Patents

Literature

141results about "Electrostatic heating/cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

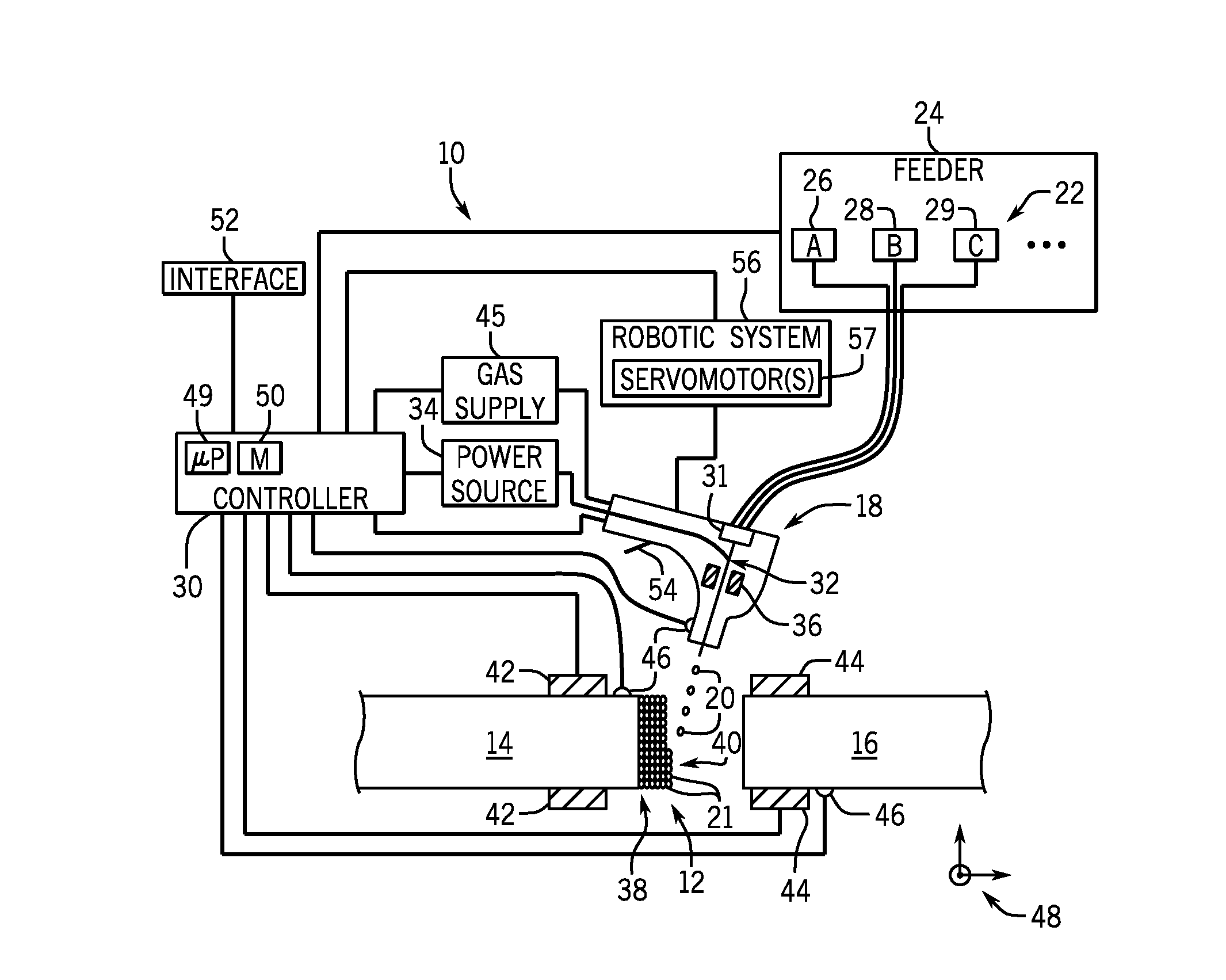

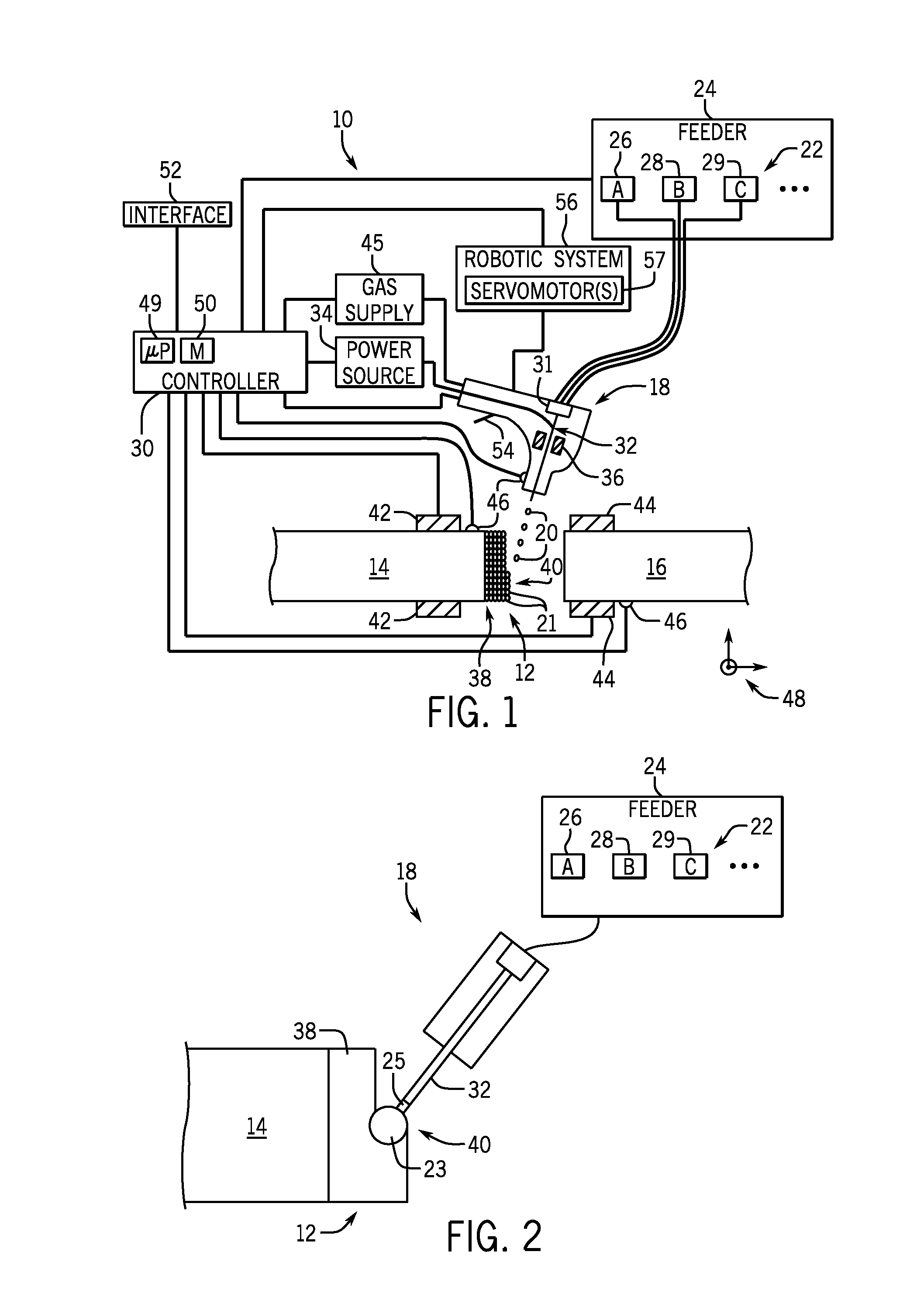

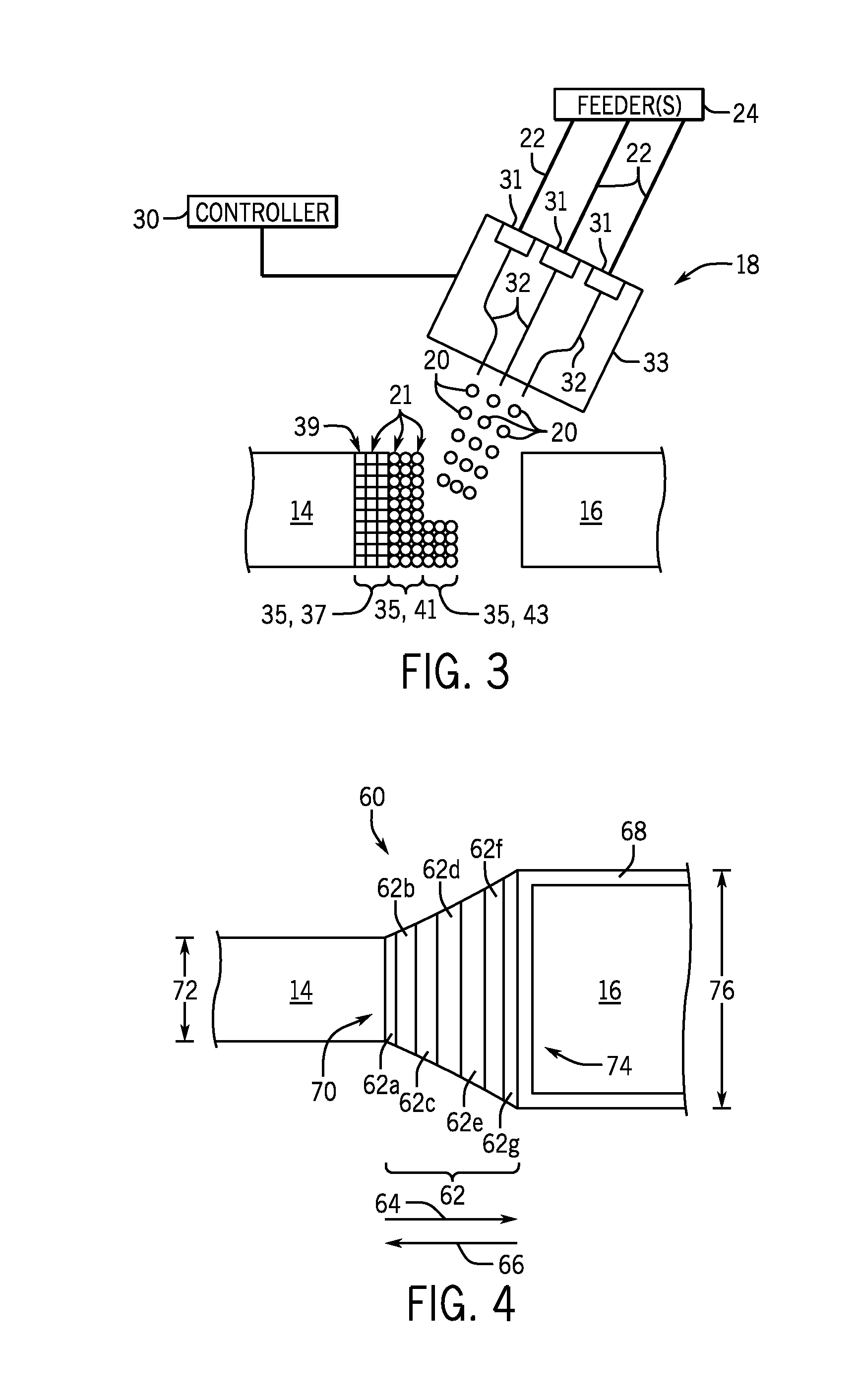

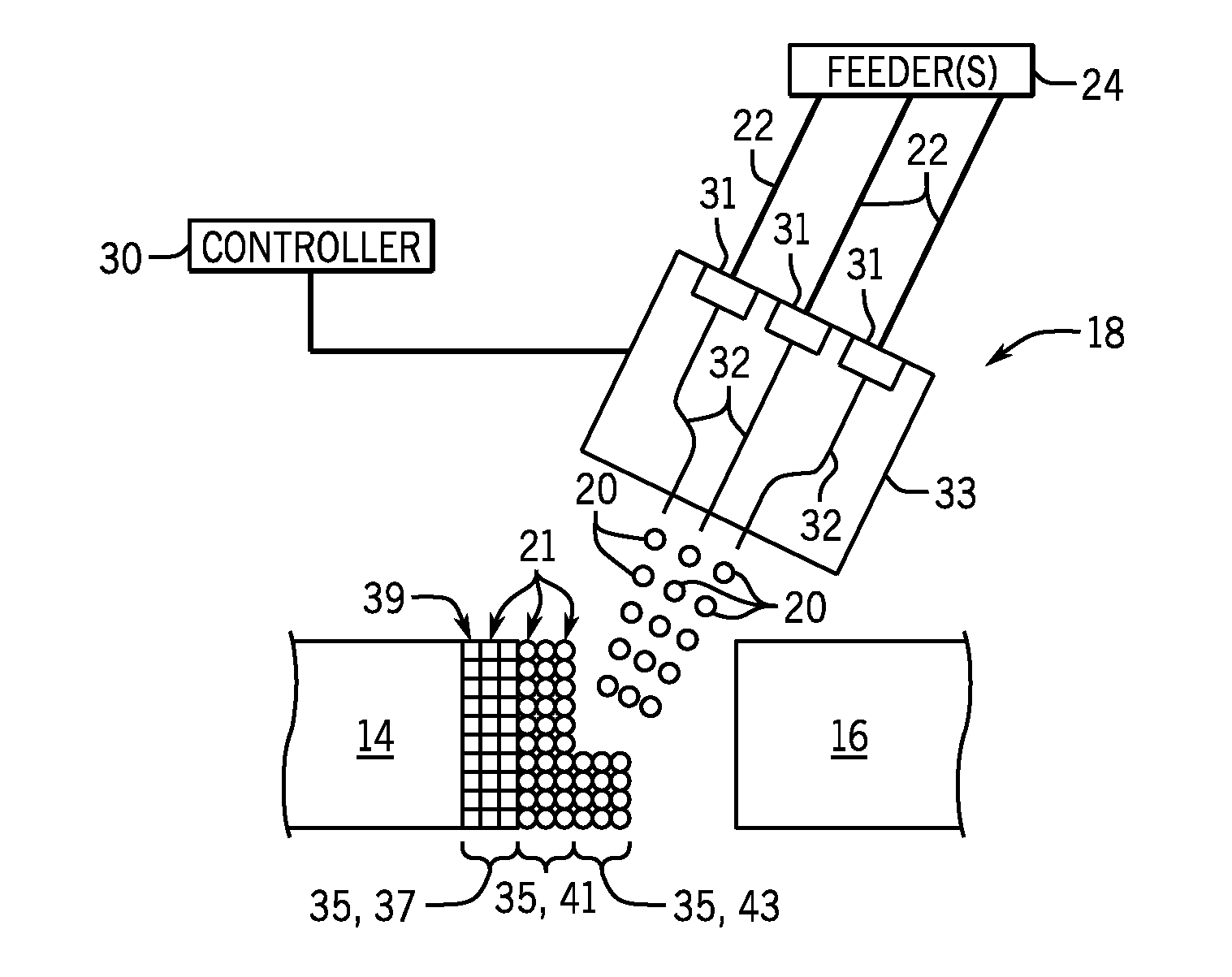

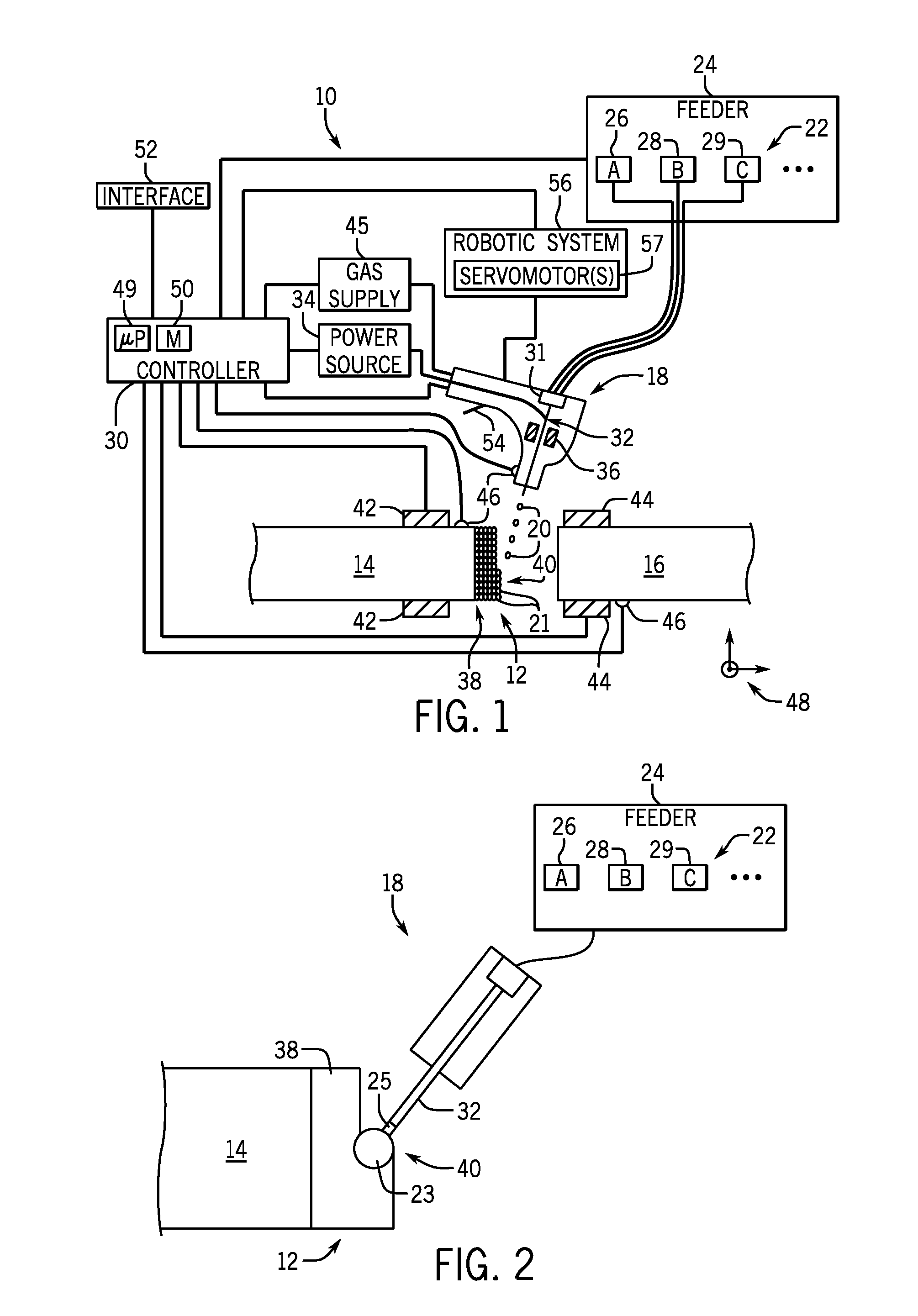

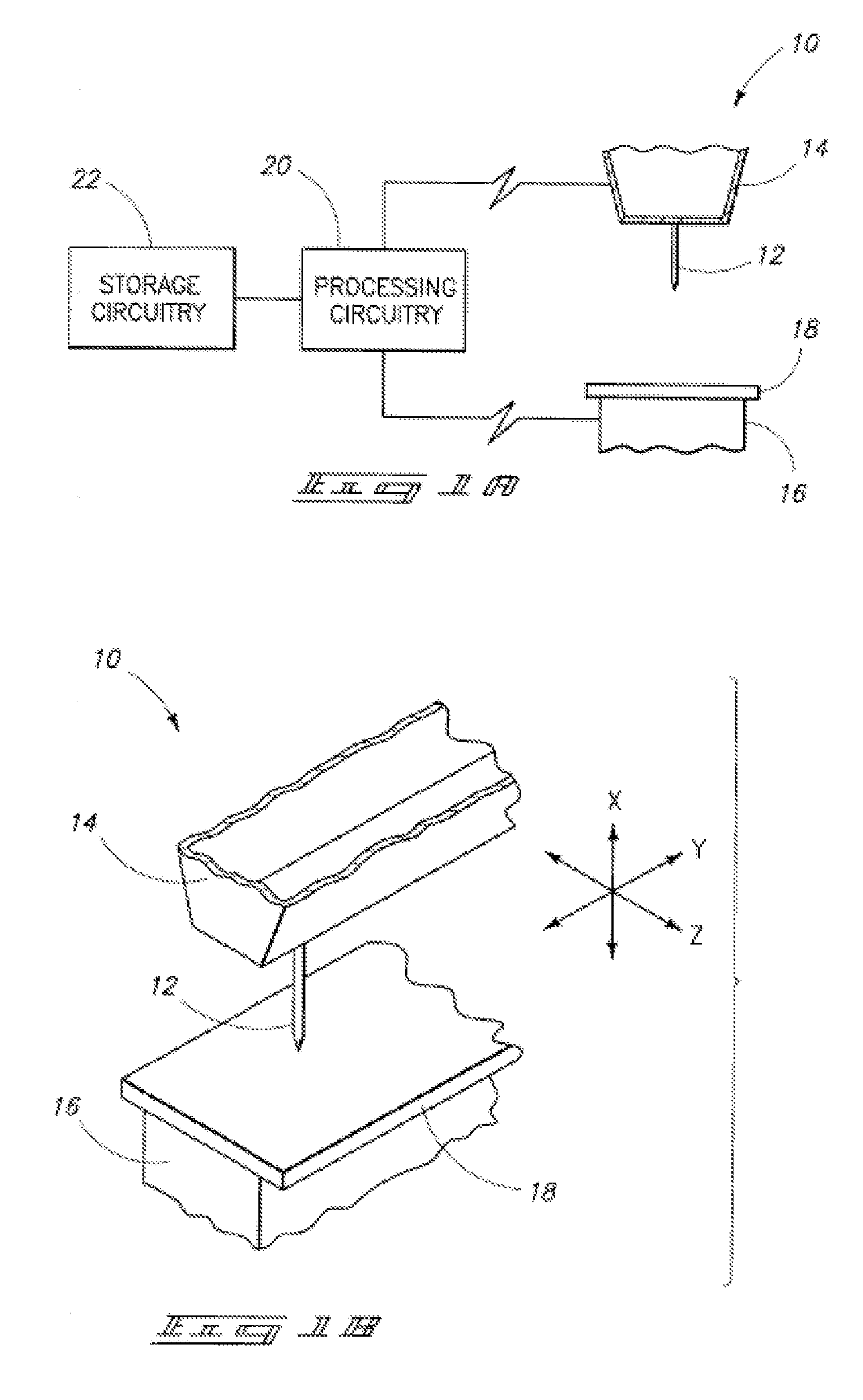

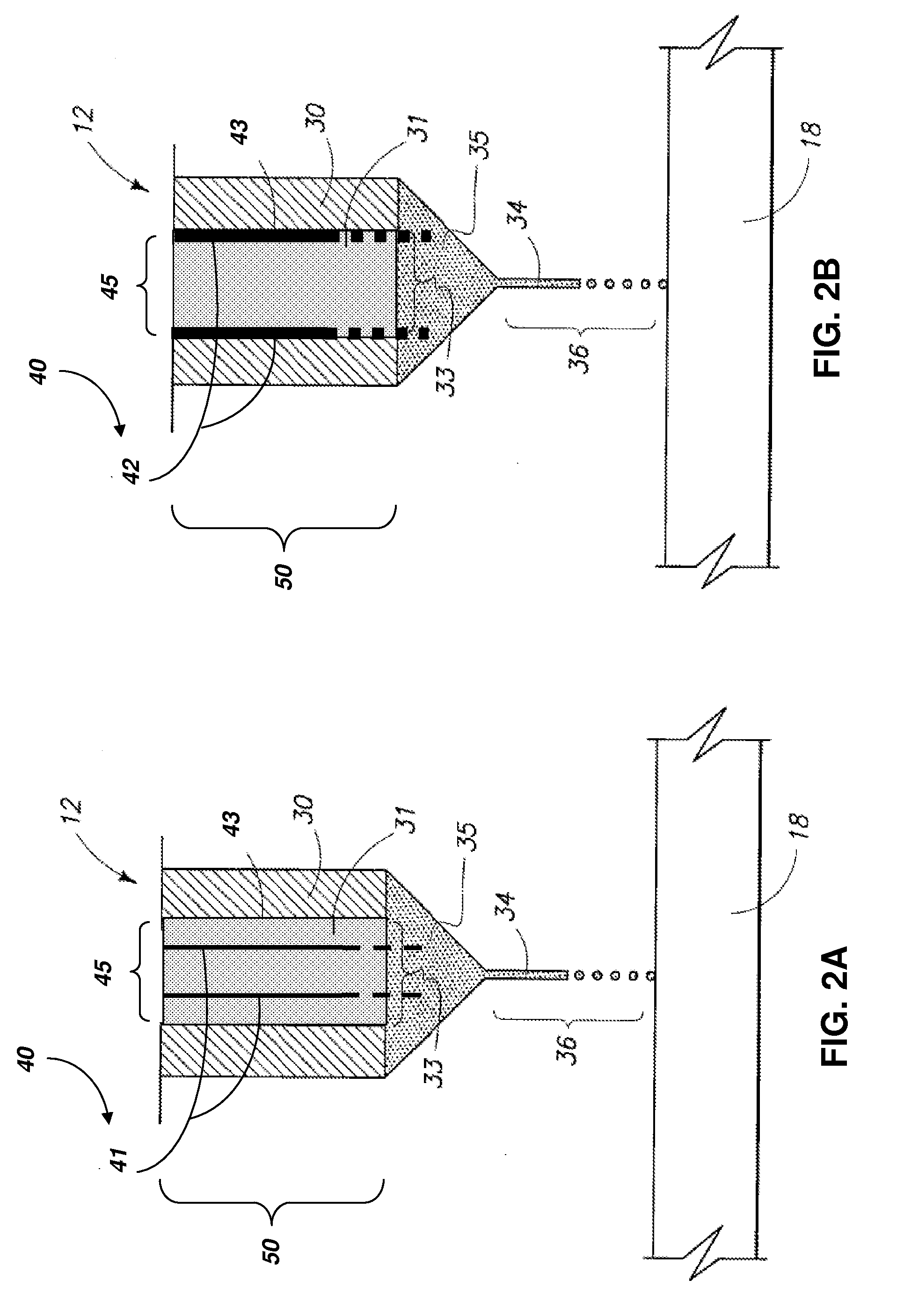

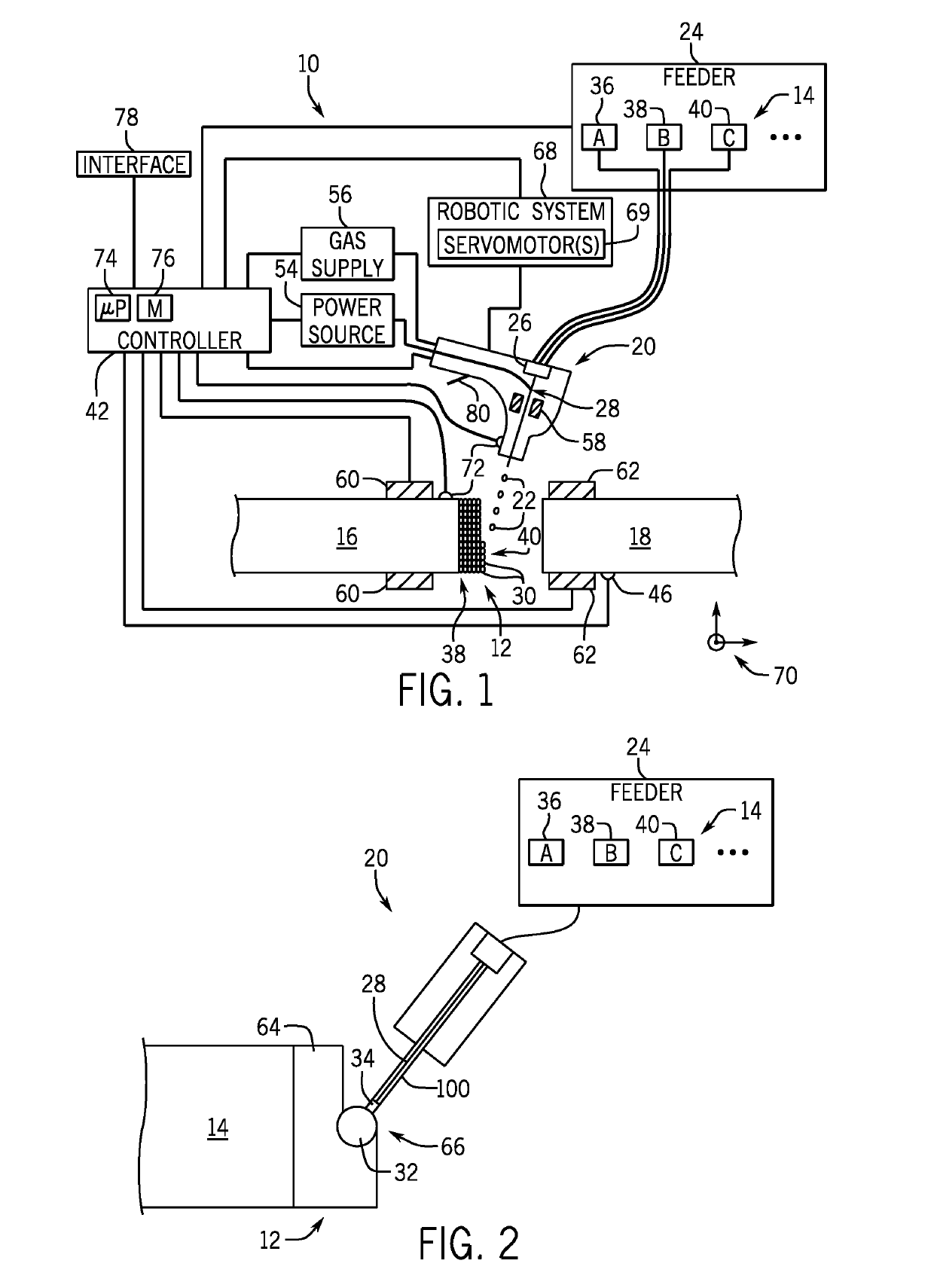

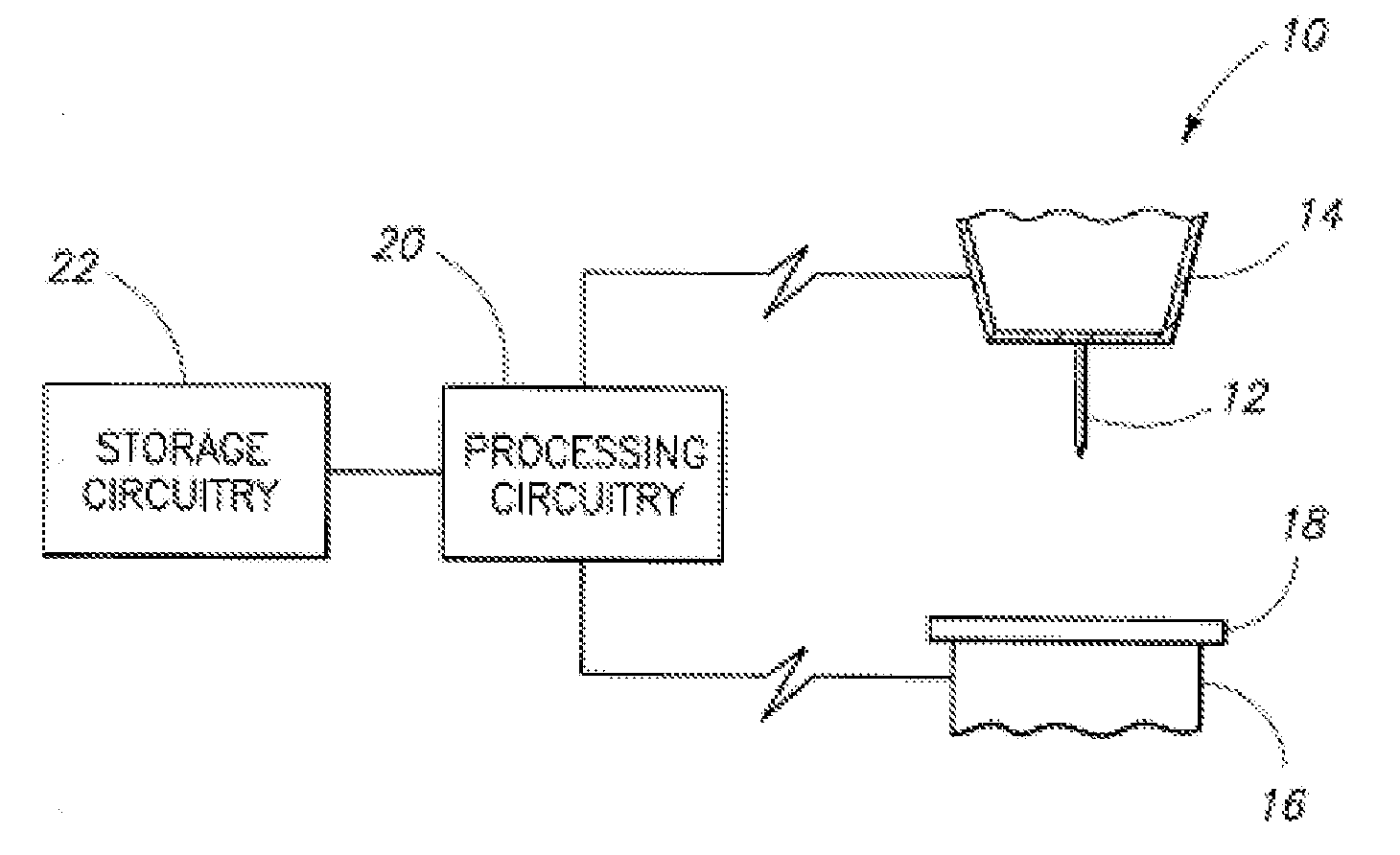

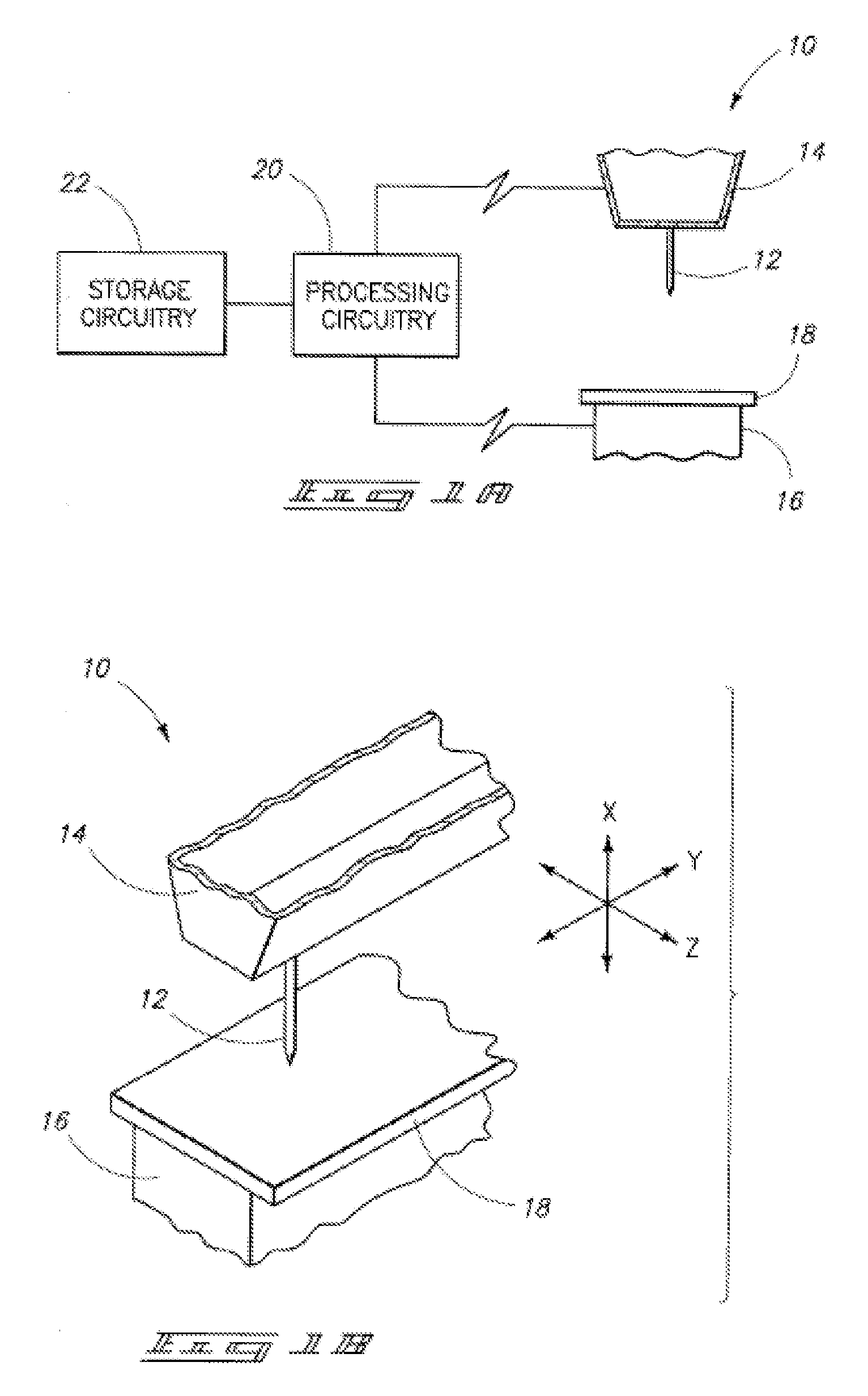

Additive manufacturing heating control systems and methods

ActiveUS20150021815A1Additive manufacturing apparatusMolten spray coatingTemperature controlControl system

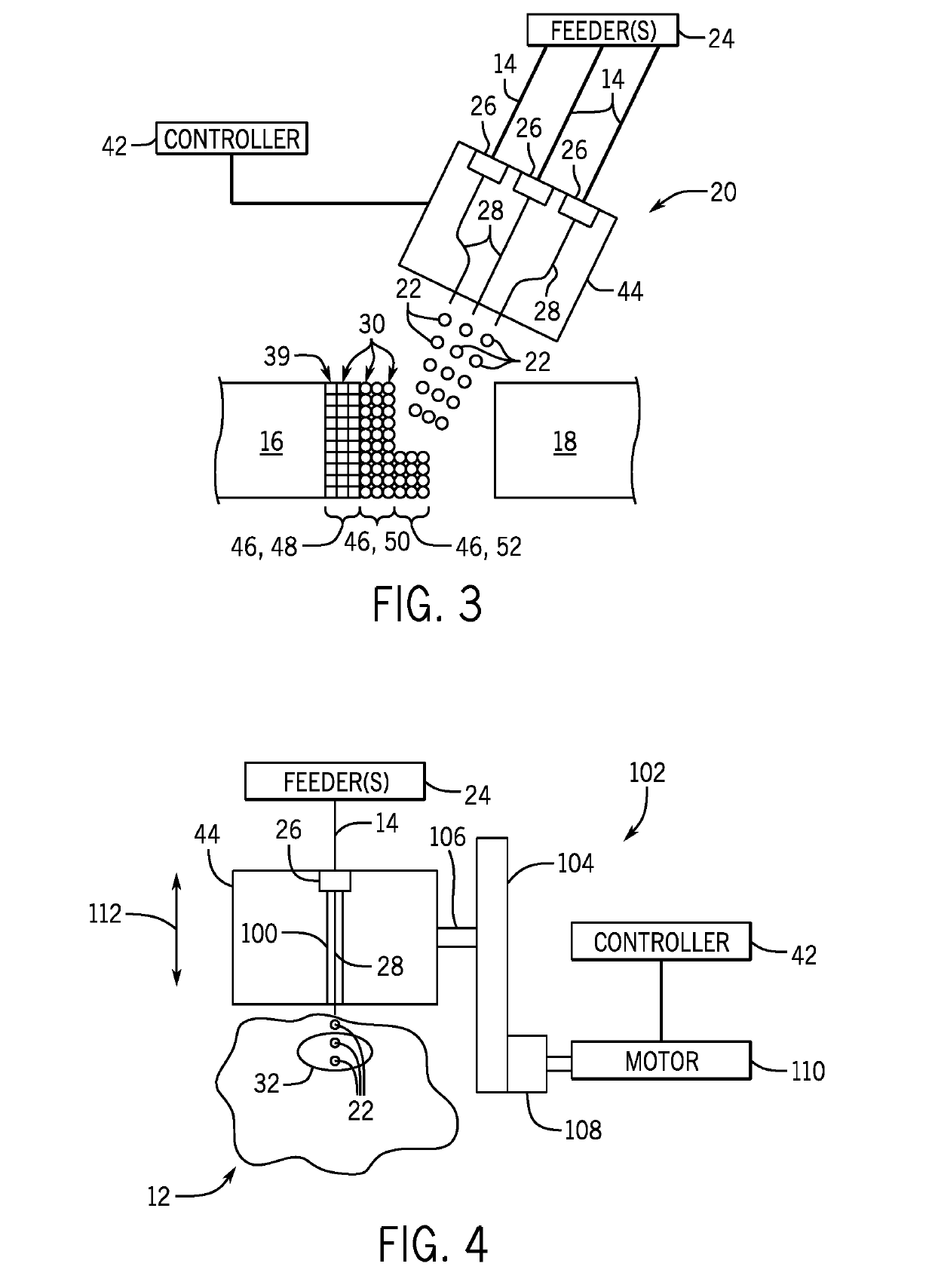

An additive manufacturing system includes an additive manufacturing tool configured to supply a plurality of droplets to a part, a temperature control device configured to control a temperature of the part, and a controller configured to control the composition, formation, and application of each droplet to the plurality of droplets to the part independent from control of the temperature of the part via the temperature control device. The plurality of droplets is configured to build up the part. Each droplet of the plurality of droplets includes at least one metallic anchoring material.

