Processing method of spunlace environment-friendly filter material

A processing method and filter material technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve problems such as product performance degradation and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

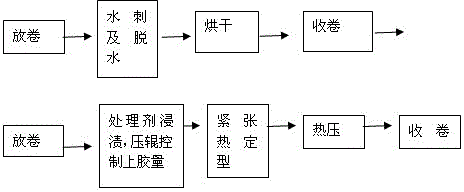

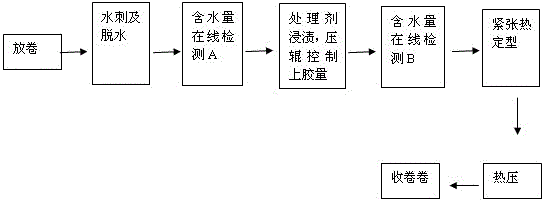

Method used

Image

Examples

Embodiment 1

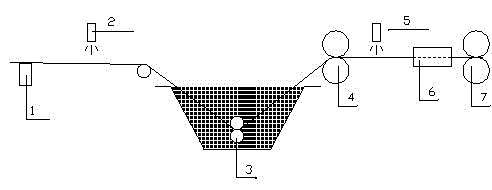

[0019] A processing method of spunlace environmental protection filter material is characterized in that the method comprises the following steps:

[0020] 1) Spunlace dehydration process. For the polyphenylene sulfide filter material with a gram weight of 400g / m2 and a pre-needling density of 60 thorns / cm2, use 300bar (positive), 350bar (reverse), 350bar (positive), 400bar (reverse), 300bar (positive) water Spunlace was performed 5 times.

[0021] 2) Process A of online moisture content detection. Control the speed of the vacuum pump through the online detection of water content A2, so that the moisture content of the filter material after the dehydration process is controlled below 50% (moisture / moisture + filter material*100%).

[0022] 3) Dilute the polytetrafluoroethylene emulsion and water at a ratio of 1:4, and add 0.1% penetrant op-10.

[0023] 4) The process of pressing rollers in the glue tank. The pressure roller in the glue tank is controlled at 10N / CM so that ...

Embodiment 2

[0028] 1) For the PTFE filter material with a gram weight of 700g / m2 and a pre-needling density of 120 thorns / cm2, use 300bar (positive), 350bar (reverse), 350bar (positive), 400bar (reverse), 300bar (positive) ) water pressure for positive and negative spunlace 5 times.

[0029] 2) Control the speed of the vacuum pump through the online detection of water content 1, so that the moisture content of the filter material after the dehydration process is controlled below 50% (moisture / moisture + filter material*100%).

[0030] 3) Dilute the polytetrafluoroethylene emulsion and water at a ratio of 1:4, and add 1% penetrant op-10

[0031] 4) The pressure roller in the glue tank, the pressure is controlled at 20N / CM so that the PTFE emulsion can penetrate into the inside of the filter material

[0032] 5) Through the difference between the online monitoring of water content 1 and the online monitoring of water content 2, the amount of glue is controlled to control the pressure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com