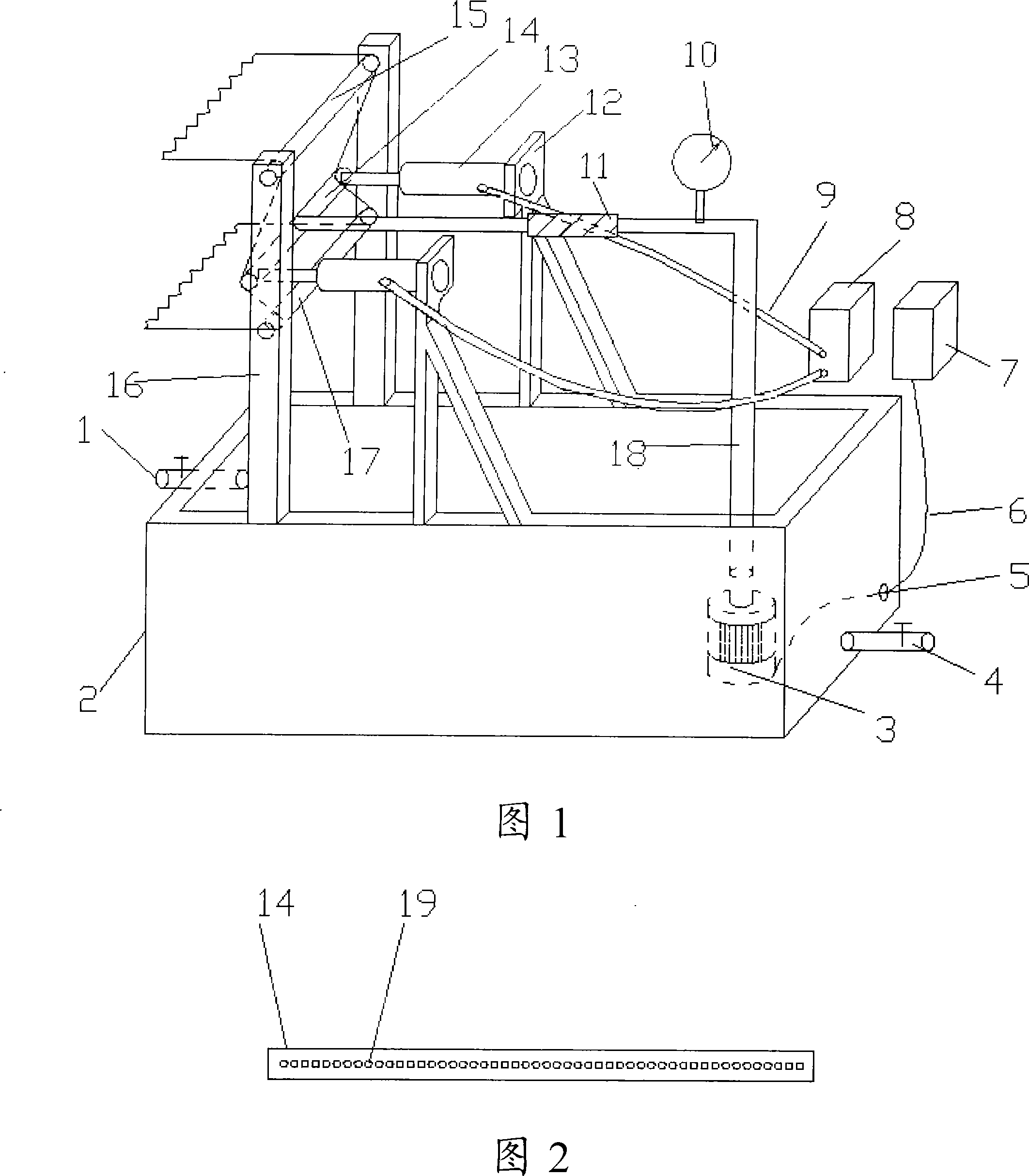

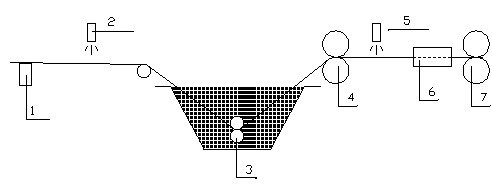

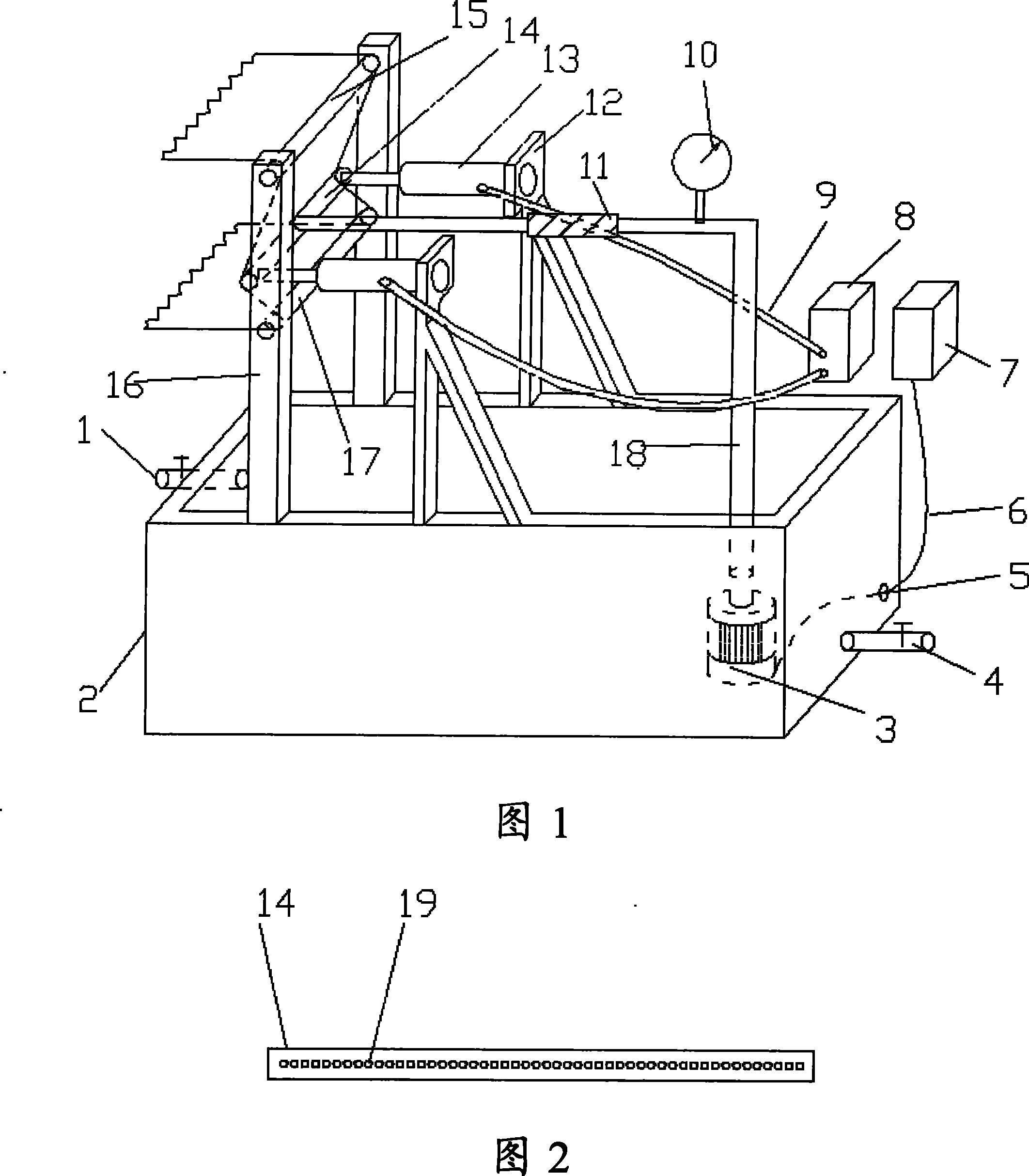

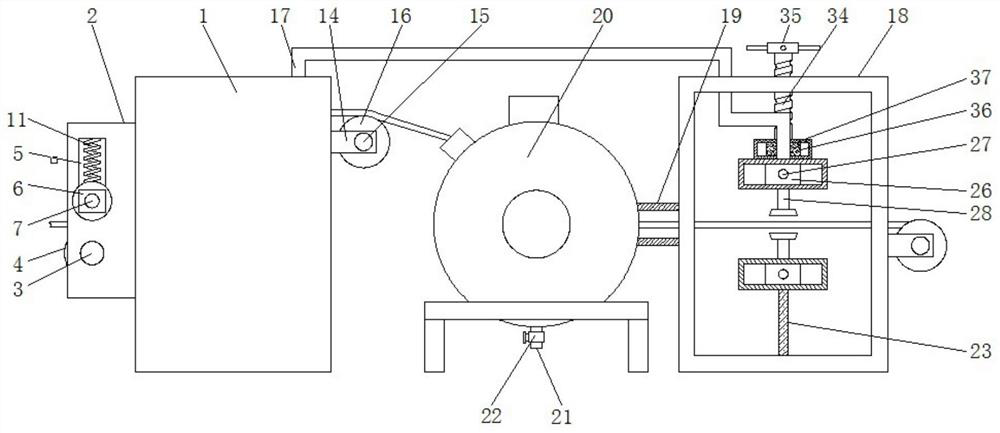

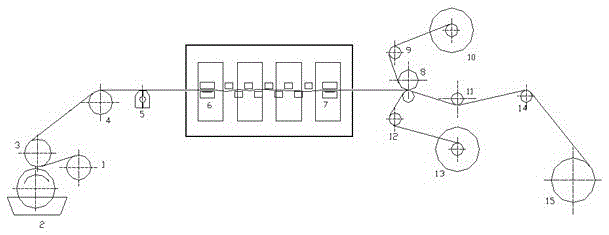

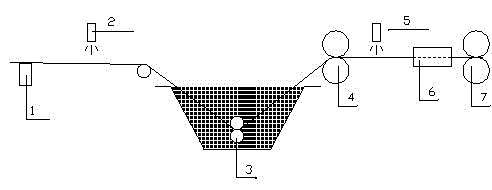

Jean topical finish injecting type damping device

InactiveCN101235584AReduce the frequency of water changesReduce water consumptionTextile treatment machine partsTextile treatment by spraying/projectingHydraulic cylinderWater use

The invention relates to a post finishing jet type wetting device for denim, which is provided with a water tank and is characterized in that a diving pump is arranged in the water tank, a water outlet of the diving pump is communicated with a jet tube through a stainless pipe and an adjustable flexible pipe, a pressure gauge is installed on the stainless pipe, a line of jet orifices are arranged on the jet tube, two hydraulic cylinders are respectively arranged on two ends of the jet tube, the hydraulic cylinders are respectively installed on supporting stands on the two sides of the water tank, liquid input ports are respectively communicated with liquid output ports of hydraulic pumps through the pipe, props are respectively installed on two sides of the water tank close to the left side in parallel, a cloth guiding roller is arranged on the middle portion between the two props, another cloth guiding roller is also arranged on the upper portion between the two props, and an output terminal of a frequency-converter is connected with an input terminal of the diving pump through a cable. The wetting device of the invention can wet the cloth surface completely, a large amount of useless water is not carried, the frequency for changing clear water is reduced, the water using amount is lowered, dyestuff and slurry which are brought away are very little, and a large amount of drying energy is saved.