Owner:ILLINOIS TOOL WORKS INC

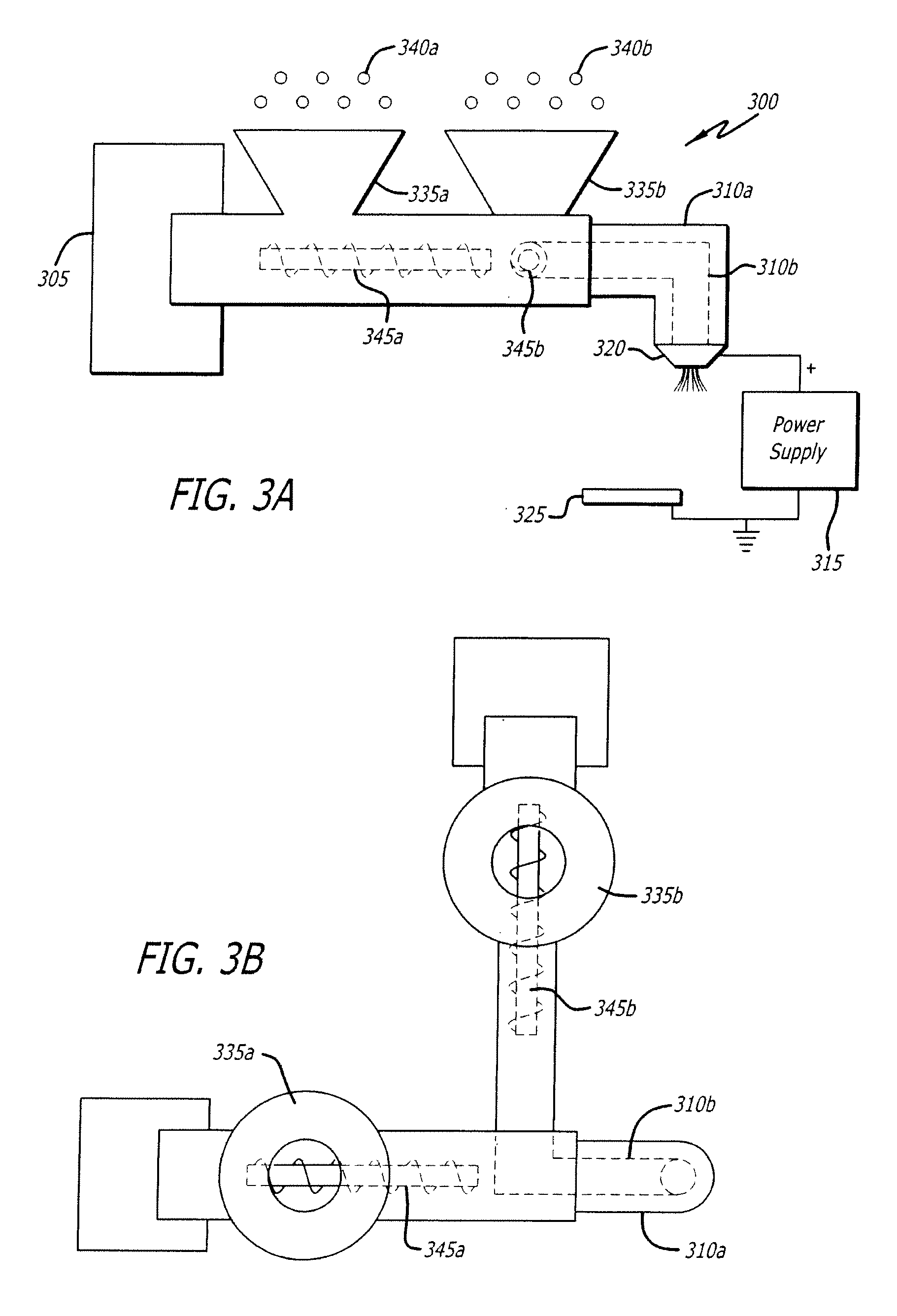

Additive manufacturing system for joining and surface overlay

An additive manufacturing system includes an additive manufacturing tool configured to receive a plurality of metallic anchoring materials and to supply a plurality of droplets to a part, and a controller configured to independently control the composition, formation, and application of each droplet to the plurality of droplets to the part. The plurality of droplets is configured to build up the part. Each droplet of the plurality of droplets includes at least one metallic anchoring material of the plurality of metallic anchoring materials.

Owner:ILLINOIS TOOL WORKS INC

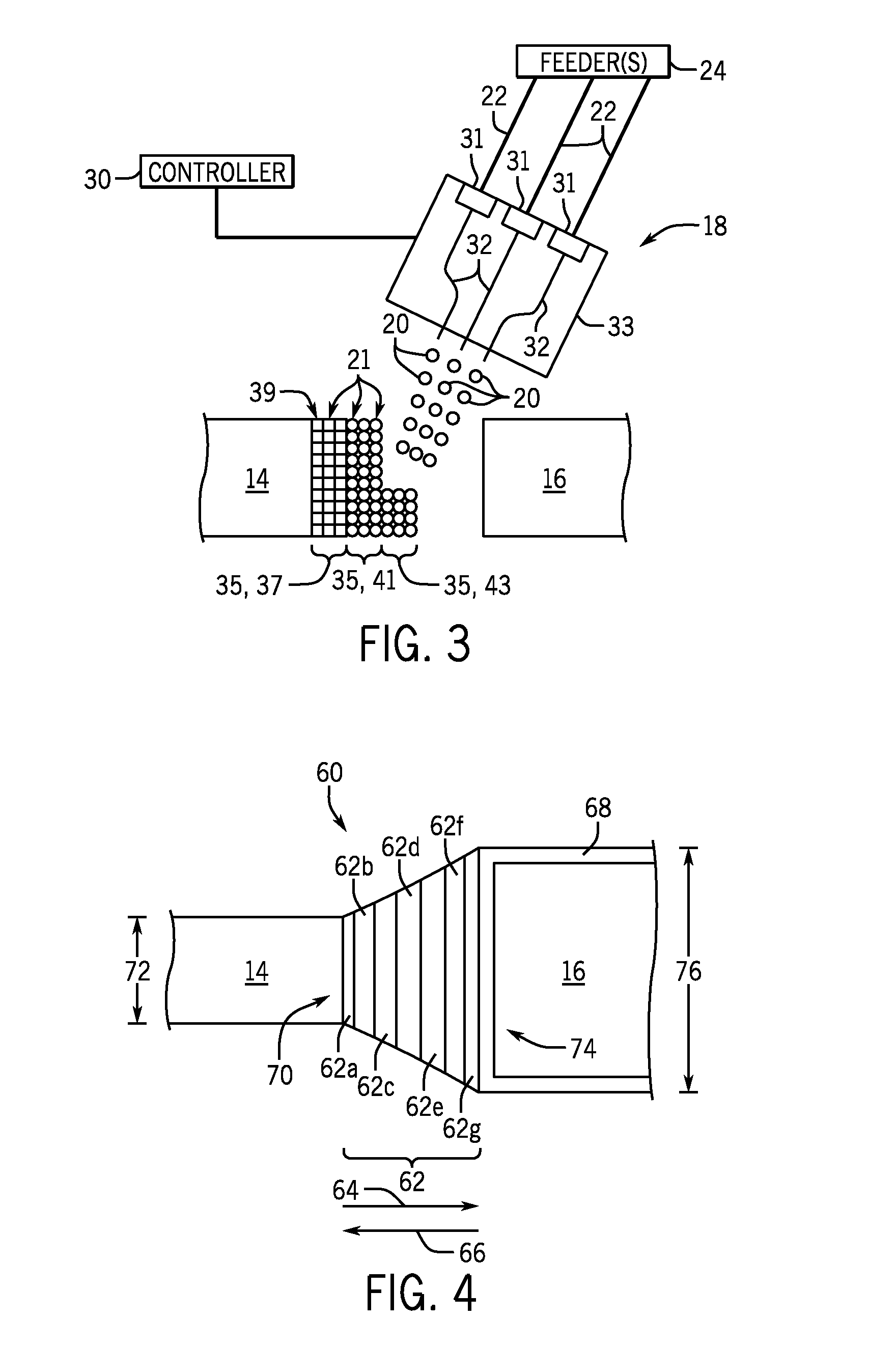

Electrospraying method for fabrication of particles and coatings and treatment methods thereof

Electrospray systems and modified electrospray systems for the fabrication of core-shell particles for controlled-release and / or sustained-release treatment and delivery are herein disclosed. The electrospray system may include between one and a plurality of co-axially situated tubes. Each tube may be electrically connected to a power supply wherein a voltage may be applied thereto. Core-shell particles may be collected on a collection target, which may be a wet or dry collector, and electrically connected to the power supply. Core-shell particles and methods of manufacture are also disclosed. The precursors of the core-shell particles may be polymer- or biomacromolecule-based solutions and may include at least one treatment agent incorporated therein. The number of “core” particle(s) within the “shell” may vary and may provide different treatment agent release profiles depending on the material and / or chemical characteristics of the polymer and / or biomacromolecule used. Methods of treating a condition are also disclosed. A treatment may include delivery of a plurality of core-shell particles which include a treatment agent to a treatment site. Delivery may be performed by a surgical procedure or by a non-invasive procedure such as catheter delivery.

Owner:ABBOTT CARDIOVASCULAR

Spray coating apparatus and spray coating method

InactiveUS20050181142A1Convenient coatingAdhesion efficiency is reducedSpraying power supplySpray nozzlesSpray nozzleSpray coating

By forming an air flow in which a quantity and a blowoff angle of the air supplied toward an atomized spray paint flow don't influence a coating pattern, there are provided a coating apparatus and a coating method, each of which does not disturb the coating pattern, does not require conditions such as wind speed and temperature of a conventional coating booth, and can perform remarkable reduction in an air conditioning energy of the coating booth, prevention of scatter of a paint, and an improvement in a paint adhesion efficiency. In a spray coating apparatus which possesses a casing and an injection nozzle provided in a tip side of the casing and which forms a coating pattern by injecting paint and shaping air from the injection nozzle to thereby form a coating film on a coated object, a first adapter which blows off the air in an injection direction of the injection nozzle is provided on an substantially concentric circle of the injection nozzle, and the first adapter covers, by blowing off the introduced air while giving it a blowoff angle slanting toward a circumferential direction, an outer periphery of the coating pattern near the injection nozzle with the air.

Owner:NIPPON PAINT CO LTD +1

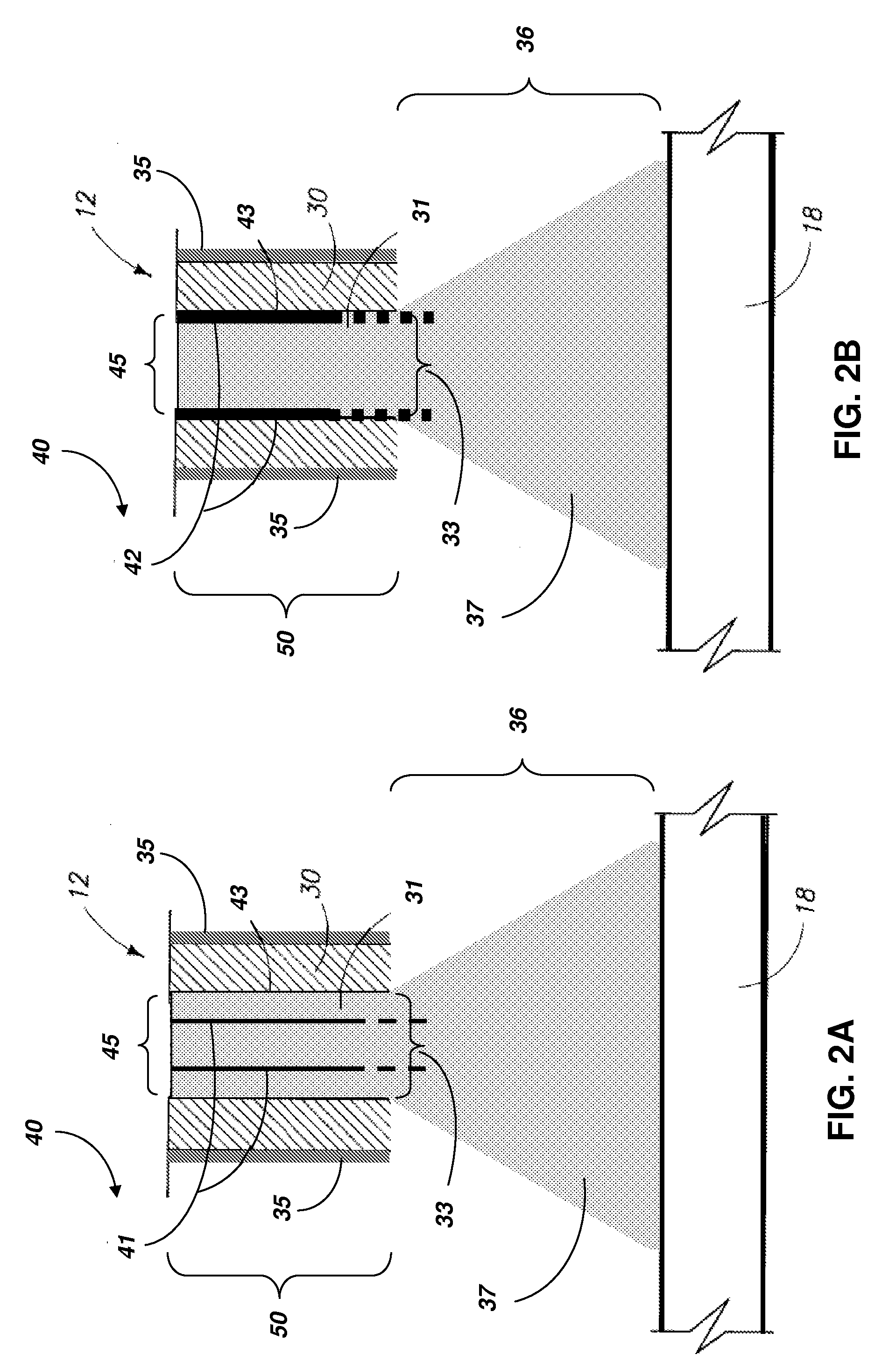

Apparatuses and methods for applying one or more materials on one or more substrates

A system that incorporates teachings of the present disclosure may include, for example, an apparatus having a tube with an ingress opening to receive a liquid, and an egress opening to release the liquid, a conductor positioned in a conduit of the tube, the conductor and the conduit having dimensions to cause a surface tension of the liquid to prevent a constant flow of the liquid from the egress opening, and a power supply coupled to the conductor to apply a charge to the liquid to overcome the surface tension and form at the egress opening a single jet stream of the liquid applicable on a substrate to create a pattern. The single jet stream can be controllable in part by a viscosity of the liquid. Additional embodiments are disclosed.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

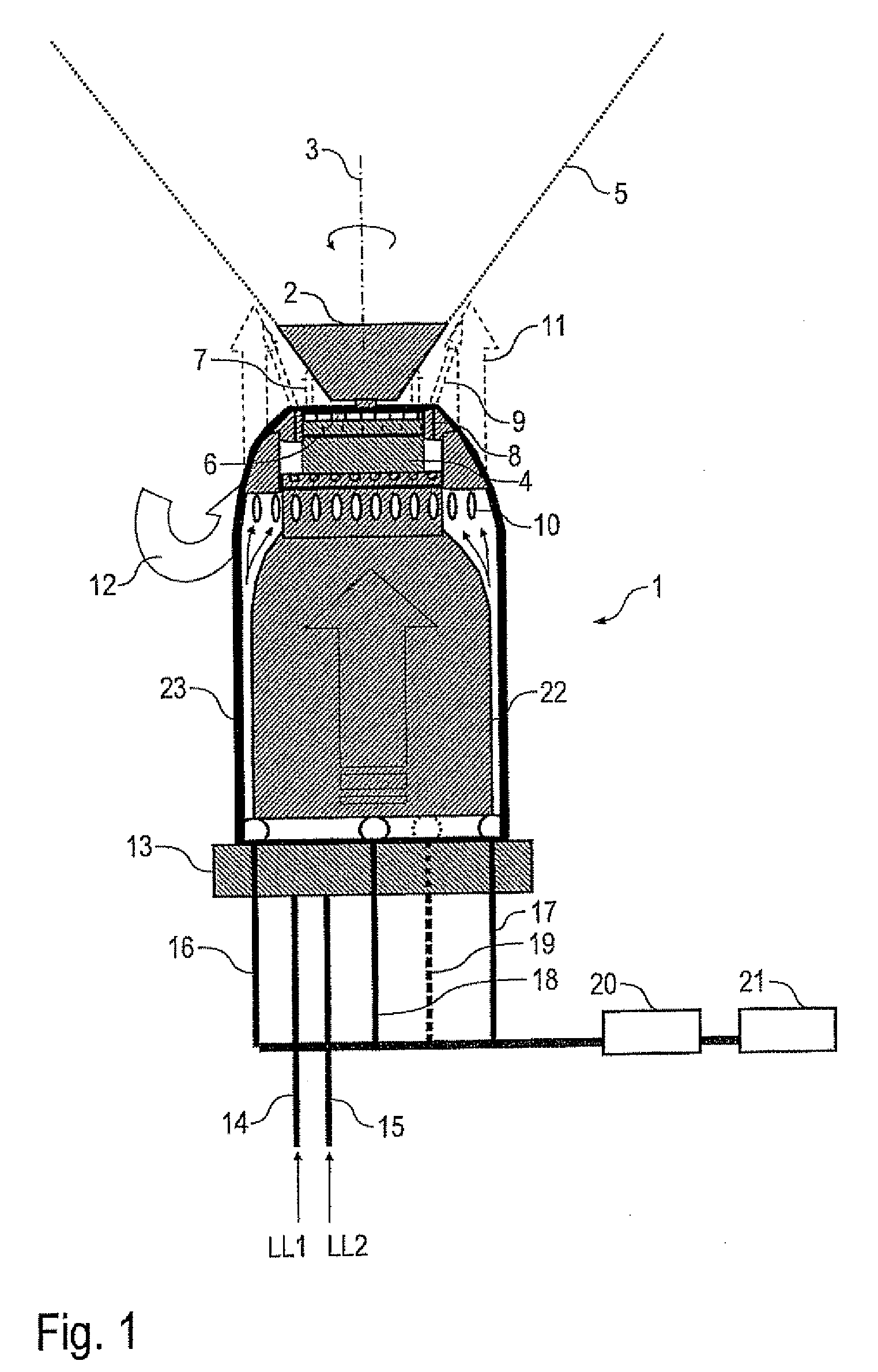

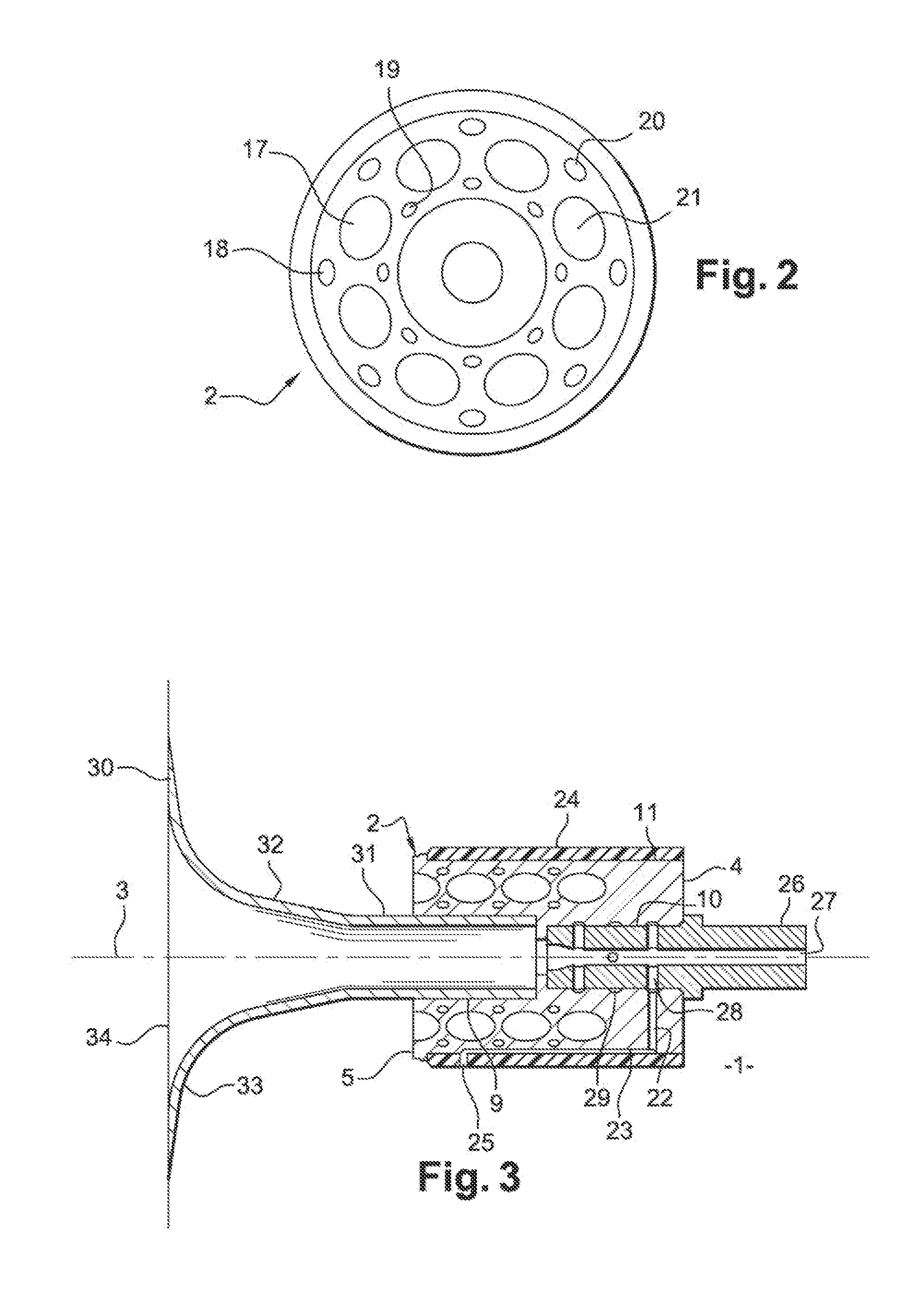

Rotational atomizer with external heating system

ActiveUS6972052B2High drive outputAvoid condensationBurnersMovable spraying apparatusTurbineHeating system

In a coating device with a rotary atomizer, for preventing the condensation of spray cabin air on components cooled by the lower-pressure exhaust air of the drive turbine of the atomizer, a heating device is provided, which can heat air flowing through the atomizer or components in heat-conductive contact with the outlet path of the turbine exhaust air.

Owner:DURR SYST INC

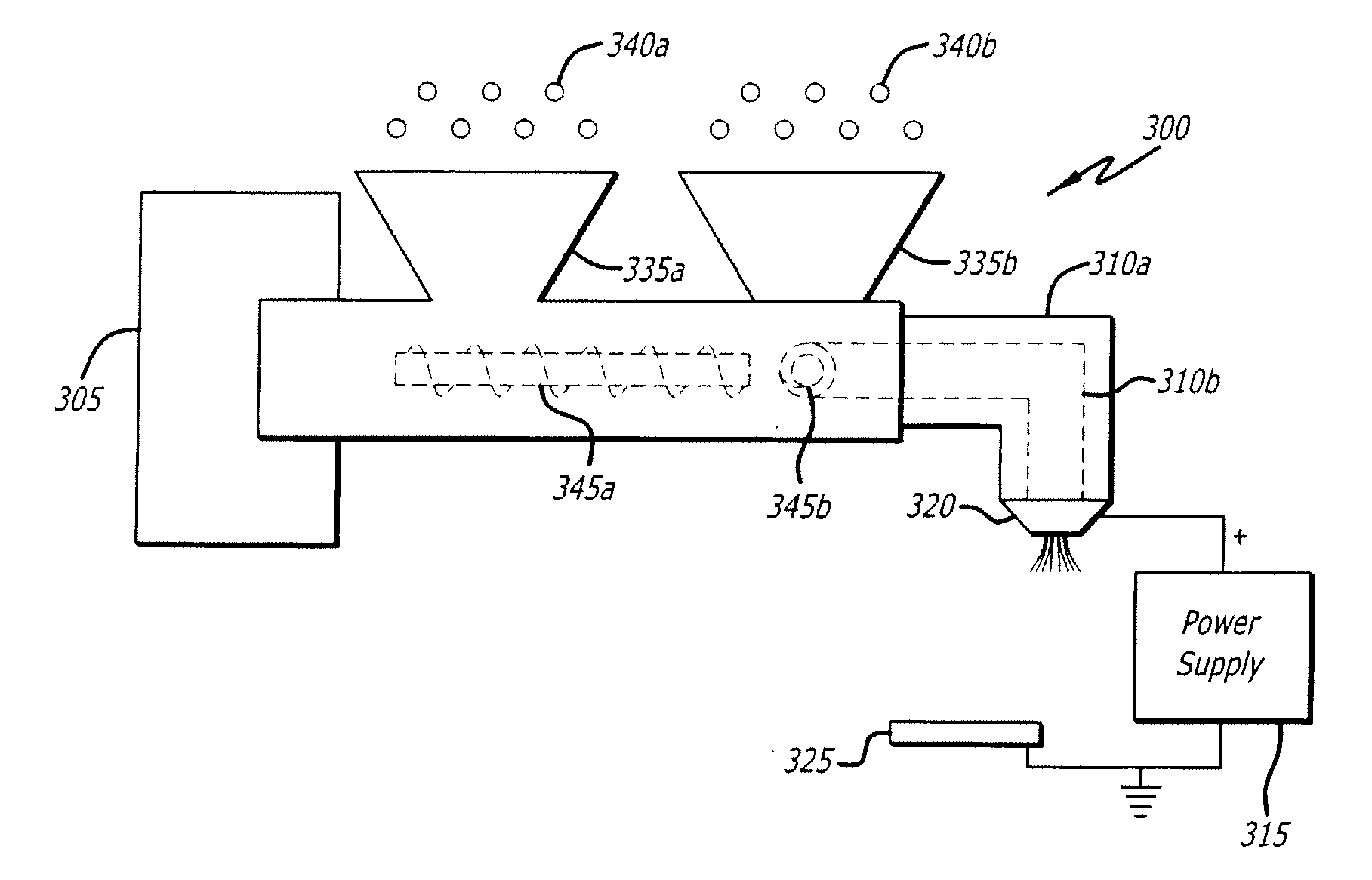

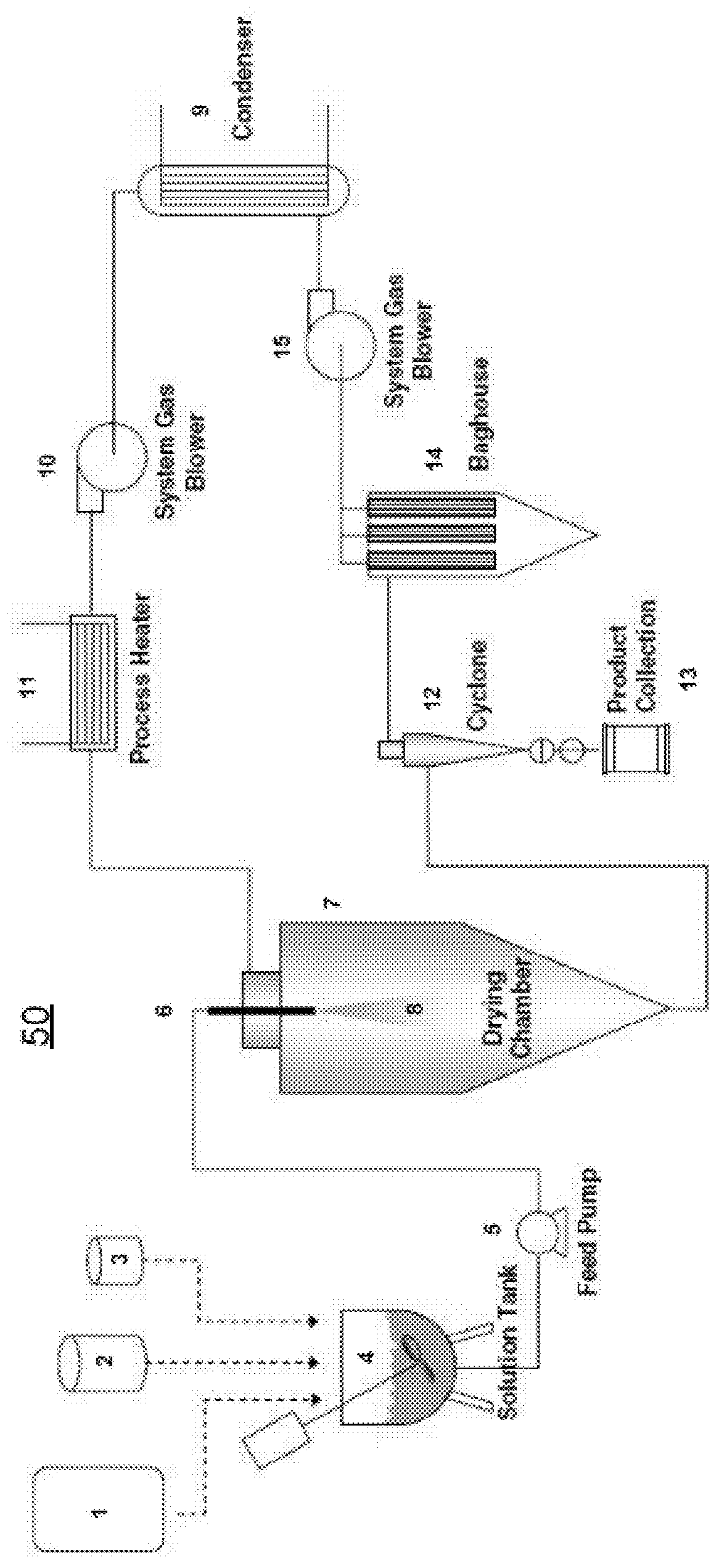

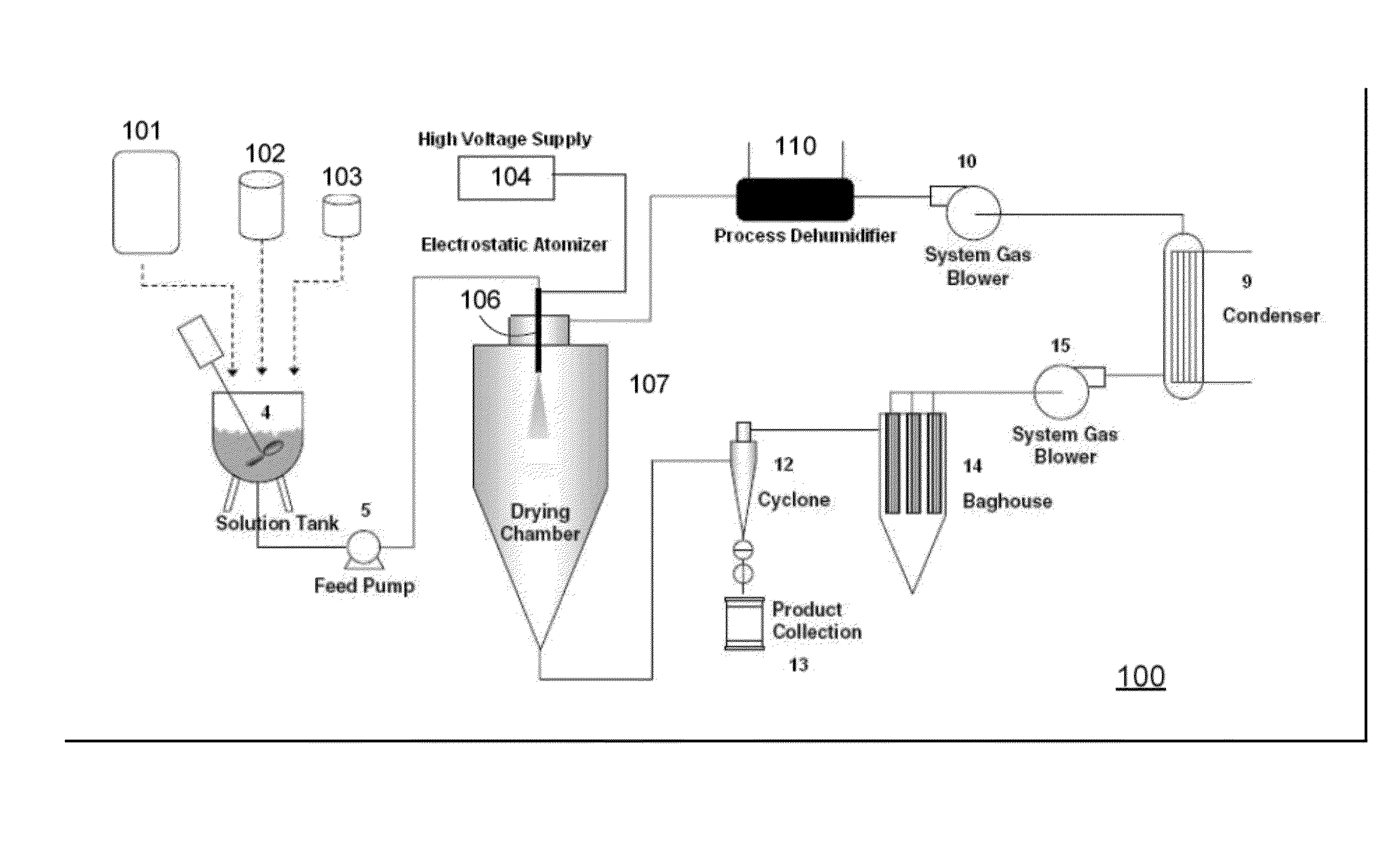

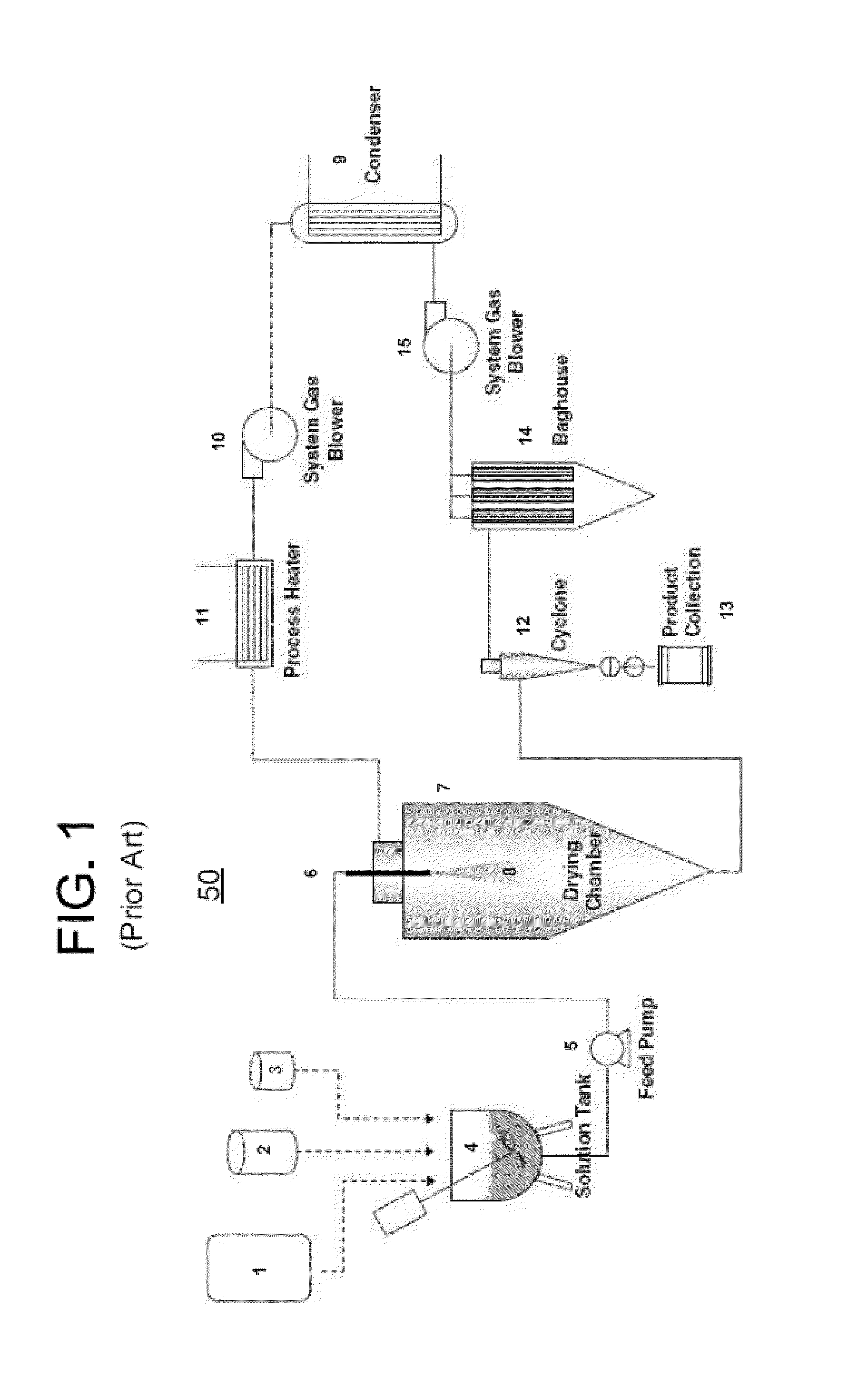

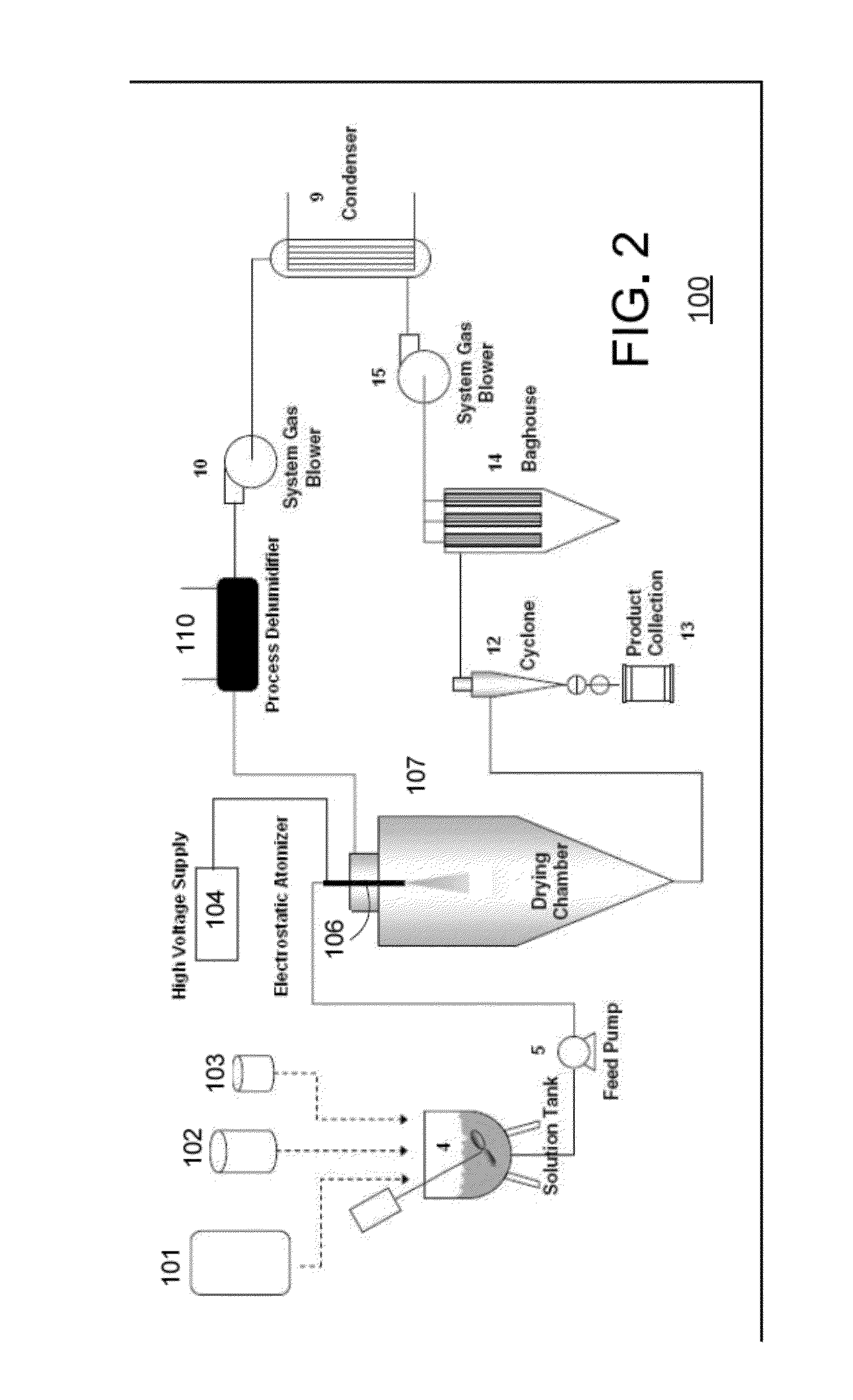

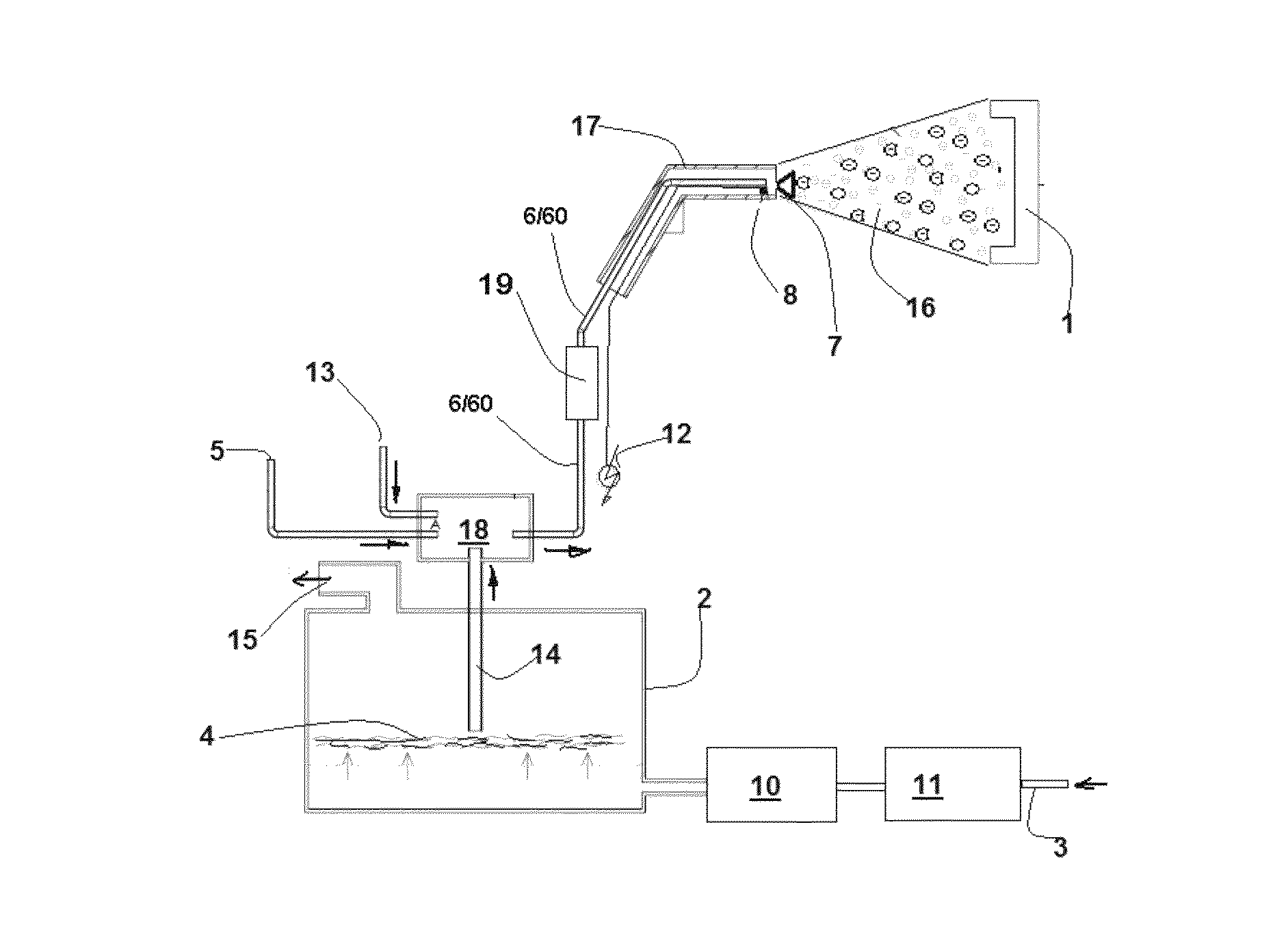

Methods and apparatus for low heat spray drying

ActiveUS9332776B1Liquid surface applicatorsDrying solid materials with heatLiquid productSufficient time

Methods and apparatus provide for spray drying a liquid product into a dried powder without applying heat, including: forming a slurry including a liquid solvent, a carrier, and an active ingredient; applying an electrostatic charge to the slurry; atomizing the charged slurry to produce a plurality of electrostatically charged, wet particles; suspending the electrostatically charged, wet particles for a sufficient time to permit repulsive forces induced by the electrostatic charge on at least some wet particles to cause at least some of such particles to divide into wet sub-particles; and continuing the suspending step, without the presence of any heated drying fluids, for a sufficient time to drive off a sufficient amount of the liquid solvent within most of the wet particles to leave a plurality of dried particles (the powder), each dried particle containing the active ingredient encapsulated within the carrier.

