Device for treating surface of workpiece in assembly line

A surface treatment and assembly line technology, applied in the direction of surface coating liquid devices, coatings, electrolytic coatings, etc., can solve the problems of surface treatment quality reduction, reduction, pollution and paint quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

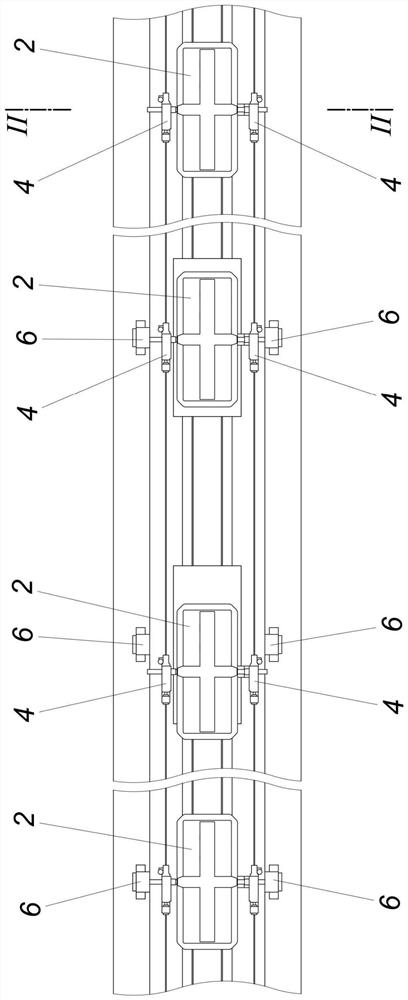

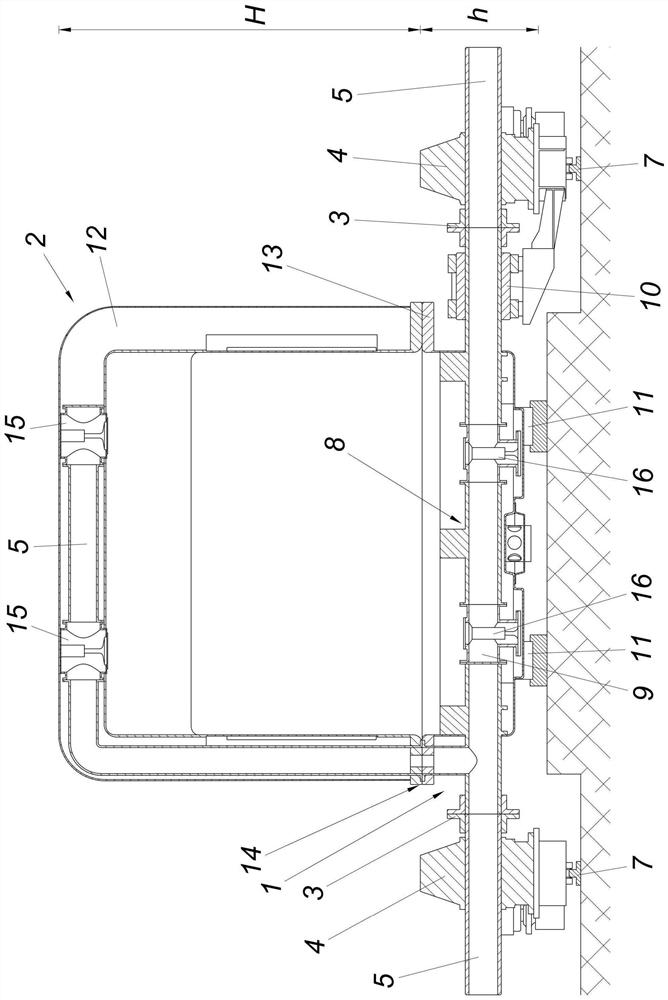

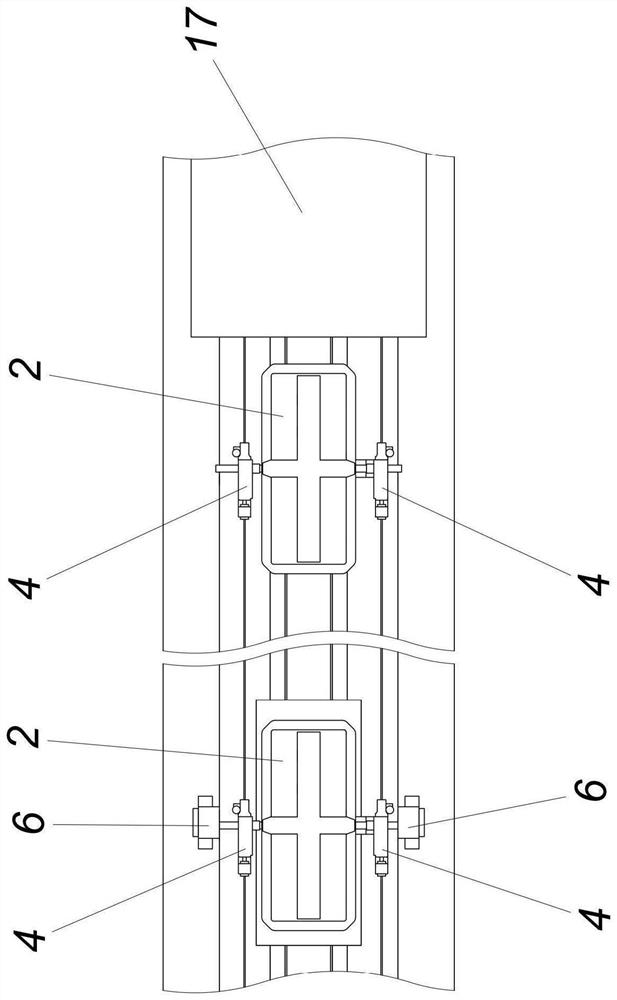

[0027] The device according to the invention for surface treatment of workpieces is, in particular, figure 2 As shown, there is a housing 2 supported on a positioning frame 1 . In order to be able to move the cover 2 along the figure 1 In the pipeline transport shown in , the positioning frame 1 is connected to the positioning drive 4 via the coupling 3 . Depend on figure 2 It is also known that two positioning drives 4 may also be provided, and the two positioning drives are respectively connected to the positioning frame 1 through the coupling member 3 . The enclosure 2 can be hermetically closed, thereby producing a reaction chamber that is closed relative to the surrounding environment. By keeping the reaction space as small as possible, a particularly resource-saving surface treatment can be achieved, since the process conditions can already be influenced and optimized with a smaller flow of working material. The control of the environment in the reaction chamber or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com