Owner:LANYAN GROUP

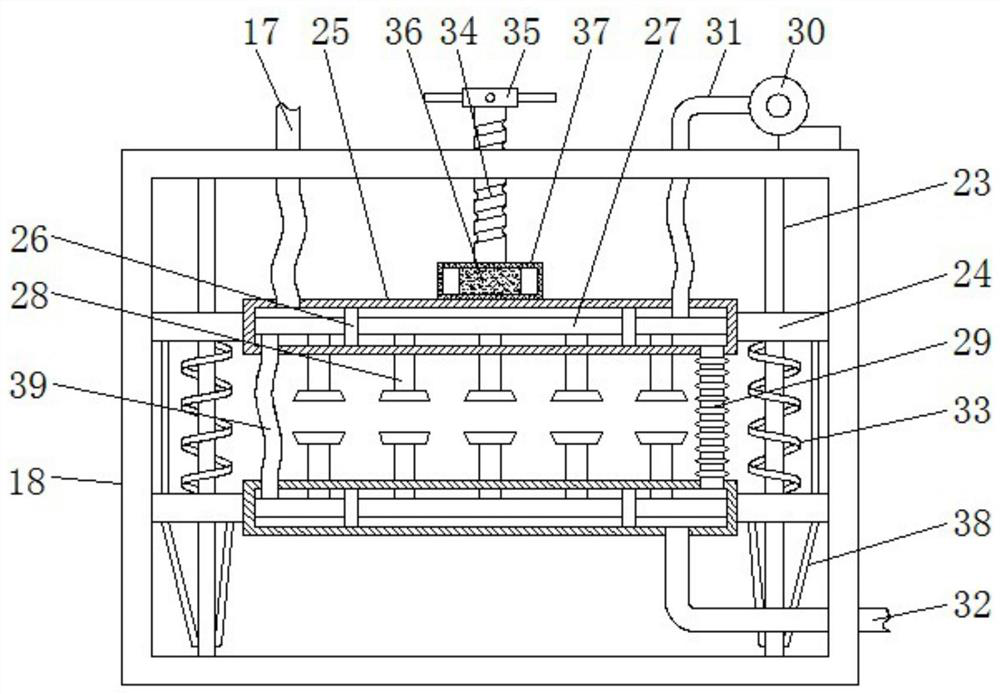

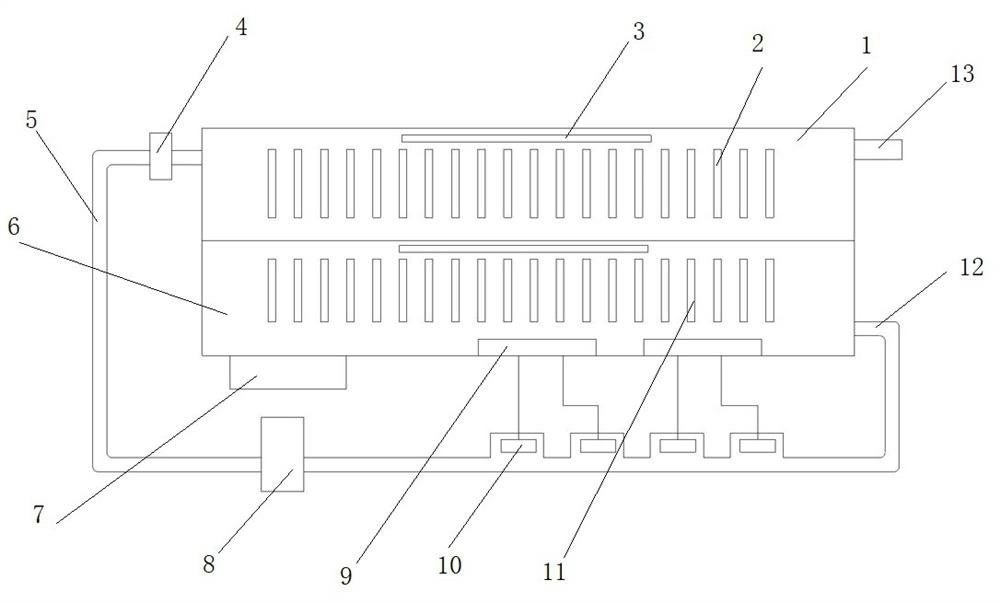

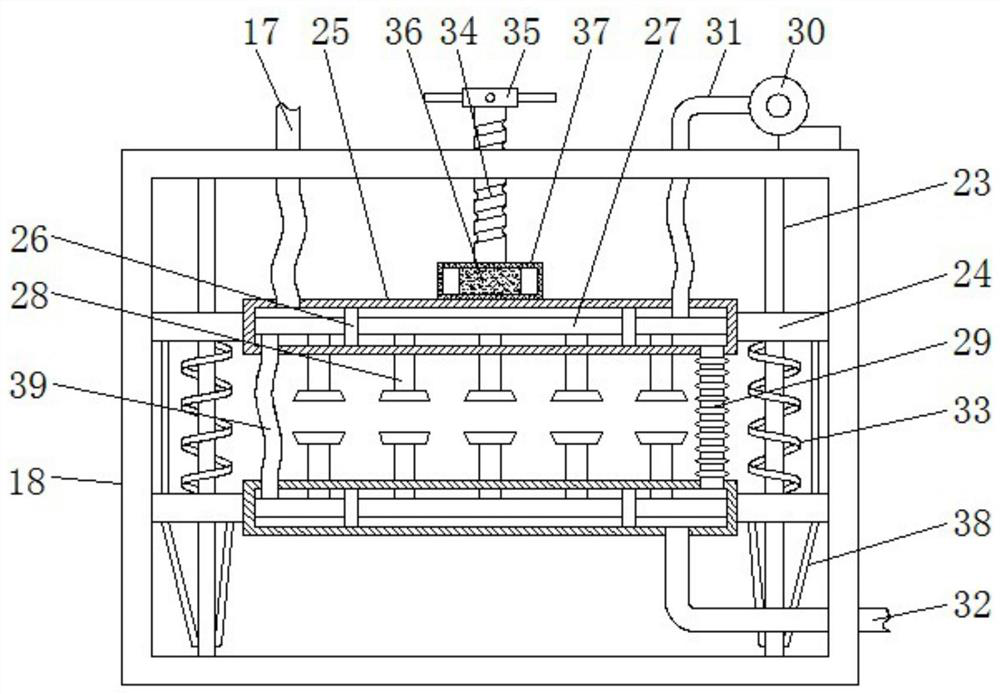

Device for cleaning and recycling circuit boards

PendingCN110560411AIncrease disturbanceResidue reductionDrying solid materials with heatDrying solid materials without heatSpray nozzleLiquid storage tank

The invention provides a device for cleaning and recycling circuit boards. The device for cleaning and recycling the circuit boards comprises a box body, a horizontal rotary disk, a cleaning groove, agroove type filter screen, a cleaning liquid storage tank, a number of cleaning liquid spray nozzles, an air pump and a number of air nozzles. The box body is hollow inside. The horizontal rotary disk is horizontally and rotatably fixed to the bottom of the inner side of the box body. A vertical rotary shaft is fixedly connected to the bottom center of the horizontal rotary disk. The vertical rotary shaft is driven by a first electric motor. Two or more hydraulic drivers are vertically fixed to the upper portion of the horizontal rotary disk. The hydraulic drivers are in central symmetry withthe center of the rotary disk as the center. The cleaning groove is connected to the horizontal rotary disk through four or more springs. Stirring blades are arranged on the inner side of the bottomof the cleaning groove. A vibrator is fixed to the bottom of the outer side of the cleaning groove. Two or more blind holes are formed in the bottom of the outer side of the cleaning groove. The topsof the hydraulic drivers are inserted into the blind holes when the hydraulic drivers elongate. The device for cleaning and recycling the circuit boards is high in cleaning efficiency and few in cleaning liquid residues.