Owner:ZOOMESSENCE INC

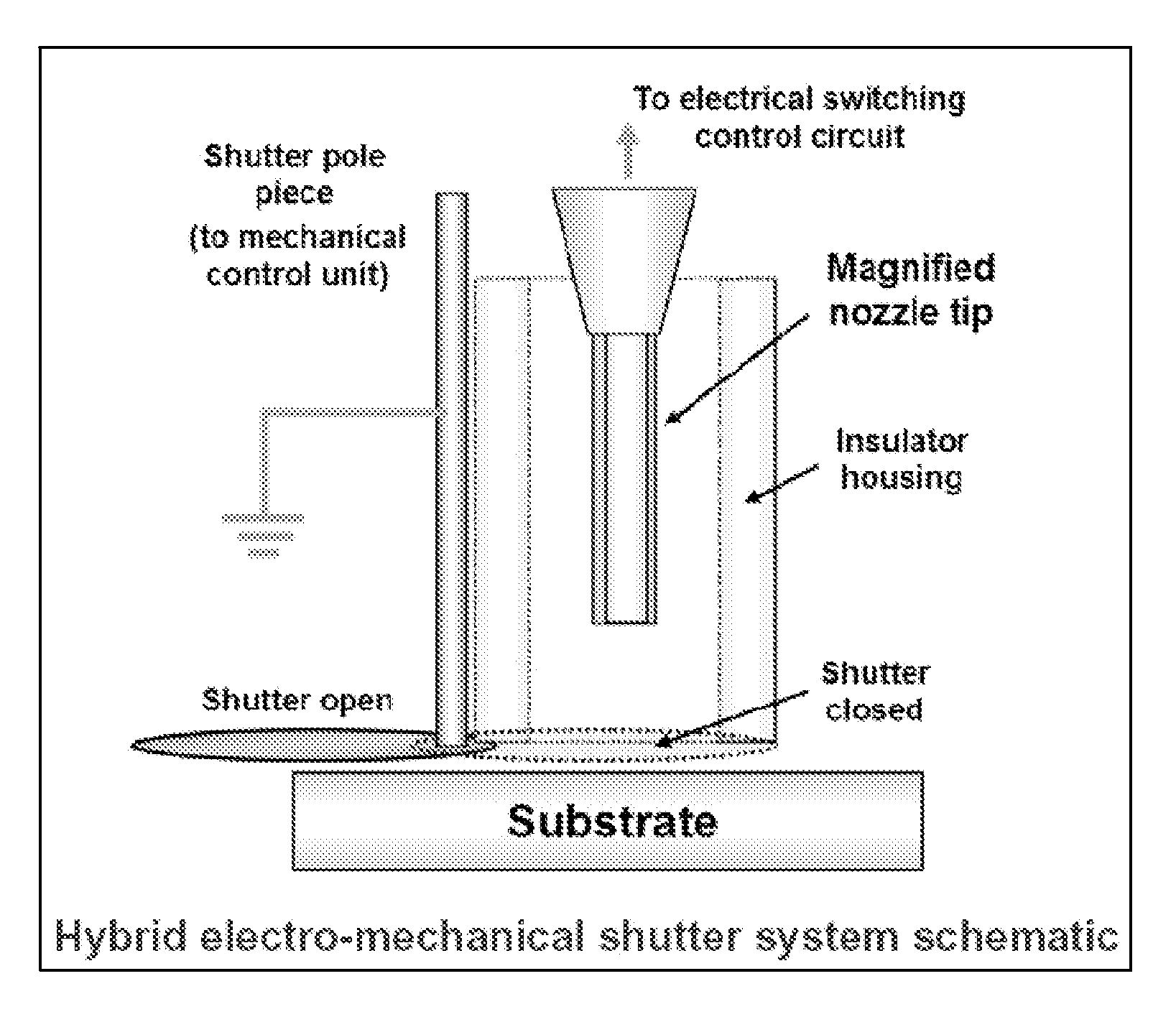

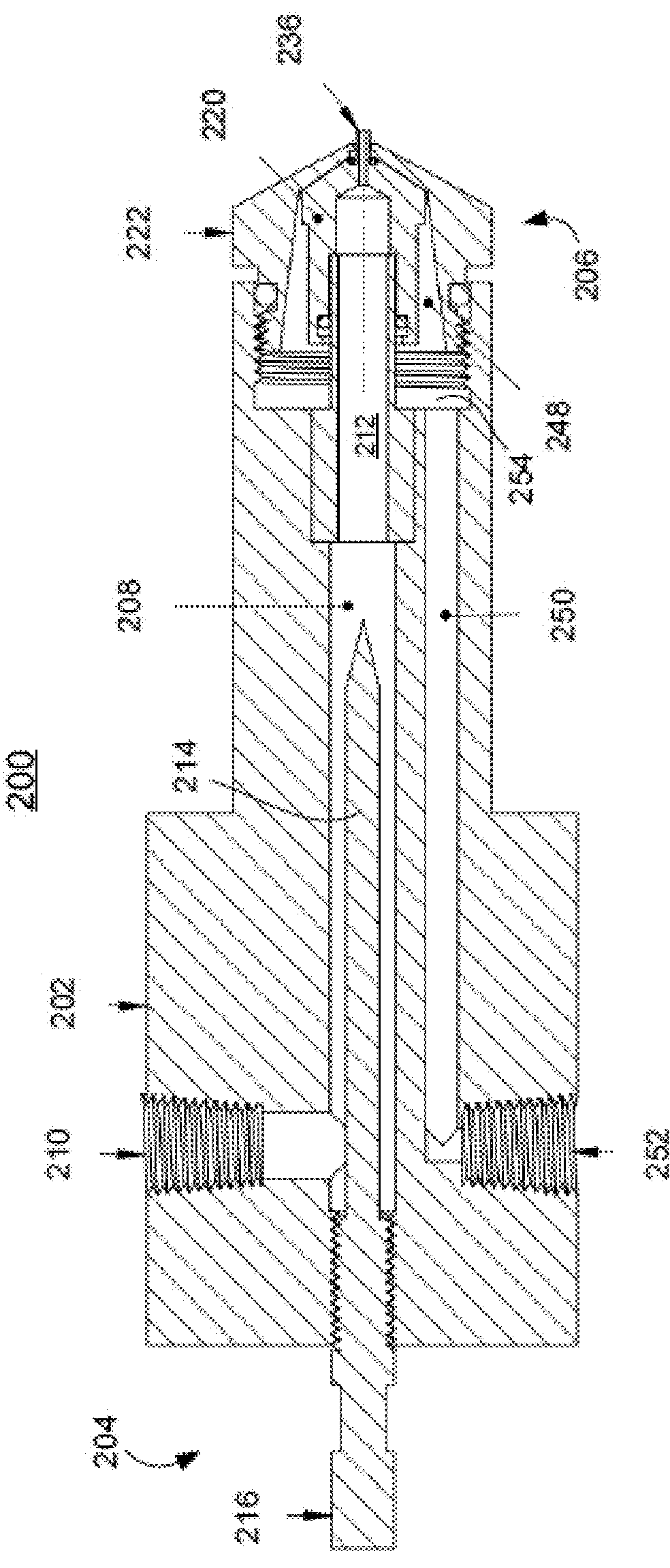

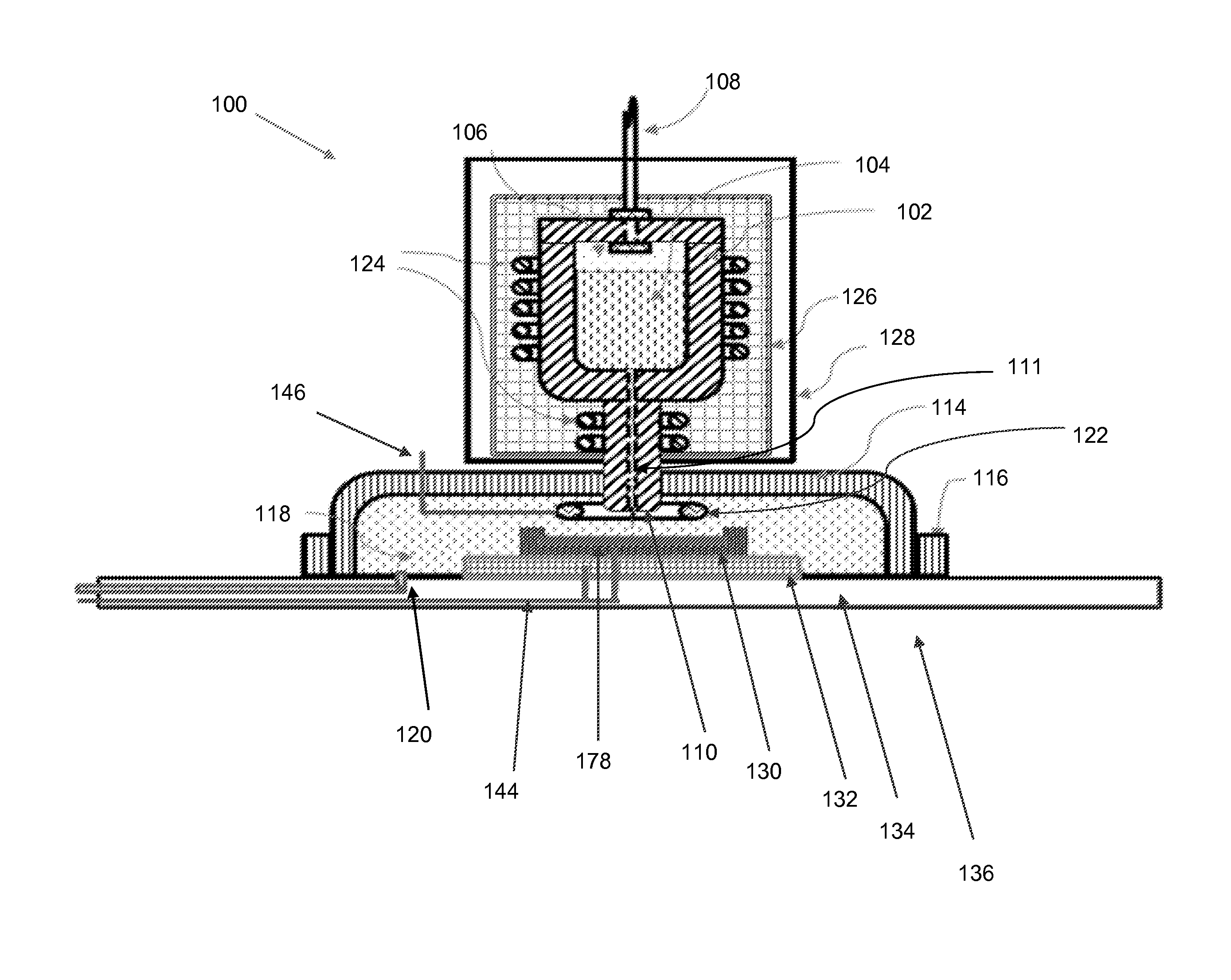

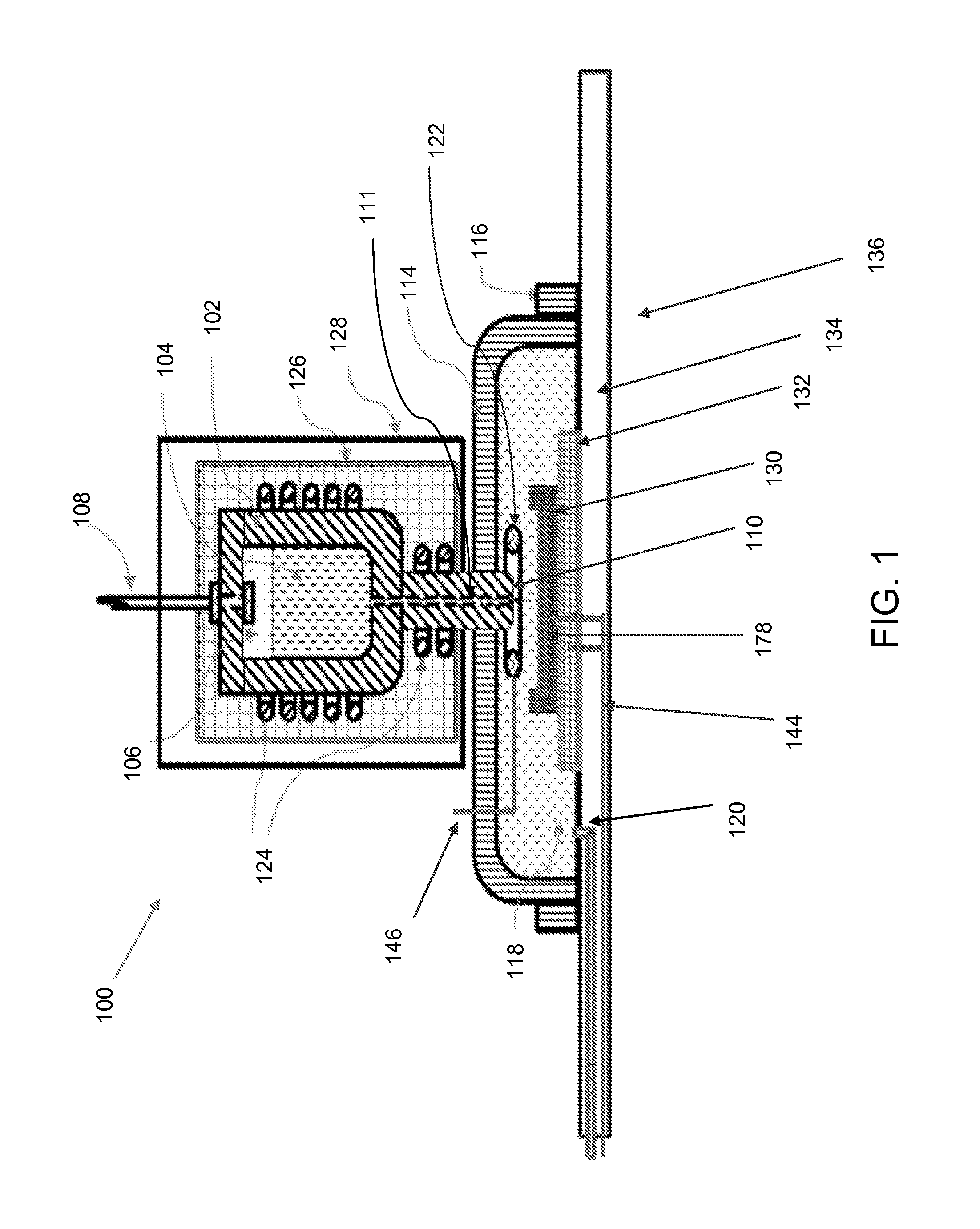

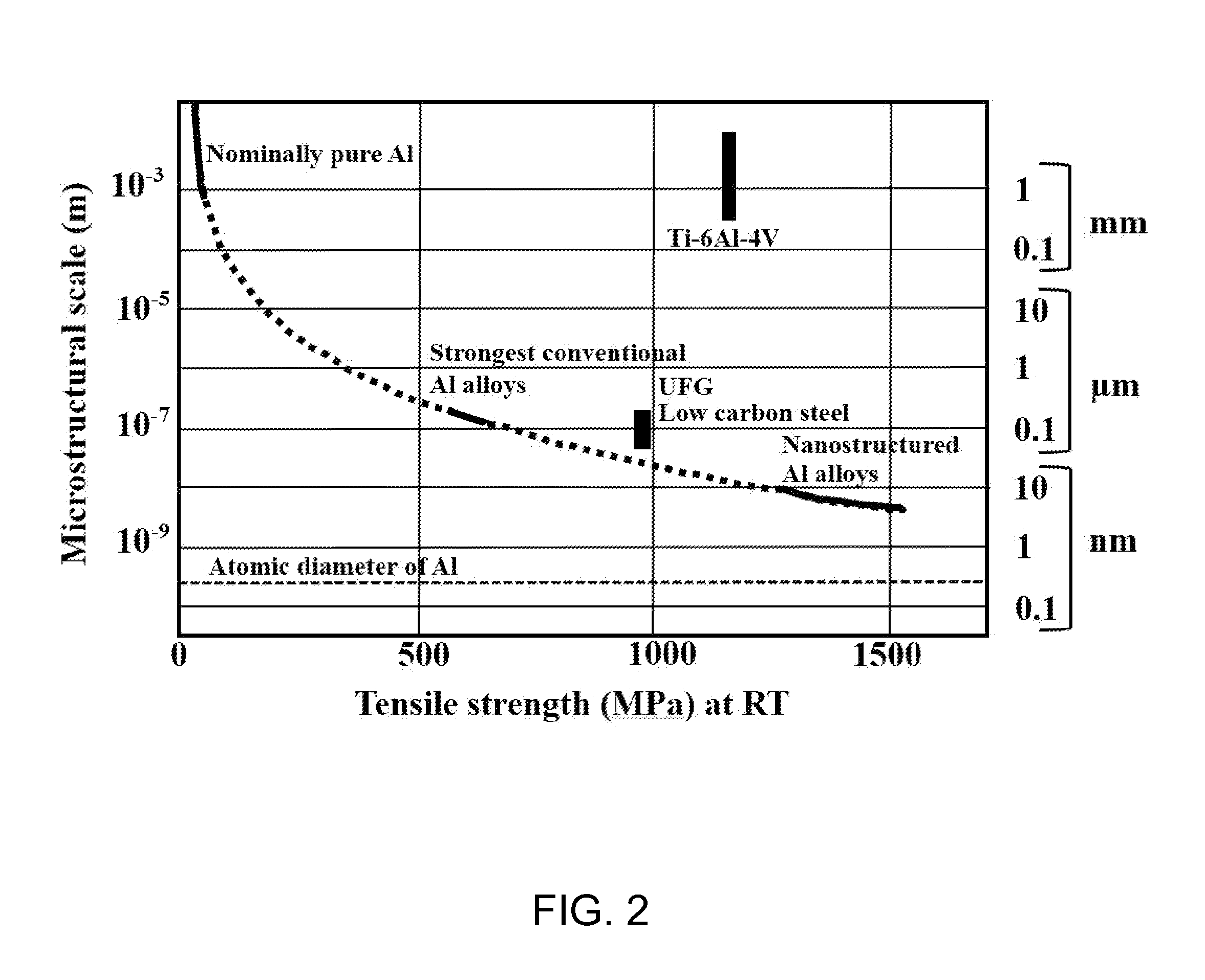

Electrospray pinning of nanograined depositions

ActiveUS20150251213A1Inhibition of recrystallizationEnhanced nucleationLiquid surface applicatorsAdditive manufacturing apparatusGrain growthElectric field

A method and apparatus for fabrication of objects retaining nano-scale characteristics. A composition is provided comprising grain growth inhibitor particles in solution with a binding agent in a molten phase. An electric field and a magnetic field are generated with a combined extraction electrode. The composition is electrosprayed from a nozzle with the electric field to form a stream of droplets. The electric field drives the droplets toward a moving stage holding an object comprising successive deposition layers. The magnetic field limits dispersion of the stream of droplets. The stage is moved laterally as the stream of droplets impacts the object to form a current deposition layer of the object. The stage is moved vertically as necessary to maintain a target stand-off distance between the nozzle and a previous deposition layer of the object, based on profile data of the previous deposition layer.

Owner:Q21 CORPORATION +1

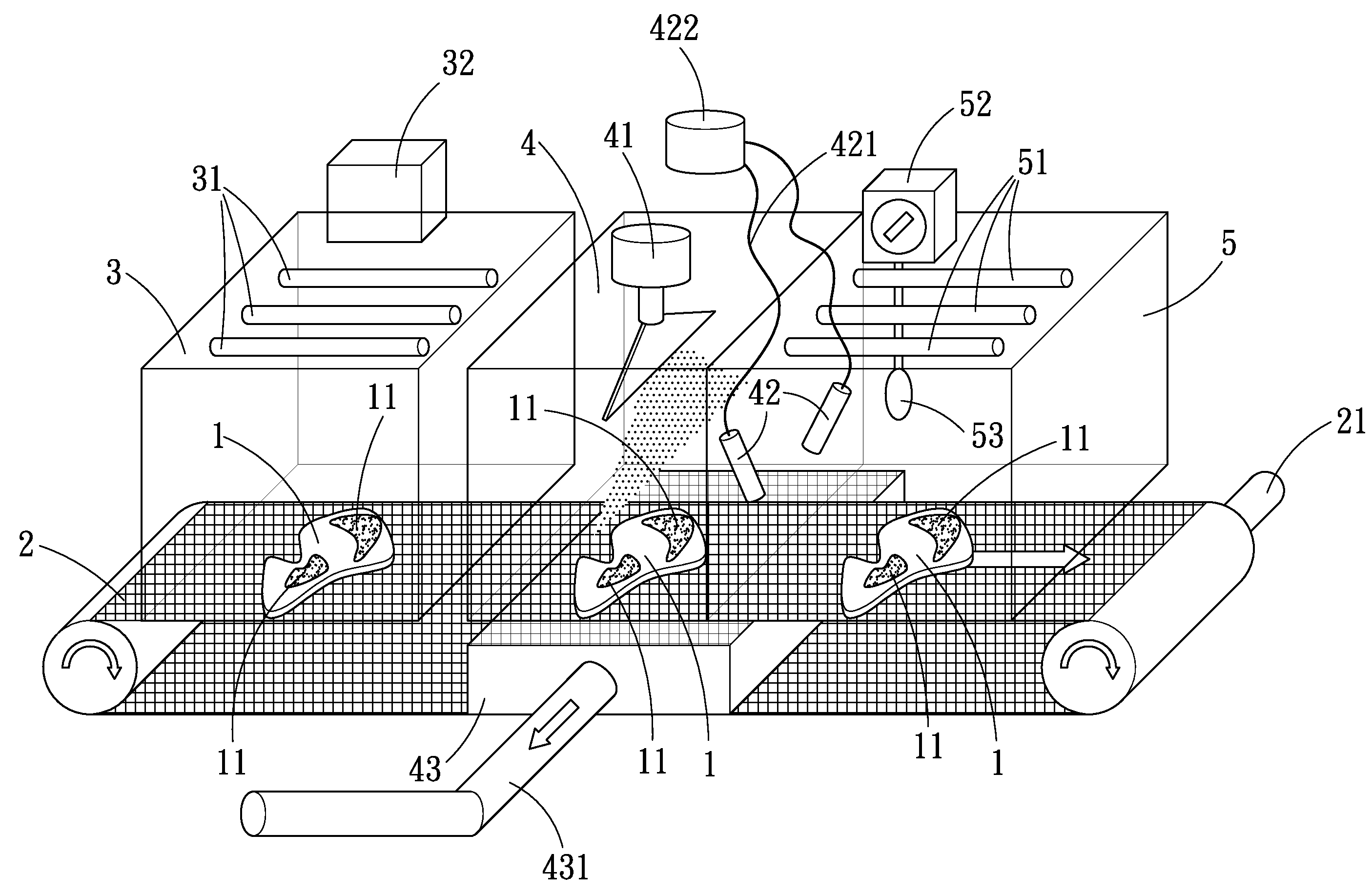

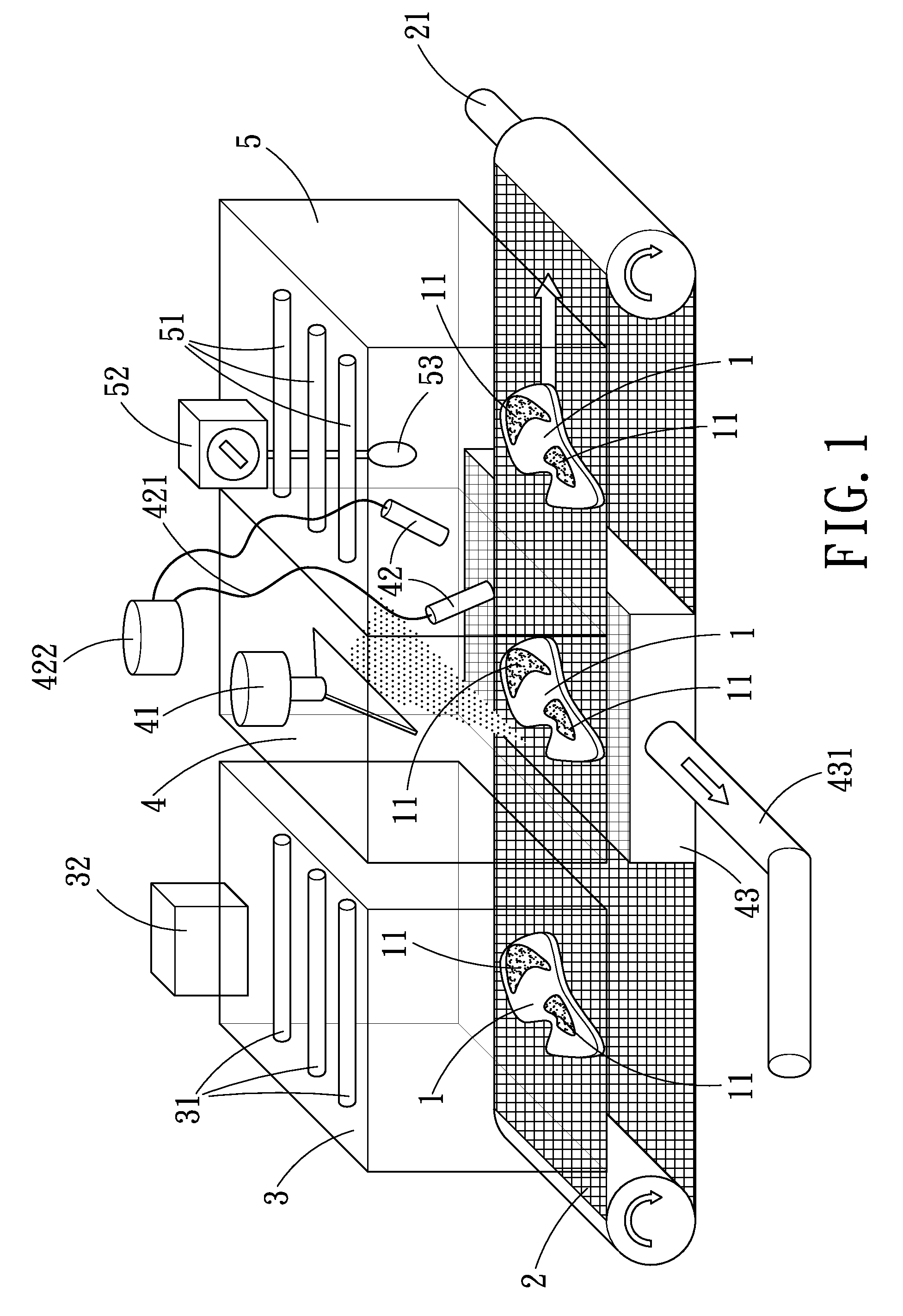

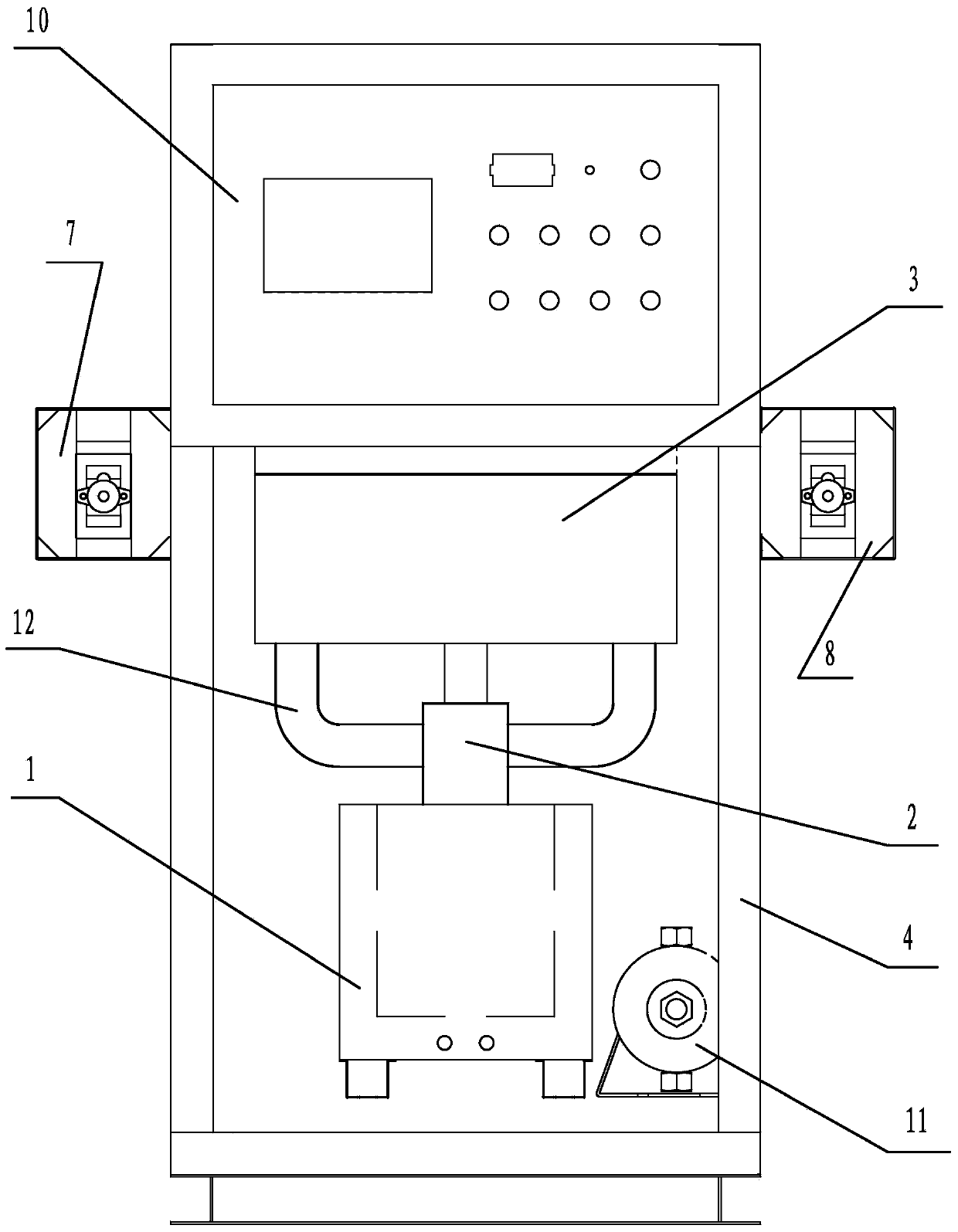

System for applying hot melt adhesive powder onto a non-metallic object surface

ActiveUS20120272899A1High degree of automationReduce labor intensityLiquid surface applicatorsElectrostatic heating/coolingUltravioletCleansing Agents

A system for applying hot melt adhesive powder onto a non-metallic object surface comprises a convey belt, a radiation chamber, a spraying chamber and a heating chamber. The convey belt is used to deliver a non-metallic object treated by a cleaning agent and a conductive liquid through the radiation chamber where the surface of the non-metallic objected is radiated by ultraviolet rays and ozone and then through the spraying chamber where the surface of the non-metallic object is sprayed with charged hot melt adhesive powder, and finally into the heating chamber where the hot melt adhesive powder attached onto the non-metallic object will be melted into a liquid adhesive film ready to be bonded.

