Method for producing modified mechanism sand and special admixture for dry-mixed mortar

A dry-mixed mortar and machine-made sand technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of poor operability of mortar construction, many soil impurities in sand, and large amount of admixtures, etc., to achieve Improve the efficiency of laying and plastering, reduce ground ash, and save cement and lime paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

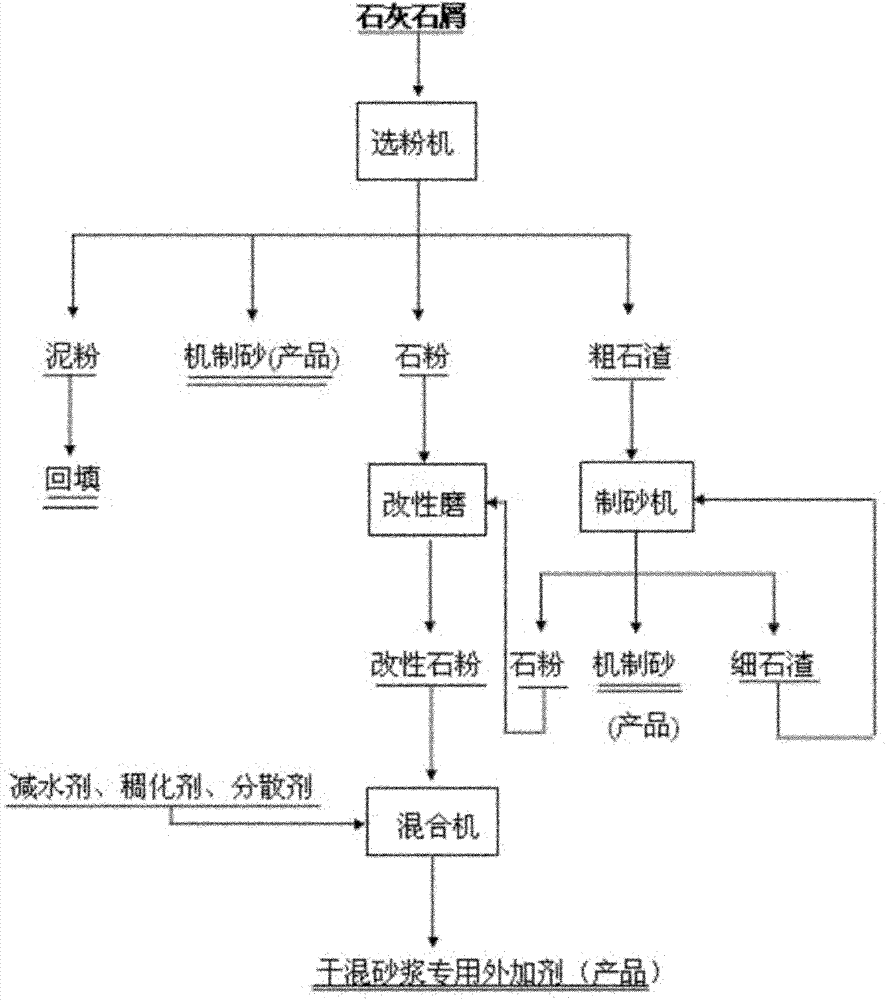

[0011] Limestone chips are continuously put into the powder separator, which is a combination of vibrating screen, frequency conversion fan, cyclone separator and bag filter. The limestone chips processed in the powder classifier are continuously discharged to obtain mud powder, stone powder, coarse gravel, and machine-made sand (products). The obtained mud powder is sent to backfill the land, and the stone powder is continuously sent to the modified mill. The sex mill is a blade hammer mill, and the modified stone powder is continuously obtained through the modified mill, which is sent to the storage tank for storage.

[0012] Get 1000 kilograms of modified stone powder and put it into the mixer, then add 10 kilograms of thickening agent (lignocellulose, produced by Changsha Defeng Building Materials Co., Ltd.), dispersant (trade name NNO diffusing agent, Hengyuan Chemical Co., Ltd., Taixing City, Jiangsu Province) Factory production) 3 kg, water reducer (polycarboxylate, pro...

example 2

[0014] Put 1 ton of modified stone powder into the mixer, then add 15 kg of thickener (lignocellulose), 5 kg of dispersant (NNO diffusing agent), and 2 kg of water reducer (polycarboxylate) into the mixer. Stir for 5 minutes to obtain the special admixture (product) for dry-mixed mortar, and all the other are the same as Example 1.

example 3

[0016] Take 1 ton of modified stone powder and put it into the mixer, then add 30 kg of thickener (lignocellulose), 7 kg of dispersant (NNO diffusing agent), and 3 kg of water reducing agent (polycarboxylate) into the mixing machine. machine, stirred for 5 minutes to obtain the special admixture (product) for dry-mixed mortar, and all the other were with example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com