Owner:QINGYUAN JINTIAN ENTERPRISE

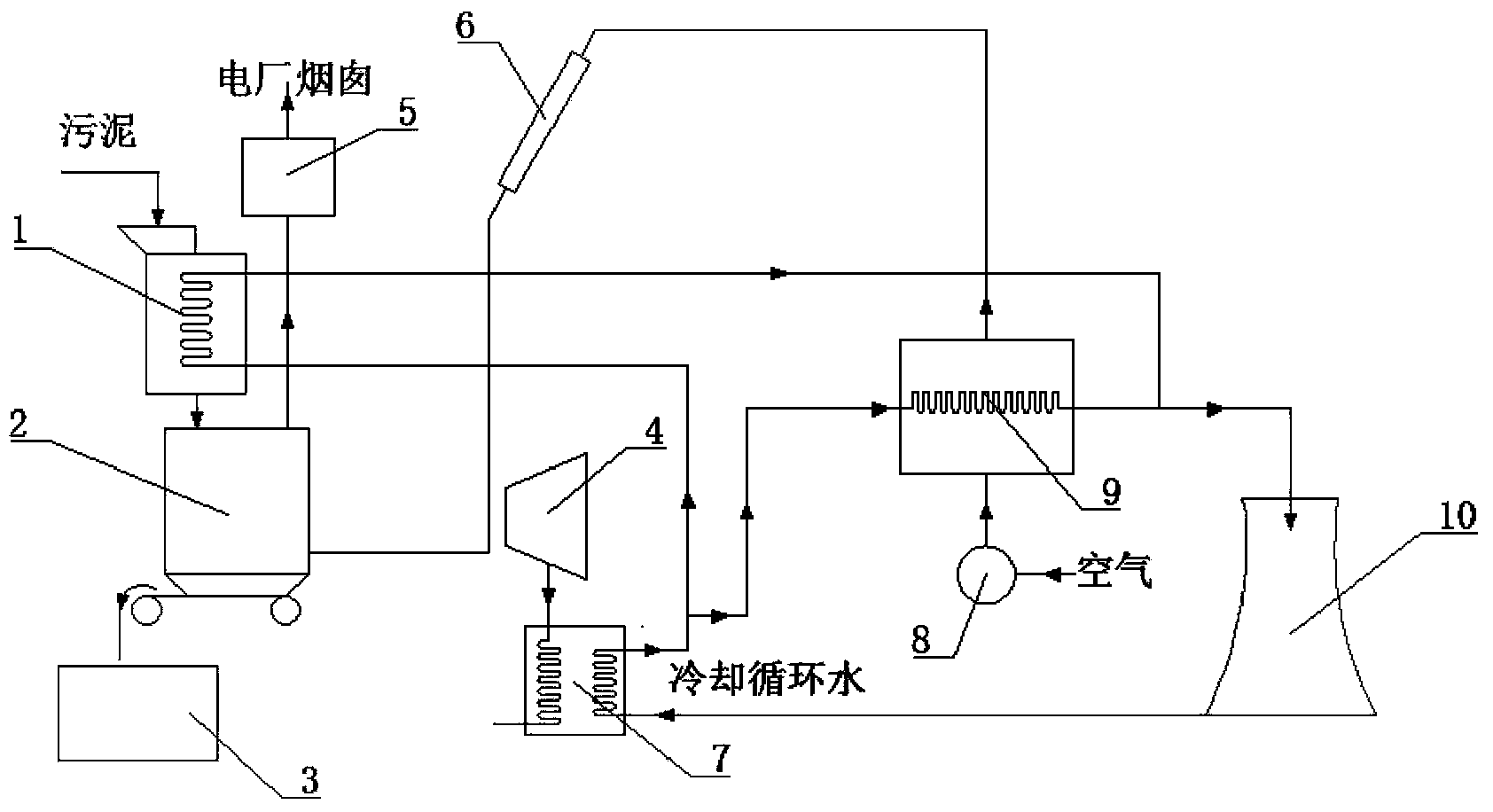

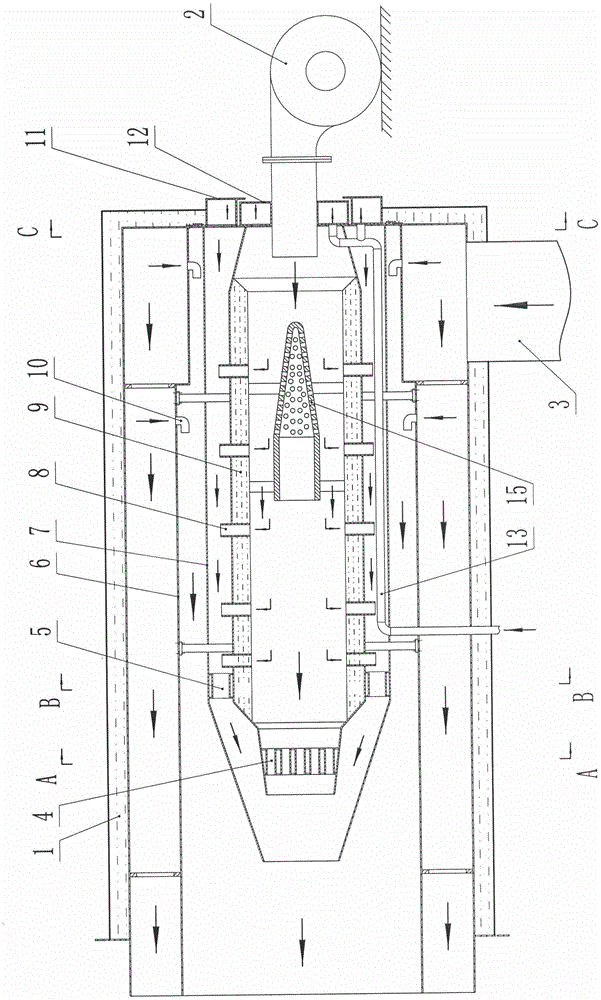

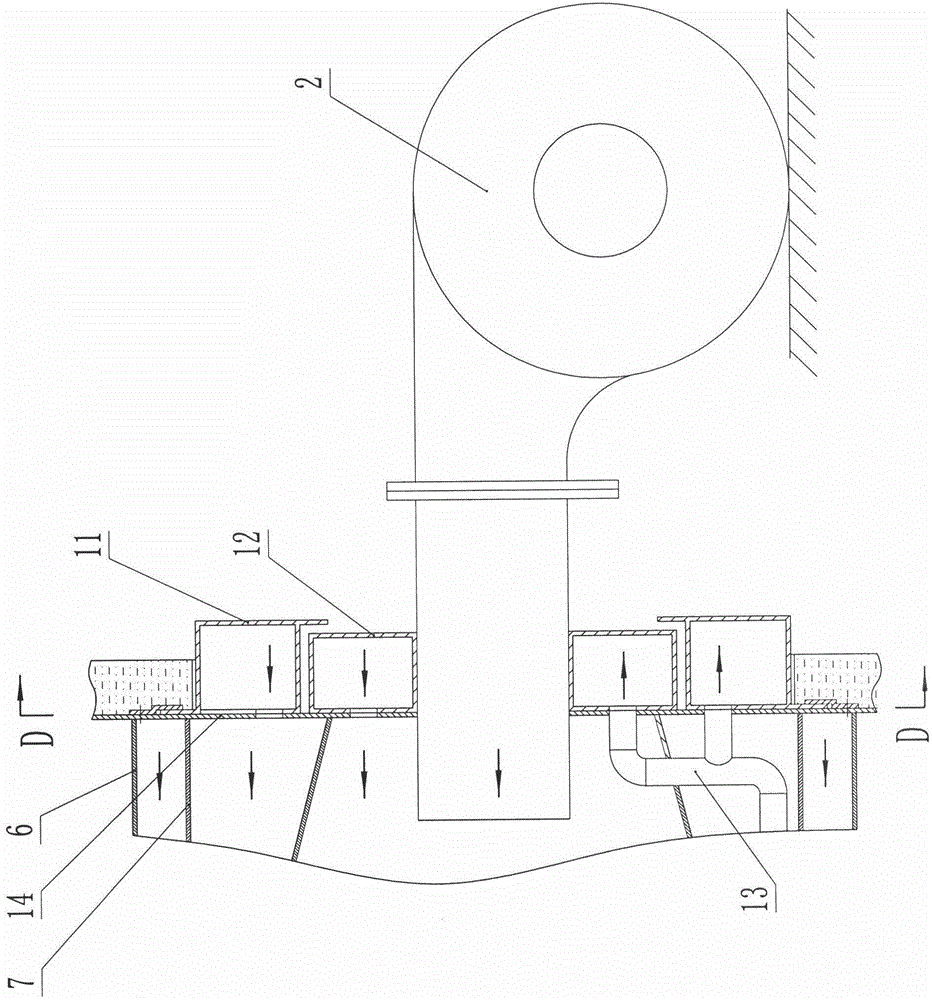

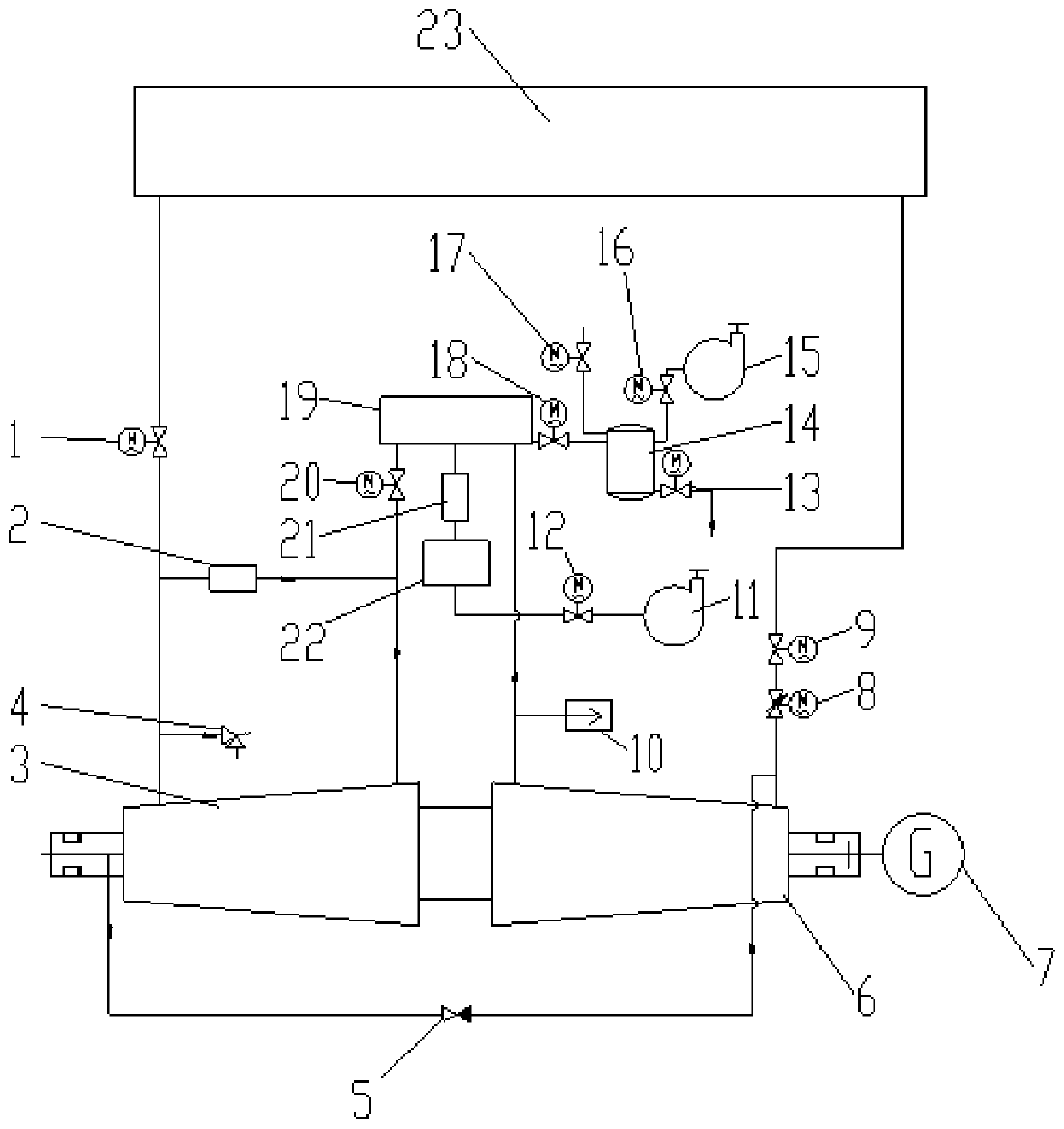

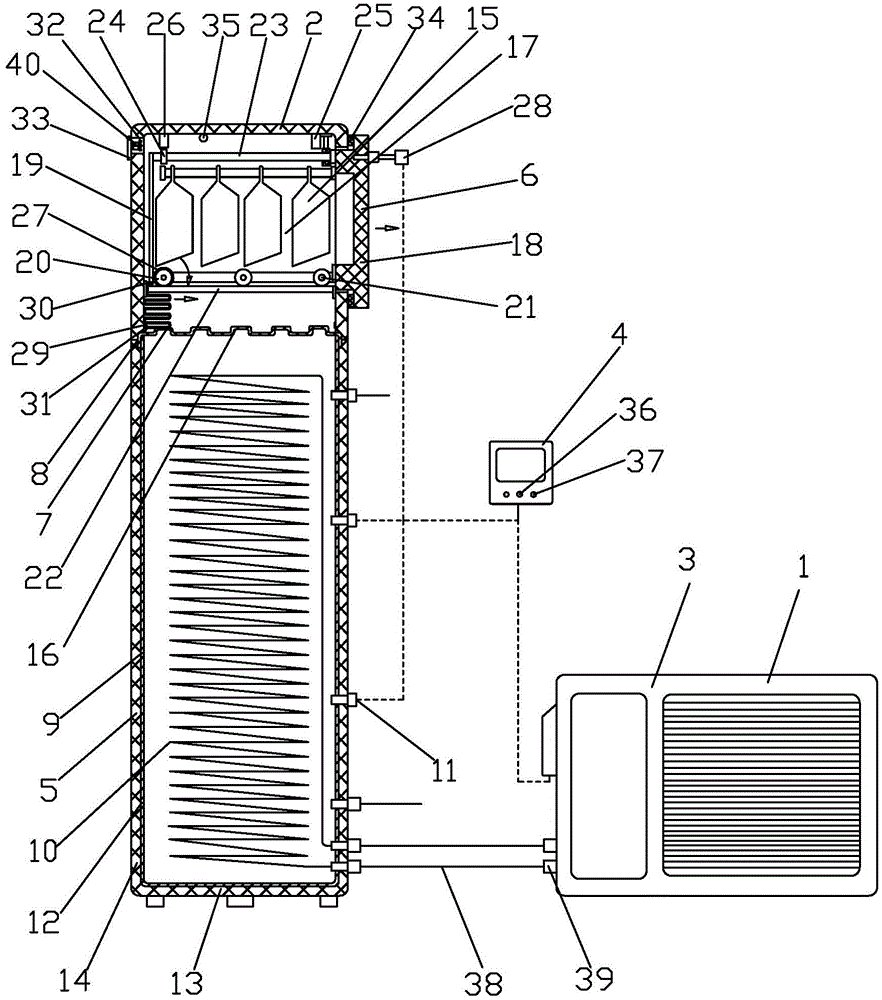

Municipal sludge drying system utilizing power plant waste heat coupling solar energy

InactiveCN104045217ASave drying energyOperableSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentFluidized bed dryingCooling tower

A municipal sludge drying system utilizing power plant waste heat coupling solar comprises a steam water process, an air flow and a sludge process. The steam water process is as below: a condenser is provided, a water channel inlet is connected with cooling tower (10) circulating water, an outlet path passes through an air-water heat exchanger (9), the other path passes through a sludge heater (1), and the two are finally sent back to the cooling tower (10); and the condenser steam source is from a steam exhaust discharged by a turbine (4). The air process is as below: a blower (8) sends the air to the heat exchanger (9), a solar heat collecting plate (6) and a fluidized bed dryer (2) in order, and the air is finally discharged into the atmosphere through a dust collector (5). The sludge process is as below: sludge disintegrated by a disintegrator is sent into a sludge heater (1), falls into the fluidized bed dryer (2) and is finally transmitted to a bunker (3) by a conveying belt. The system makes full use of waste heat in the power plant and solar energy of the plant area, and improves the thermal economy of the power plant; the sludge is treated by drying technology to achieve stabilization, harmlessness and reduction. The invention lays the foundation for further resource utilization and has important practical significance.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

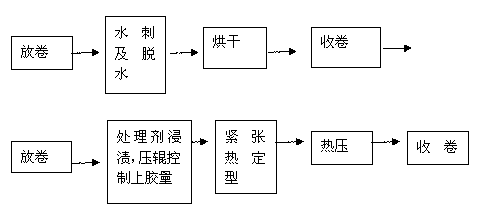

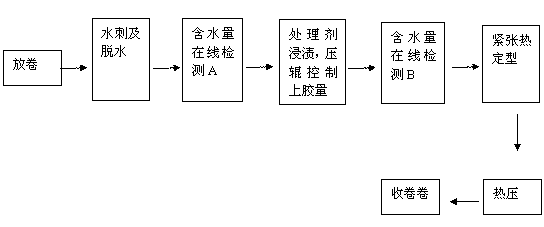

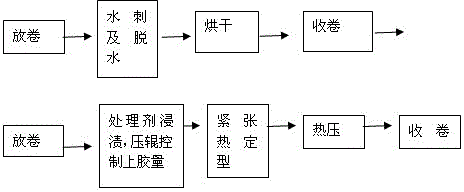

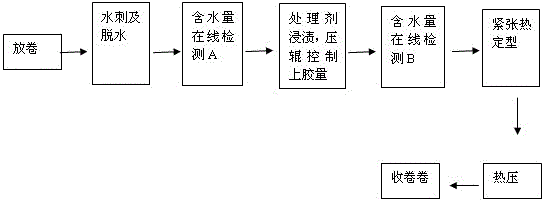

Processing method of spunlace environment-friendly filter material

ActiveCN103301686AShort processSave drying energyFibre typesFiltration separationPore water pressureVacuum pump

The invention discloses a processing method of a spunlace environment-friendly filter material. The processing method of the spunlace environment-friendly filter material comprises the following steps of: carrying out front-back spunlace on a filter material with the gram weight of 60-120 needling / cm<2> and pre-needling density of 400-700g / m<2> by adopting water pressure of 300-400 BAR; controlling the speed of a vacuum pump through water content on-line detection 1 so that the moisture percentage of the filter material subjected to a dehydration technology is controlled to less than 50%; adding a pressing roller in a glue groove, and controlling the pressure to be 10N-20N / CM so that teflon emulsion permeates into the filter material; controlling the glue quantity and the pressure of the pressing roller through the difference value of water content on-line detection A and water-content on-line detection B, thereby controlling the dry weight ratio of teflon emulsion to the filter material to achieve (1:9)-(3:7); and drying and sizing, and controlling the product thickness and surface smoothness through hot pressing. According to the processing method of the spunlace environment-friendly filter material, immersion treatment is directly carried out after spunlace, and then drying and sizing are carried out, and the existing process of drying after spunlace is omitted, thus the technology process is shortened, and 50% of drying energy consumption is saved.

Owner:南京际华三五二一环保科技有限公司

Decorative material midbody with split-packaged chemical additive

InactiveCN102674757AFlexible and convenient quality control measuresSave drying energyChemical additionMaterials science

The invention discloses a decorative material midbody with split-packaged chemical additives and relates to a novel material, in particular to the production and the application of a novel decorative material. The decorative material midbody with split-packaged chemical additives is packaged by classification according to the length of quality guarantee periods of component materials, wherein a component A consists of chemical additives, fillers and pigments with the quality guarantee period being above six months, and a component B consists of hydraulic inorganic solidifying materials with the quality guarantee period being only three months. The decorative material midbody with split-packaged chemical additives has the advantages that the advantage that the quality guarantee period of the component A is long is exerted, the difficulty in storage and transportation is reduced and the wastage of fillers, pigments and additives is reduced; and the emphasized safekeeping and storage of the component B with the short quality guarantee period are facilitated, the component B can be taken out from the unused midbody for timely use or be replaced by new component B when the deadline of the quality guarantee period approaches, and the situations of potential engineering hazards and energy wastage are avoided.

Owner:上海绿特丹保温工程有限公司

Garment printing device for textile

ActiveCN111806079APrinting does not affectImprove singeing effectSingeingDrying gas arrangementsTextile printerRotational axis

The relates to the technical field of printing equipment for textile industry, and discloses a garment printing device for textile. The garment printing device comprises a singeing machine. One side of the singeing machine is fixedly connected with two side plates. The bottoms of the two side plates are provided with a first rotating shaft in a movable and sleeved mode. The middle part of the first rotating shaft is fixedly sleeved by a first cloth-guiding roller mounted between the two side plates. The top of each of the side plates is respectively provided with a sliding slot. The interior of each of the two sliding slots is sleeved by a movable pipe in a movable mode. The middle parts of the movable pipes are sleeved by a rotating shaft in a movable mode. The middle part of the rotatingshaft is fixedly sleeved by a positioning plate. The garment printing device for textile enables the bottom of a spiral blade to be matched with the top of the first cloth-guiding roller to press textile tightly through the elasticity of a spring, and uses the rotating shaft to drive the spiral blade to turn, so that the textile is always in a flat state, thus the high effect of singeing the textile is ensured and the dyeing of the textile cannot be affected.

Owner:晋江市嘉艺服装织造有限公司

Jean topical finish injecting type damping device

InactiveCN101235584BReduce the frequency of water changesReduce water consumptionTextile treatment machine partsTextile treatment by spraying/projectingHydraulic cylinderWater use

The invention relates to a post finishing jet type wetting device for denim, which is provided with a water tank and is characterized in that a diving pump is arranged in the water tank, a water outlet of the diving pump is communicated with a jet tube through a stainless pipe and an adjustable flexible pipe, a pressure gauge is installed on the stainless pipe, a line of jet orifices are arrangedon the jet tube, two hydraulic cylinders are respectively arranged on two ends of the jet tube, the hydraulic cylinders are respectively installed on supporting stands on the two sides of the water tank, liquid input ports are respectively communicated with liquid output ports of hydraulic pumps through the pipe, props are respectively installed on two sides of the water tank close to the left side in parallel, a cloth guiding roller is arranged on the middle portion between the two props, another cloth guiding roller is also arranged on the upper portion between the two props, and an outputterminal of a frequency-converter is connected with an input terminal of the diving pump through a cable. The wetting device of the invention can wet the cloth surface completely, a large amount of useless water is not carried, the frequency for changing clear water is reduced, the water using amount is lowered, dyestuff and slurry which are brought away are very little, and a large amount of drying energy is saved.