Owner:ORISOL ASIA

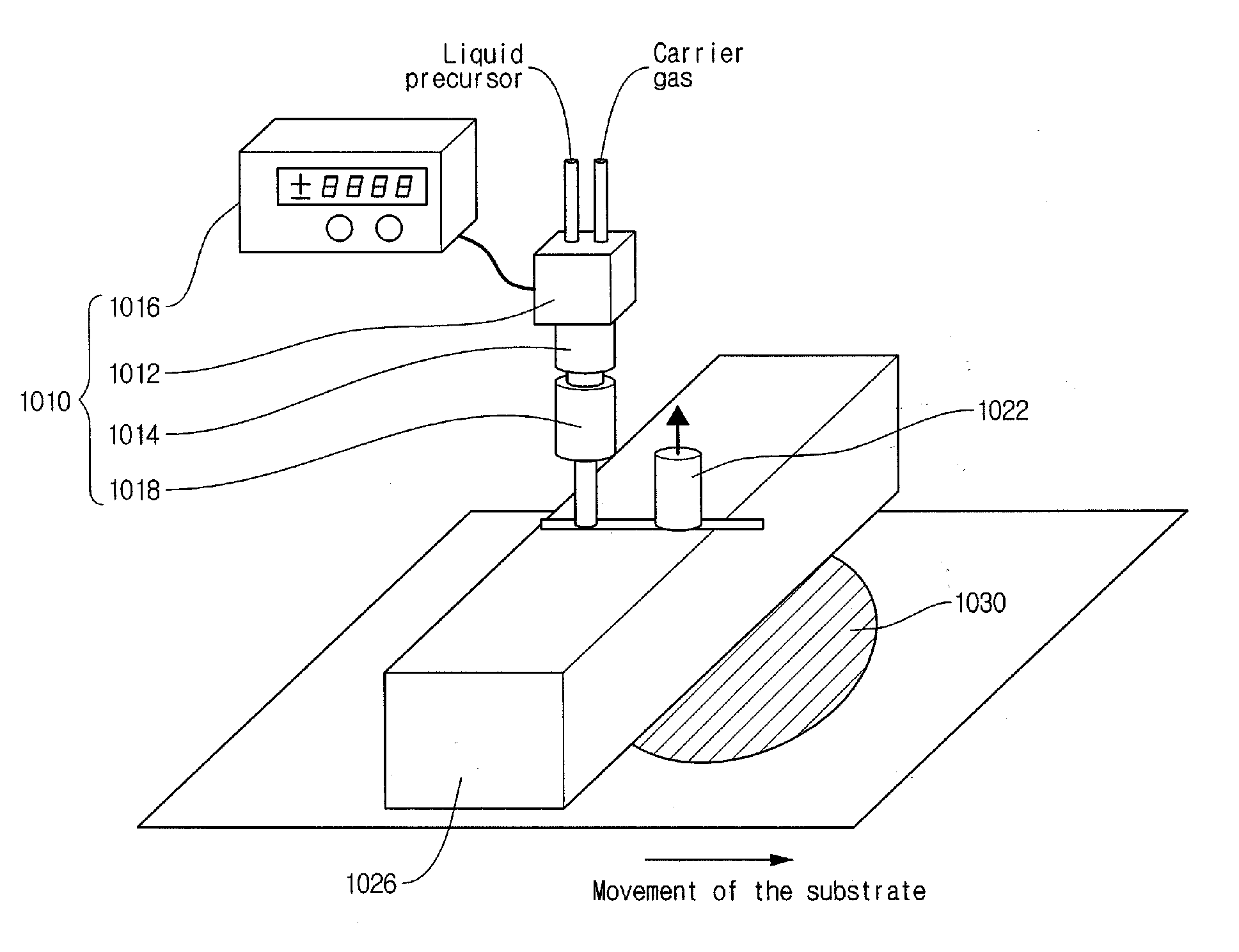

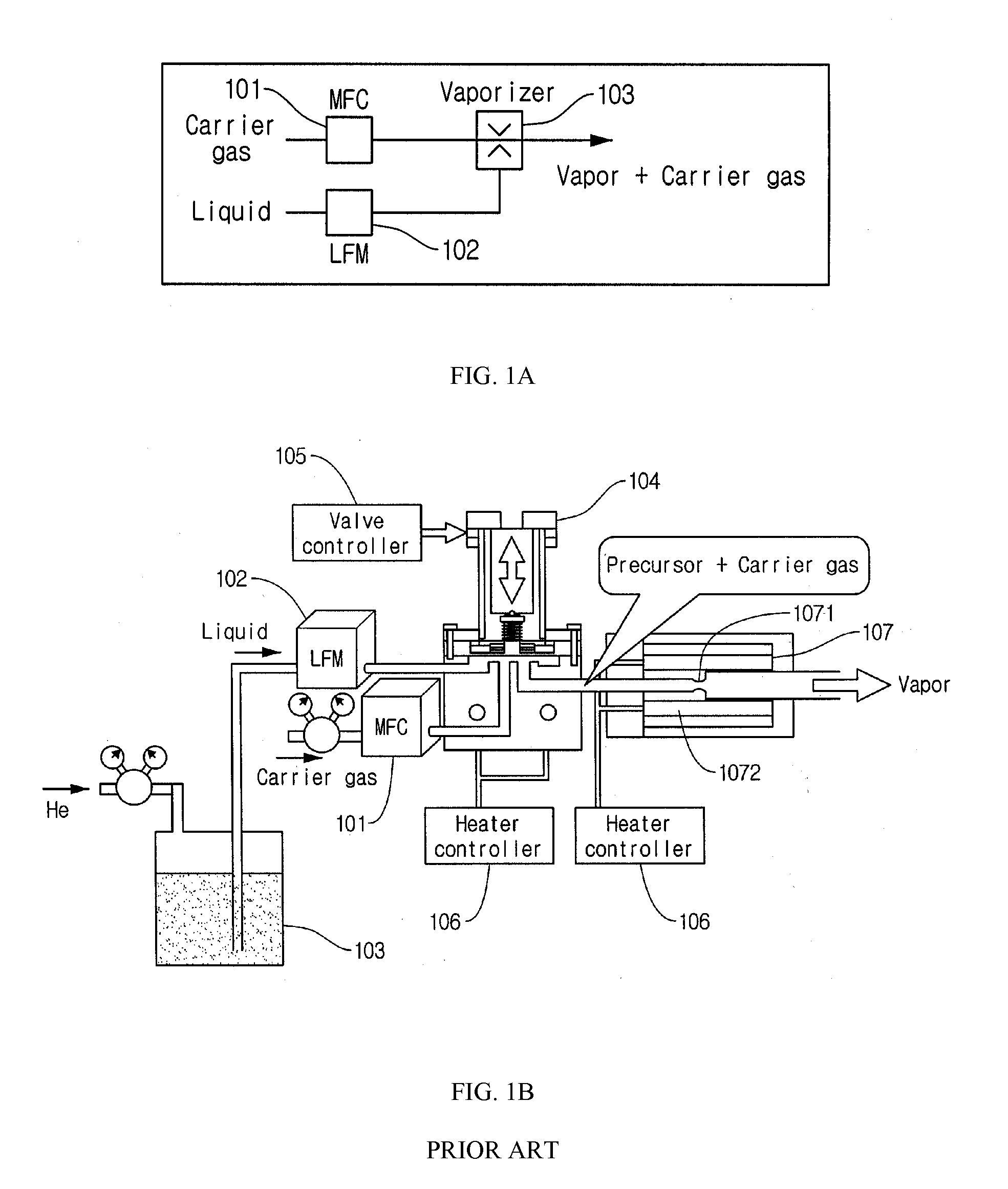

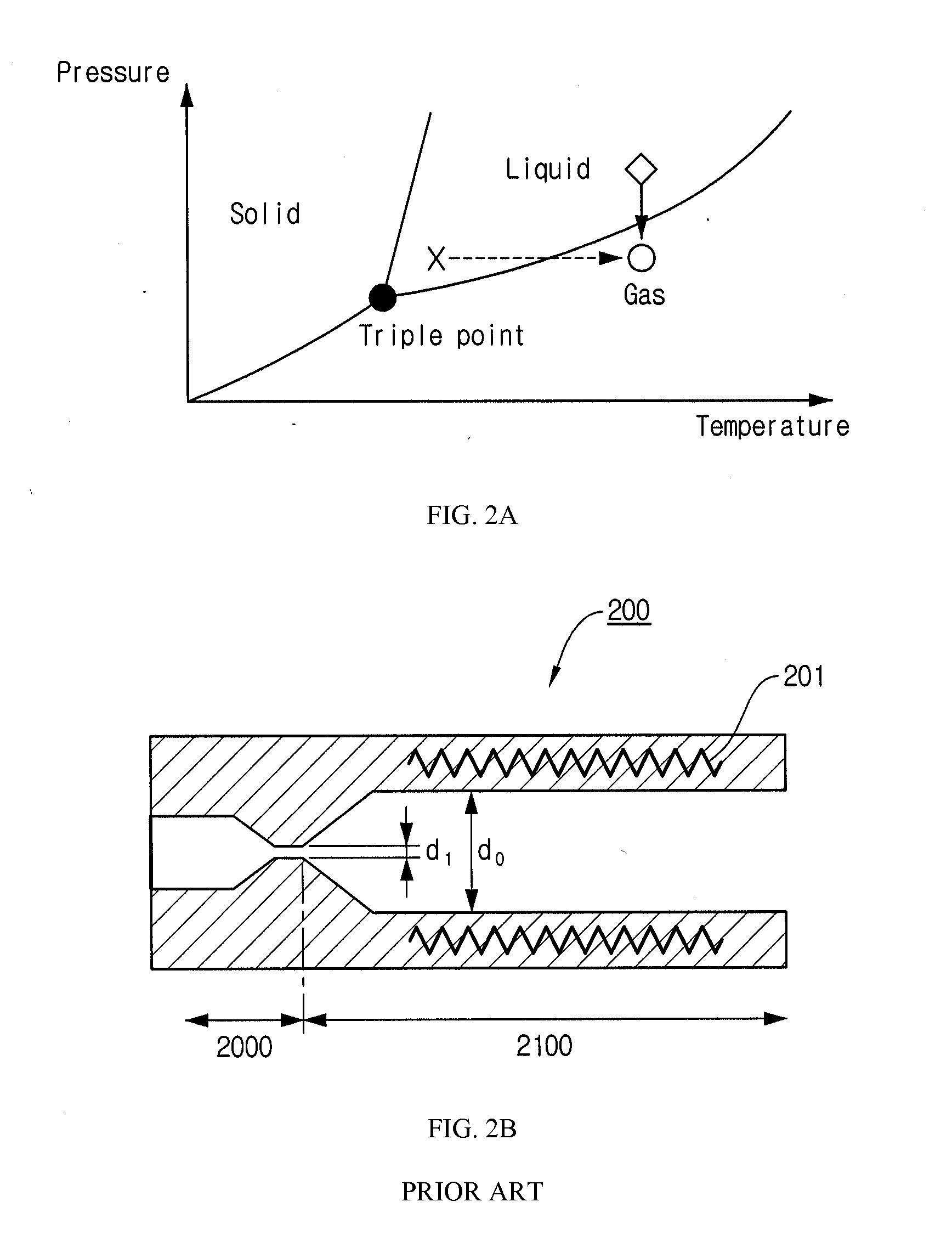

Vaporizing or atomizing of electrically charged droplets

InactiveUS20110262650A1Small sizeSemiconductor/solid-state device manufacturingPretreated surfacesGas phaseEngineering

A vaporizing apparatus includes a chamber, a nozzle for dispersing a liquid into droplets, an electrode electrically isolated from the nozzle, and a heater for generating a vapor by applying heat to the droplets. The voltage source applies charges to the droplets by applying a voltage between the nozzle and the electrode. The vaporizing apparatus may be used to devices that deposit organic or inorganic thin films by chemical vapor deposition and / or atomic layer deposition processes, devices for supplying precursor materials that are deposited to form a thin film in organic light emitting diodes, devices that supply organic or inorganic precursor materials for encapsulation, and devices for supplying organic or inorganic polymer.

Owner:VEECO ALD

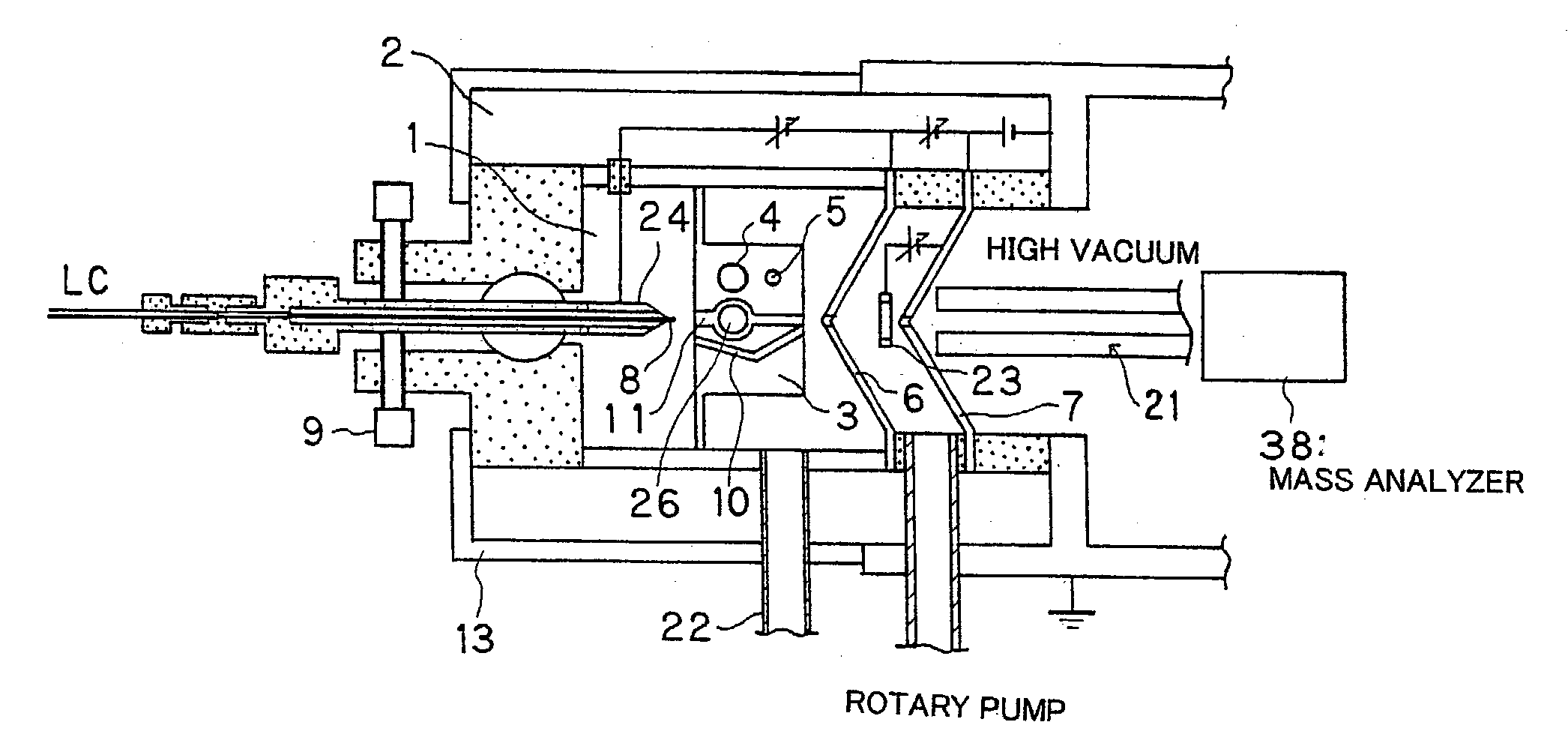

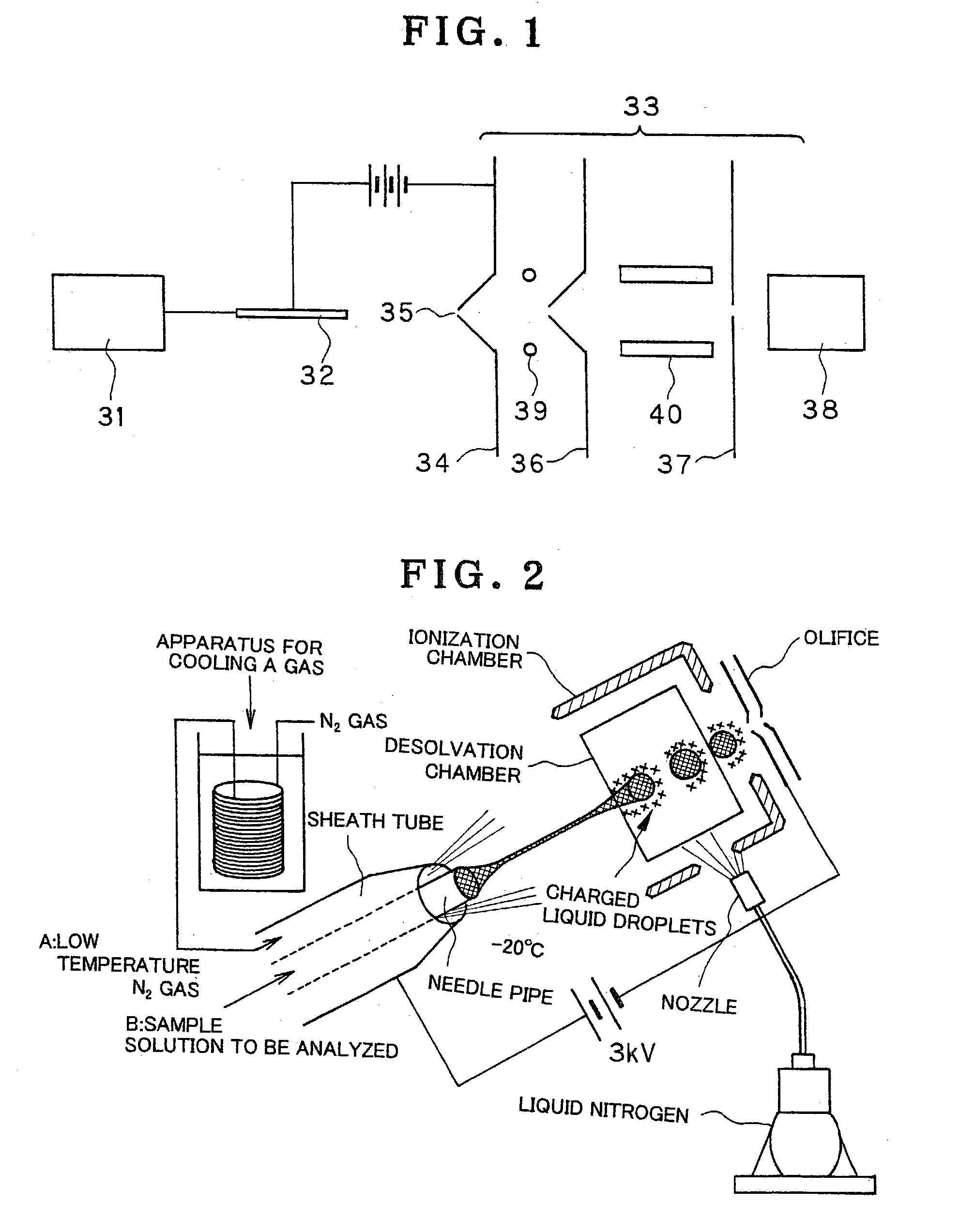

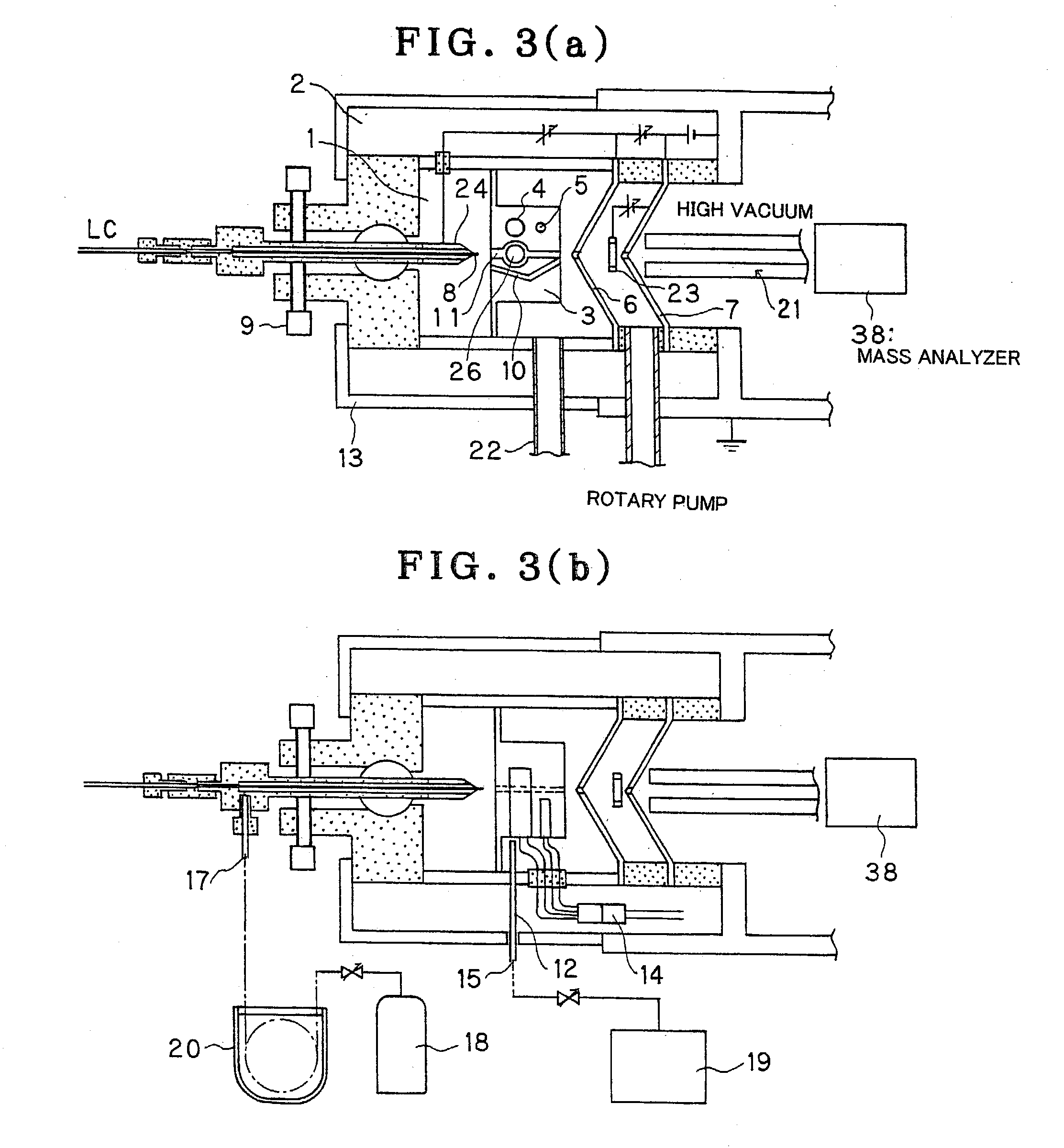

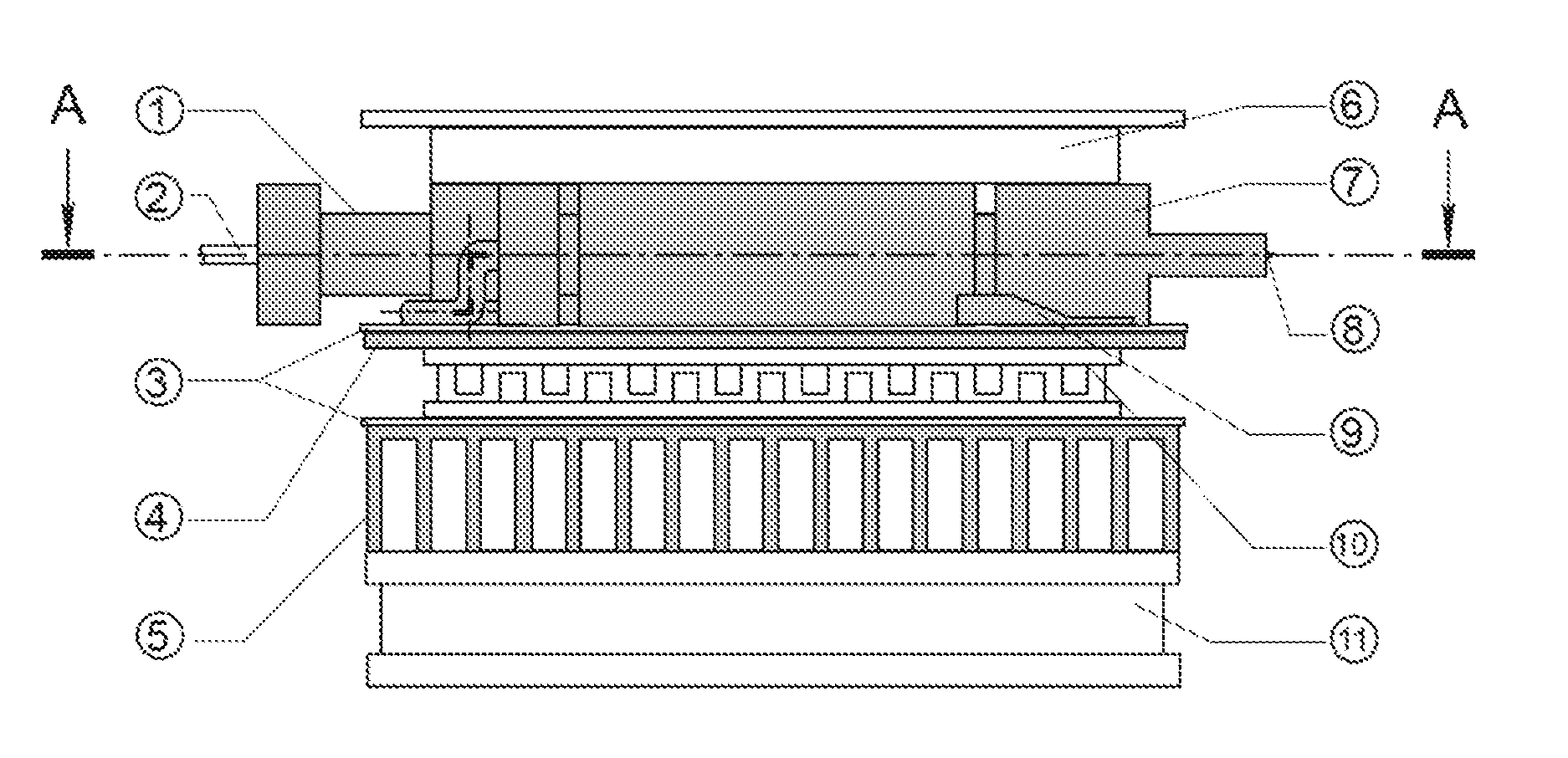

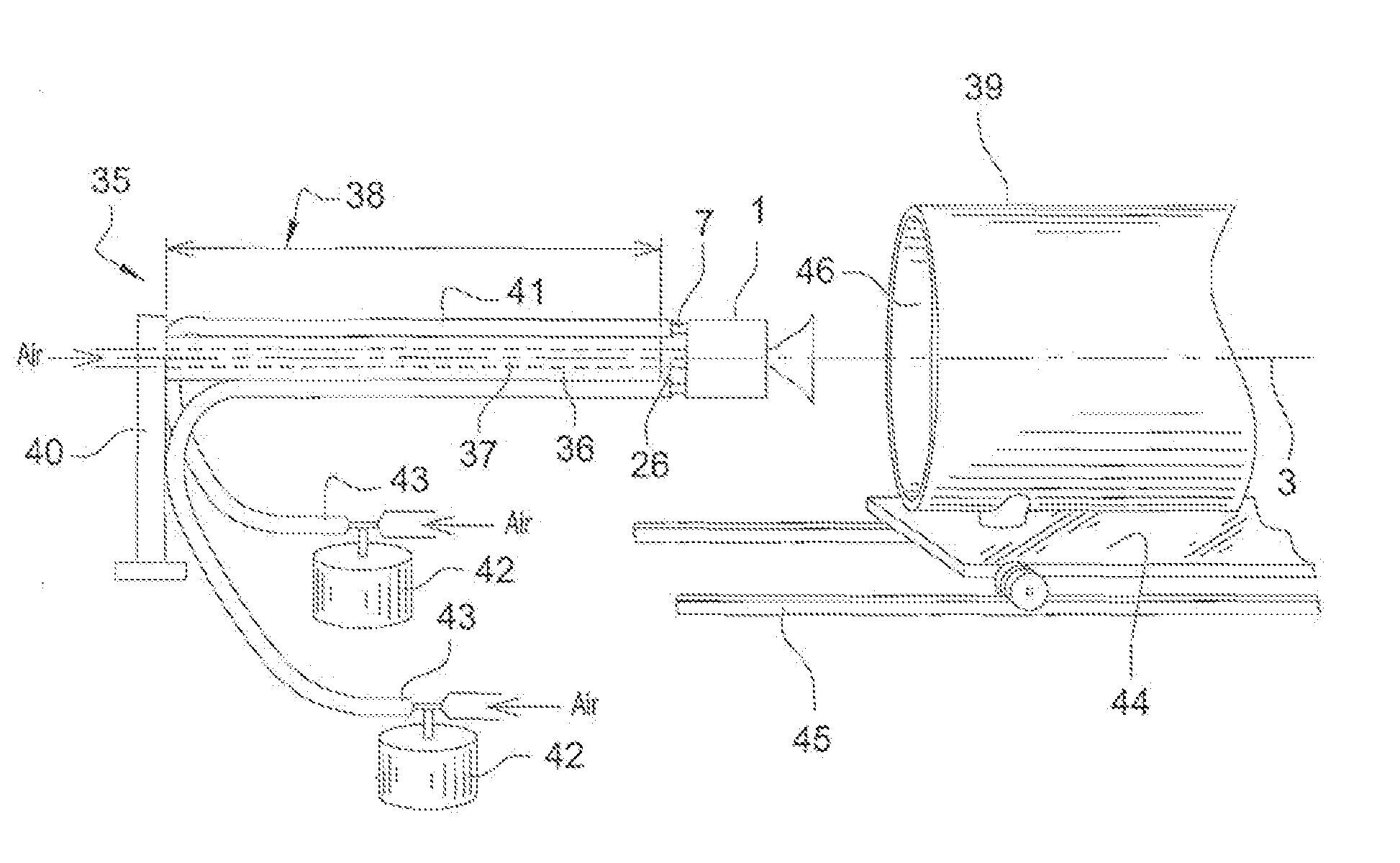

Cold spray mass spectrometric device

ActiveUS6977369B2Easy to handlePrevent leakageIon-exchange process apparatusComponent separationTemperature controlSolvation

The instrument cold sprays a solution sample at a low temperature and desolvates the sample. Under this condition, a mass analysis is performed. The instrument comprises a needle pipe (8) through which the solution sample is passed, a sheath tube (24) formed coaxially with the needle pipe (8) and passing a temperature-controlled nebulizing gas therethrough, the above-described desolvation block (3), means for cooling the block (15), means for heating the block (4), and a temperature sensor (5) for detecting the temperature of the block (3). The block (3) has a passage for charged liquid droplets of the solution sample cold sprayed from the tip of the needle pipe (8), and acts to remove the solvent from the charged liquid droplets flowing through the passage. A coldspray mass spectrometer is offered which has a desolvation block whose temperature can be easily controlled. In the instrument, condensation of water and electrical leakage are prevented for a long time. The instrument can perform measurements stably and is easy to handle.

Owner:JAPAN SCI & TECH CORP +1

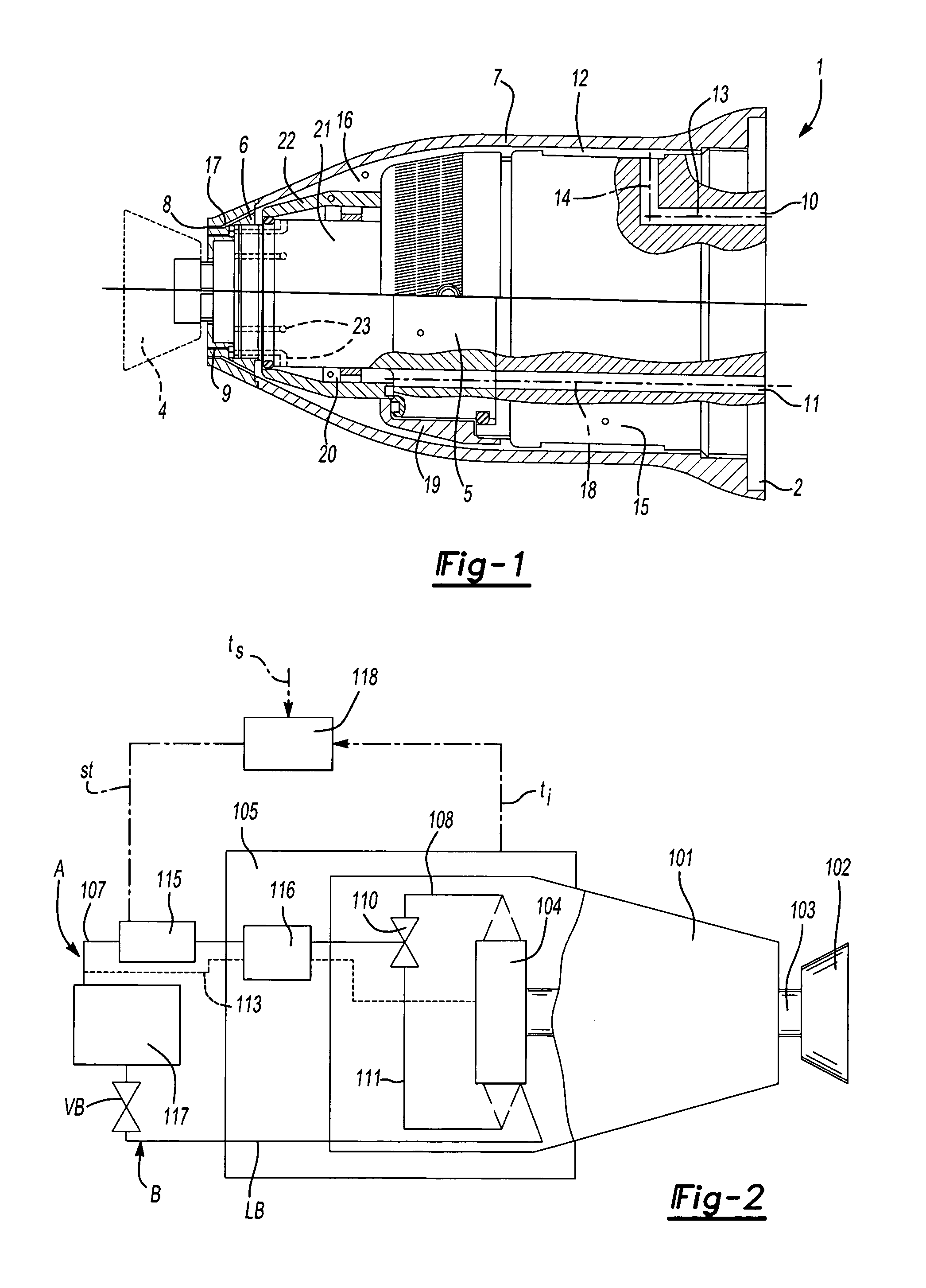

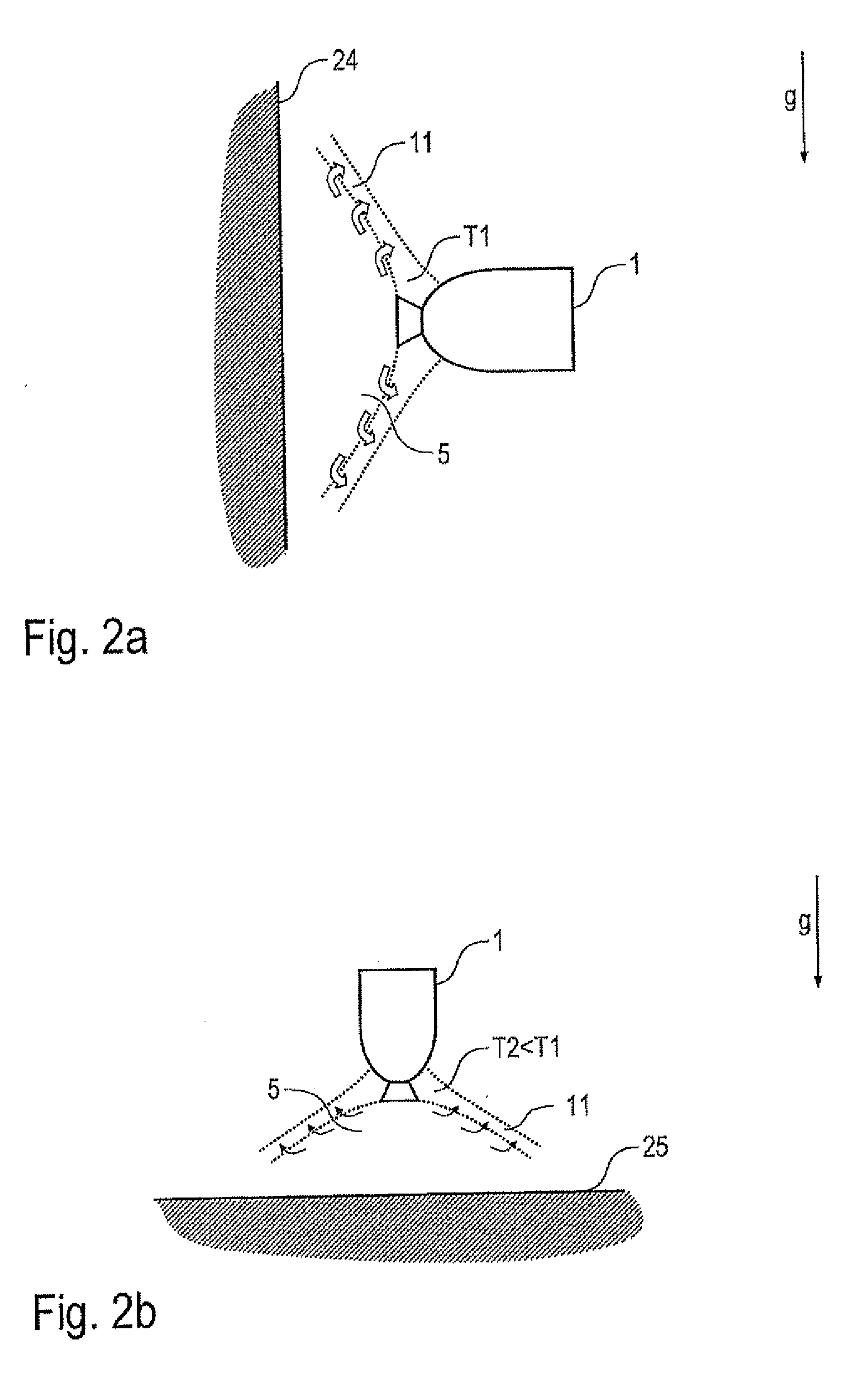

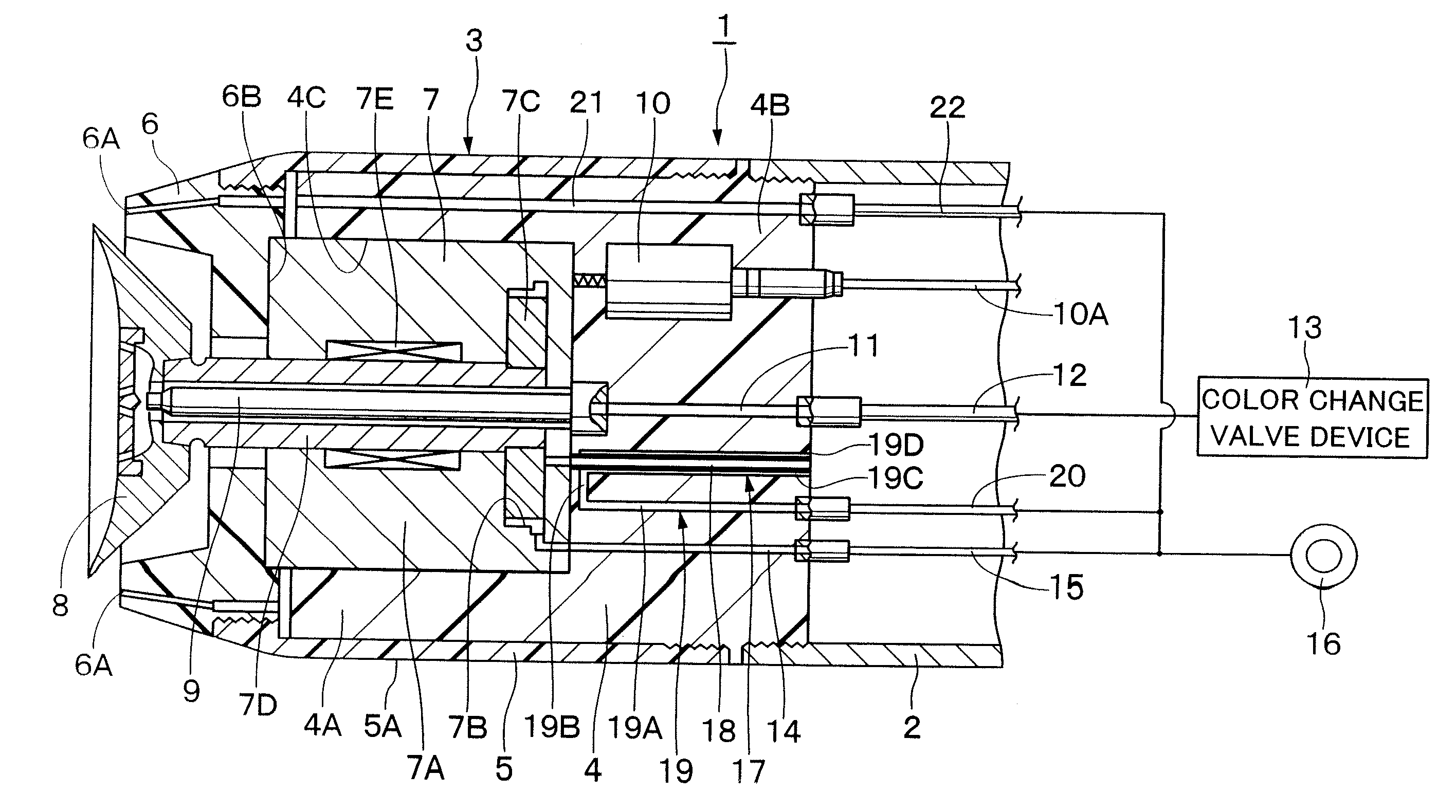

Atomizer and associated operating method

ActiveUS20070262170A1Reduce pollutionQuick clean upLiquid surface applicatorsSpray nozzlesEngineeringNozzle

The invention relates to an atomizer and method of operation for an atomizer having an application element for applying a spray of coating medium on a component to be coated and at least one integrated shroud air nozzle for delivering conditioned shroud air which at least partially surrounds the spray of the coating medium.

Owner:DURR SYST INC

Methods and apparatus for low heat spray drying

ActiveUS20160223255A1Liquid surface applicatorsDrying solid materials with heatLiquid productSufficient time

Methods and apparatus provide for spray drying a liquid product into a dried powder without applying heat, including: forming a slurry including a liquid solvent, a carrier, and an active ingredient; applying an electrostatic charge to the slurry; atomizing the charged slurry to produce a plurality of electrostatically charged, wet particles; suspending the electrostatically charged, wet particles for a sufficient time to permit repulsive forces induced by the electrostatic charge on at least some wet particles to cause at least some of such particles to divide into wet sub-particles; and continuing the suspending step, without the presence of any heated drying fluids, for a sufficient time to drive off a sufficient amount of the liquid solvent within most of the wet particles to leave a plurality of dried particles (the powder), each dried particle containing the active ingredient encapsulated within the carrier.

