Municipal sludge drying system utilizing power plant waste heat coupling solar energy

A technology of coupling solar energy and municipal sludge, applied in the field of drying municipal sludge system, can solve the problems of large energy consumption and consumption, and achieve the effect of high sludge dehydration rate, improved thermal parameters, and large drying degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

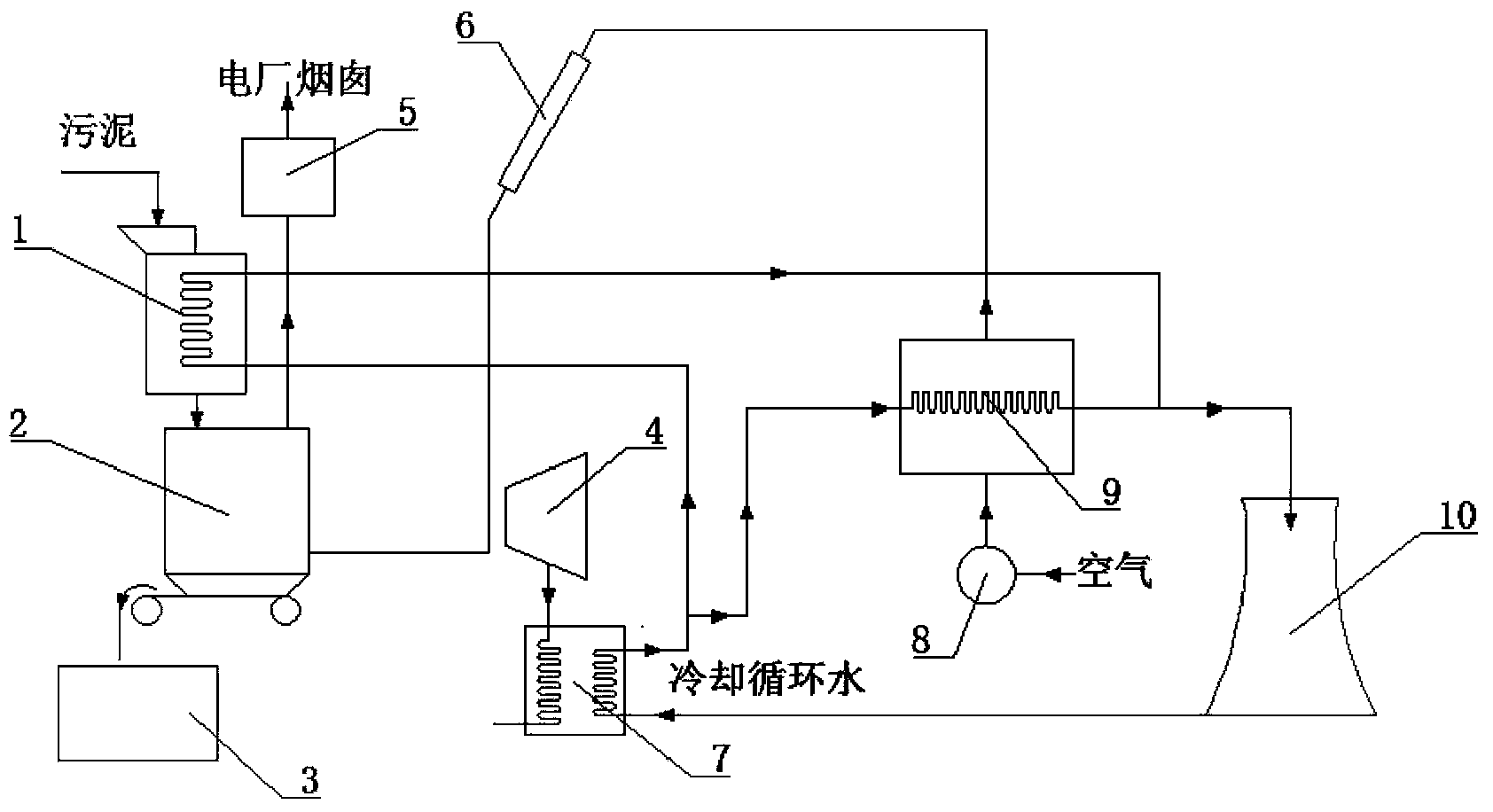

[0018] The present invention provides a system for drying urban sludge by using waste heat from a power station coupled with solar energy. The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

[0019] Such as figure 1 As shown, the sludge enters the sludge heater 1 after being pulverized, falls into the fluidized bed dryer 2 after being heated by circulating water, is dried by hot air at a higher temperature, and finally is sent to the silo 3 by the coal conveyor belt, and is left for Next resource utilization.

[0020] The exhaust steam discharged from the steam turbine 4 is condensed into water in the condenser 7, and the heat is released to the circulating water to heat up the circulating water. After the condensed water comes out of the condenser 7, the steam-water process of the power plant is completed; the circulating water in the condenser In 7, the exhaust st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com