Owner:LANYAN GROUP

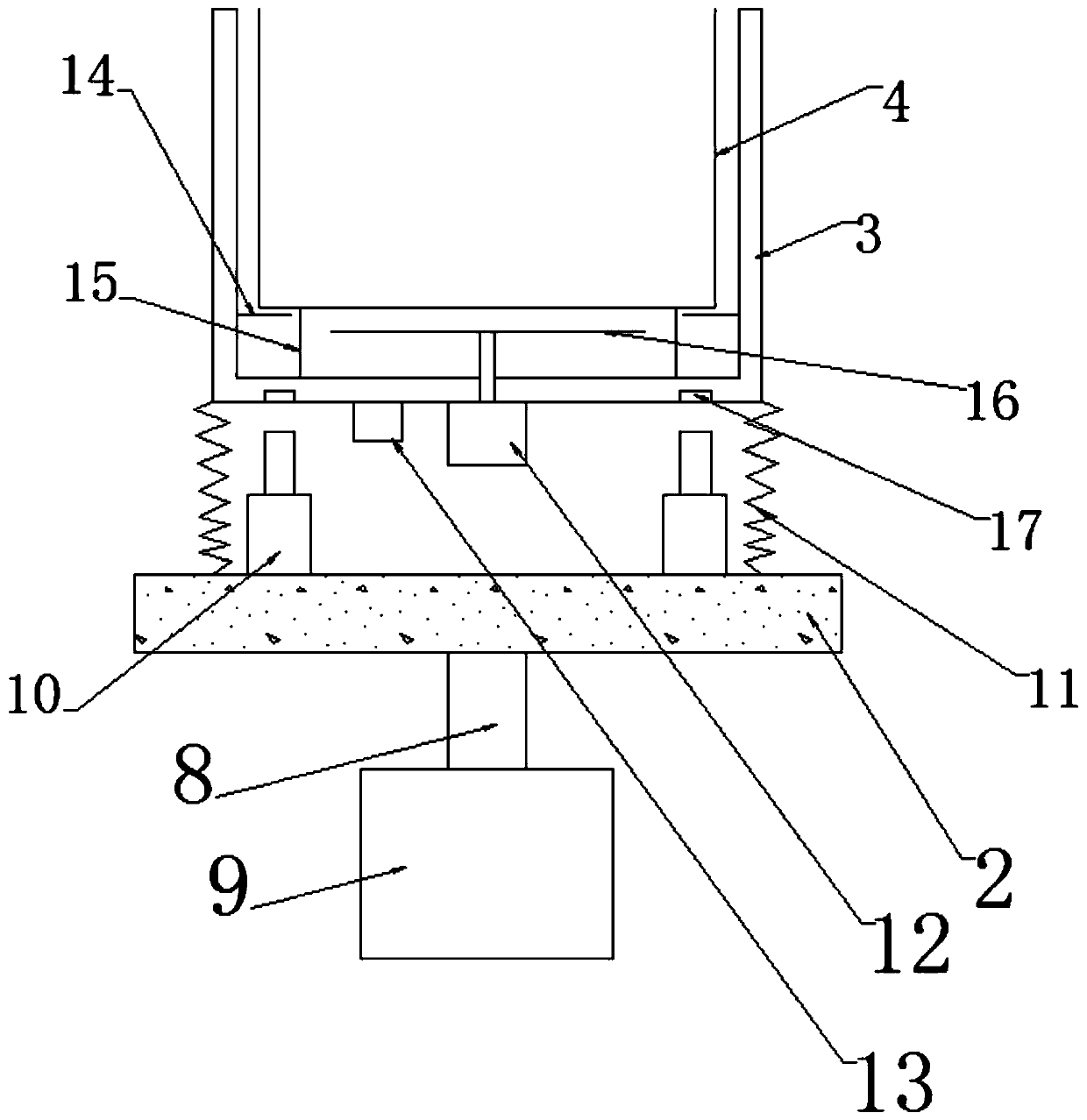

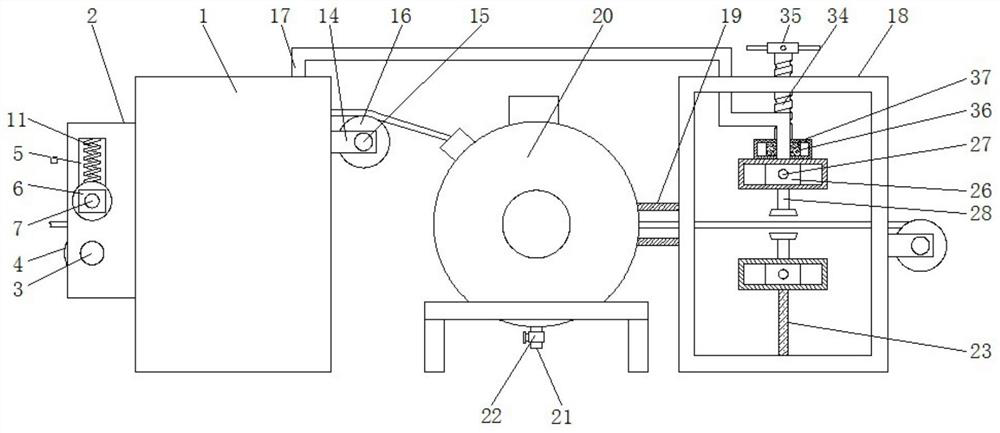

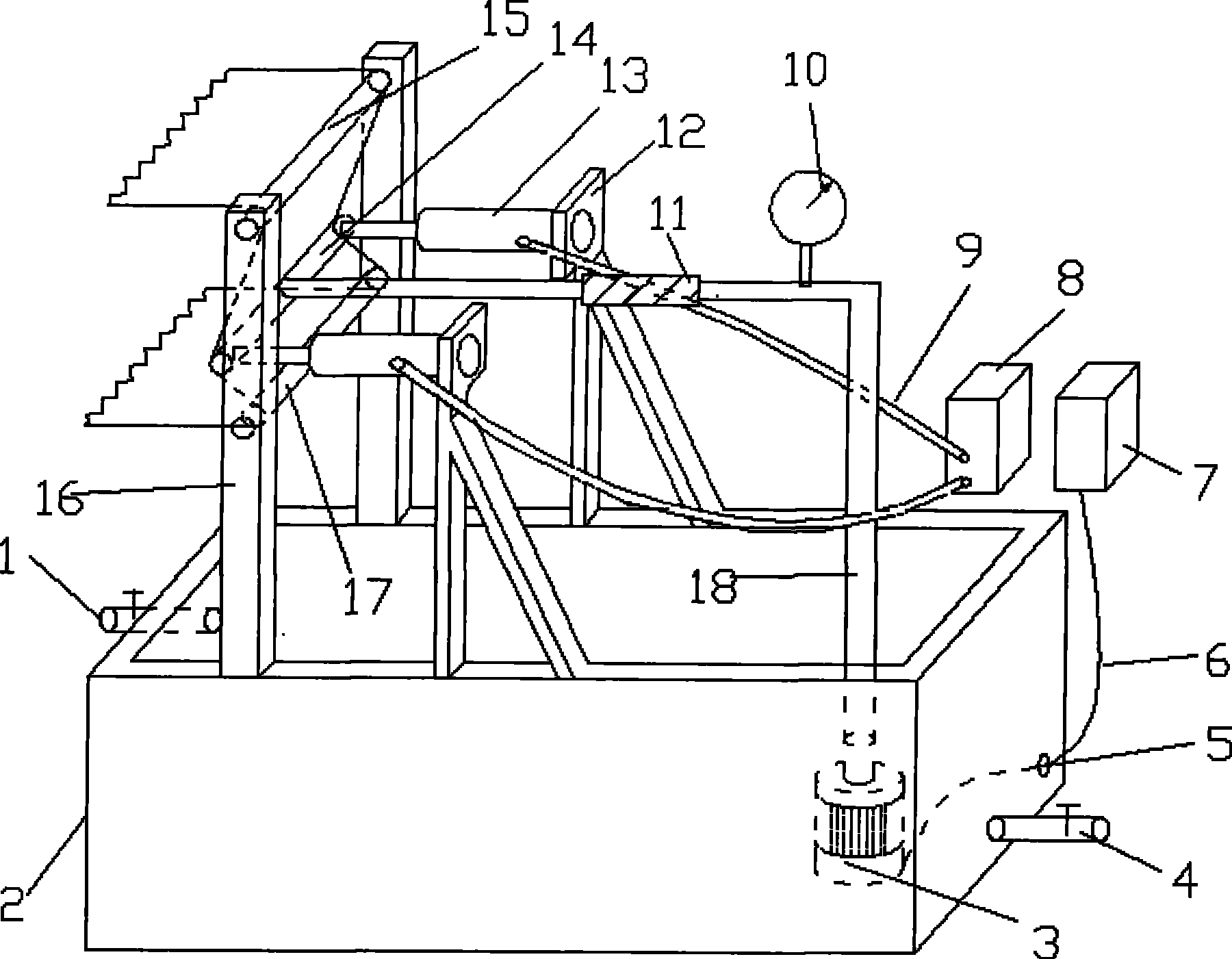

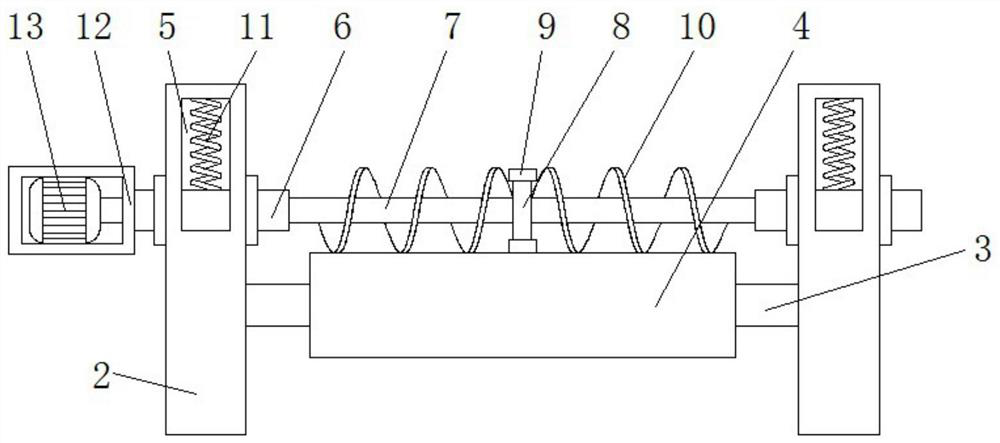

Using method of intelligent energy-saving extruding type washing machine

InactiveCN107142654APrevent offlineImplement recyclingOther washing machinesWashing machine with receptaclesPulp and paper industryVacuum pump

The invention discloses a using method of an intelligent energy-saving extruding type washing machine. The intelligent energy-saving extruding type washing machine comprises an outer barrel, an inner barrel, a barrel cover, an extruding device, a drainage device, a water inlet electromagnetic valve, an air energy drying device, a control box and a controller; in drying flow, elastic washing pads and clothes are overlapped in the barrel layer by layer, and clothes are extruded and washed by an extruding plate and washing water; after discharging the washing water, clothes are extruded and cleaned by the extruding plate and cleaning running water; after cleaning clothes, the cleaning running water is discharged, and clothes are vacuum-dewatered b the vacuum pump; the using method solves the problems of mutual dragged and coiled clothes when the clothes are washed by an ordinary washing machine; after completing the washing flow, the controller controls the air energy drying device to work, and uses the air energy to dry the clothes after washing and cleaning; when air heated by the radiator passes through the energy-saving box, the evaporator absorbs the heat of air heated by the radiator, and recycles heat; thus the drying energy source is saved.

Owner:东莞市皓奇企业管理服务有限公司

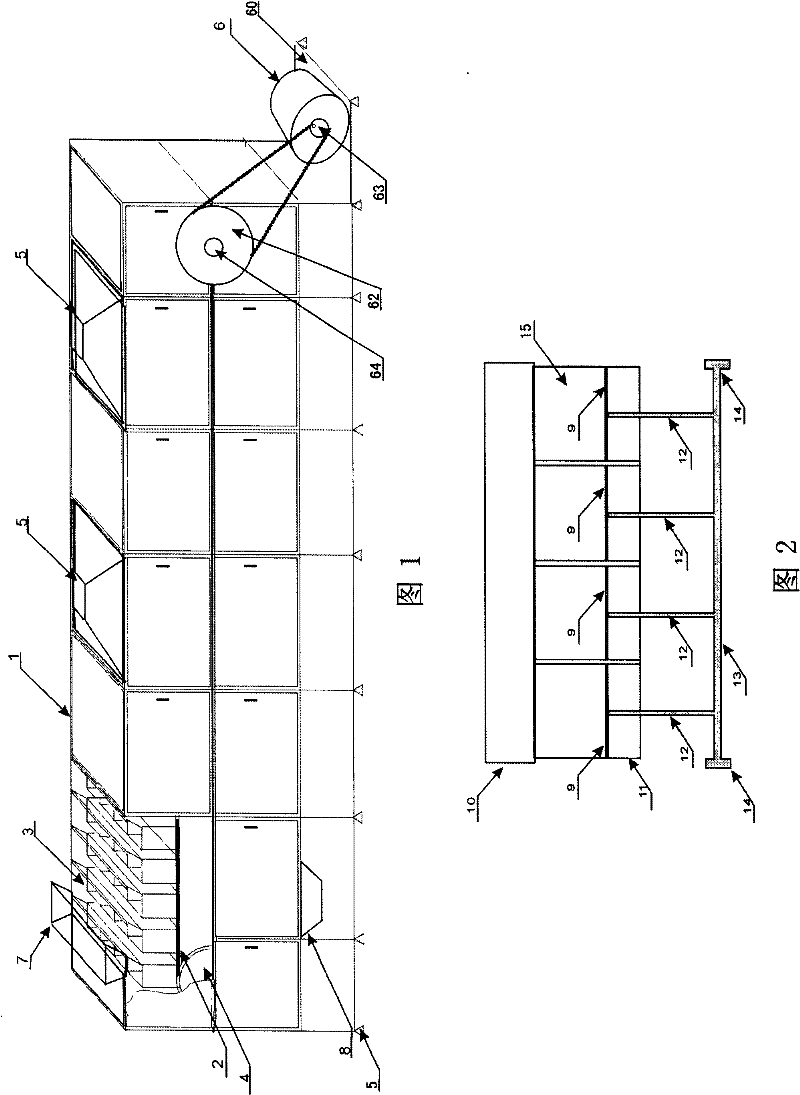

Drying system for gypsum boards without paper surface

PendingCN112936542ATake advantage ofReduce drying costsDrying gas arrangementsCeramic shaping apparatusProcess engineeringFuel gas

A drying system for gypsum boards without a paper surface belongs to the field of gypsum board production and comprises a gypsum board solidification plant, a solidification room conveying device, a drying tail gas conveying pipeline, a drying room, a fuel gas drying device, a fan, an air energy drying device indoor unit, an air energy drying device outdoor unit, a drying room conveying device, a drying room air outlet and a solidification room air outlet. The gypsum board solidification plant and the drying room are arranged side by side, and a roof is made of transparent materials and is a relatively closed space. The solidification room conveying device is installed in the gypsum board solidification plant and can convey gypsum boards from one end of the gypsum board solidification plant to the other end of the gypsum board solidification plant. The system has the characteristics of energy conservation and full utilization of solar energy and waste heat.