Owner:ZOOMESSENCE INC

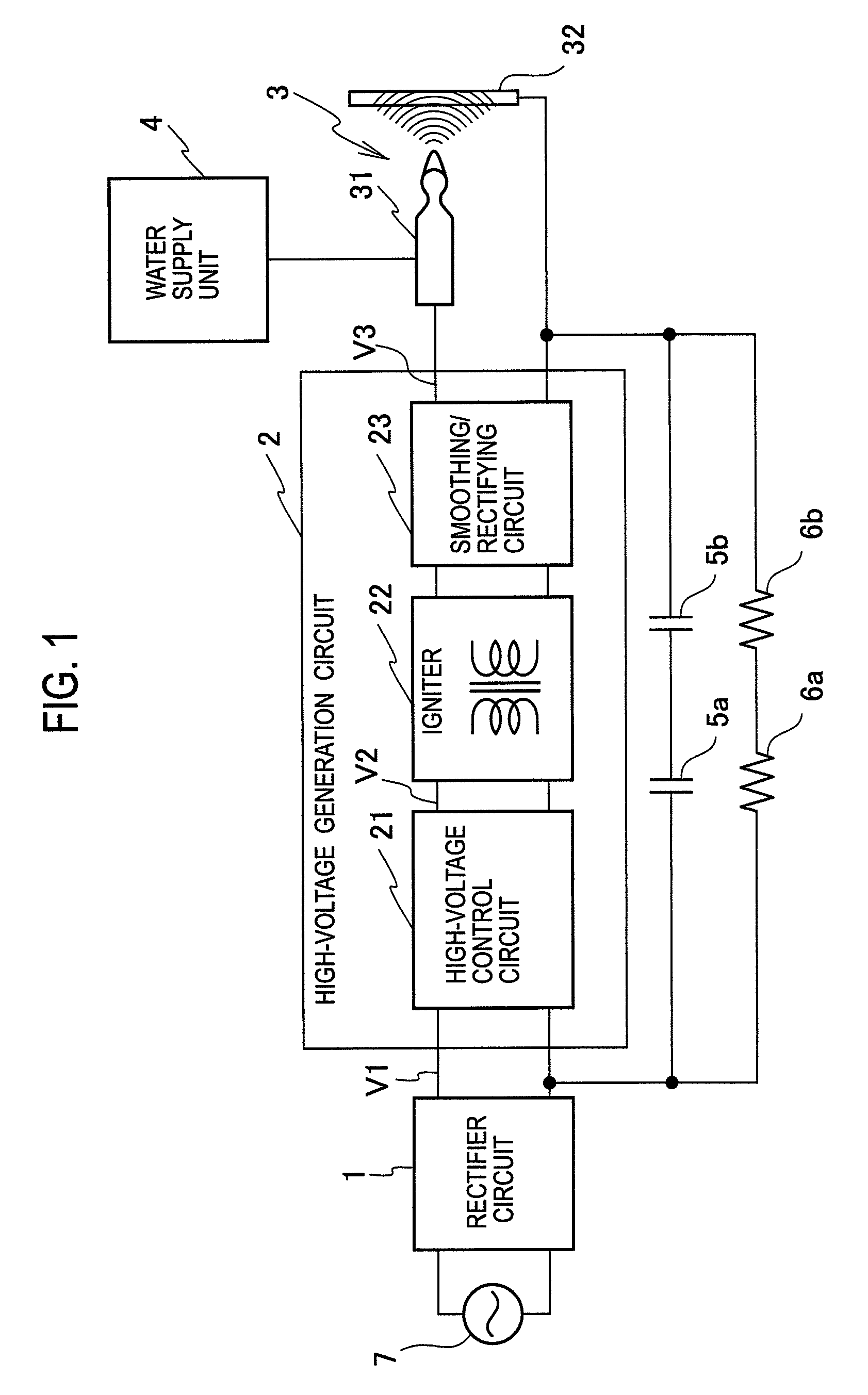

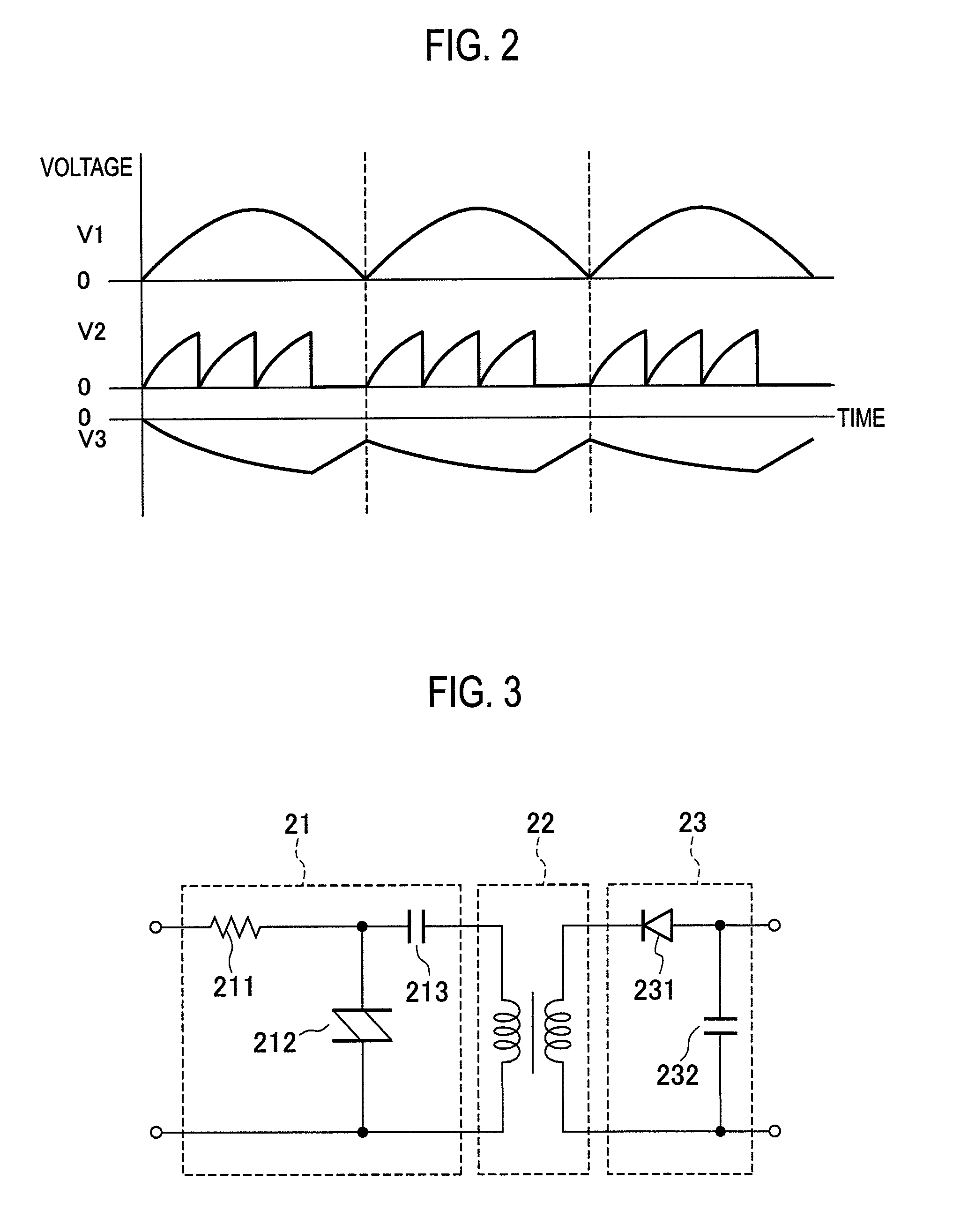

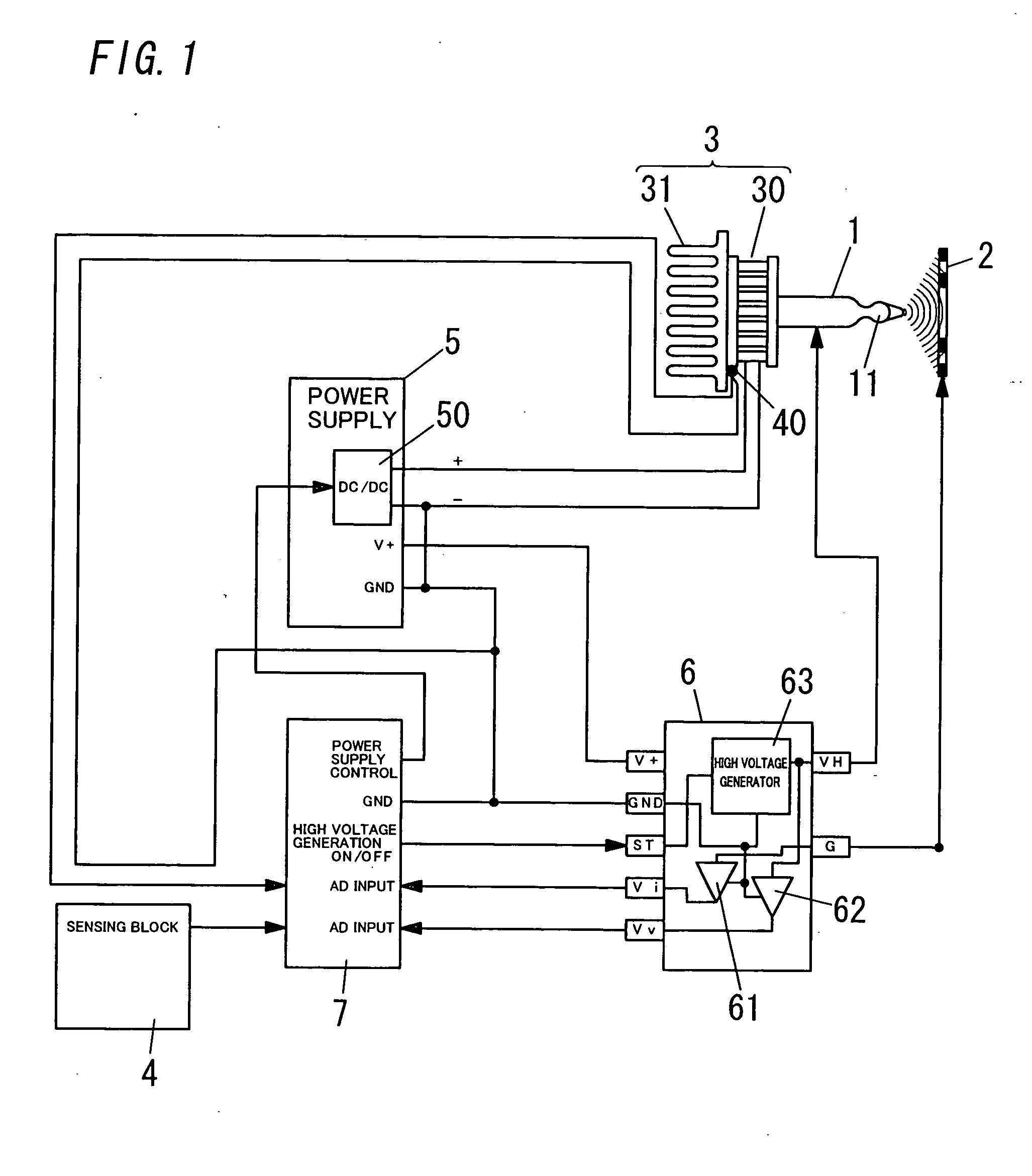

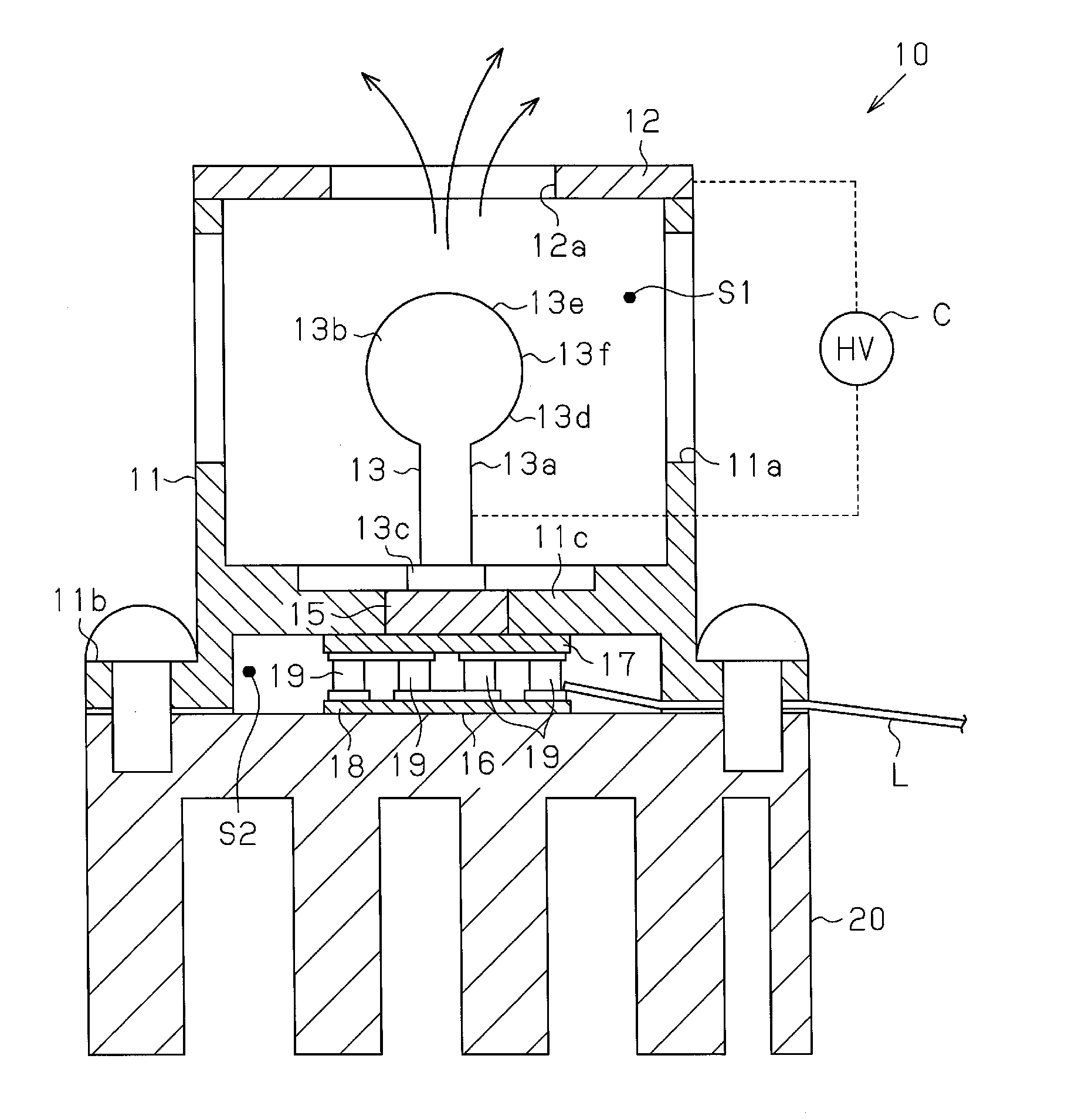

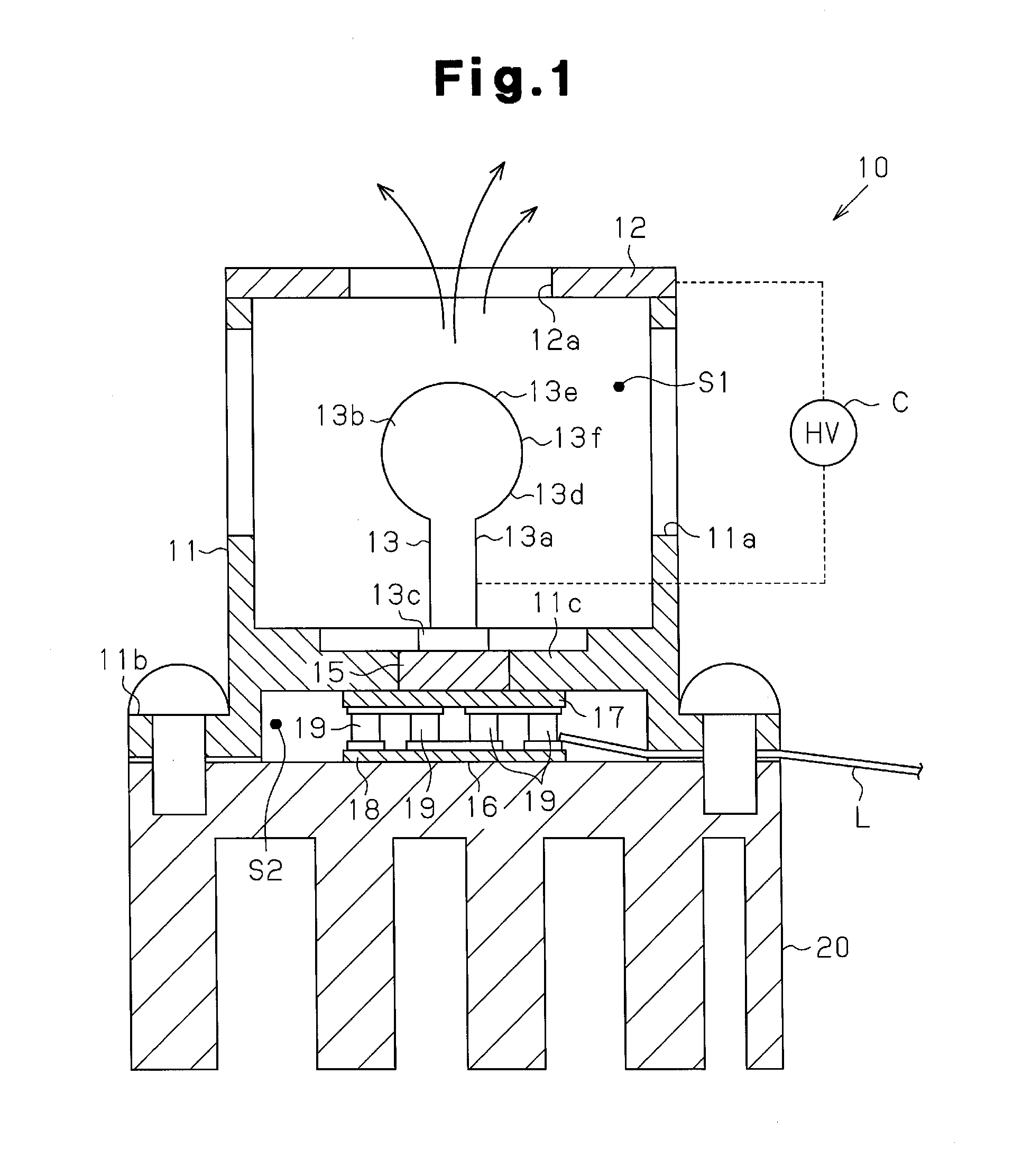

Electrostatic atomizer and hot air blower having the same

There is provided an electrostatic atomizer that electrostatically atomizes a liquid supplied to a discharge electrode by electric discharge caused by an electric field formed in response to voltage application to the discharge electrode. The electrostatic atomizer has a high-voltage generation circuit that generates a pulse voltage to be applied to the discharge electrode, and the high-voltage generation circuit includes a high-voltage control circuit that converts an input AC signal to a pulse signal, and an igniter that steps up the pulse signal obtained by the high-voltage control circuit to a voltage value of the pulse voltage to be applied to the discharge electrode.

Owner:MATSUSHITA ELECTRIC WORKS LTD

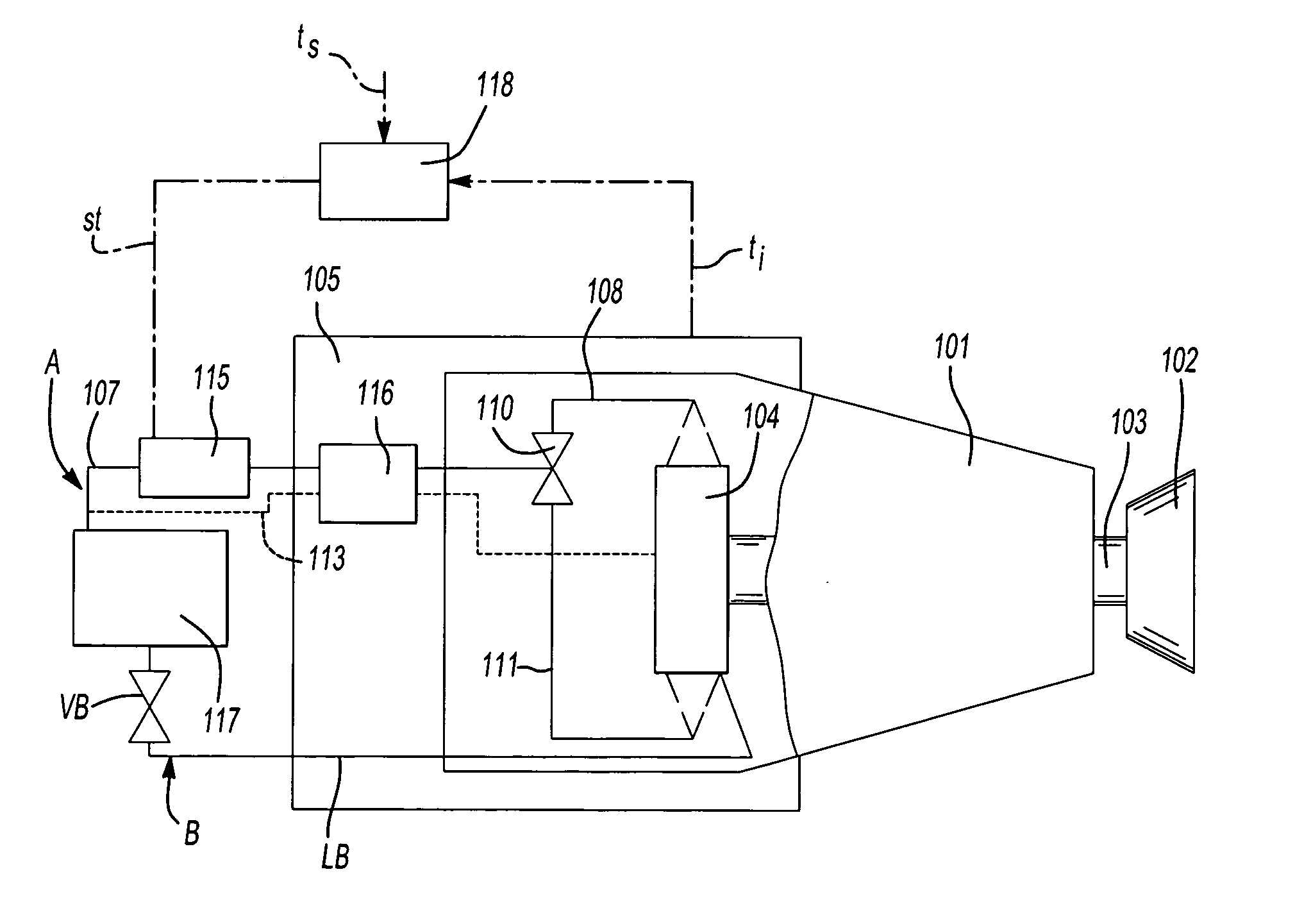

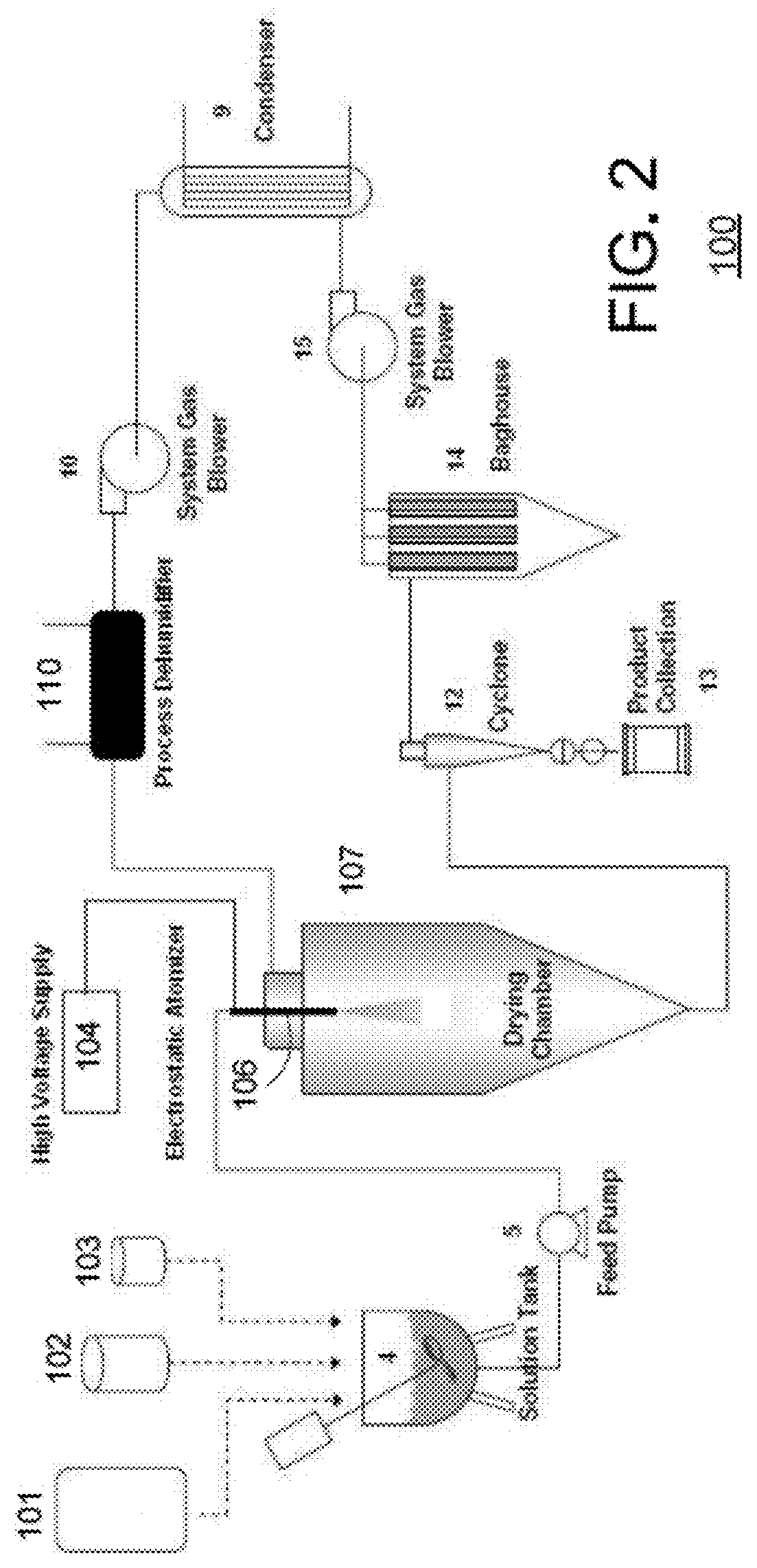

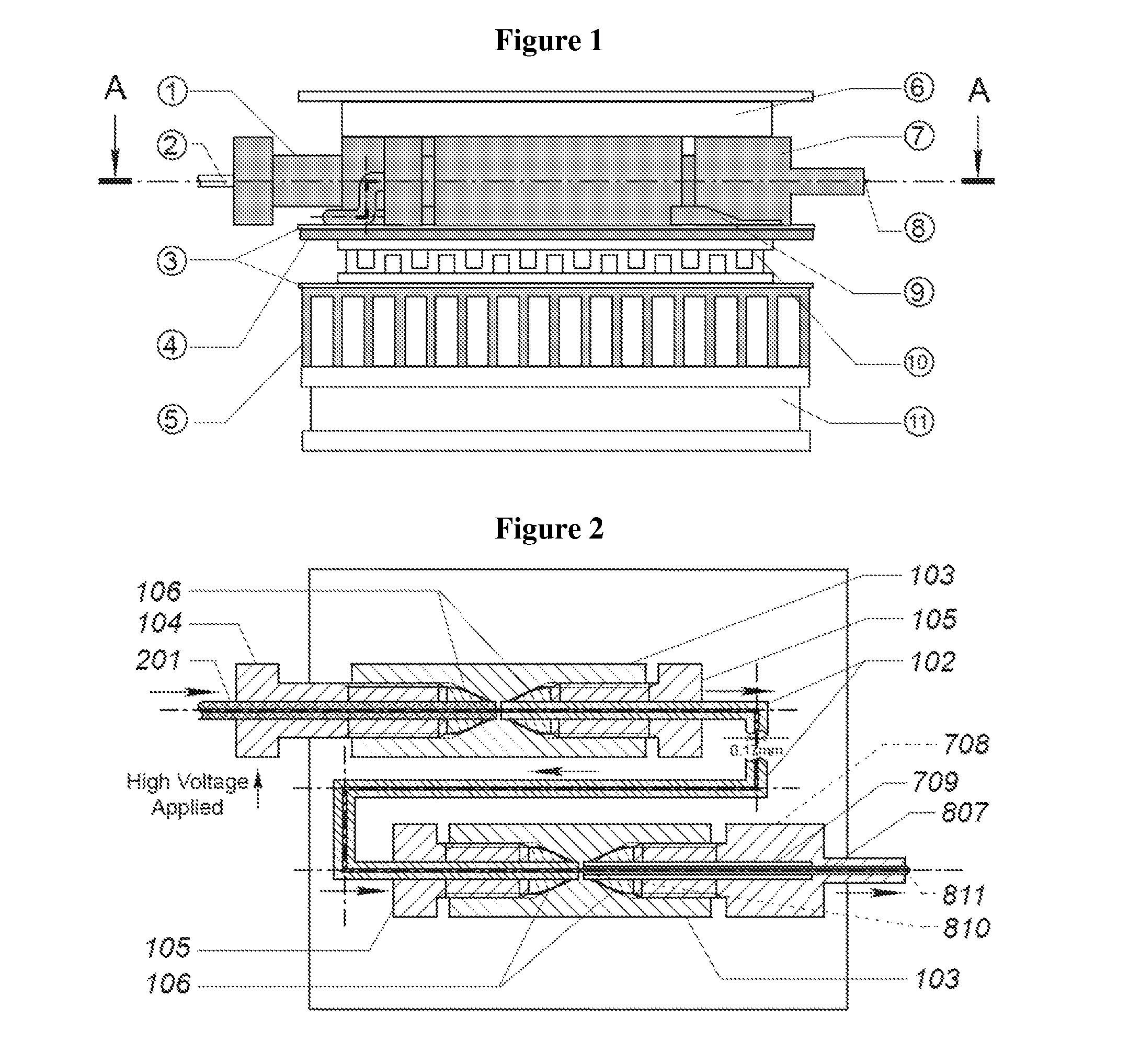

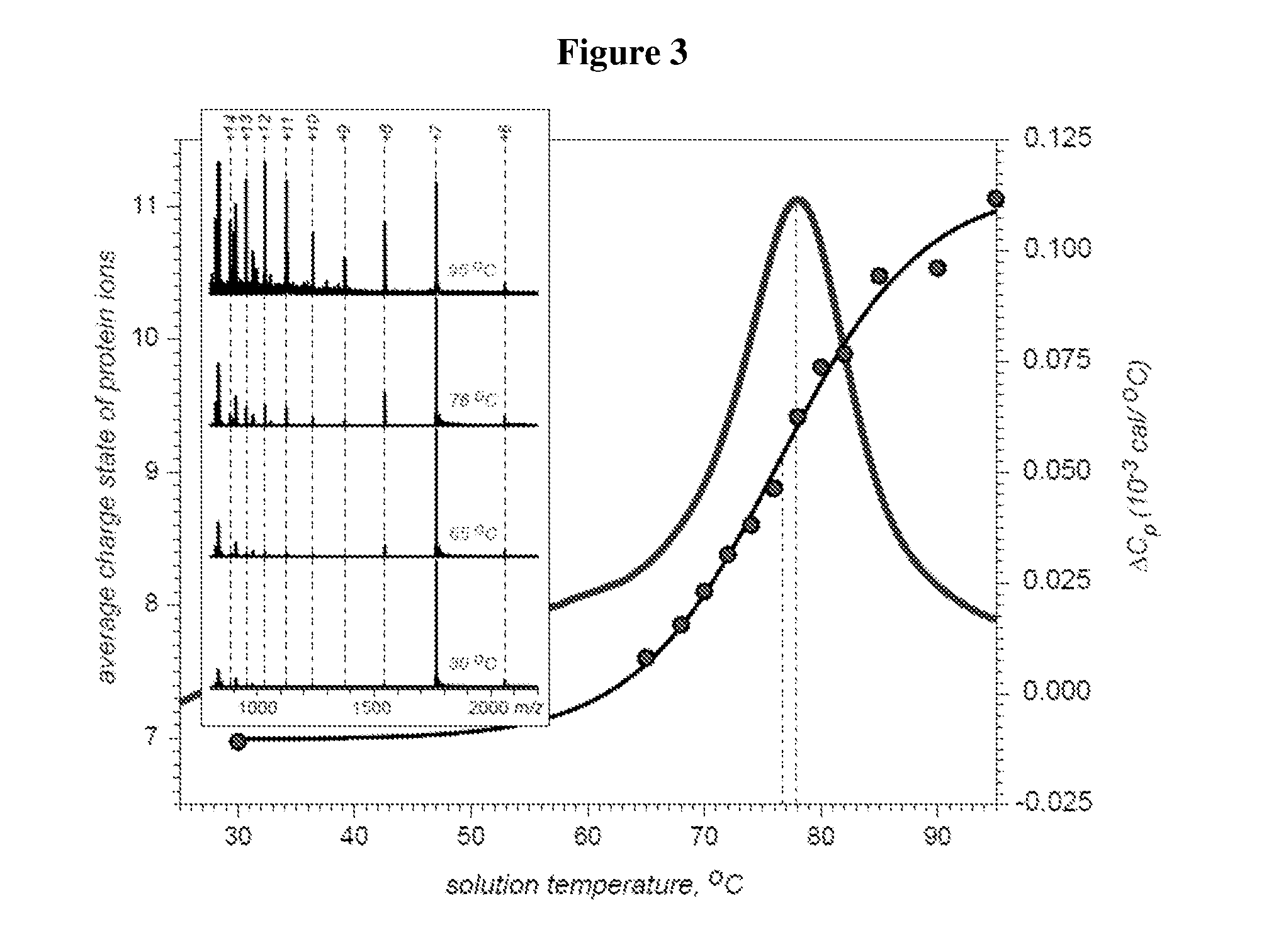

Temperature-controlled electrospray ionization source and methods of use thereof

Disclosed herein is an electrospray ionization source that provides improved temperature control compared to prior sources. A combination of a continuous flow sample design and the use of a long heat shield combine to improve thermal control and reduce memory effects observed with prior designs. The temperature-controlled source is particularly useful for the study of biomolecules, particularly the study of protein aggregation.

Owner:UNIV OF MASSACHUSETTS

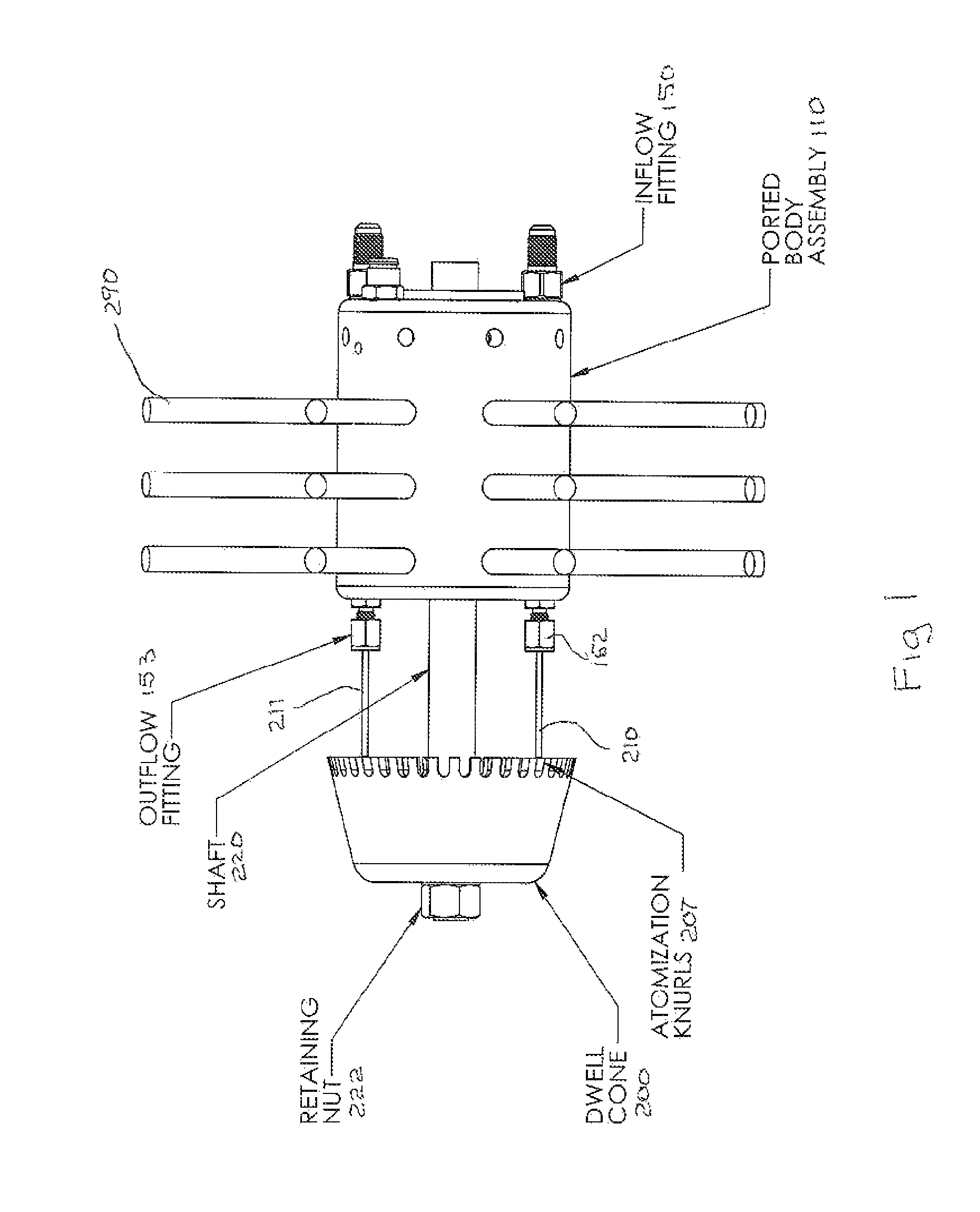

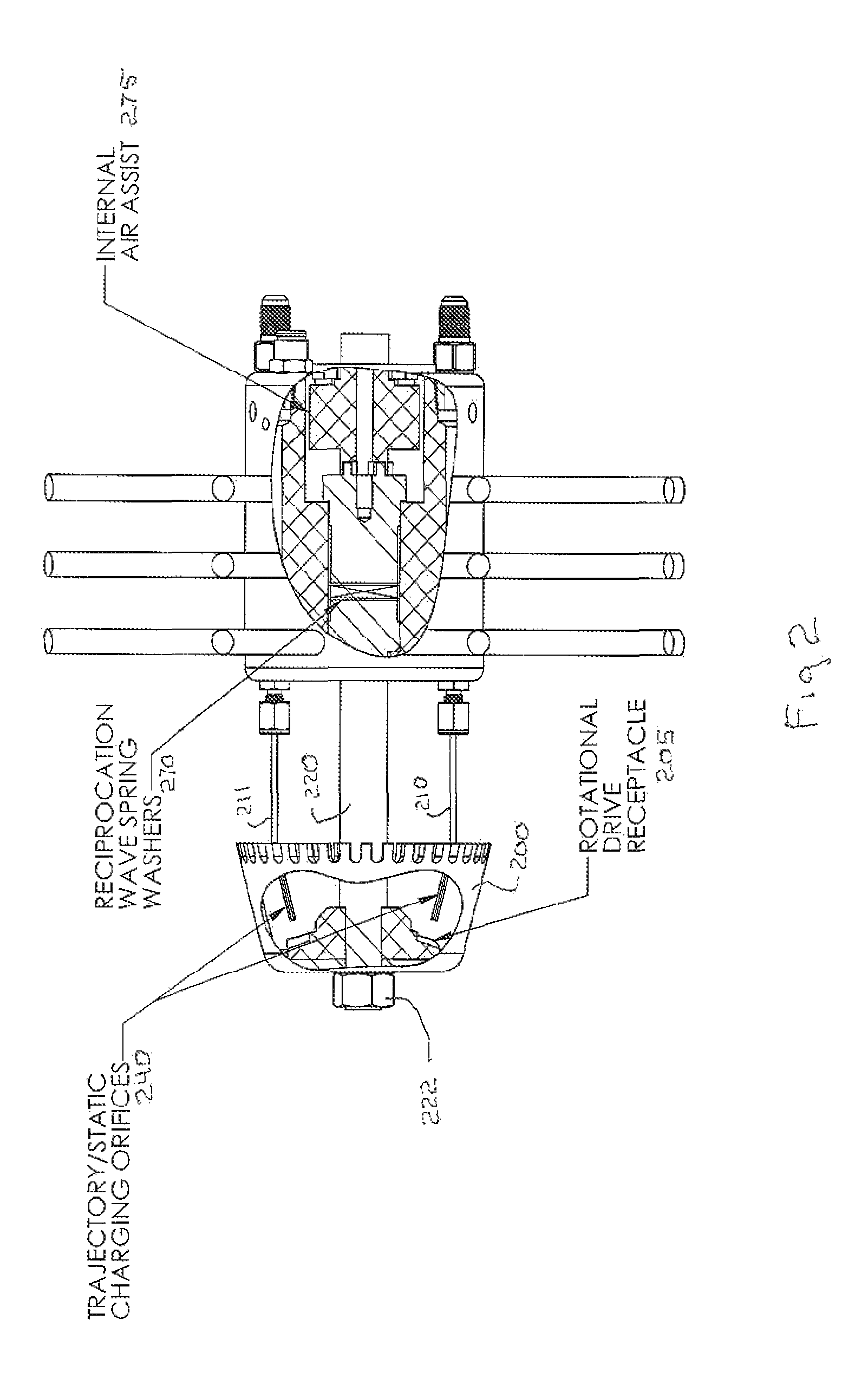

Imparted charge in situ pipelining device

InactiveUS7992514B1Low viscosityIncrease lining buildBurnersLiquid spraying plantsNitrogenEngineering

The invention pertains to a lining device that can be pulled through a pipe having an approximate diameter between 1 and 36 inches. The device sprays an electrically charged lining mixture 360° onto the inside pipe surface. The lining mixture is electro-statically charged to facilitate full encapsulation and adhesion to all pipe wall surfaces in a circumferentially uniform thickness. The lining device can be contained in a multipart housing having flexible rod-like components that hold the device in the center of the longitudinal axis of the pipe. The lining mixture is conveyed to the device through heated non expanding hose. The non expanding properties facilitate the delivery of the lining under pressure to the device. The device also incorporates a dwell cone having a knurled edge that atomizes the lining mixture as it is centrifugally thrown onto the pipe wall. The device may further incorporate nitrogen in mixing the lining material.

