A single compound preparation method for double-sided coating of aluminum-plastic film for power lithium battery

A double-sided coating and aluminum-plastic film technology, applied in the coating field, can solve the problems of high manufacturing cost, unstable quality, long production line, etc., and achieve the effects of simple process, saving drying energy, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

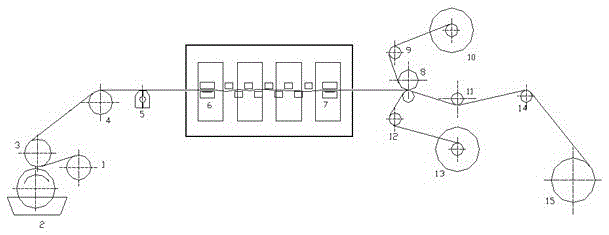

[0012] Reference figure 1 , This specific embodiment adopts the following technical solution: its preparation method is: the aluminum foil to be coated is glued on the first side by gravure coating, and then glued on the second side by quantitative extrusion coating, double-sided The coated material enters a suspension oven for non-contact drying. The cured adhesive film is combined with the two-sided laminated substrate for on-line five-layer compounding to achieve double-sided coating and double-sided pressing at one time.

[0013] The specific operation steps of this specific implementation manner are:

[0014] 1. Coating on the first side: first send the aluminum foil of the aluminum plastic film to the first gravure coating mechanism 2, the second gravure coating mechanism 3, and realize the single-sided glue of the aluminum foil.

[0015] 2. Second side coating: pass the above-mentioned coated material through the transmission wheel 4, and install a precision extrusion-type co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com