Owner:荆州三迪建筑科技有限公司

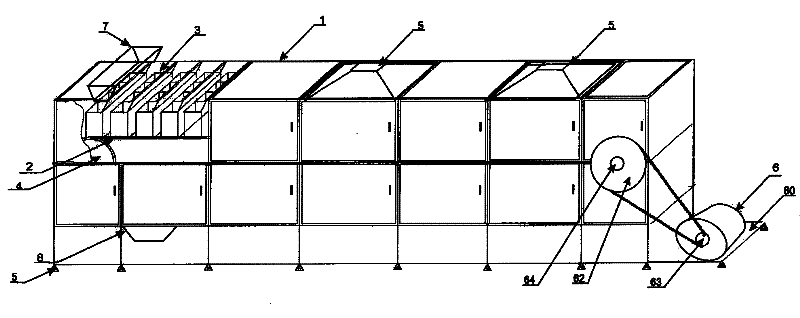

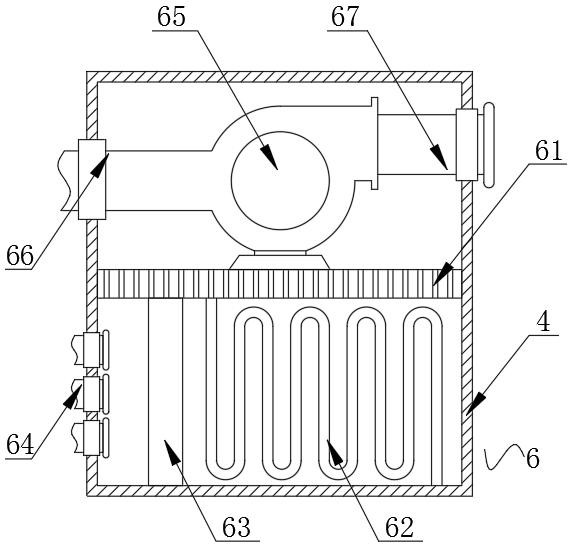

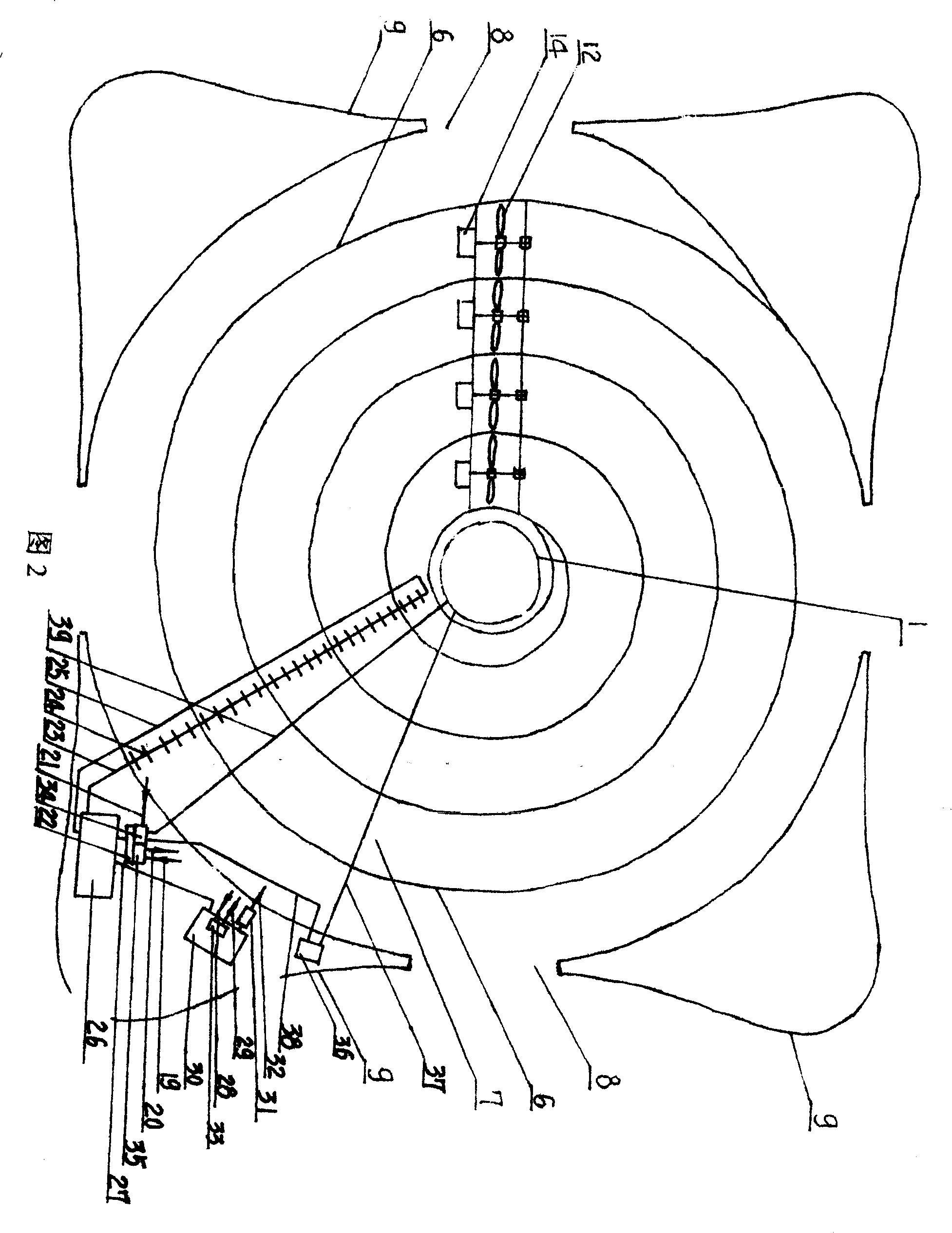

Combustion-supporting device of combustion chamber of egg tray machine drying box

InactiveCN105570925AReduce pollutionSave drying energyCombustion processDrying gas arrangementsCombustion chamberEngineering

The invention discloses a combustion-supporting device of a combustion chamber of an egg tray machine drying box. According to the combustion-supporting device, an inner combustion-supporting chamber and an outer combustion-supporting which are sequentially in looping connection with the combustion chamber in a spaced manner are connected with an air distributing disc on the end face of the combustion chamber; the position, opposite to the air distributing disc, of the outer side face of a shell is in looping connection with an inner air ring and an outer air ring; an end face air inlet hole of the inner air ring and an end face air inlet hole of the outer air ring correspondingly communicate with an end face inner air inlet hole and an end face outer air inlet hole of the air distributing disc; an end face air outlet hole of the inner air ring and an end face air outlet hole of the outer air ring are opposite to an end face inner air outlet hole and an end face outer air outlet hole of the air distributing disc and rotationally communicate with the inner combustion-supporting chamber and the outer combustion-supporting in a fine tuning manner; a hot air outlet of the inner combustion-supporting chamber is connected with an inner combustion-supporting disc; the position close to a hot air outlet of the outer combustion-supporting chamber is connected with an outer combustion-supporting ring in looping connection with the outer diameter of the inner combustion-supporting chamber; and the periphery of the inner combustion-supporting chamber is connected with a guide pipe communicating with the outer combustion-supporting chamber. During work, flames which are not fully combusted are fully combusted through five times of combustion supporting of a conical combustion supporting bypass pipe, the inner combustion-supporting chamber, the outer combustion-supporting chamber, the inner combustion-supporting disc and the outer combustion-supporting d ring, drying energy is effectively saved, and pollution to the air environment is obviously reduced.

Owner:程义浩

Production process of multilayer solid wood composite floor with high-water-content veneer veneering

PendingCN113894884ASave resourcesSimple production processWood veneer joiningCoating impregnationWood veneerSolid wood

The invention belongs to the technical field of building materials, and relates to a production process of a multilayer solid wood composite floor with a high-water-content wood veneer veneering. The process comprises the following steps of gluing and veneering, cold pressing, hot pressing, balanced curing, cutting, primer coating, forming, finish coating and finished product packaging, in the gluing and veneering process, the surface of a criss-cross multilayer board base material is coated with melamine-modified urea resin glue, the single-face glue applying amount is 80-130 g / m < 2 >, a layer of hard broadleaf wood veneer / wood veneer with the high water content is pasted after glue applying, the water content ranges from 10% to 20%, and the thickness ranges from 0.6 mm to 2.0 mm. Adjusting and improving are carried out on an existing production process, the production process is simple, the cost is low, dry energy is saved, the moisture return phenomenon caused by large rainwater, water content difference of various regions and the like in the transportation process is avoided, the high-water-content wood veneer is fully utilized, and existing forest resources are saved; and the prepared floor has no problems of buckling deformation, tile bending or cracking and the like, and the physical and mechanical properties meet the requirements of various indexes.

Owner:圣象地板(句容)有限公司

Intelligent extruding washing machine

InactiveCN107177950APrevent offlineImplement recyclingOther washing machinesTextiles and paperWater dischargeLaundry washing machine

The invention discloses an intelligent extruding washing machine. The washing machine comprises an outer barrel, an inner barrel, a barrel cover, an extruding device, a draining device, a water inlet solenoid valve, an air energy drying device, a control box and a controller; the extruding device comprises an electric pushing rod and extruding plates, the draining device comprises a water extracting box, a float ball, draining solenoid valves, a vacuumizing solenoid valve and a vacuum pump, and the controller is provided with water level sensors, a limiting switch and a water extracting sensor; in the washing process, clothes are put into the inner barrel, extruding and washing are conducted on the clothes by means of the extruding plates and washing water at first, after the washing water is drained, extruding and cleaning are conducted on the clothes by means of the extruding plates and cleaning tap water, and after the clothes are cleaned, the cleaning tap water is drained, and vacuum water extracting is conducted on the clothes by means of the vacuum pump. The problem of drawing and winding of the clothes with one another by means of an ordinary washing machine is solved, and loose thread or deformation of the clothes in the washing process is avoided.

Owner:东莞市皓奇企业管理服务有限公司

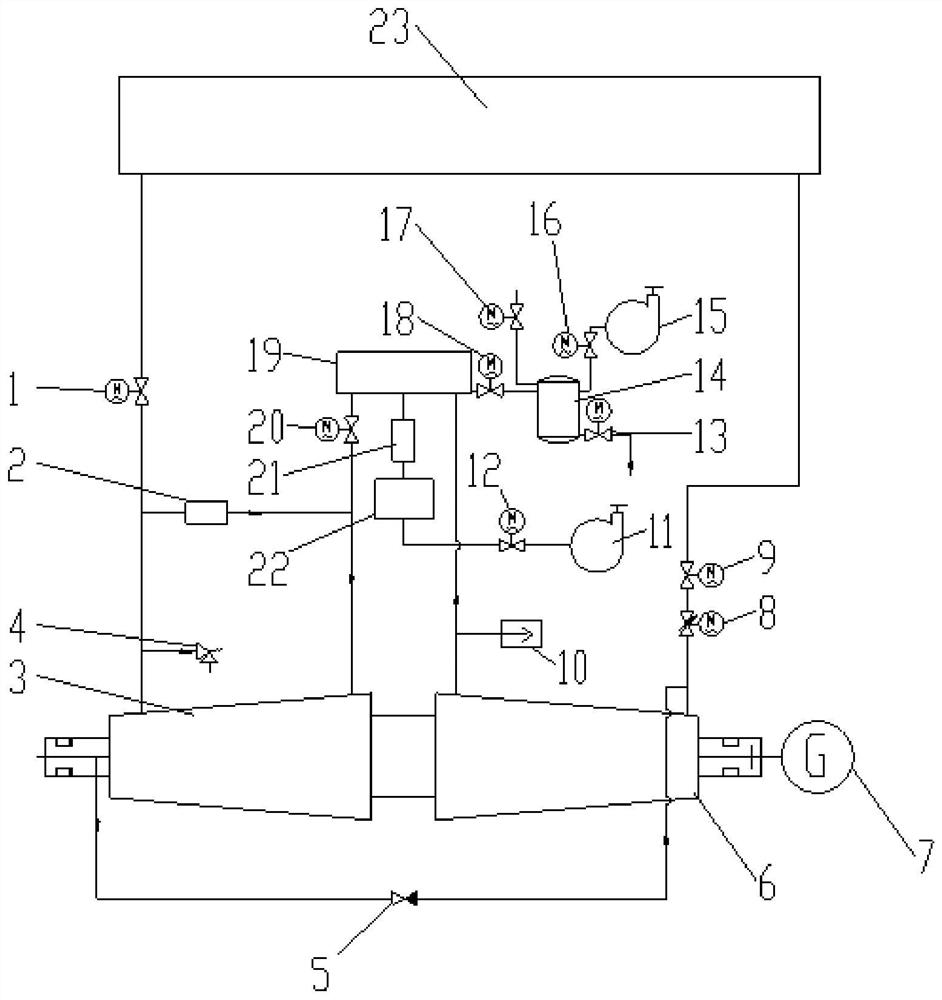

Closed efficient waste heat utilization circulating system of humid air turbine compressor

ActiveCN110975310AIncrease profitReduce manufacturing costEvaporator accessoriesMachines/enginesWater storageWater storage tank

The invention discloses a closed efficient waste heat utilization circulating system of a humid air turbine compressor. The closed efficient waste heat utilization circulating system comprises a humidair compressor turbine compression-expansion system and a humid air gas-water separation system. The humid air compressor turbine compression-expansion system comprises a stop valve I, a regulating valve and a humid air turbine which are communicated with an outlet of a drying chamber. The wet air compressor turbine compression-expansion system further comprises a wet air compressor communicatedwith an inlet of the drying chamber through a stop valve VIII. The humid air gas-water separation system comprises a humid air gas-water separator, and the humid air gas-water separator is communicated with a vacuum water storage tank. The system has the beneficial effects that waste gas can circulate in the closed system, pollutants such as dust and toxic and harmful waste gas are prevented frombeing discharged into the atmosphere, so that the effect of protecting the environment is achieved, heat energy in the waste gas can be recycled, the energy utilization rate is increased, and the production cost can be effectively reduced.