Owner:QUEST INSPAR +2

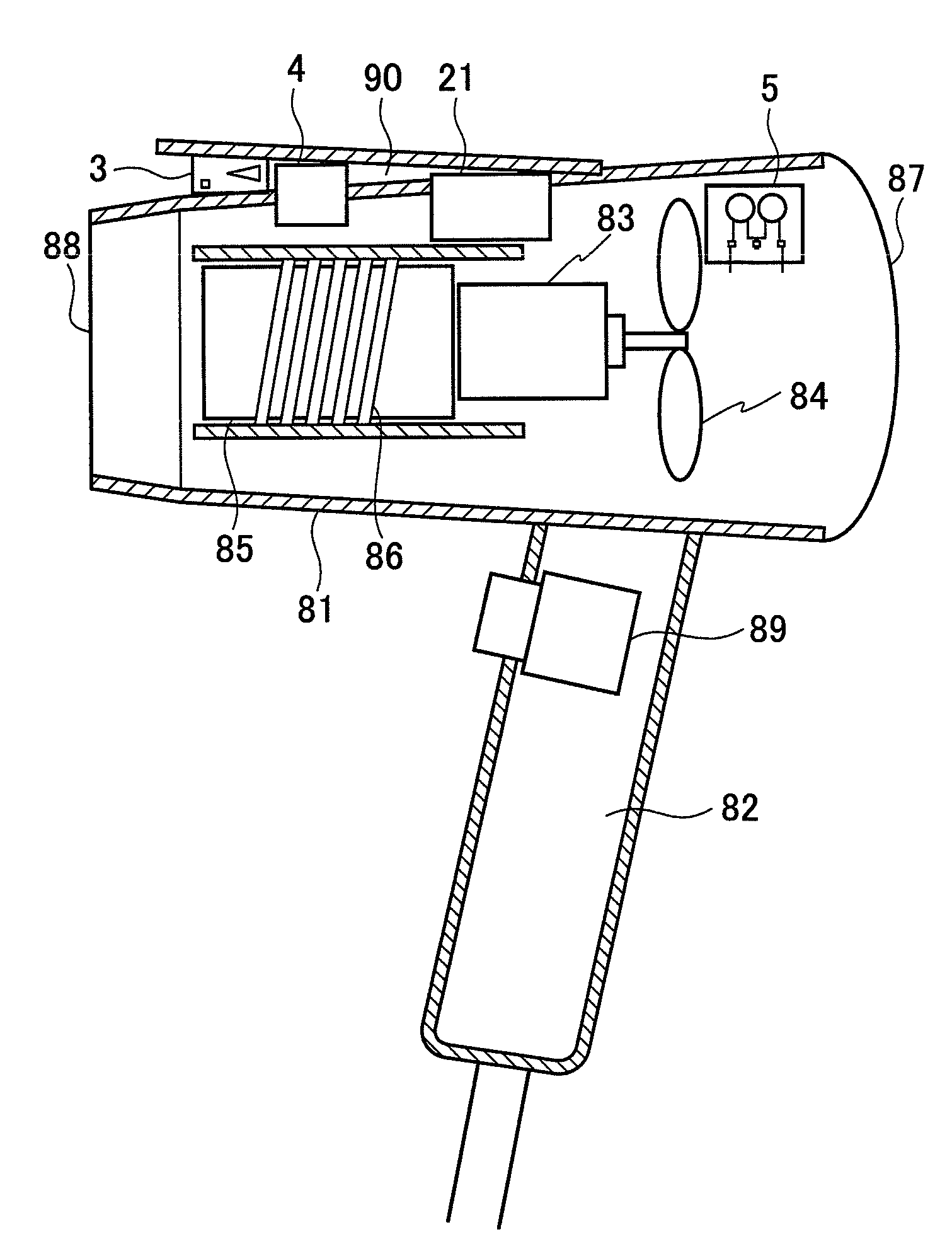

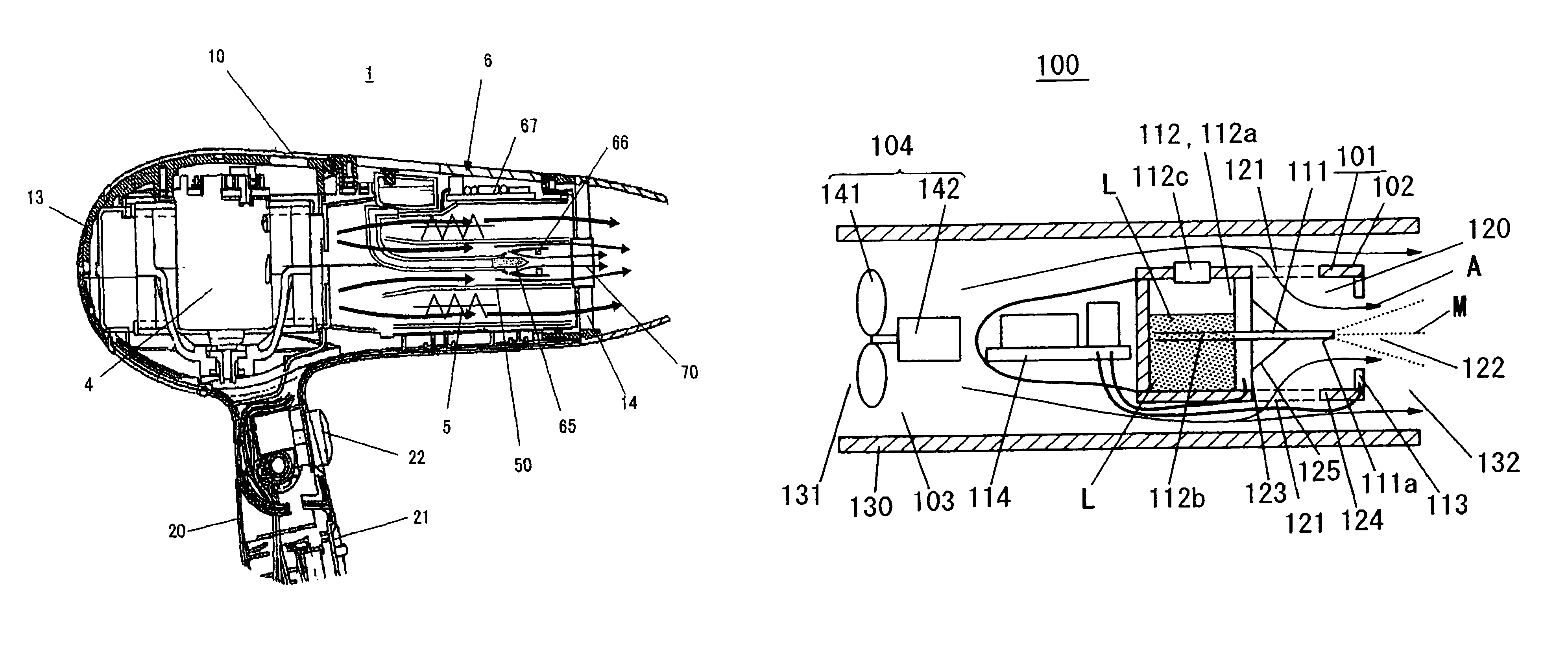

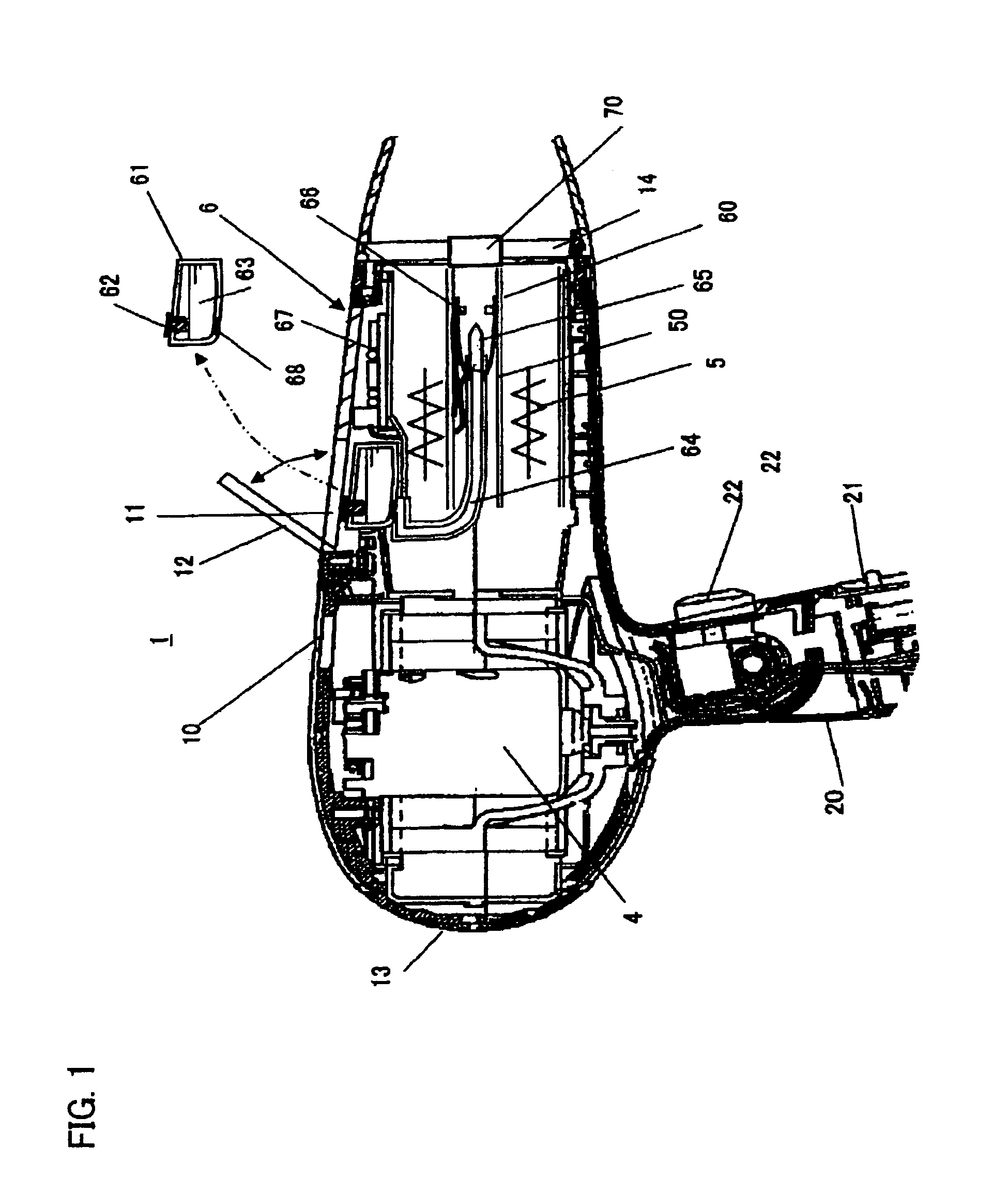

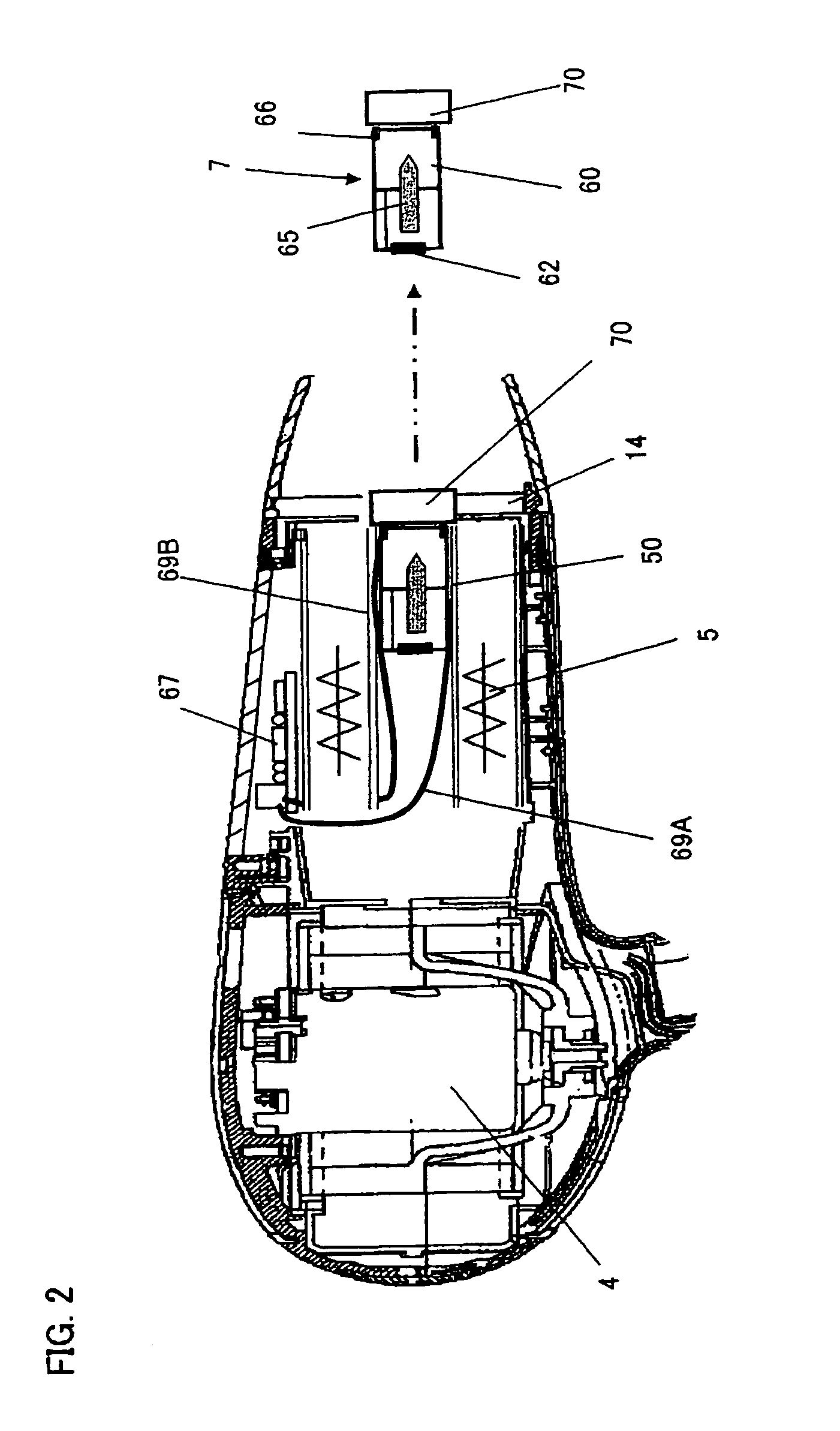

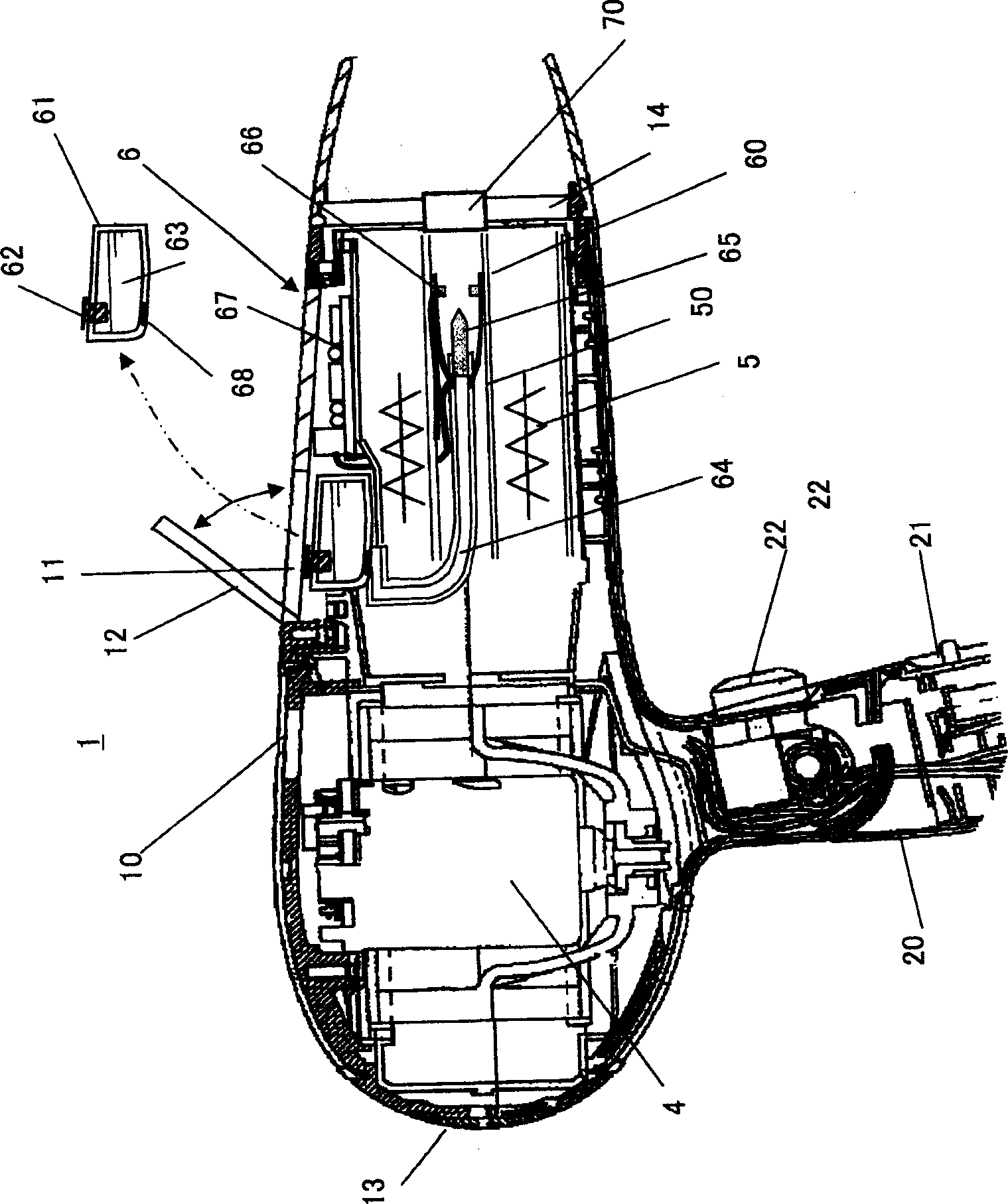

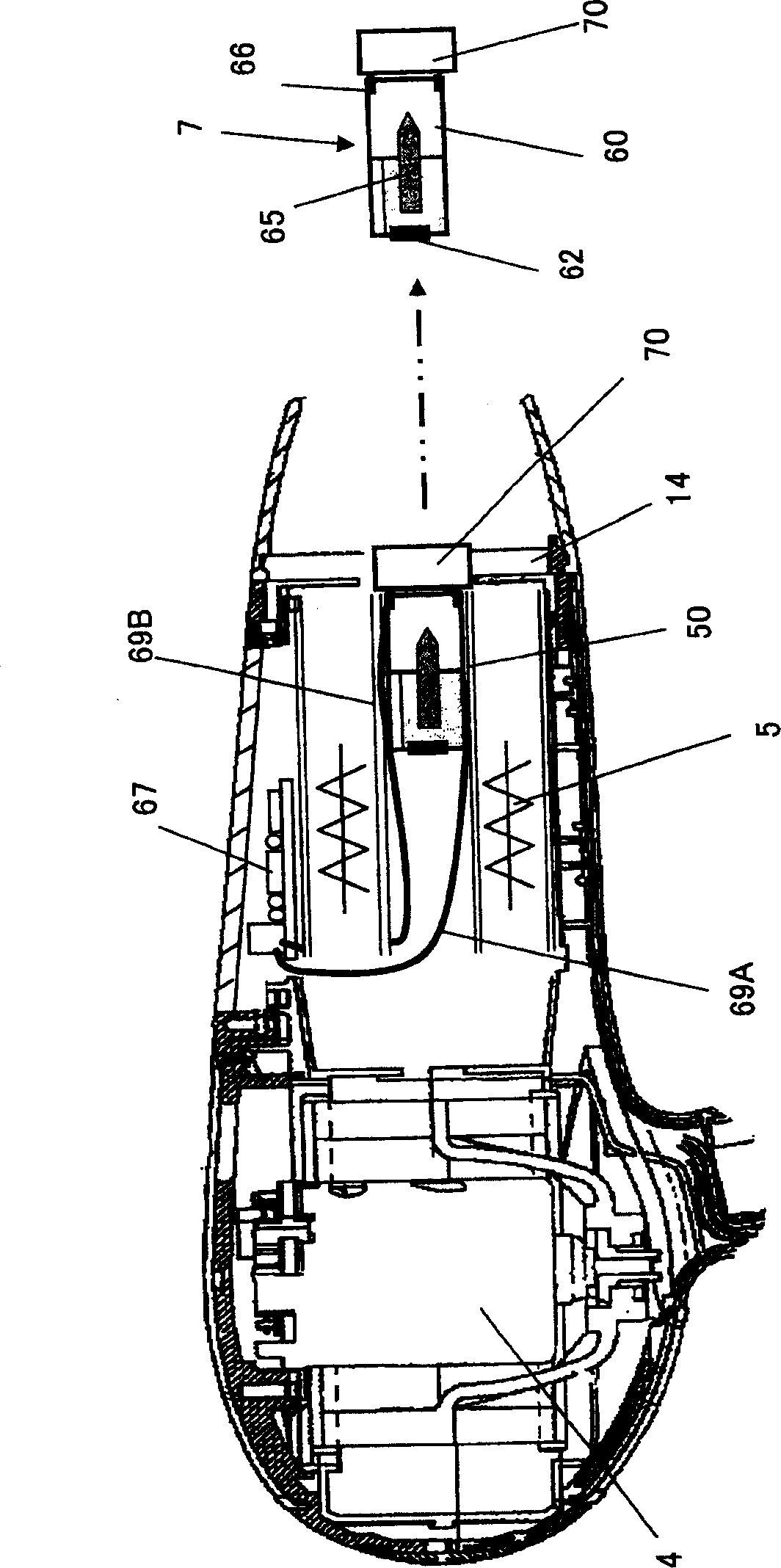

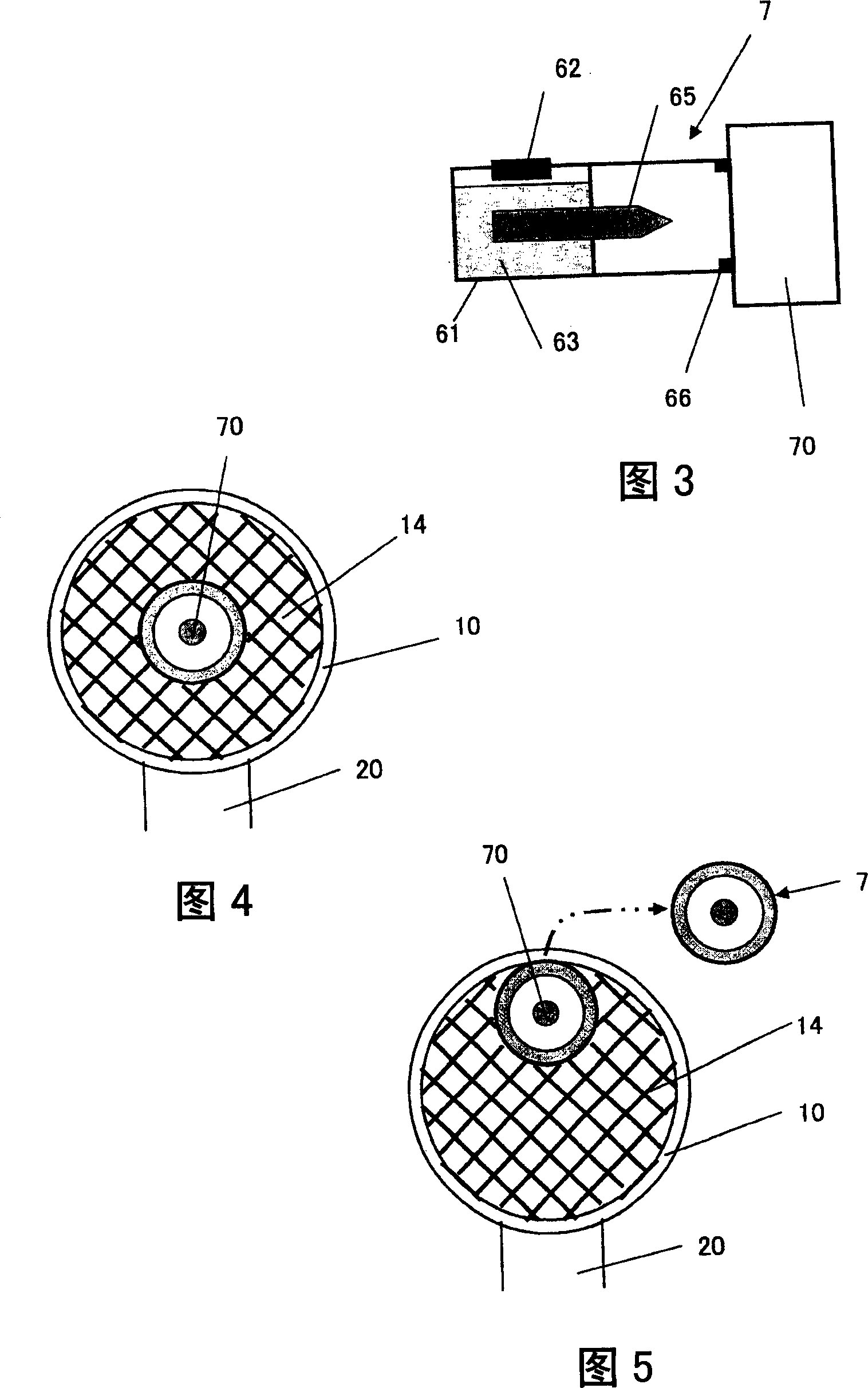

Electrostatic atomizing hairdryer and electrostatic atomizer

InactiveUS7350317B2Improving moisture-holding characteristicGiving hair gathered up feeling and shineCurling-ironsCurling-tongsEngineeringAirflow

In an electrostatic atomizing hairdryer, electrostatically atomized mist generated in an electrostatic atomizing unit is effectively scattered into airflow emitted from a main body of the hairdryer so that the mist can be sprayed to hair uniformly and a time necessary for treatment of hair can be shortened. A tank constituting the electrostatic atomizing unit is detachably provided on a portion in the vicinity of an outer periphery of the main body, and an electrode unit for generating the mist is provided in a path of airflow sucked in an inside of the main body so as to be insulated from heat of a heating unit by an adiabator. A mist emitting opening from which the mist is emitted is disposed on a plane substantially the same as and at substantially the center of an air exit opening of the main body. Thereby, the mist emitted from the mist emitting opening is effectively scattered into the airflow emitted from the air exit opening.

Owner:MATSUSHITA ELECTRIC WORKS LTD

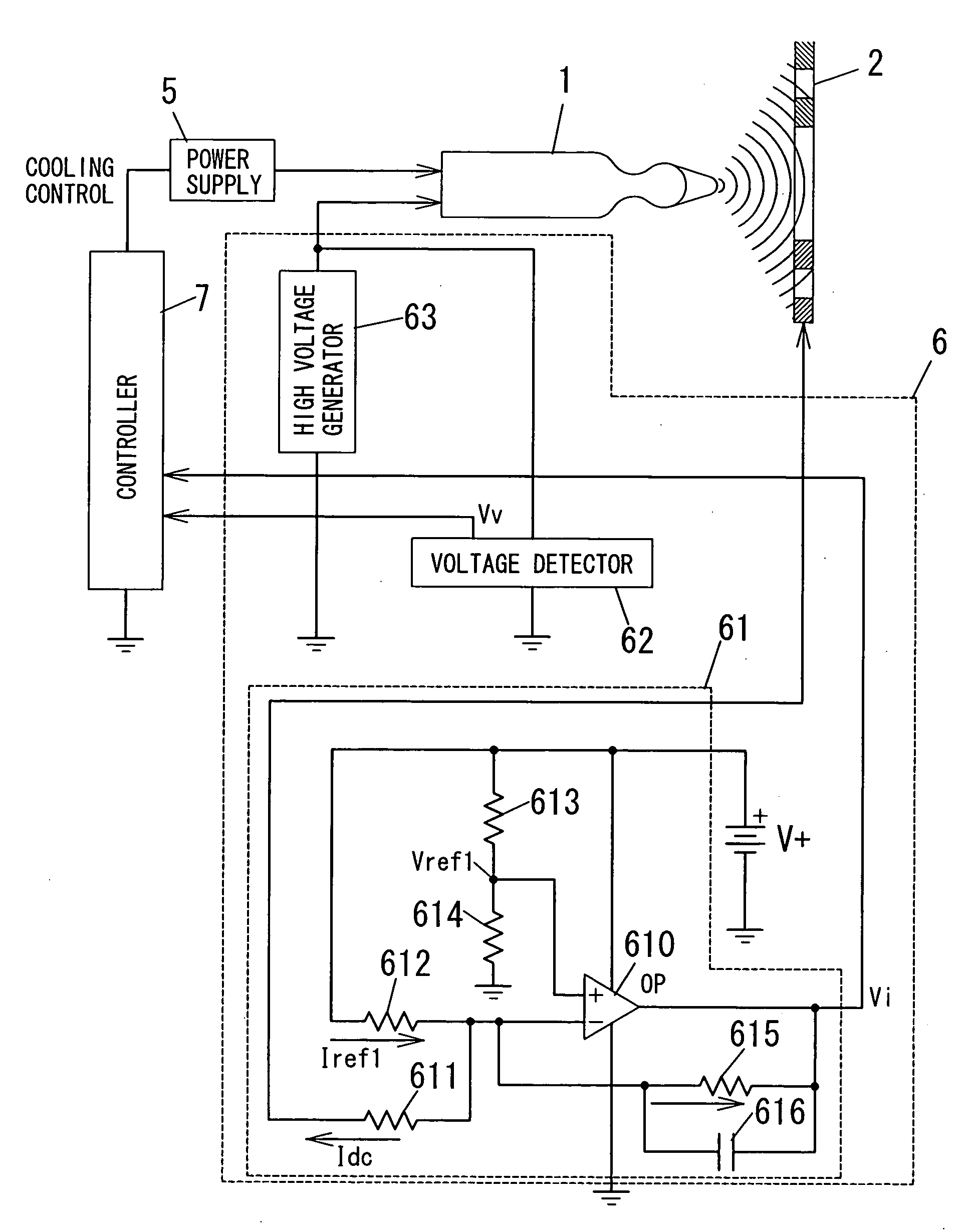

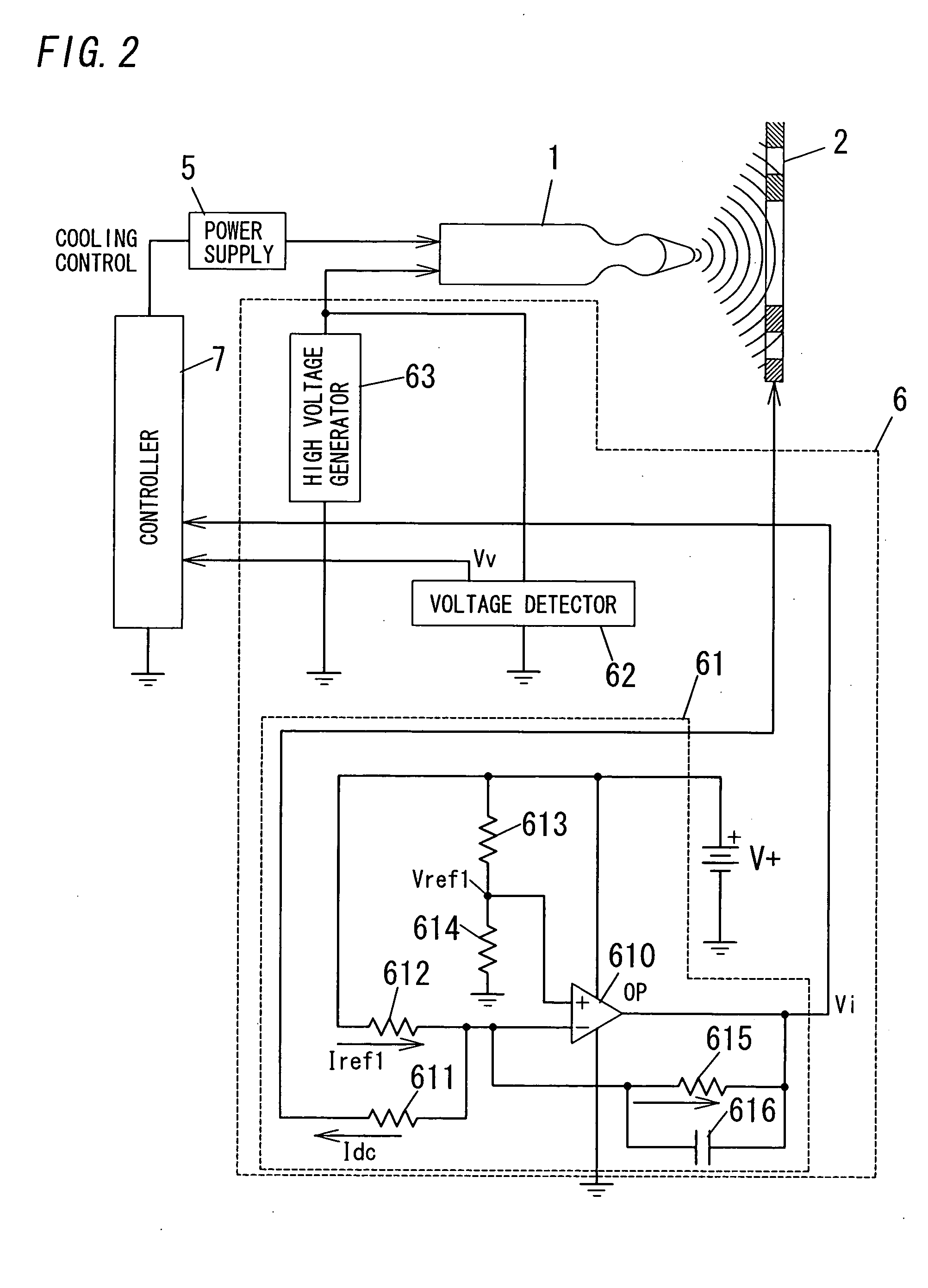

Electrostatic Atomizer

InactiveUS20090206185A1Save troubleHigh voltageBurnersLiquid spraying plantsEngineeringHigh pressure

An electrostatic atomizer comprising a discharge electrode, a counter electrode, a cooling source, a high voltage power supply and a voltage detector. The cooling source cools the discharge electrode to form thereon dew as water. The power supply applies high voltage for discharge across the electrodes. The detector detects voltage between the electrodes. The power supply includes a control device and a voltage stabilizing device that are opposite to each other in temperature characteristic. The control device operates to pick up the voltage detected with the detector via the voltage stabilizing device, and to adjust the high voltage applied across the electrodes through feedback control so that the voltage corresponds to specified discharge voltage.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Spray coating apparatus and spray coating method

InactiveCN1874848AReduce conditioning energyReduce flow rateLiquid surface applicatorsSpraying power supplySpray coatingSpray nozzle