Owner:DONGFANG TURBINE CO LTD

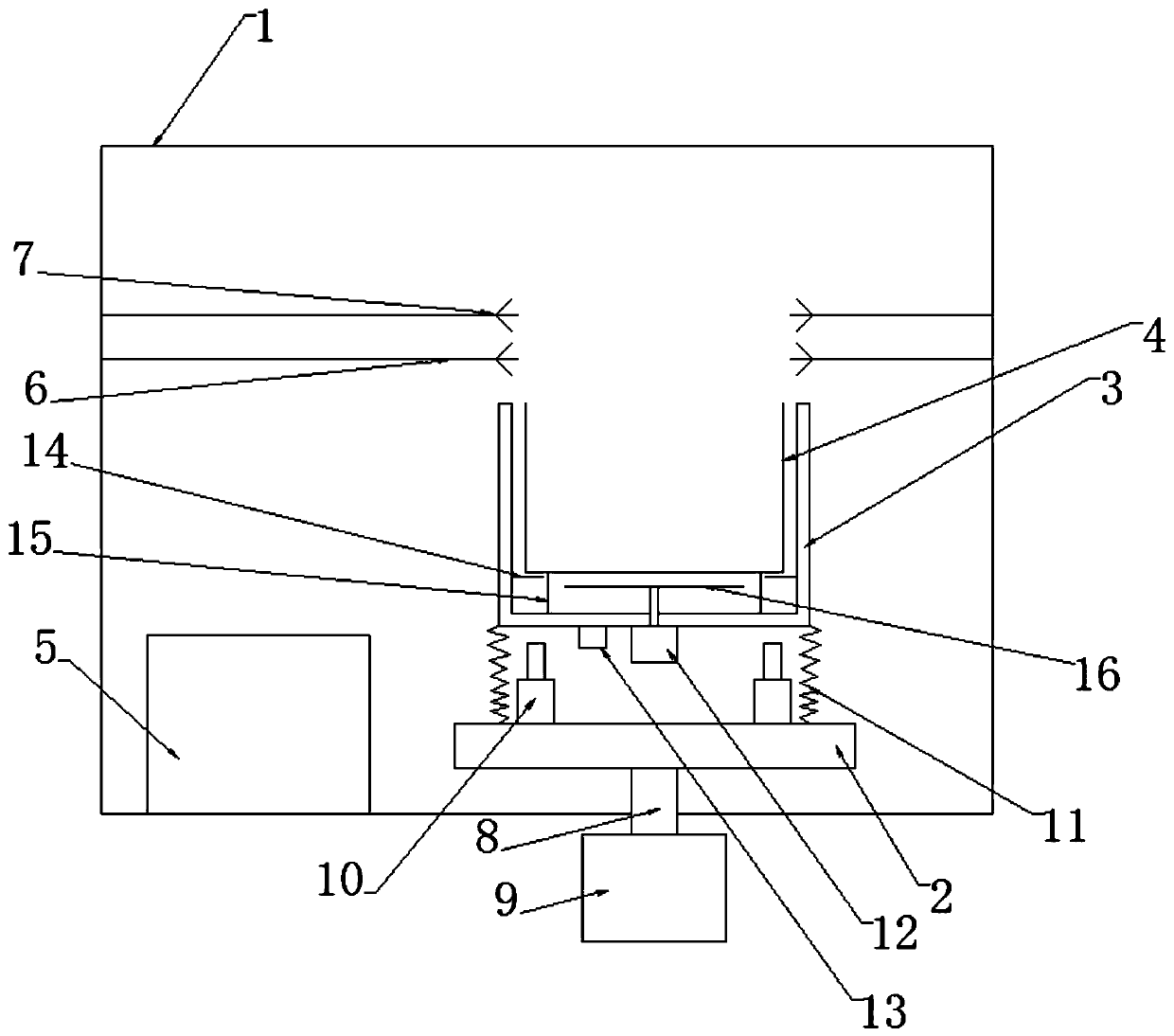

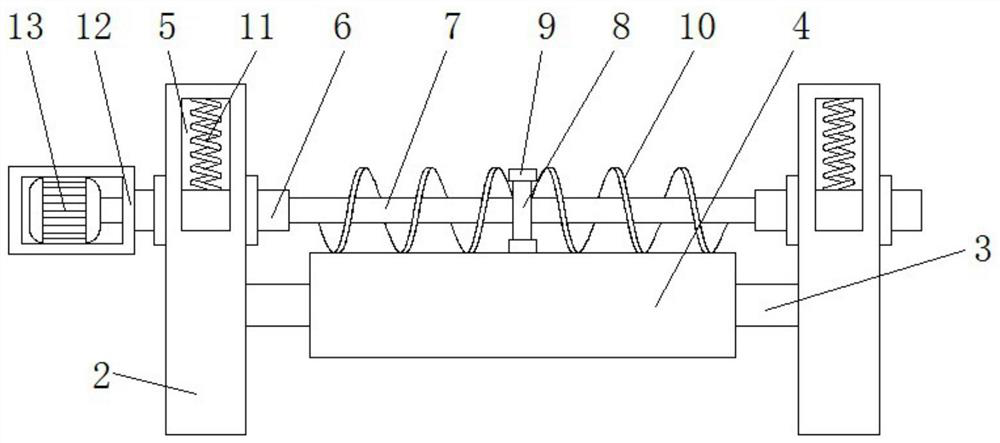

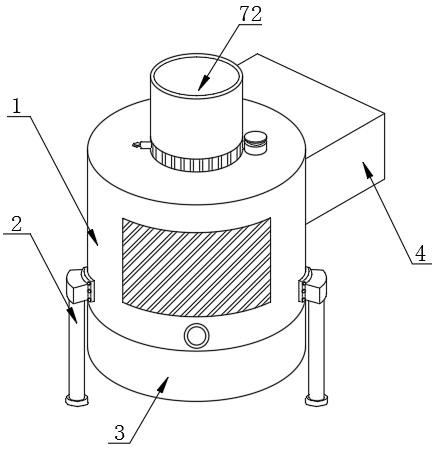

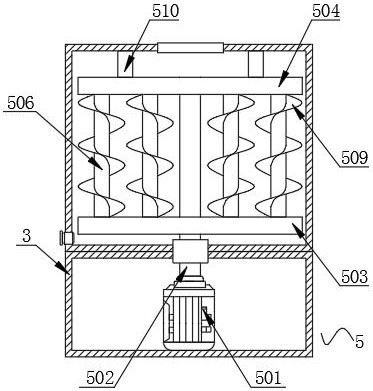

Agricultural seed moisture determination equipment and determination method

InactiveCN112213231AAvoid influenceShorten the calculation timeWeighing by removing componentAgricultural scienceWater vapor

The present invention discloses an agricultural seed moisture determination equipment and determination method. The equipment comprises a drying tank, a supporting base is fixedly connected to the outer surface of the drying tank, a motor box is fixedly connected to the bottom of the drying tank, and a dehumidifying box is fixedly connected to the upper portion of the right side of the outer surface of the drying tank; and a stirring mechanism is arranged in the drying tank and the motor box, and a dehumidifying mechanism is arranged in the dehumidifying box. The invention relates to the technical field of moisture determination. According to the agricultural seed moisture determination equipment and the determination method, the dehumidifying mechanism is arranged, the work of the semiconductor cooling and heating sheet and the dehumidifier is utilized, and the fan device, the first air outlet pipe, the dehumidifier, the air inlet pipe and the second air outlet pipe are matched, so that raw materials in the drying tank can be dried; and meanwhile, water vapor generated during drying can be removed, so that the drying efficiency can be improved, the required drying energy can be greatly saved, and meanwhile, the determination result is more accurate.

Owner:李琴

A kind of clothing printing device for textile

ActiveCN111806079BPrinting does not affectImprove singeing effectSingeingDrying gas arrangementsTextile printerRotational axis

The invention relates to the technical field of printing equipment in the textile industry, and discloses a printing device for textile clothes, including a singeing machine, two side plates are fixedly connected to the side of the singeing machine, and the bottom ends of the two side plates are connected to each other. The movable sleeve has a first rotating shaft, and the fixed sleeve in the middle of the first rotating shaft is equipped with a first cloth guide roller located between two side plates. The tops of the two side plates are respectively provided with chute, and the two A moving tube is movably socketed inside the chute, a rotating shaft is movably socketed in the middle of the two moving pipes, and a positioning plate is fixedly socketed in the middle of the rotating shaft. The clothing printing device for textile uses the elastic force of the spring to make the bottom of the helical blade cooperate with the top of the first cloth guide roller to press the textile, and uses the rotating shaft to drive the helical blade to turn the rudder, so that the textile is always in a flat state, thus ensuring The effect of textile singeing is high, so that it does not affect the dyeing of textiles.

Owner:晋江市嘉艺服装织造有限公司

A single compound preparation method for double-sided coating of aluminum-plastic film for power lithium battery

ActiveCN104124472BSolve the cumbersomenessSolve the costFinal product manufactureCell component detailsProduction lineSingle fold

The invention discloses a double-sided coating single-composite preparation method for aluminum-plastic films of power lithium batteries, which relates to the technical field of coating methods. Its preparation method is as follows: the aluminum foil to be coated is glued on the first surface by gravure coating, and then glued on the second surface by quantitative extrusion coating, and the material after double-sided coating enters the suspension oven. Non-contact drying is carried out, and the cured adhesive film and the double-sided lamination substrate are combined on-line five layers to realize double-sided coating and double-sided lamination at one time. It can not only solve the cumbersome and high manufacturing cost problems of double coating and double winding in the aluminum-plastic film coating process, but also solve the problem of long production line due to double coating, double compounding and single winding. The disadvantages of large area occupation and unstable quality can effectively reduce the cumbersome operation, save drying energy, and save land space. At the same time, the process is relatively simple, which is conducive to stable quality.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

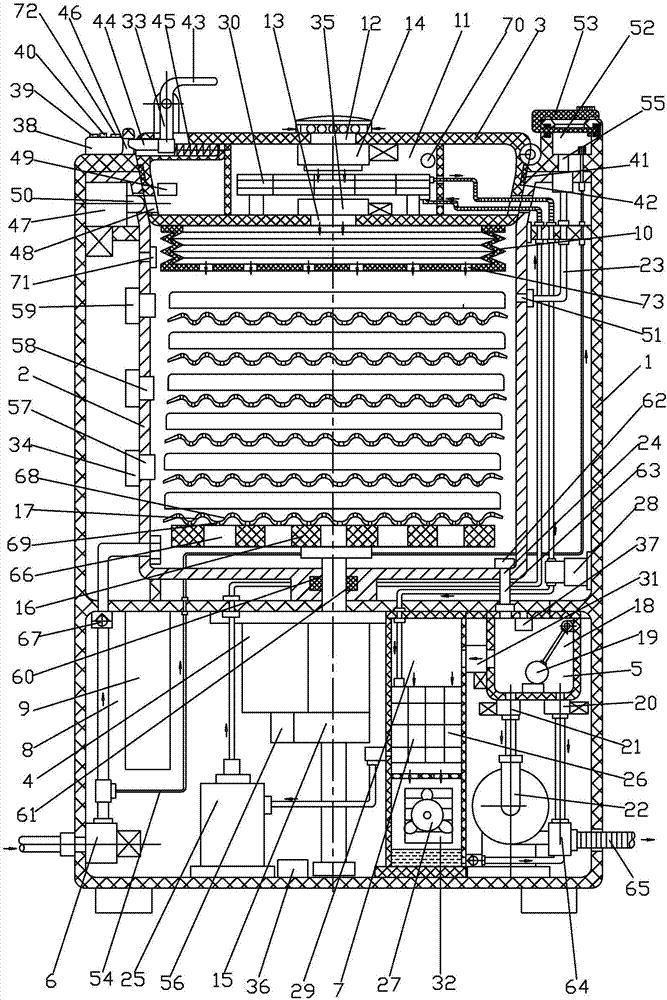

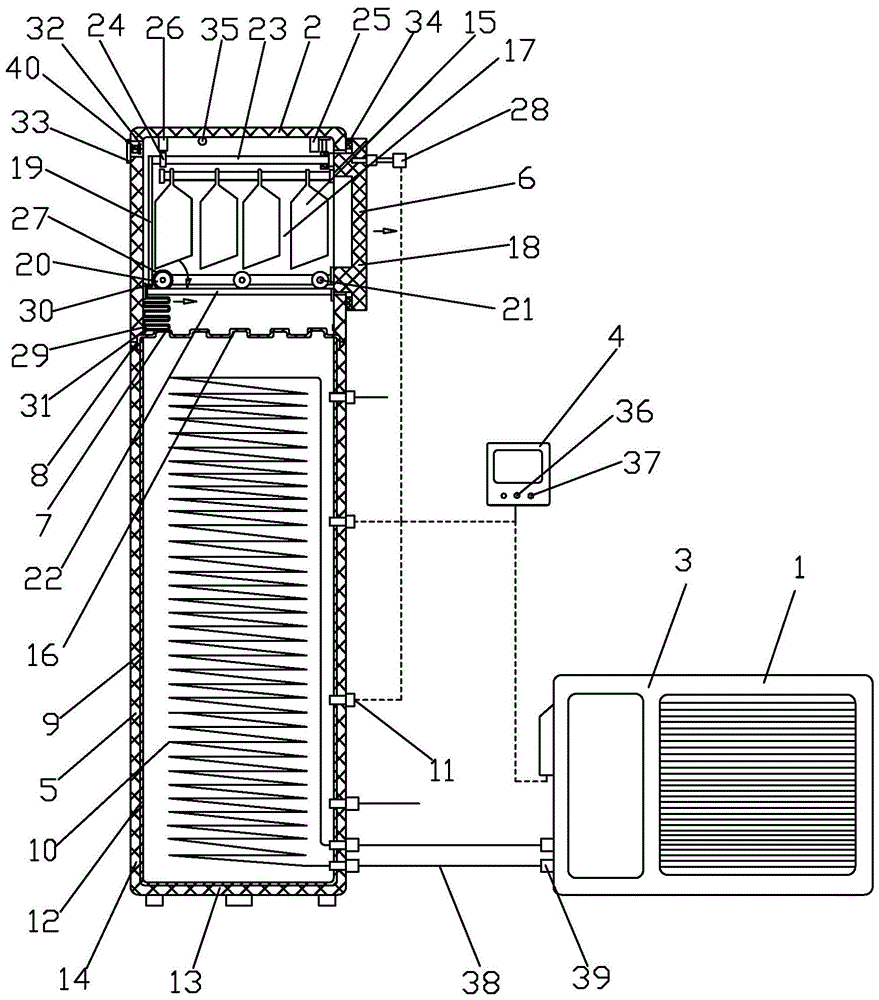

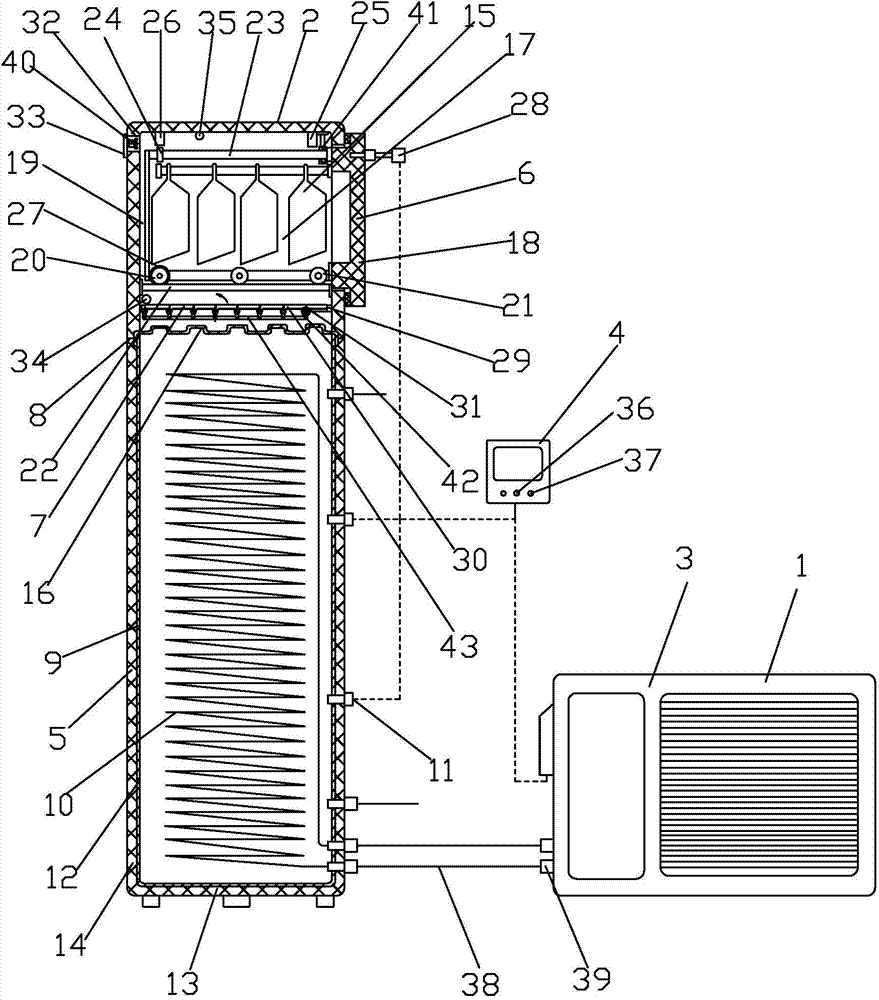

Intelligent environmentally friendly clothes drying water heater device

InactiveCN104566971AImprove protectionSave drying energyFluid heatersTextiles and paperThermal insulationEngineering

Disclosed is an intelligent environmentally friendly clothes drying water heater device. The intelligent environmentally friendly clothes drying water heater device comprises an air energy water heater and a clothes drying box, wherein the air energy water heater comprises a main computer, a linear controller and a heat preservation water tank, the clothes drying box comprises an intelligent door, a thermal insulation curtain and a connection port, the heat preservation water tank comprises a metal liner, a condenser and a temperature sensing bag, the upper end of the metal liner is connected with the connection port of the clothes drying box in seal mode, and the intelligent door comprises a movable door and a rainwater sensor. When the intelligent environmentally friendly clothes drying water heater device is used, the linear controller is used to control the condenser to heat water in the metal liner and the metal liner. When weather is good, the linear controller is used to control the movable door and a clothes drying frame to open and move out, sunlight is used to dry clothes, and simultaneously the clothes drying frame drags the thermal insulation curtain so as to close the thermal insulation curtain. In rainy days, the linear controller controls the movable door to automatically close, and simultaneously the clothes drying frame drags the thermal insulation curtain so as to open the thermal insulation curtain, air is used to dry the clothes, and therefore the intelligent environmentally friendly clothes drying water heater device has clothes drying and hot water supplying functions, and saves clothes drying energy.

Owner:ANHUI RENRENJIA SOLAR ENERGY

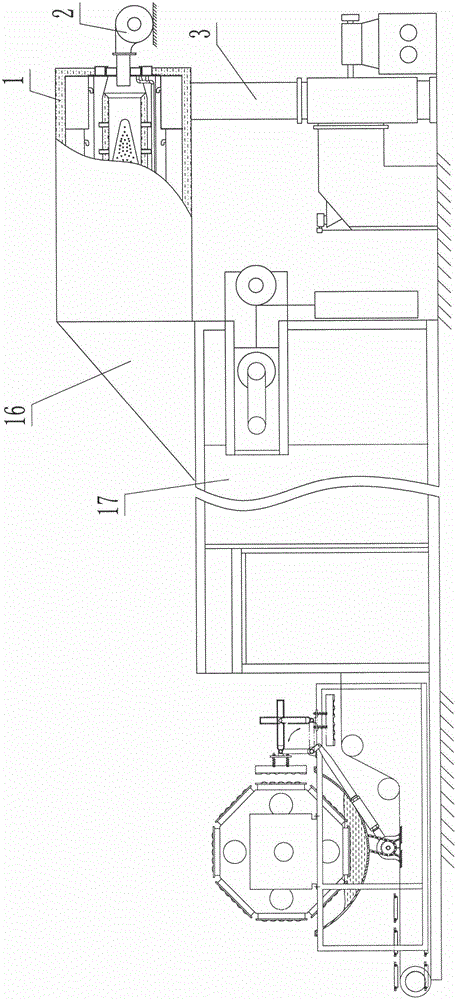

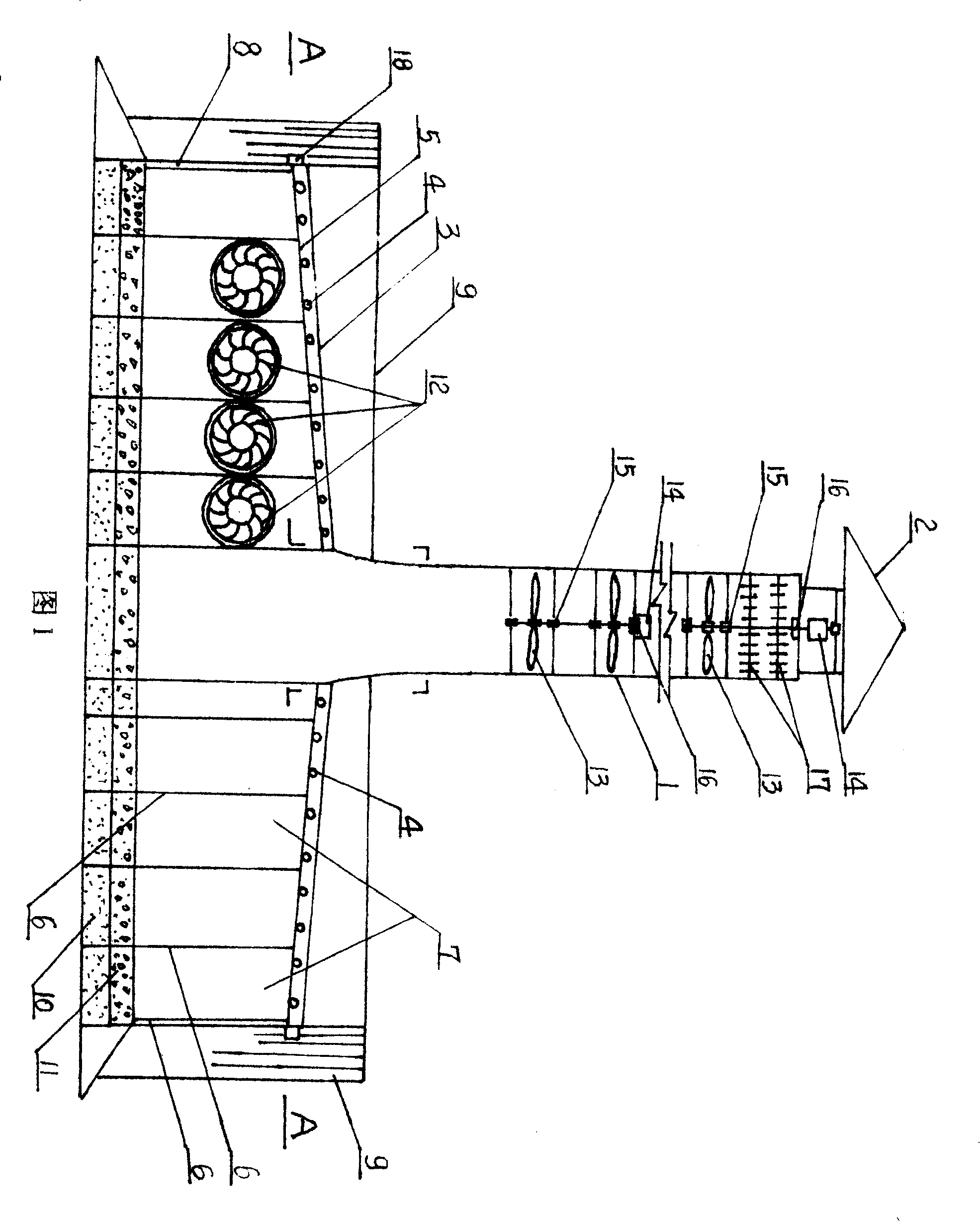

Apparatus for electricity generation by refuse incineration and hot air flow

InactiveCN100385169CReduce unit kilowatt investmentEliminates problems with large voltage fluctuationsContinuous combustion chamberSolar heat devicesThermal energyCombustion

The invention relates to a new waste burning hot gas flow generate device which can solve the problems of the waste of our country with much water, lower heat quantity and large caloricity change. The invention can make innocent treatment on the waste and fully use the heat energy to improve the economic benefits of waste generates station. The invention comprises a solar energy collection system; a waste drying combustion adjuvant system; a wind collection burning hot air flow system; a heat energy storing and releasing system; a waste burning system; a hot air flow generating system; and the heat energy recycle system.

Owner:HEBEI AGRICULTURAL UNIV.

Combustion-supporting device in the combustion chamber of the drying box of the egg tray machine

InactiveCN105570925BReduce pollutionSave drying energyCombustion processDrying gas arrangementsCombustion chamberEngineering

The invention discloses a combustion-supporting device of a combustion chamber of an egg tray machine drying box. According to the combustion-supporting device, an inner combustion-supporting chamber and an outer combustion-supporting which are sequentially in looping connection with the combustion chamber in a spaced manner are connected with an air distributing disc on the end face of the combustion chamber; the position, opposite to the air distributing disc, of the outer side face of a shell is in looping connection with an inner air ring and an outer air ring; an end face air inlet hole of the inner air ring and an end face air inlet hole of the outer air ring correspondingly communicate with an end face inner air inlet hole and an end face outer air inlet hole of the air distributing disc; an end face air outlet hole of the inner air ring and an end face air outlet hole of the outer air ring are opposite to an end face inner air outlet hole and an end face outer air outlet hole of the air distributing disc and rotationally communicate with the inner combustion-supporting chamber and the outer combustion-supporting in a fine tuning manner; a hot air outlet of the inner combustion-supporting chamber is connected with an inner combustion-supporting disc; the position close to a hot air outlet of the outer combustion-supporting chamber is connected with an outer combustion-supporting ring in looping connection with the outer diameter of the inner combustion-supporting chamber; and the periphery of the inner combustion-supporting chamber is connected with a guide pipe communicating with the outer combustion-supporting chamber. During work, flames which are not fully combusted are fully combusted through five times of combustion supporting of a conical combustion supporting bypass pipe, the inner combustion-supporting chamber, the outer combustion-supporting chamber, the inner combustion-supporting disc and the outer combustion-supporting d ring, drying energy is effectively saved, and pollution to the air environment is obviously reduced.

Owner:程义浩

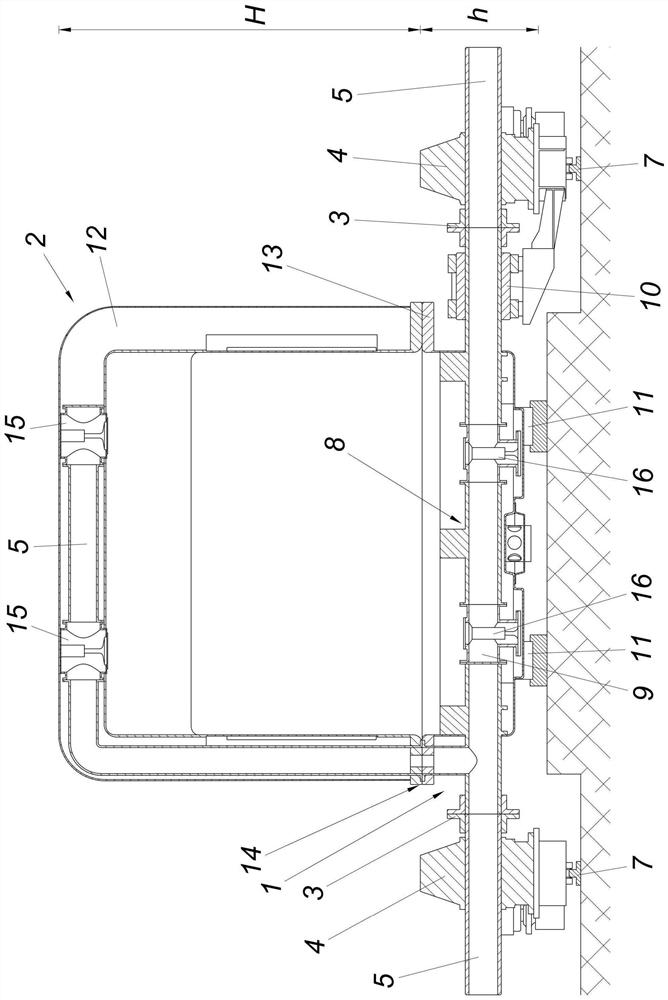

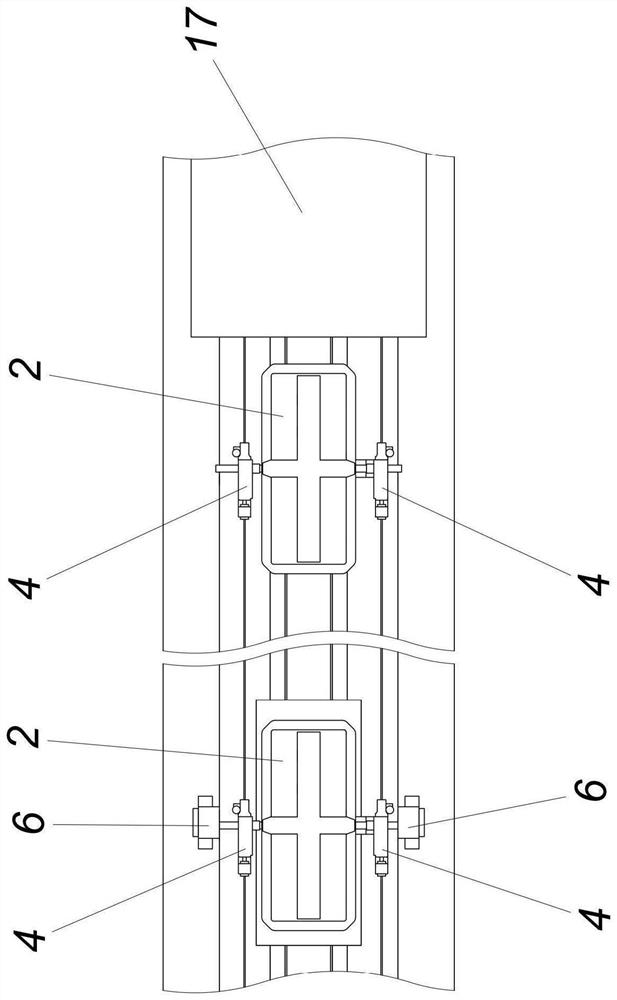

Device for treating surface of workpiece in assembly line

PendingCN114729465ASave drying energyEasy to adjustLiquid spraying plantsLiquid surface applicatorsProduction lineCoupling

The invention relates to a device for the surface treatment of workpieces in a production line, comprising a positioning frame (1) for the workpieces to be treated, said positioning frame having couplings (3) for positioning a drive (4). In order to increase productivity independently of the surface treatment without having to endure losses in terms of the surface quality of the coating, it is proposed that a sealably closable housing (2) is supported on the positioning frame (1), said housing having a connecting line (5) for exchanging working material with different working material supply units (6) arranged along the line.