Owner:NIPPON PAINT CO LTD +1

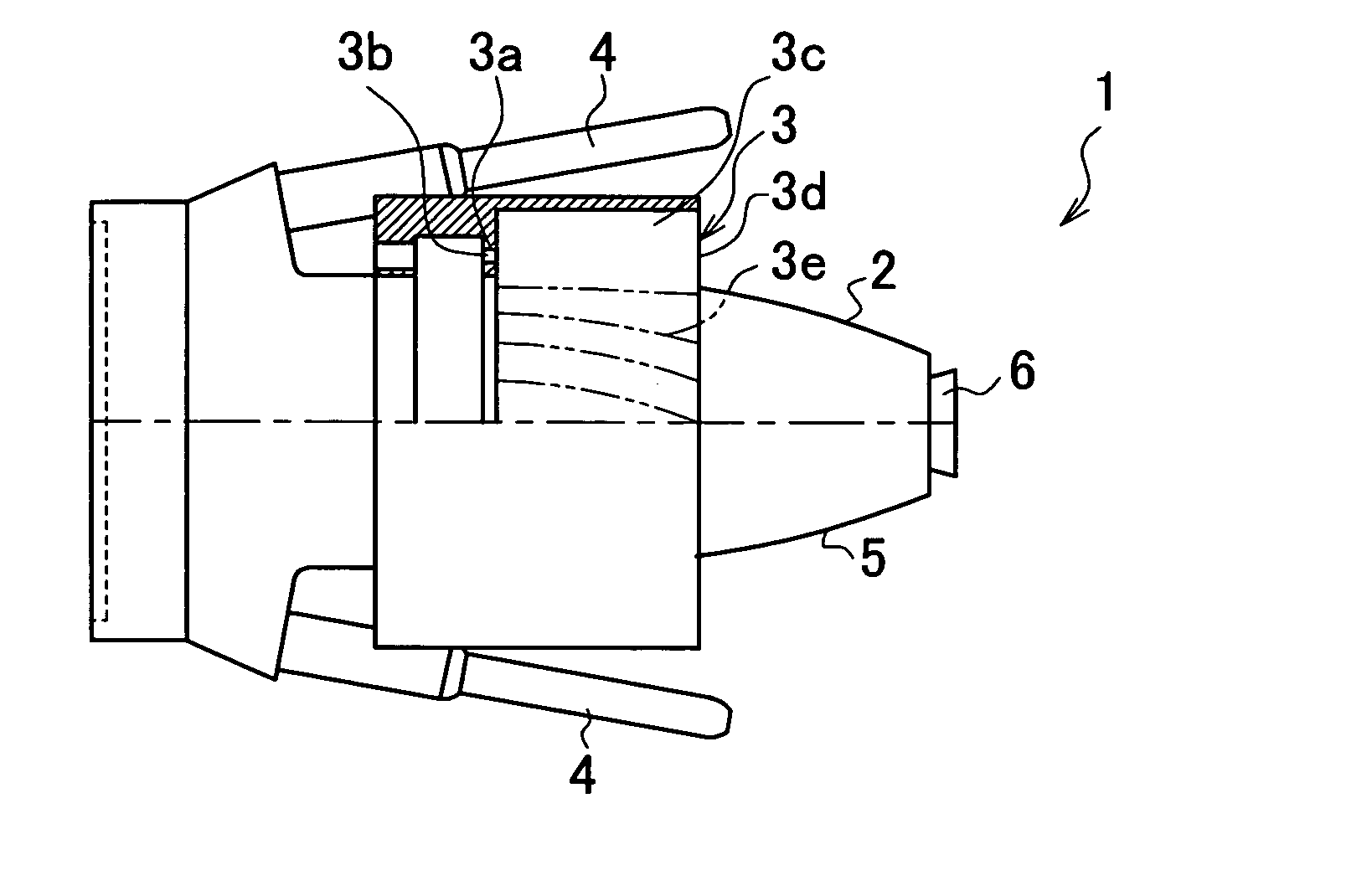

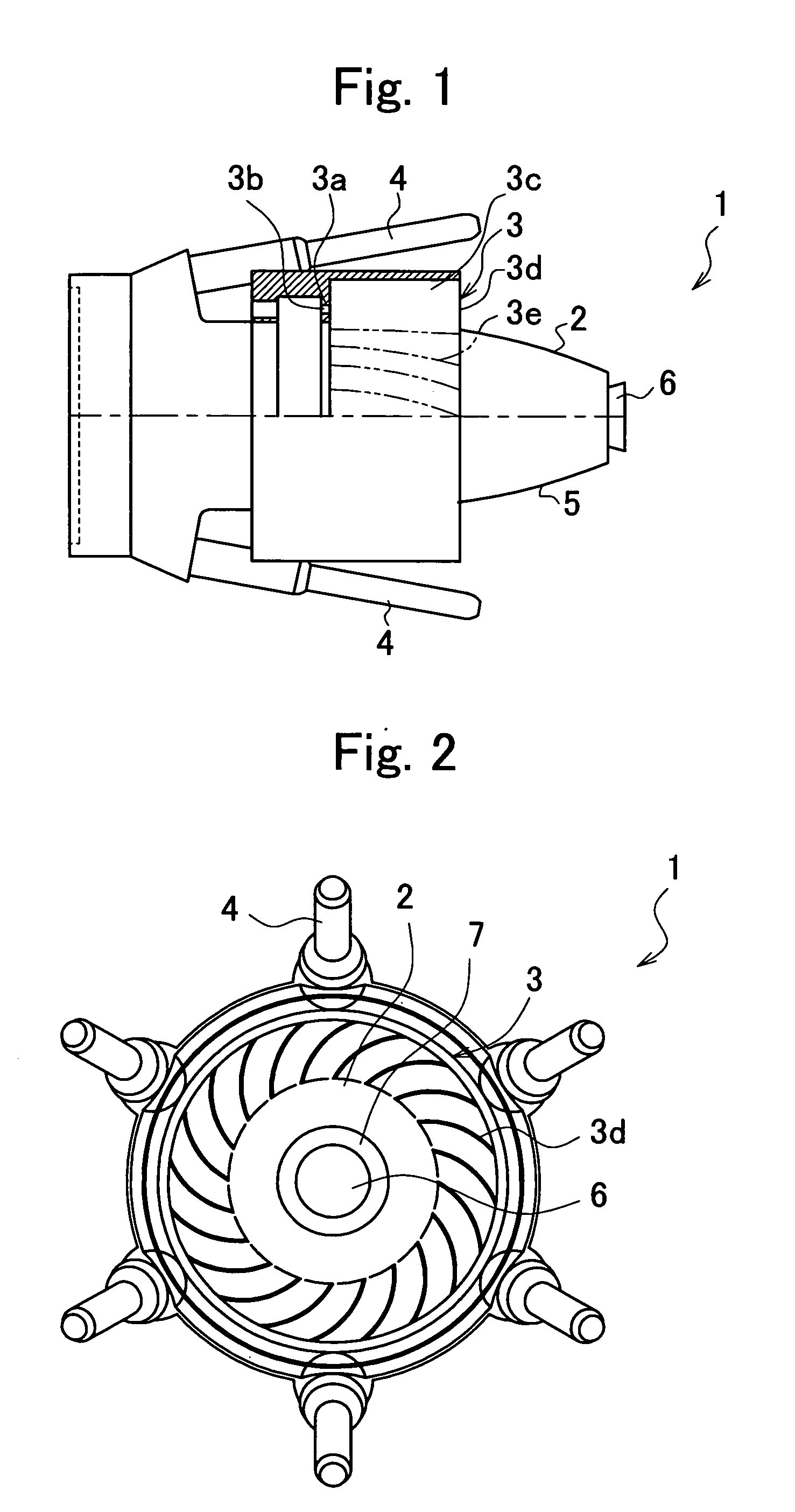

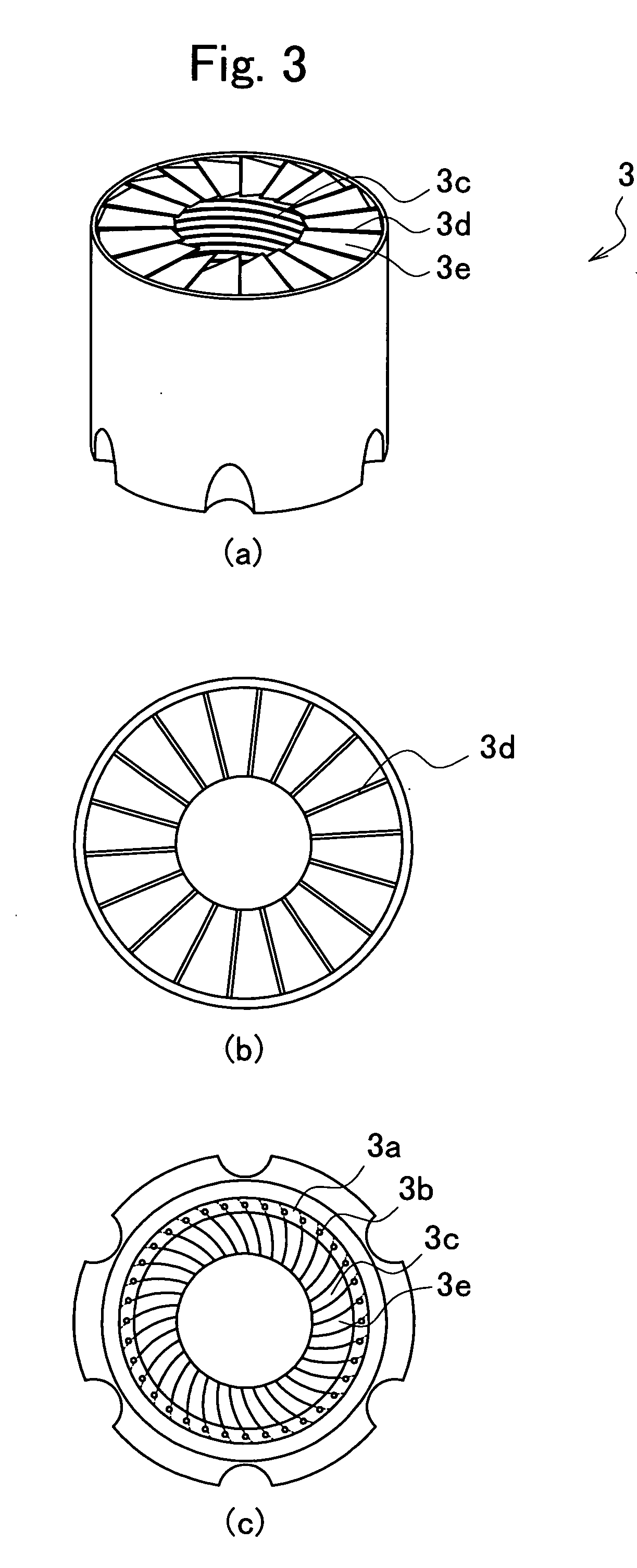

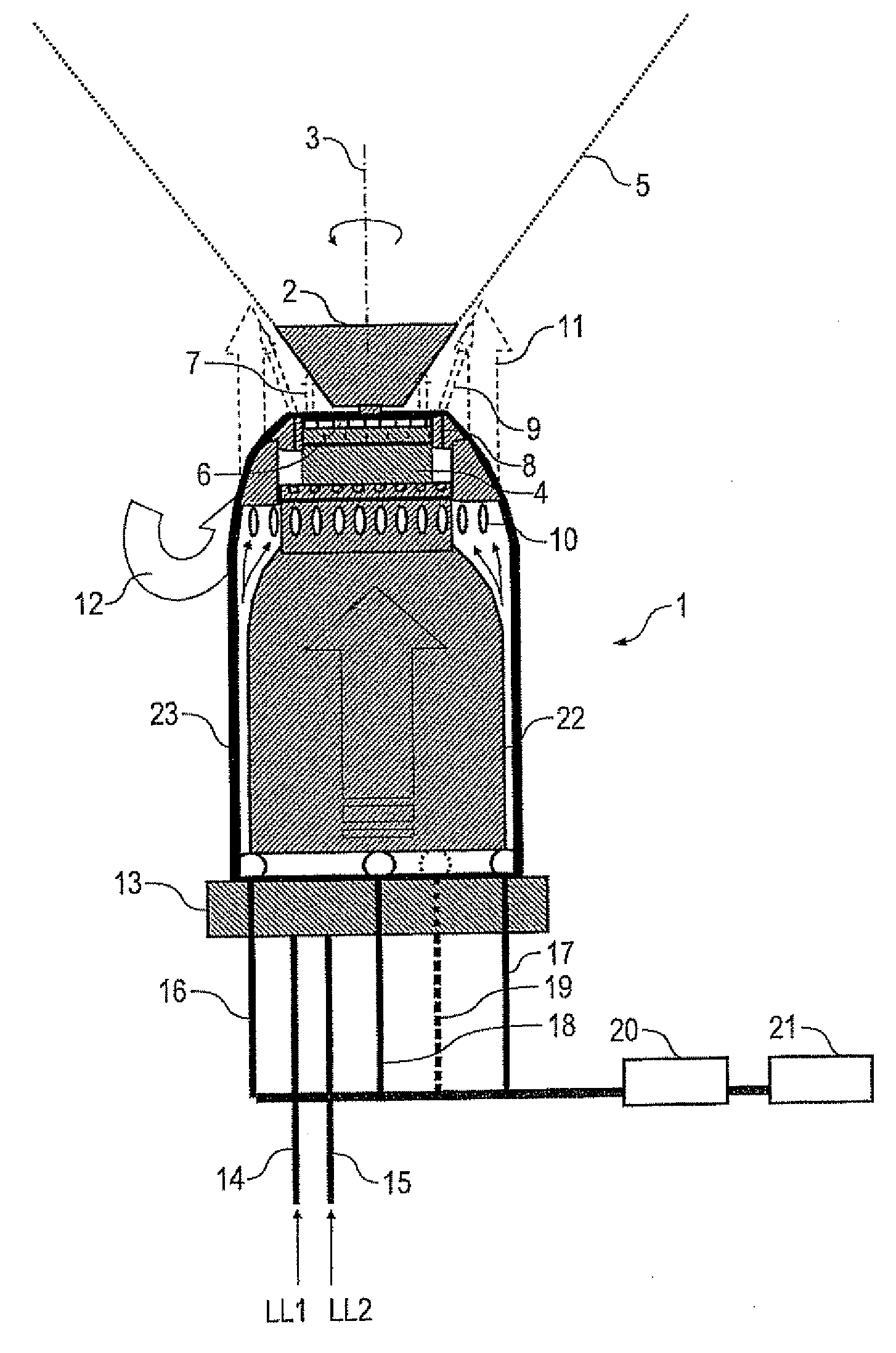

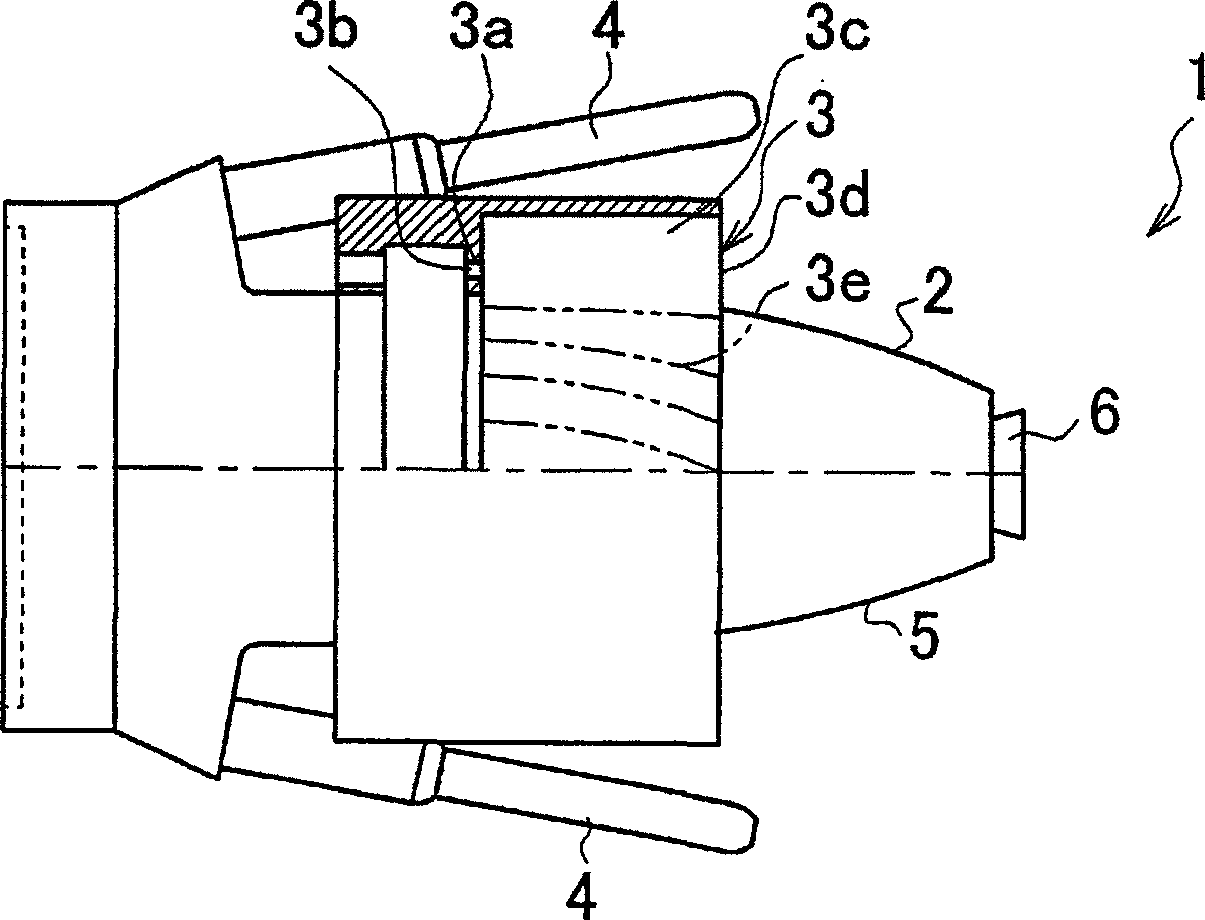

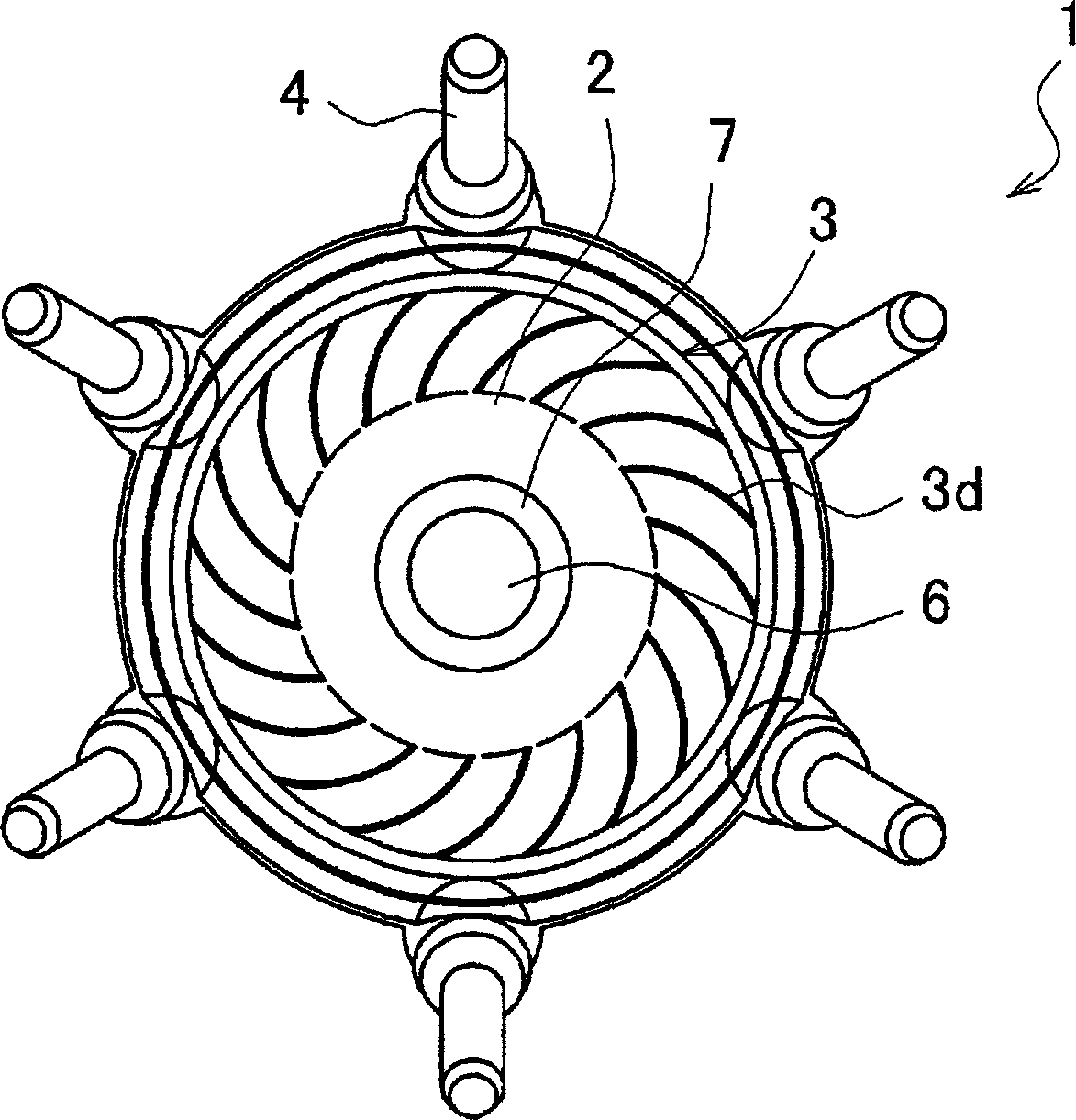

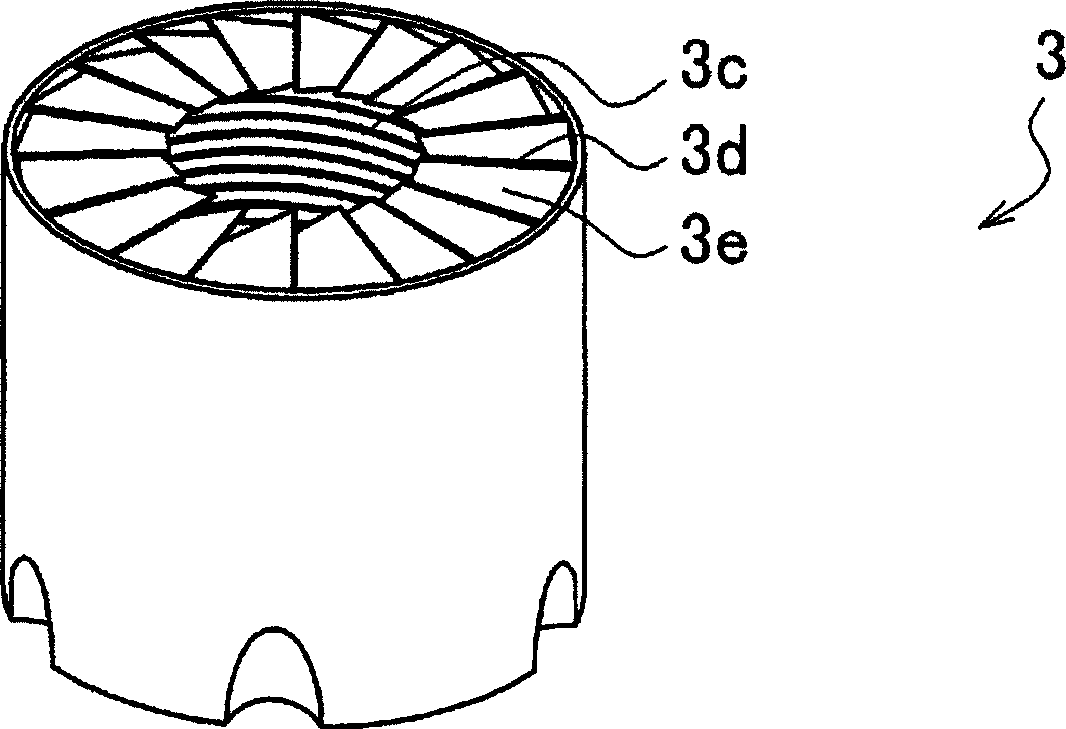

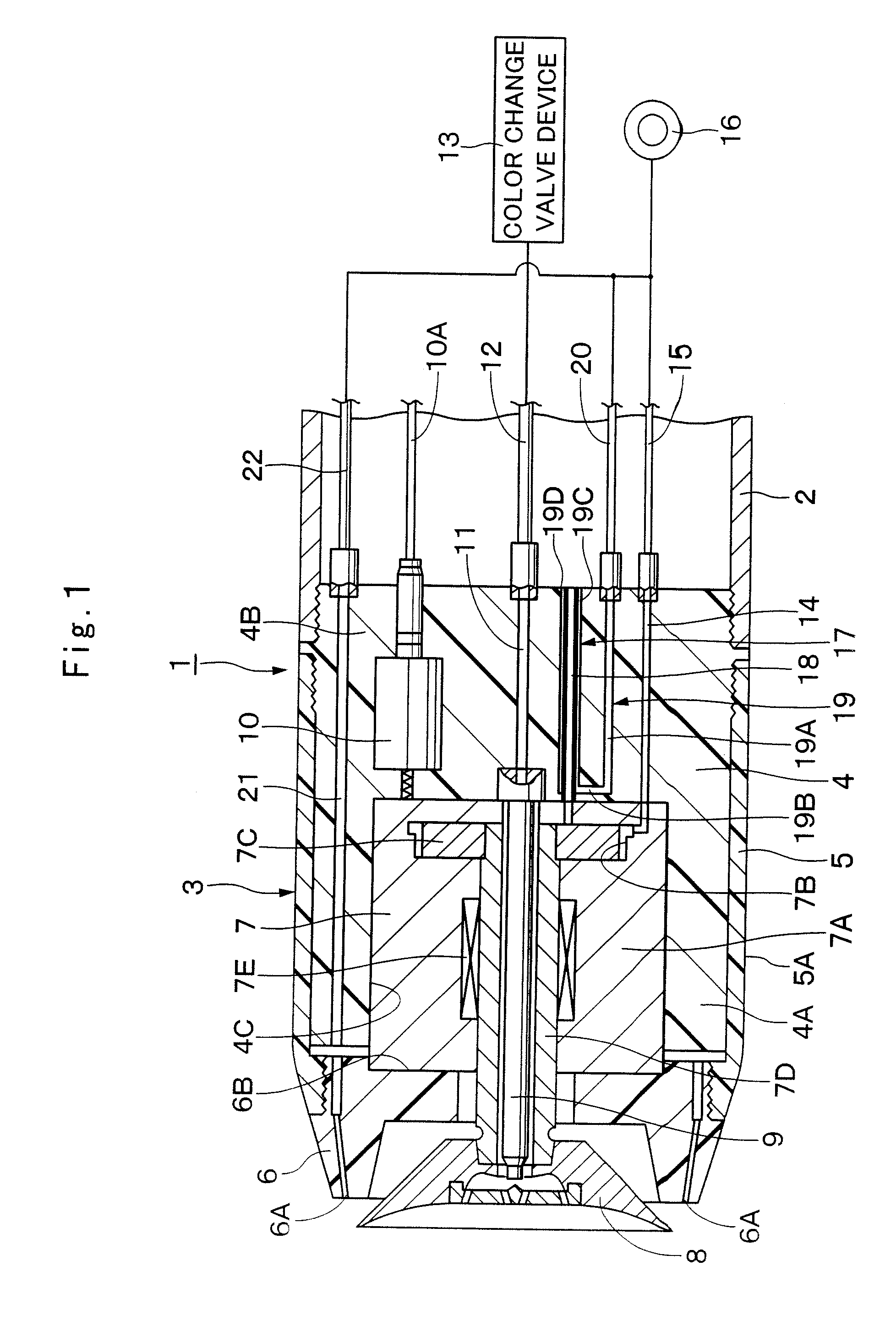

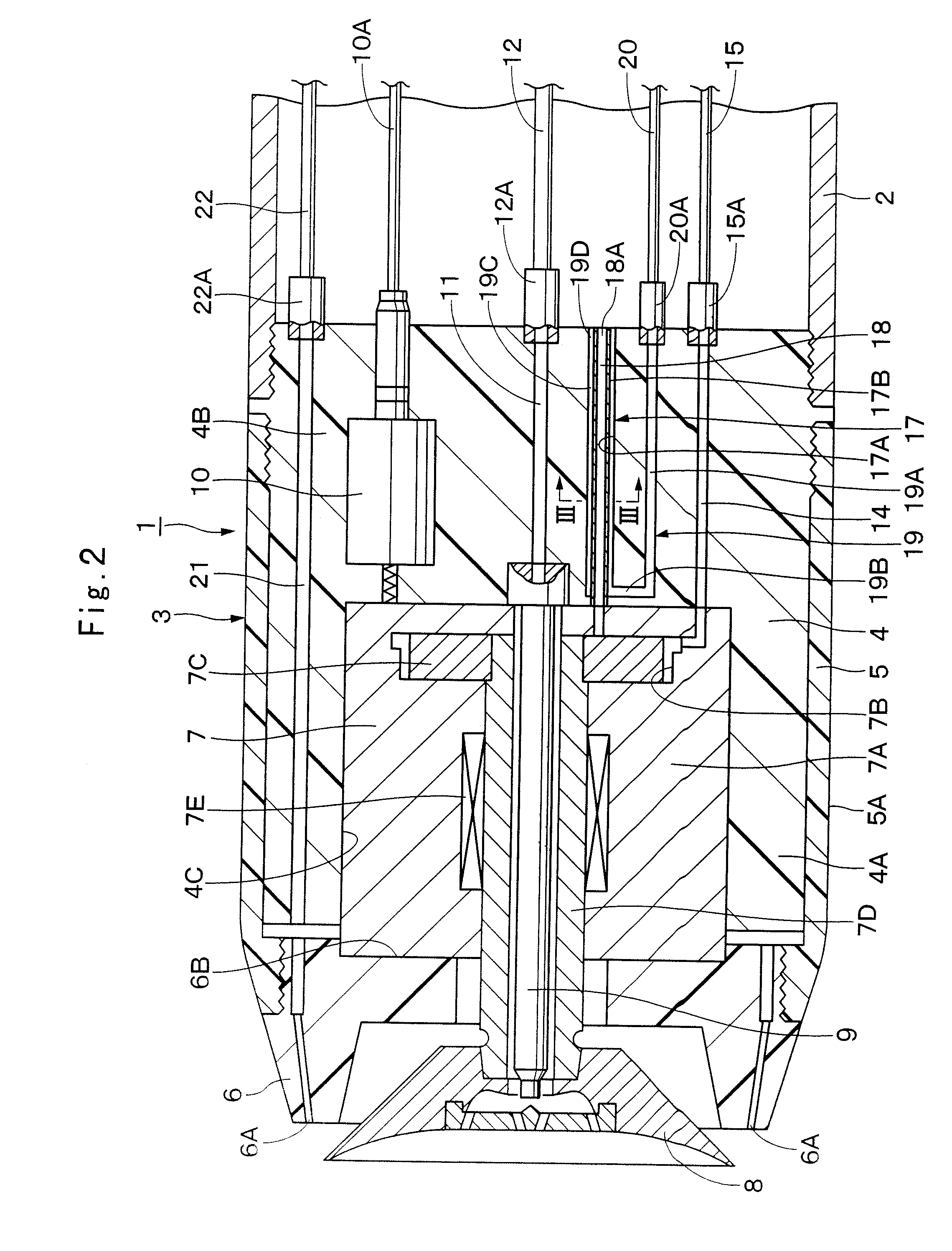

Rotary atomizing-head type coating machine

ActiveUS20090020635A1Well formedAvoid condensationLiquid surface applicatorsMovable spraying apparatusTurbinePneumatic motor

A rotary atomizing-head type coating machine, wherein a paint passage for flowing a paint to a rotary atomizing-head, a turbine air passage flowing a turbine air to the turbine of an air motor, a discharge air passage for flowing the turbine air after driving the turbine to the outside in the form of a discharge air, and a heat insulating air discharge passage of a heat insulated air passage axially extending while surrounding the discharge air passage and allowing hot heat insulated air to flow therein are formed in the bottom part of a housing body forming a housing. Thus, even if the turbine air expanded in a heat insulated state and reduced in temperature flows in the discharge air passage, the housing can be prevented from being cooled by the discharge air by flowing a heat insulated air with a temperature higher than that of the discharge air in the heat insulated air discharge passage.

Owner:ABB (SCHWEIZ) AG

Electrostatic atomizing hairdryer and electrostatic atomizer

InactiveCN1754482APrevent evaporationEnsure the amount of sprayCurling-ironsCurling-tongsThermal insulationSpray nozzle

The invention provides a static atomization blower and a static atomization device, which can cause the haze produced by the static atomization device (6) to be efficiently dispersed in the air current which is ejected from the main body part (10) of the blower (1), and can spray the haze onto the hair, and then can shorten the time for caring the hair. A container (61) forming the static atomization device (6) can be freely assembled and unassembled near the outer periphery of the main body part (10); an electrode part (60) producing haze is arranged in the flow way of the air current which is sucked into the main body part(10), and is isolated from the heat of the heating part (5) by a thermal insulation component (50). Furthermore, a haze spraying nozzle (70) for spraying haze is arranged on an approximate same plane with the air ejecting nozzle (14) of the main body part (10) and on the approximately center position. The haze sprayed from the haze spraying nozzle (70) is efficiently dispersed in the air current which is ejected from the air ejecting nozzle (14).

Owner:PANASONIC ELECTRIC WORKS CO LTD

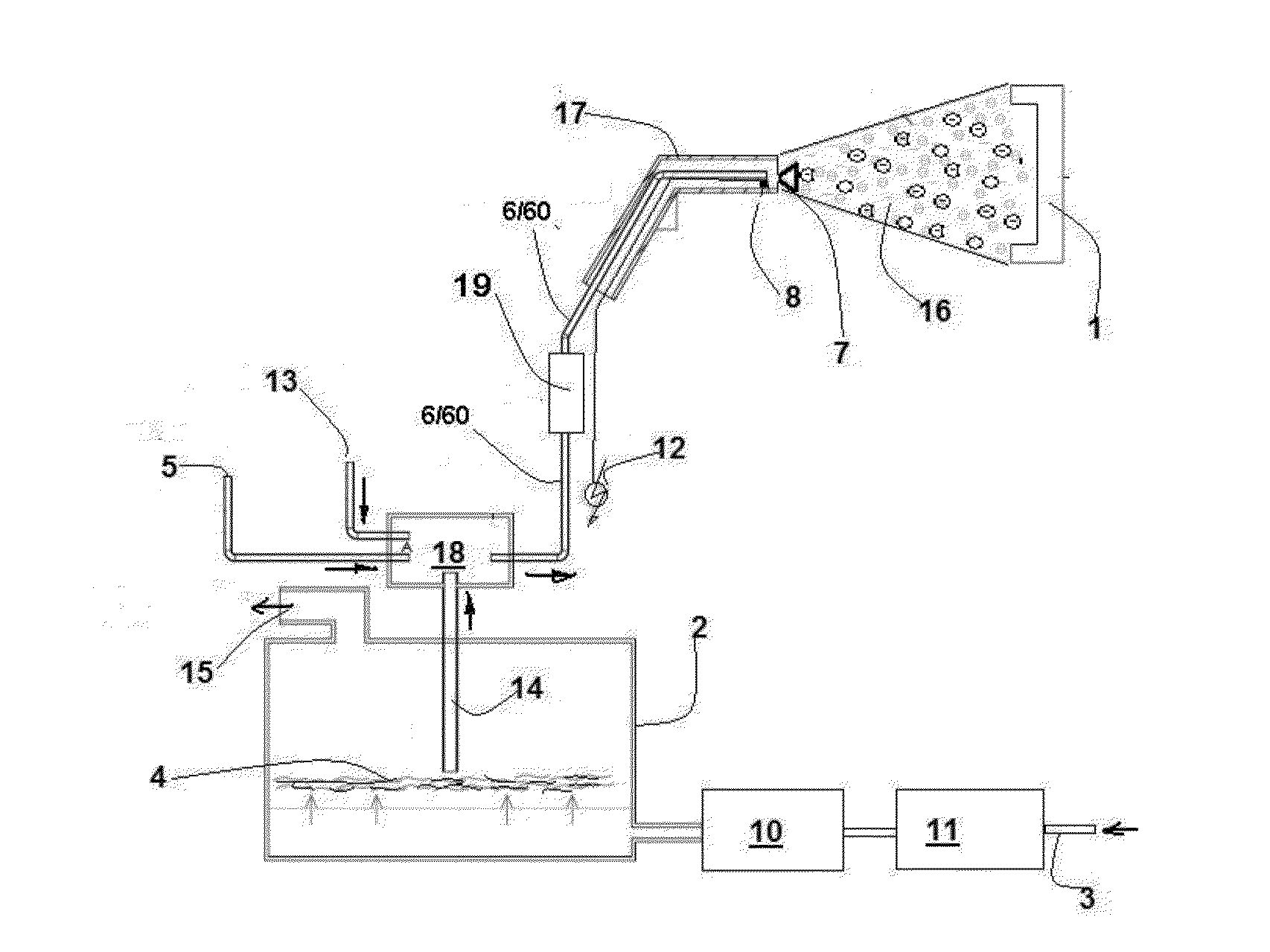

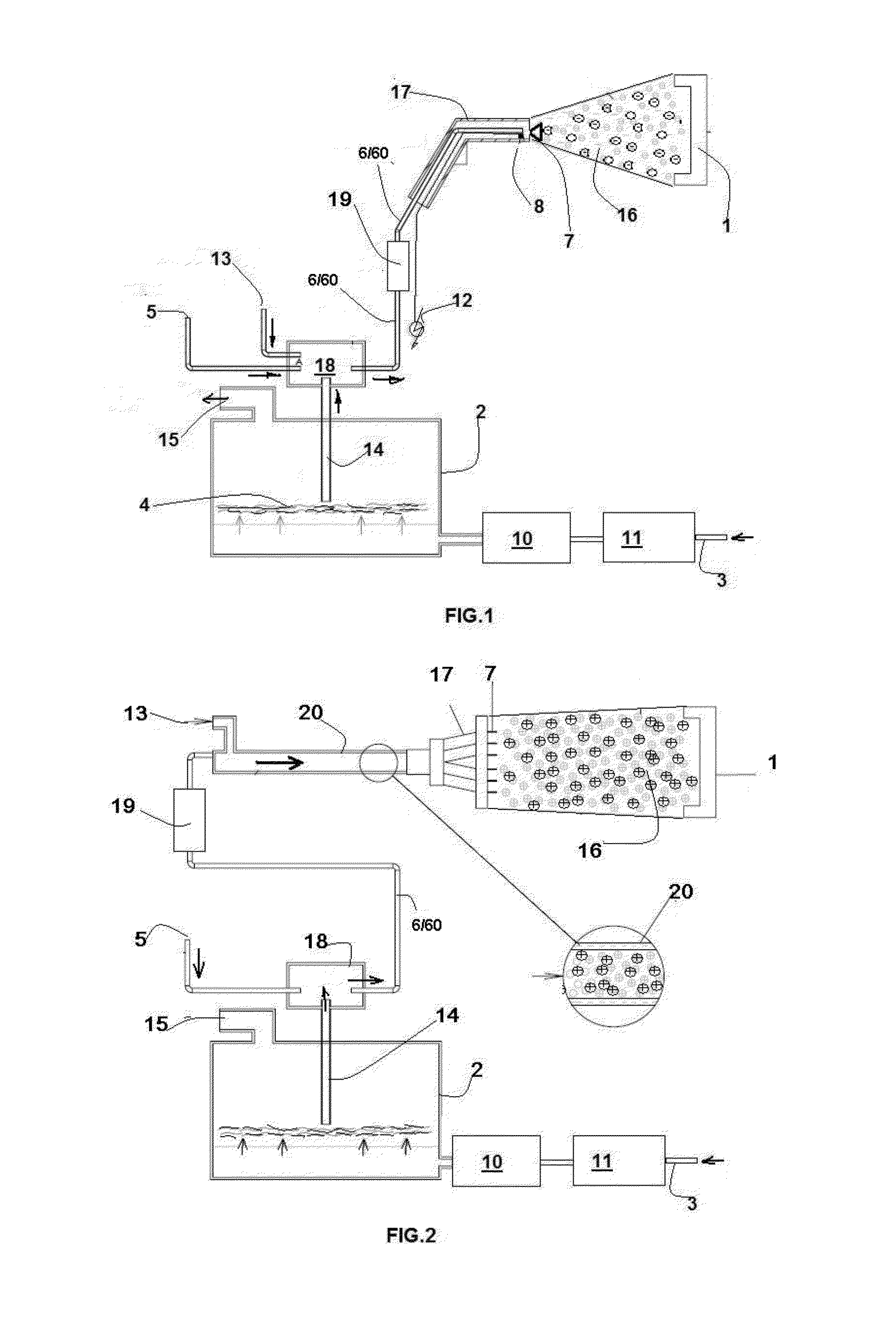

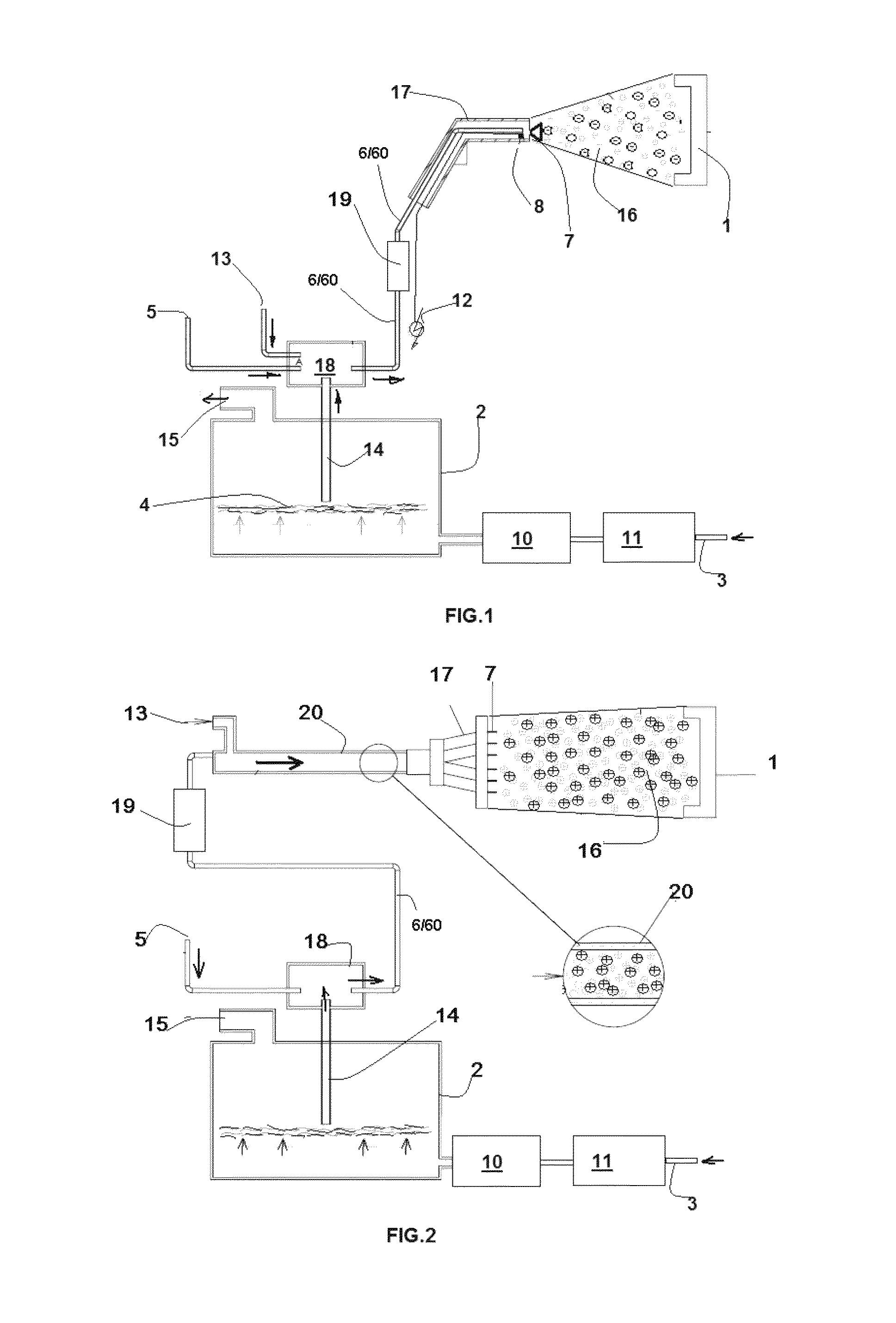

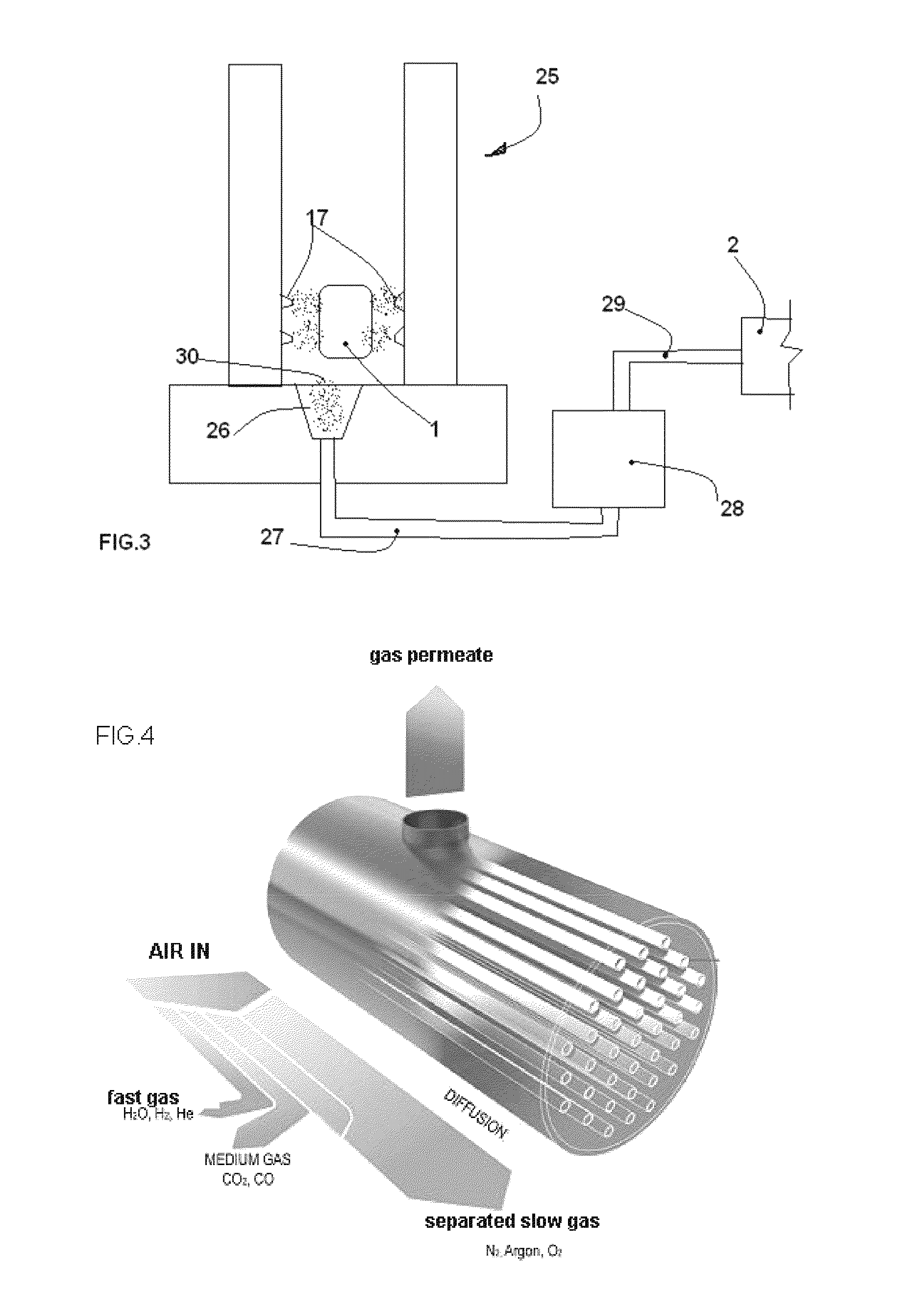

Method and apparatus for electrostatic painting

ActiveUS20140099448A1Improve homogeneityPromote atomizationBurnersLiquid spraying plantsWorking fluidEngineering

A device and method for electrostatic powder coating include: obtaining continuously a working fluid constituted by air deprived of undesirable substances; supplying the working fluid, between 0.5 bar and 10 bar, in a container containing an amount of coating powder; extracting from the container; a first flow made up of working fluid and powder; atomizing the first flow with working fluid at a pressure of between 0.5 bar and 10 bar; supplying working fluid at a pressure of between 0.5 bar and 10 bar to create a second transport flow made up of working fluid and atomized powder; charging the second flow electrostatically under pressure; and sending the second electrostatically charged flow of working fluid and atomized powder onto a substrate, at a temperature of between −15° C. and +45° C., and a device and method for electrostatic painting including heating / cooling temperature adjustment of the painting mixture.