Owner:斯泰尔控股有限公司

Intelligent environmental protection drying clothes water heater device

InactiveCN104566971BImprove protectionSave drying energyFluid heatersTextiles and paperThermal insulationSmart water

Disclosed is an intelligent environmentally friendly clothes drying water heater device. The intelligent environmentally friendly clothes drying water heater device comprises an air energy water heater and a clothes drying box, wherein the air energy water heater comprises a main computer, a linear controller and a heat preservation water tank, the clothes drying box comprises an intelligent door, a thermal insulation curtain and a connection port, the heat preservation water tank comprises a metal liner, a condenser and a temperature sensing bag, the upper end of the metal liner is connected with the connection port of the clothes drying box in seal mode, and the intelligent door comprises a movable door and a rainwater sensor. When the intelligent environmentally friendly clothes drying water heater device is used, the linear controller is used to control the condenser to heat water in the metal liner and the metal liner. When weather is good, the linear controller is used to control the movable door and a clothes drying frame to open and move out, sunlight is used to dry clothes, and simultaneously the clothes drying frame drags the thermal insulation curtain so as to close the thermal insulation curtain. In rainy days, the linear controller controls the movable door to automatically close, and simultaneously the clothes drying frame drags the thermal insulation curtain so as to open the thermal insulation curtain, air is used to dry the clothes, and therefore the intelligent environmentally friendly clothes drying water heater device has clothes drying and hot water supplying functions, and saves clothes drying energy.

Owner:ANHUI RENRENJIA SOLAR ENERGY

Intelligent energy-saving water heater

ActiveCN104501408ASave drying energyLow manufacturing costFluid heatersTextiles and paperProcess engineeringSource water

The invention provides an intelligent energy-saving water heater. The intelligent energy-saving water heater comprises an air-source water heater an a clothes drying box; the air-source water heater comprises a main machine, a wired controller and a heat preserving water tank; the clothes drying box comprises an intelligent door, a heat insulation door and a connector; the intelligent door comprises a movable door and a rainwater sensor; the wired controller is equipped with a clothes drying intelligent switch and a movable door control switch; the wired controller controls a condenser to heat water in an inner metal tank and the inner metal tank; the heated inner metal tank is separated from a clothes drying cavity of the clothes drying box through the heat insulation door; the intelligent door is controlled by the wired controller and the rainwater sensor to be opened and closed; the wired controller, a temperature sensor and a humidity sensor are used for controlling the heat insulation door to be opened and closed; clothes can be dried through the sunshine in a sunny day or dried with the air source in a rainy day; therefore, the intelligent energy-saving water heater has the functions of drying the clothes and supplying hot water, the energy for drying the clothes is saved, and moreover, the manufacturing cost is decreased.

Owner:临沂高新区金蓝领劳务有限公司

Processing method of spunlace environment-friendly filter material

ActiveCN103301686BShort processSave drying energyFibre typesFiltration separationDry weightPore water pressure

The invention discloses a processing method of a spunlace environment-friendly filter material. The processing method of the spunlace environment-friendly filter material comprises the following steps of: carrying out front-back spunlace on a filter material with the gram weight of 60-120 needling / cm<2> and pre-needling density of 400-700g / m<2> by adopting water pressure of 300-400 BAR; controlling the speed of a vacuum pump through water content on-line detection 1 so that the moisture percentage of the filter material subjected to a dehydration technology is controlled to less than 50%; adding a pressing roller in a glue groove, and controlling the pressure to be 10N-20N / CM so that teflon emulsion permeates into the filter material; controlling the glue quantity and the pressure of the pressing roller through the difference value of water content on-line detection A and water-content on-line detection B, thereby controlling the dry weight ratio of teflon emulsion to the filter material to achieve (1:9)-(3:7); and drying and sizing, and controlling the product thickness and surface smoothness through hot pressing. According to the processing method of the spunlace environment-friendly filter material, immersion treatment is directly carried out after spunlace, and then drying and sizing are carried out, and the existing process of drying after spunlace is omitted, thus the technology process is shortened, and 50% of drying energy consumption is saved.

Owner:南京际华三五二一环保科技有限公司

A Closed High Efficiency Waste Heat Utilization Circulation System of Humid Air Turbine Compressor

ActiveCN110975310BIncrease profitReduce manufacturing costEvaporator accessoriesMachines/enginesWater storageExhaust fumes

The invention discloses a humid air turbine compressor closed-type high-efficiency waste heat utilization circulation system, comprising a humid air compressor turbo compression-expansion system and a wet air gas-water separation system; the humid air compressor turbo compression-expansion system; The expansion system includes a shut-off valve I, a regulating valve and a humid air turbine connected to the outlet of the drying chamber; the humid air compressor turbine compression-expansion system also includes a humid air compressor connected to the inlet of the drying chamber through a shut-off valve VIII; The wet air gas-water separation system includes a wet air gas-water separator, and the wet air gas-water separator is communicated with a vacuum water storage tank. The beneficial effects of the present invention are: this scheme can make the waste gas circulate in the closed system, avoid dust, toxic and harmful waste gas and other pollutants from entering the atmosphere, thereby protecting the environment, and the heat energy in the waste gas can be recycled and improved. The energy utilization rate is improved, and the production cost can be effectively reduced.

Owner:DONGFANG TURBINE CO LTD

Sludge resource treatment apparatus and sludge treatment method using the same

ActiveCN102276130BSave drying energyReduce energy consumptionSludge treatment by de-watering/drying/thickeningIncinerator apparatusWater vaporSludge

The invention discloses a sludge resource treatment apparatus and a sludge treatment method using the same. The apparatus comprises a collecting filter, a sludge conveying device, a waste heat drying column, a cyclone separator, a rotary kiln, a draught fan, an airheater, a gathering tank, a deodorizing tower, a gas-liquid separator and a chimney, wherein the sludge conveying device, the waste heat drying column, the cyclone separator, the draught fan, and the deodorizing tower are successively connected through pipelines. When the sludge is anhydrated by the sludge resource treatment apparatus, the sludge generated by a sewage treatment plant is treated with gravity settlement to filter free water, dried with waste heat from the rotary kiln in the waste heat drying column and enters intothe rotary kiln to realize drying or sintering of the sludge; stink, flue gas and water vapor generate during the process is guided into the deodorizing tower for treatment by the draught fan. The treatment apparatus of the present invention has a compact and stable structure, small land occupation, is convenient for maintenance, and can be prepared into container overlap to facilitate carrying and save space.

Owner:陈海渊

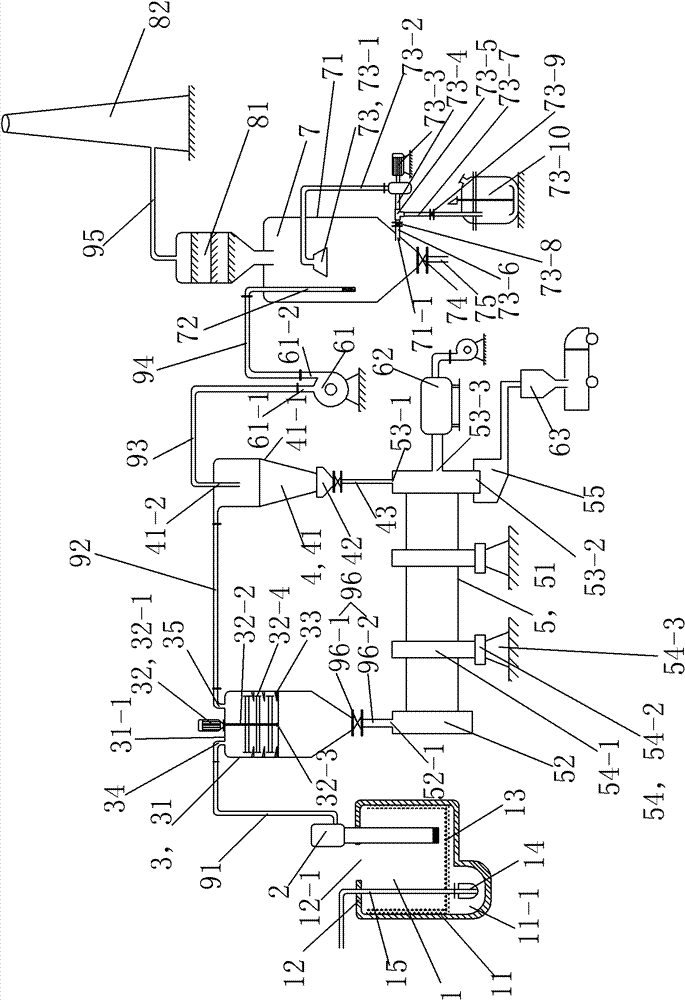

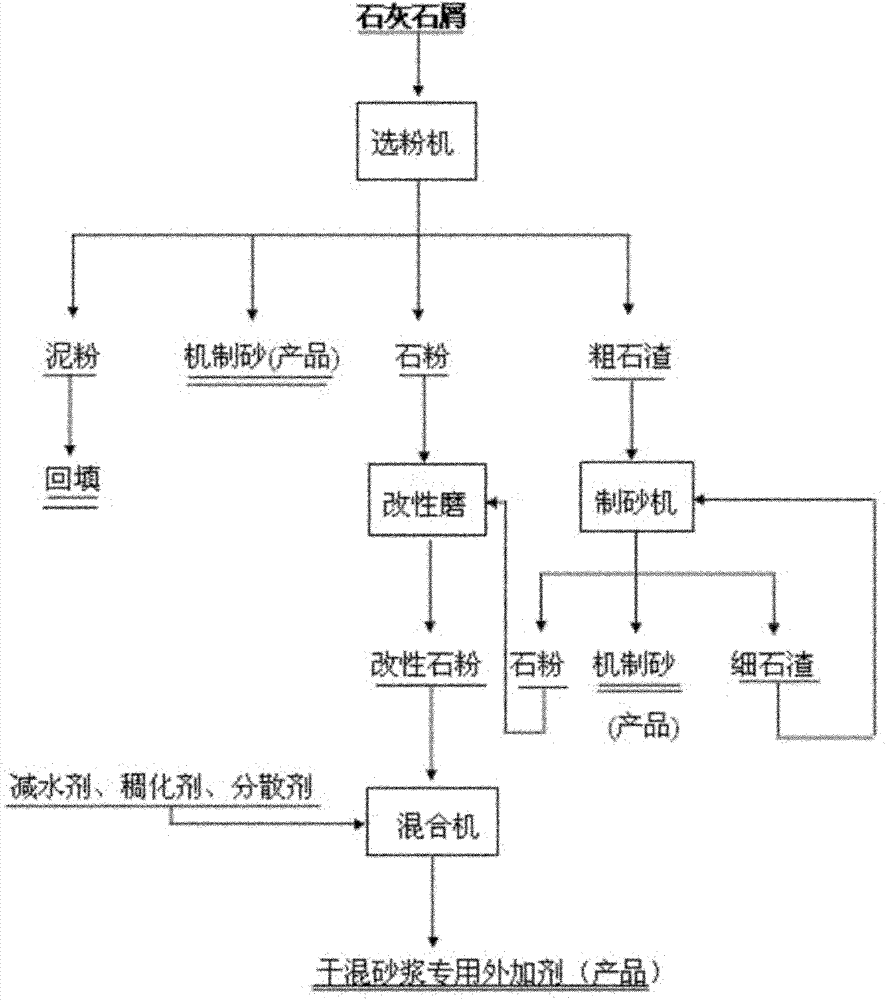

Method for producing modified mechanism sand and special admixture for dry-mixed mortar

The invention discloses and aims at providing a method for producing modified mechanism sand and special admixture for dry-mixed mortar. Lime stone chips are utilized as raw materials in the method and the method is characterized by including the steps as follows: A, powder selection, putting the lime stone chips in a powder selecting machine, separating mechanism sand, soil powder, stone powder and coarse stone ballast; B, modification of stone powder, putting the stone powder obtained from the step A into a modification mill for treatment to obtain modified stone powder; C, mixing, putting the modified stone powder obtained from the step B into a mixer and adding a thickening agent , a dispersing agent and a water reducing agent to obtain the special admixture for the dry-mixed mortar; and D, sand making, putting the coarse stone ballast obtained from the step A into a sand making machine for treatment to obtain fine stone ballast, mechanism sand and stone powder, wherein the stone powder returns to the modification mill and the fine stone ballast returns to the sand making machine. The method is mainly used for producing the modified mechanism sand and the special admixture forthe dry-mixed mortar.

Owner:HUNAN ZHENXING BUILDING MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com