Owner:EUROSIDER S DI MILLI OTTAVIO & C

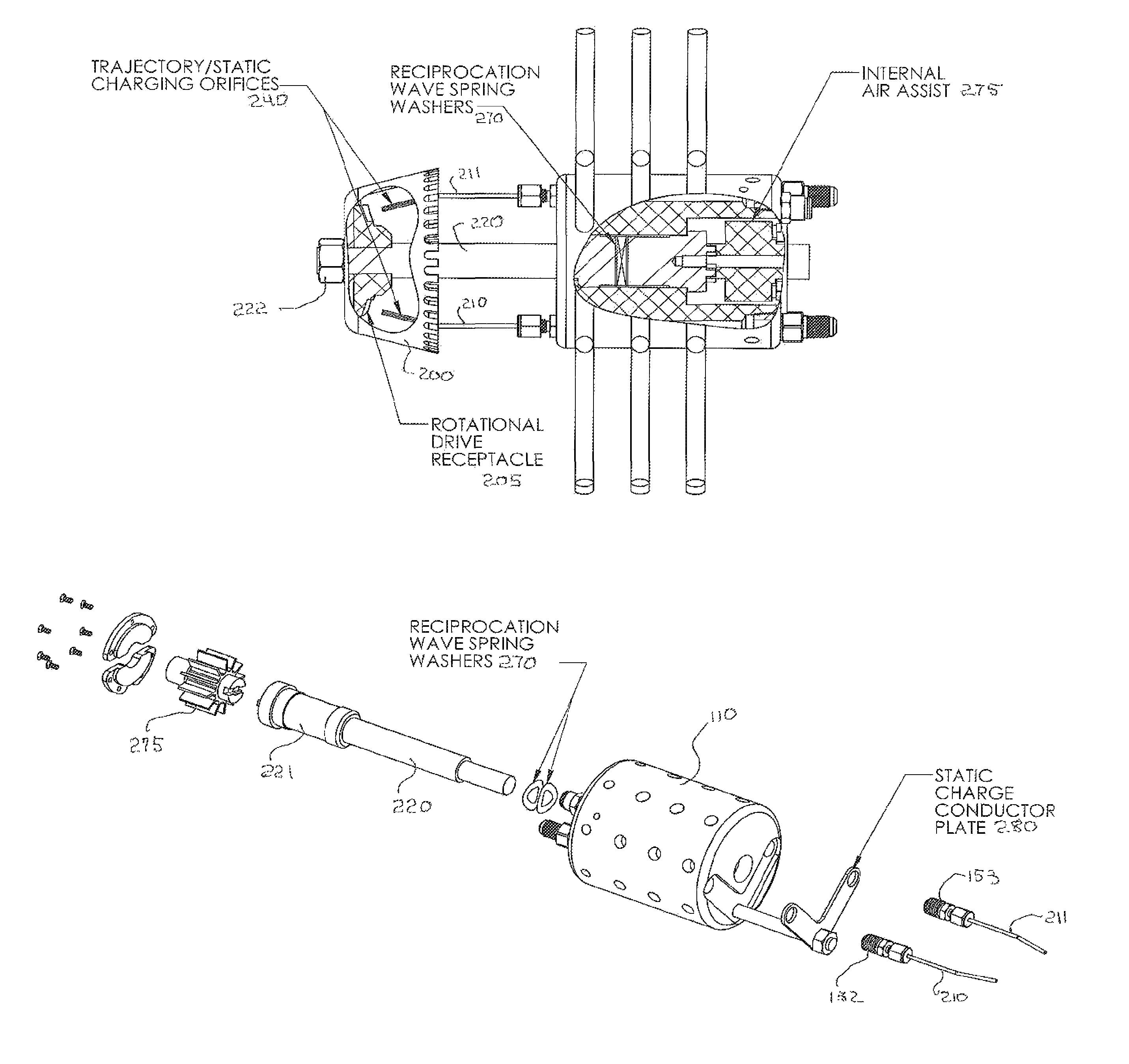

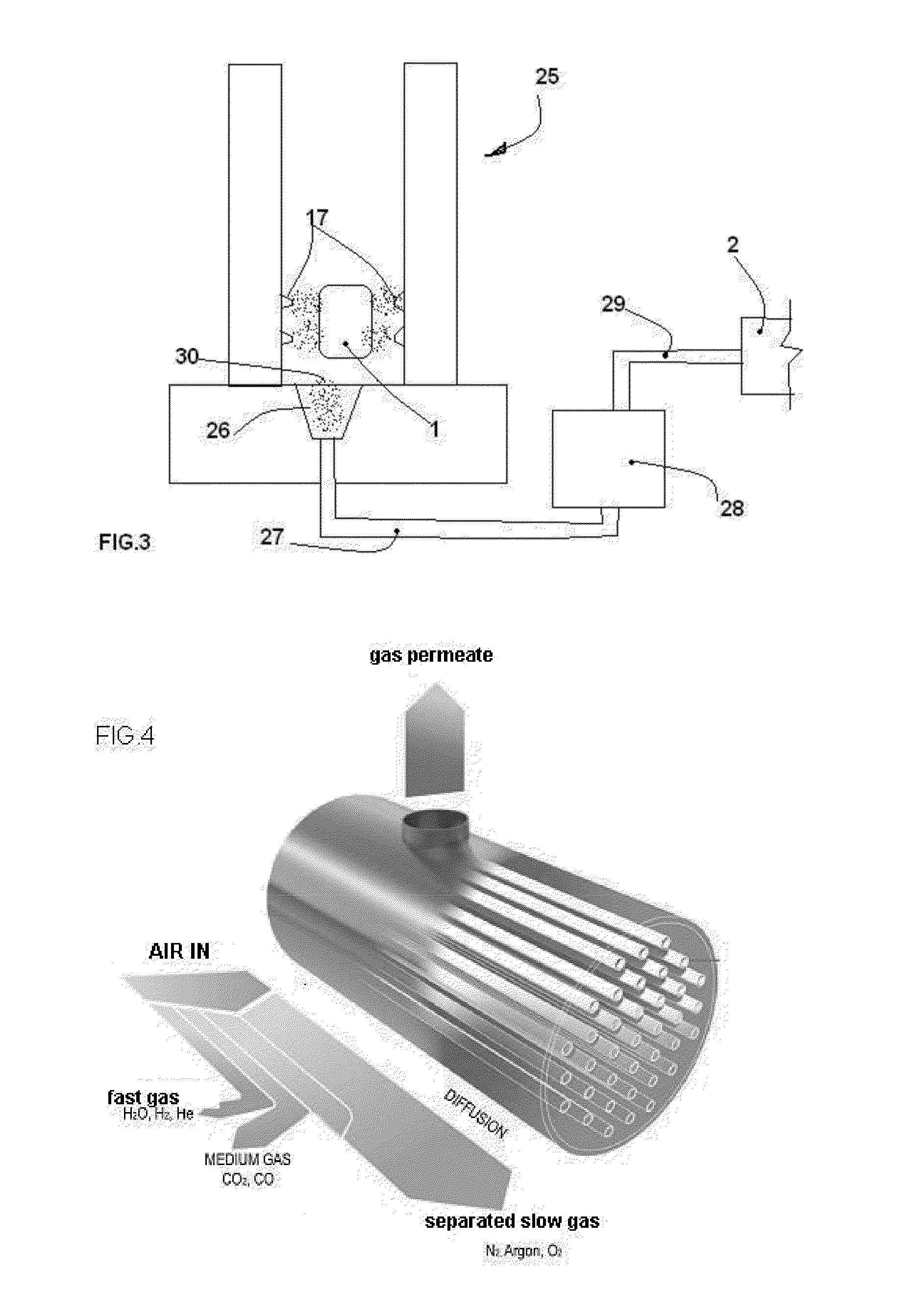

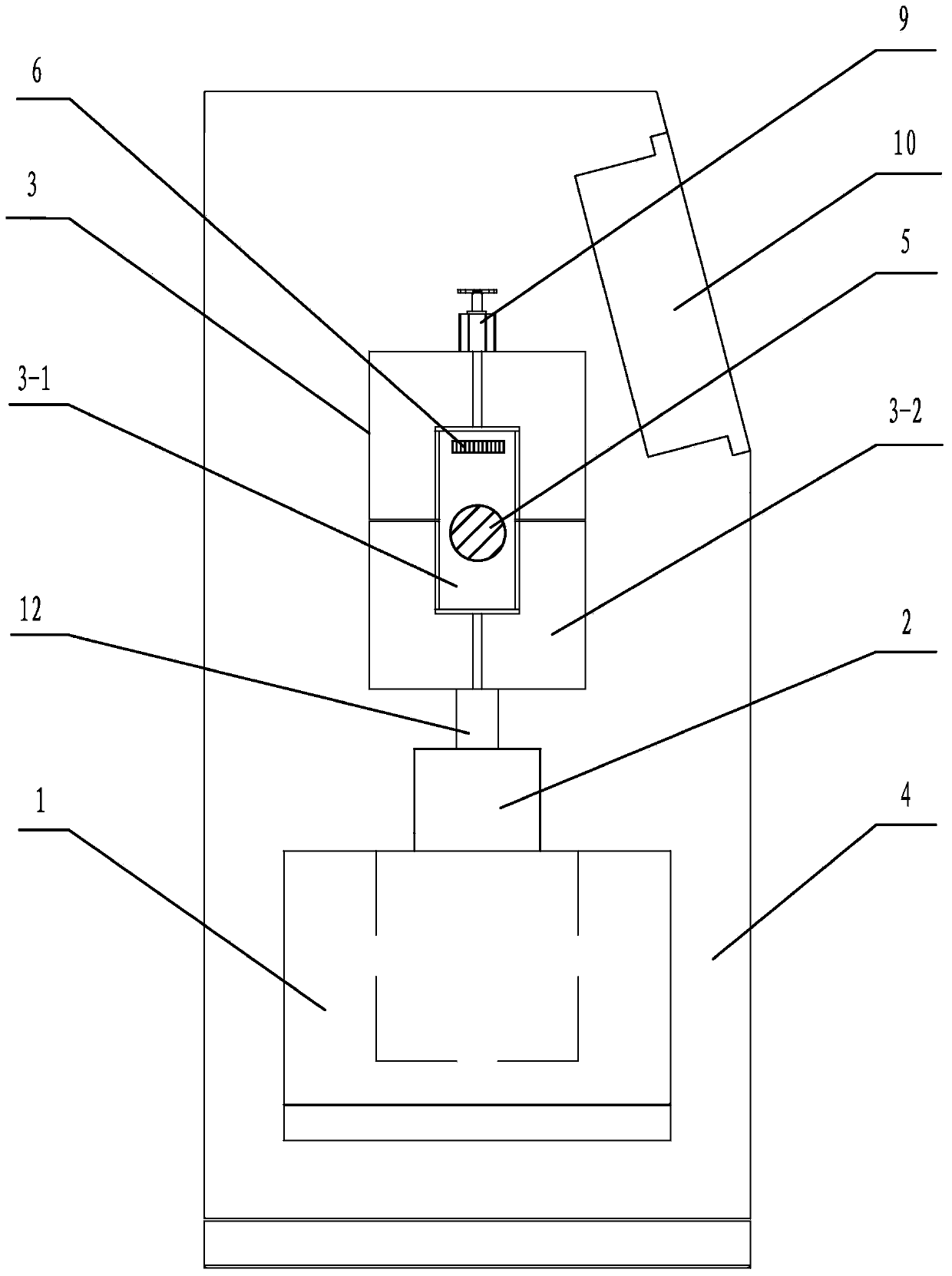

Immobilization apparatus

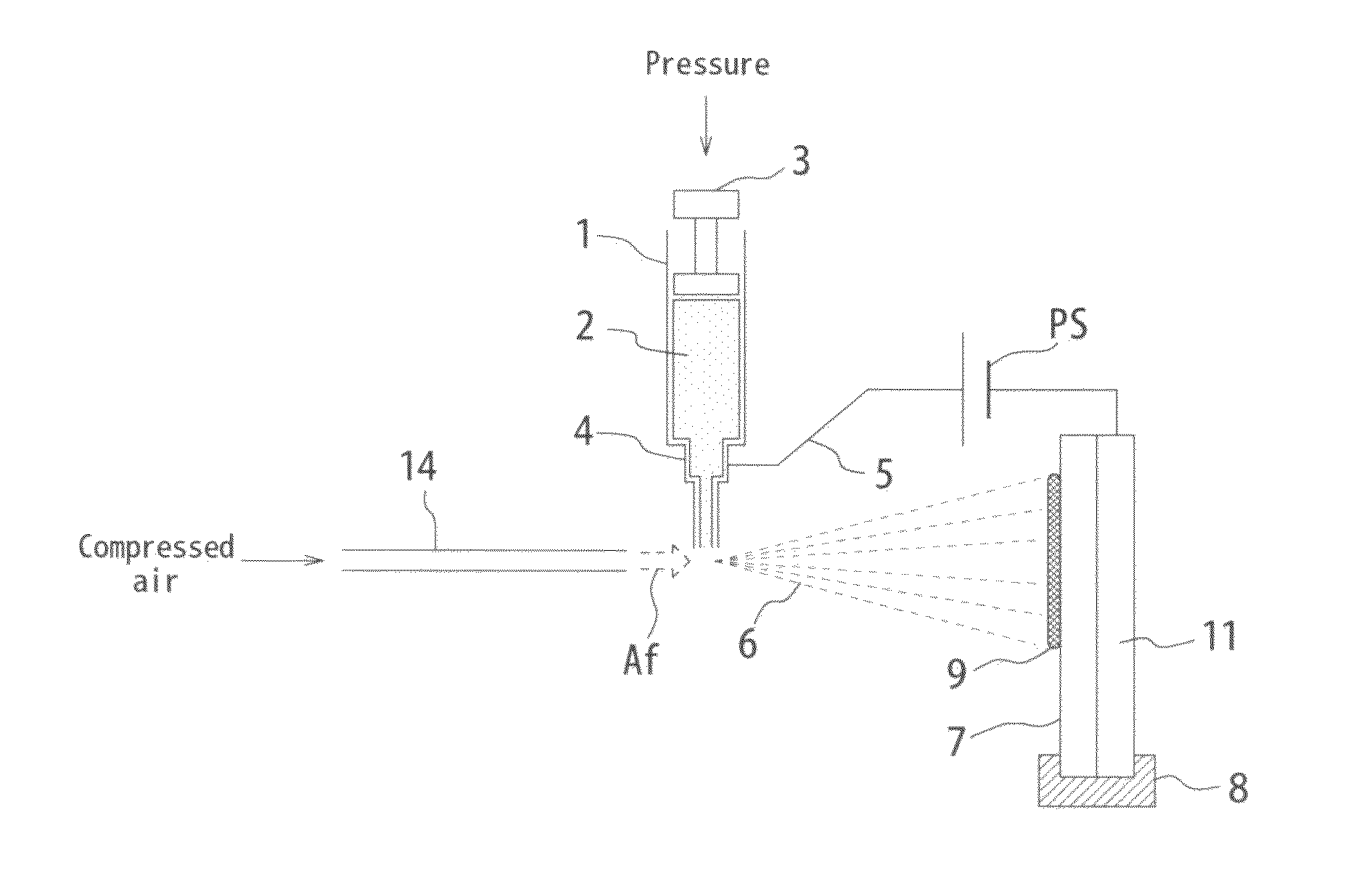

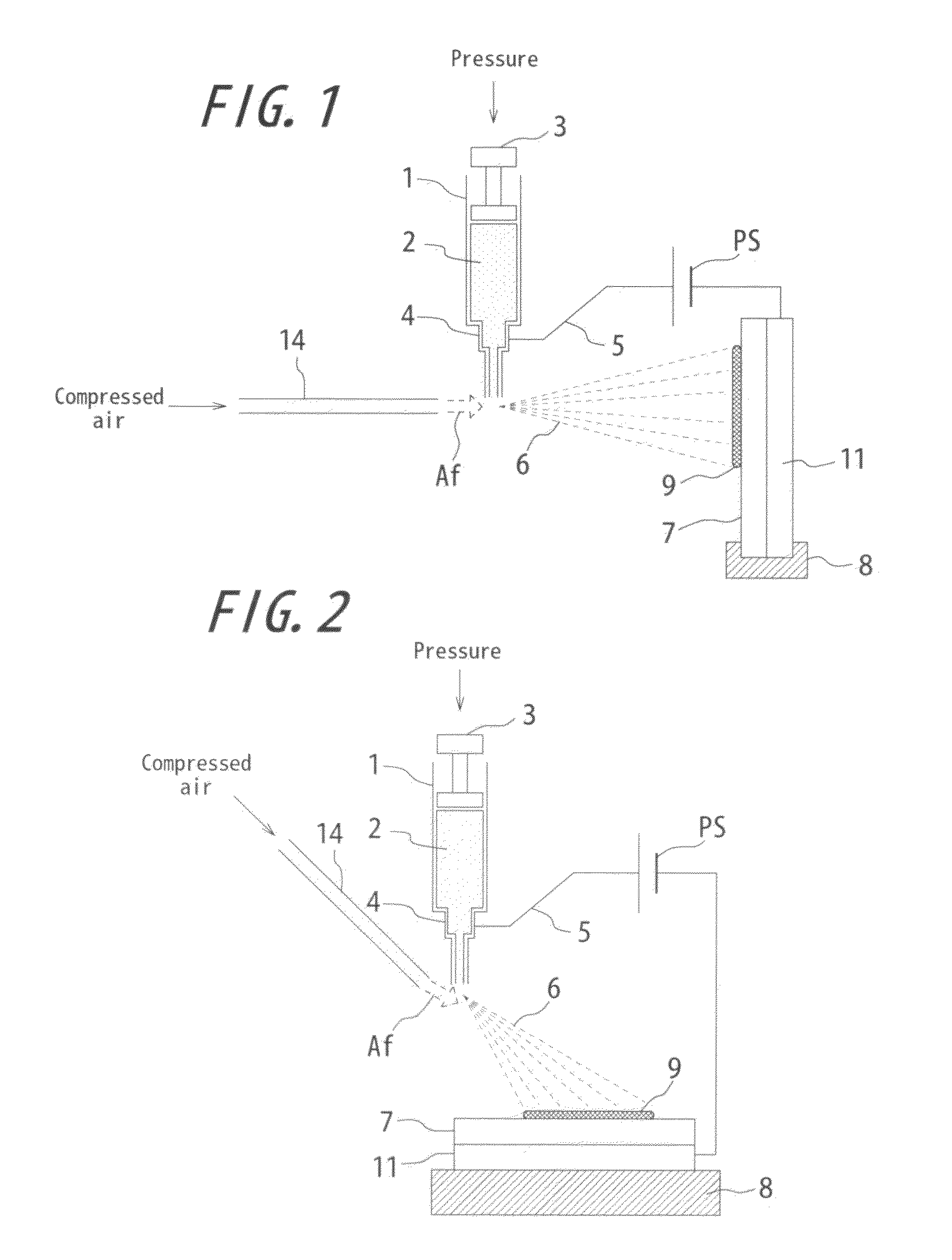

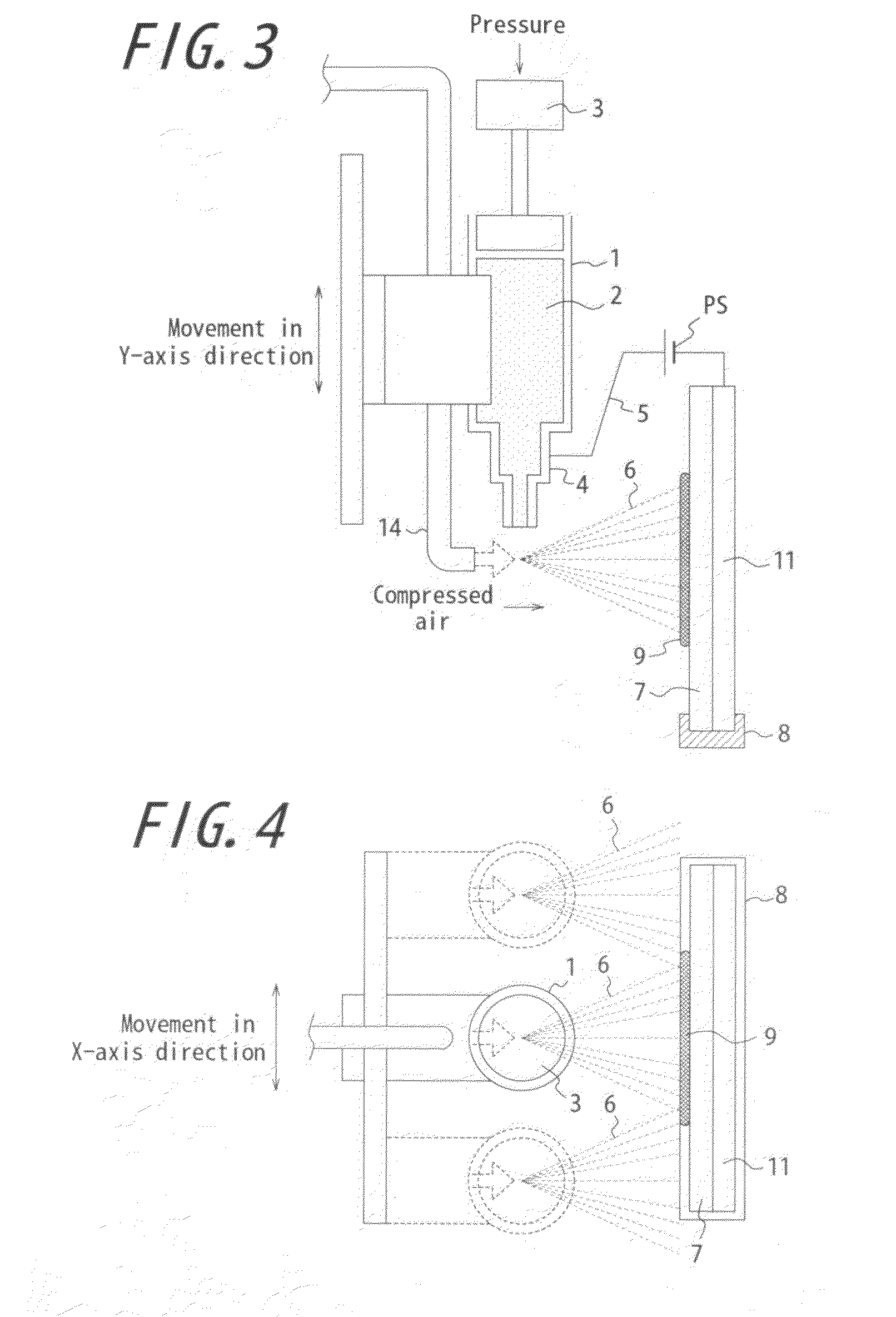

InactiveUS20110017134A1Promote generationIncrease speedLiquid surface applicatorsElectrostatic heating/coolingEngineeringStatic electricity

The invention is an immobilization apparatus comprising: a container (1) having a nozzle (4) formed for exhausting a solution; a charging means (PS, 5, 4) for charging the sample solution within the container; and an airflow generating means for generating airflow (Af) crashing into the sample solution. The immobilization apparatus is configured to operate the charging means and the airflow generating means simultaneously, atomize the solution into microparticulate substances charged while maintaining its activity and functionality by the electrostatic force due to the charge of the sample solution charged by the charging means and the crash energy due to the crash of the airflow generated by the airflow generating means into the sample solution, and exhaust it from the exhaust outlet (4), and the charged microparticulate substances are deposited on a substrate (7) by the electrostatic force.

Owner:TANIOKA AKIHIKO +2

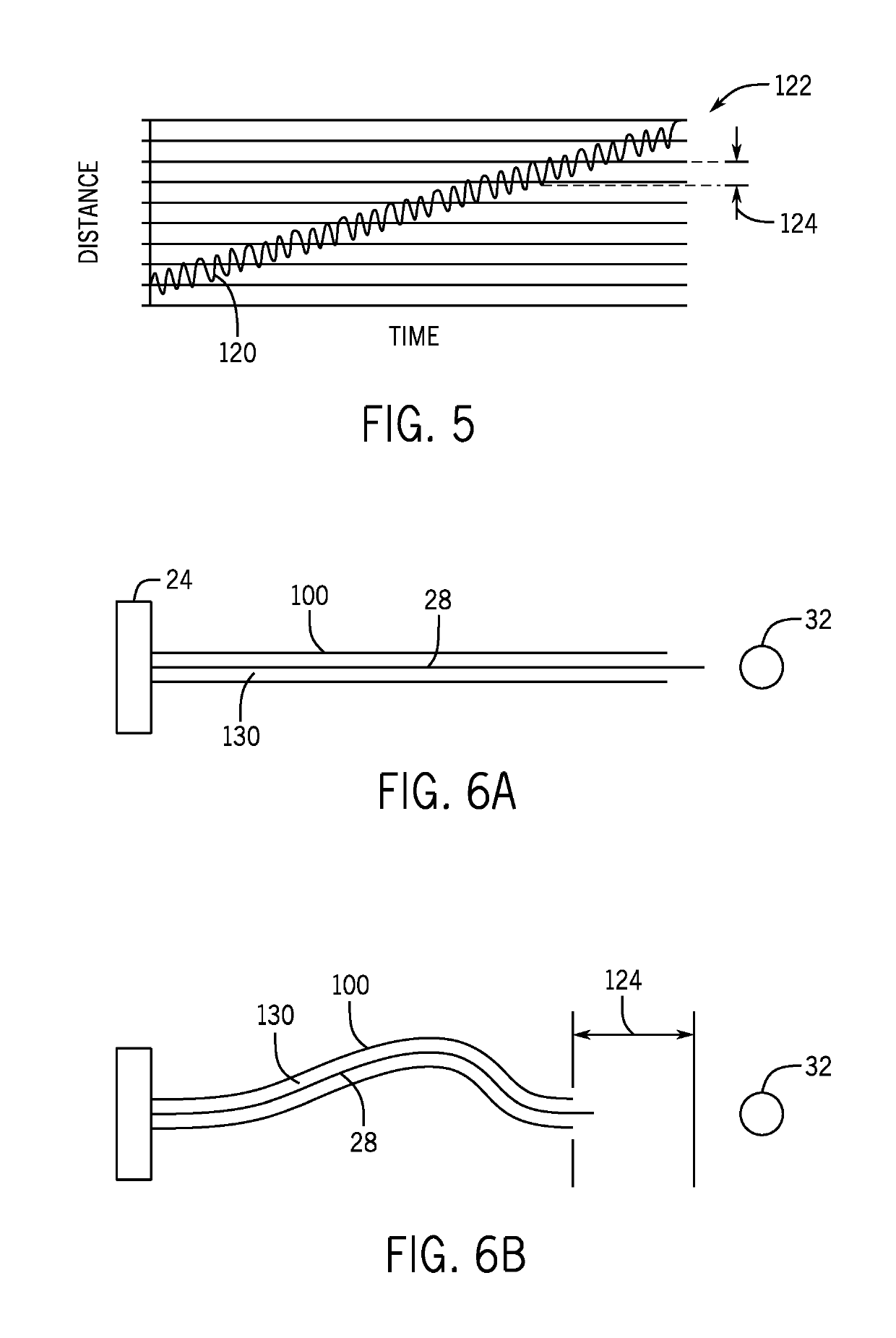

Metal manufacturing systems and methods using mechanical oscillation

ActiveUS20190099769A1Increase wire feeding speedAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringControl circuit

Present embodiments include a system that includes a welding tool configured to receive a welding wire from a wire feeder, to receive welding power from a power source, and to supply the welding wire to a workpiece during a welding process. The system also includes a mechanical oscillation system configured to mechanically oscillate a structural component toward and away from the workpiece. The structural component is external to the wire feeder and the power source. The system further comprises control circuitry configured to control the welding power based on feedback relating to the welding process.

Owner:ILLINOIS TOOL WORKS INC +1

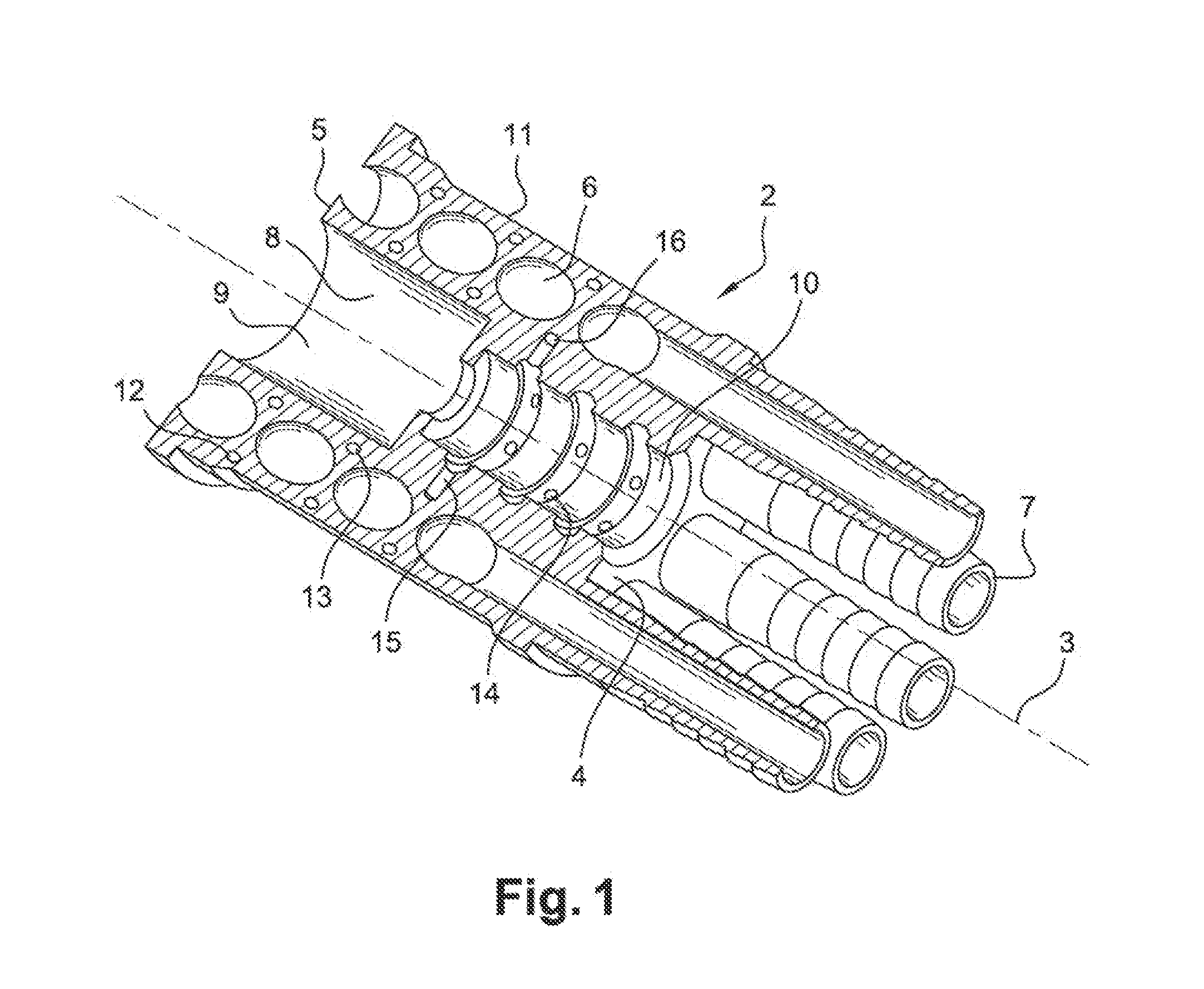

Spraying device and method

The present invention relates to a spraying nozzle, a spraying device including such a nozzle, and a spraying method implementing such a device. A nozzle for projecting powdery sold products for coating objects. The nozzle comprises a body having an essentially cylindrical shape and comprises at least two tunnels extending there through and insulated from each other. Each tunnel developing helically about a main axis of the nozzle. The tunnels are independently supplied with a fluid / powdery solid(s) mixture. The helical shape of the tunnels makes it possible to obtain a powerful jet with a conical shape capable of coating the inner surfaces of tubular objects.

Owner:ARKEMA FRANCE SA

Apparatus and method for applying a film on a substrate

InactiveUS20090258153A1Streamlining disclosureLiquid spraying plantsLiquid surface applicatorsElectrical conductorSurface tension

A system that incorporates teachings of the present disclosure may include, for example, an apparatus having a plurality of applicators, each applicator with an ingress opening to receive a liquid, and an egress opening to release the liquid, and a conductor positioned in a conduit of each of the plurality of applicators, the conductor and the conduit having dimensions to cause a surface tension of the liquid to prevent a constant flow of the liquid from the egress opening. Each conductor of the plurality of applicators can be coupled to one of one or more power sources operable to apply a charge to the liquid to overcome the surface tension and form at the egress opening of each applicator a plurality of jet sprays of the liquid applicable on a substrate to form a thin film. Additional embodiments are disclosed.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

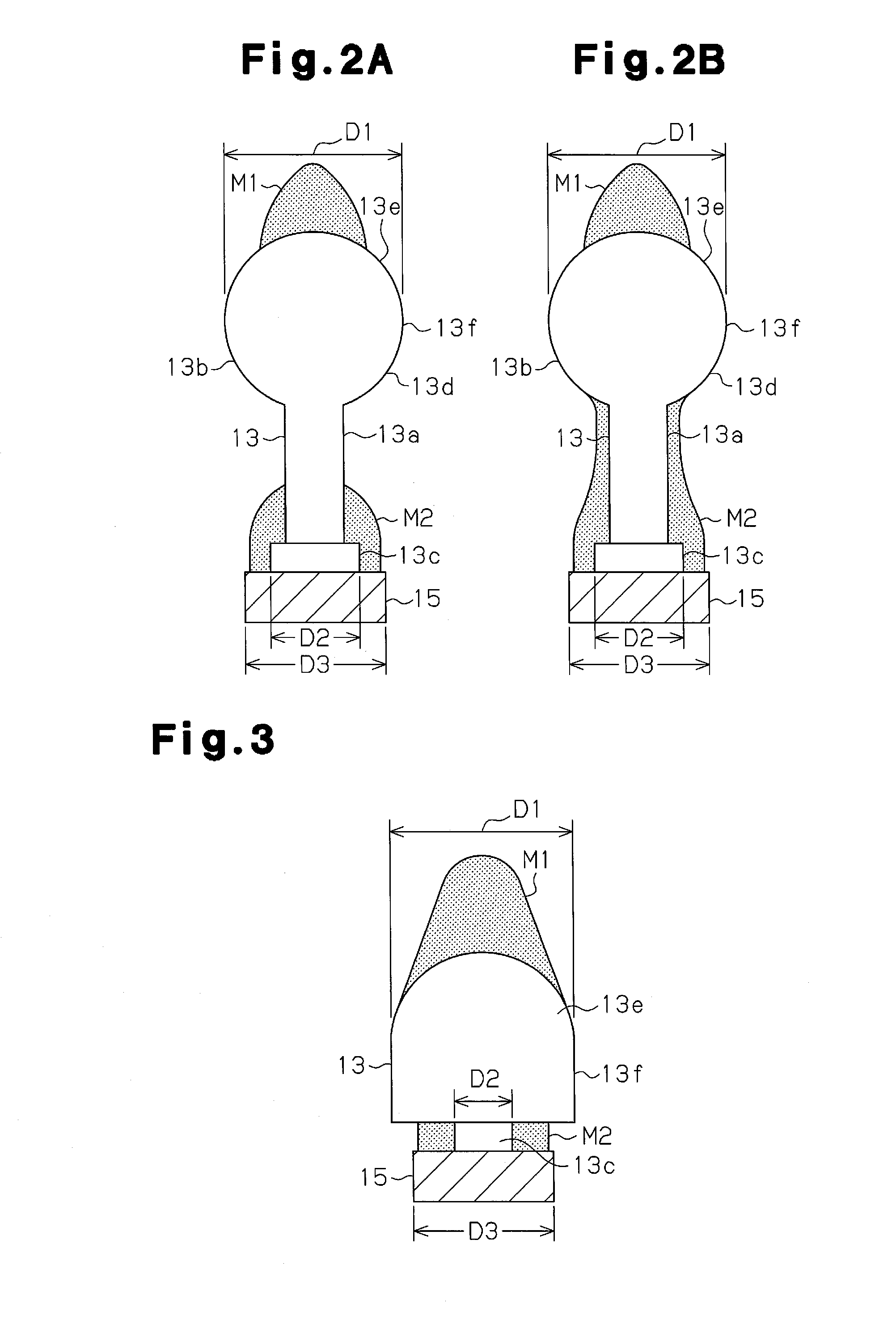

Electrostatic atomizing device

The atomizing electrode of the electrostatic atomizing device has a discharging part and a base. A portion of the atomizing electrode between the discharging part and the base is a large diameter part with a diameter larger than the base. The large diameter part separates condensed water retained near the base from condensed water retained on the discharging part.

Owner:PANASONIC CORP

Metal wires high pressure static oiler

InactiveCN103752439AEfficient use ofStable oil mist environmentLiquid spraying plantsLiquid surface applicatorsFuel tankHigh pressure

The invention discloses a metal wires high pressure static oiler. The metal wires high pressure static oilere comprises a high pressure system in a machine body, an oil supplying heating system, a leading device and an oiler. The oiler is made of insulating materials, an oil channel is formed in the middle portion of the oiler and the metal wires can go through the oil channel, oil mist channels are arranged on the left portion and the right portion of the oiler respectively, an entrance and a exit for the metal wires correspond to the oil channel and are arranged on the machine body. The oil supplying heating system comprises an oil tank, a filter, a heating device, a digital oil pump and an atomization sprayer connected with a high pressure air source. The leading device comprises pipelines, an electronic control valve and a pressure regulating valve are arranged in the pipelines, the pipelines are communicated with the atomization sprayer and the oil mist channels, the high pressure system is a dense high voltage terminal, and the high voltage terminal is arranged inside the oil channel and locates above or below the metal wires to be processed. The metal wires high pressure static oiler solves the homogeneity and the quantitative control problem in greasing the metal wires to be processed, reduces environmental pollution and improves operational safety.

Owner:GUILIN HONGGUI ELECTRONICS TECH

Method and apparatus for electrostatic painting

ActiveUS9266128B2Evenly distributedHigh speedLiquid spraying plantsLiquid supply arrangementsWorking fluidEngineering

A device and method for electrostatic powder coating include: obtaining continuously a working fluid constituted by air deprived of undesirable substances; supplying the working fluid, between 0.5 bar and 10 bar, in a container containing an amount of coating powder; extracting from the container; a first flow made up of working fluid and powder; atomizing the first flow with working fluid at a pressure of between 0.5 bar and 10 bar; supplying working fluid at a pressure of between 0.5 bar and 10 bar to create a second transport flow made up of working fluid and atomized powder; charging the second flow electrostatically under pressure; and sending the second electrostatically charged flow of working fluid and atomized powder onto a substrate, at a temperature of between −15° C. and +45° C., and a device and method for electrostatic painting including heating / cooling temperature adjustment of the painting mixture.

Owner:EUROSIDER S DI MILLI OTTAVIO & C

Electrostatically atomizing device

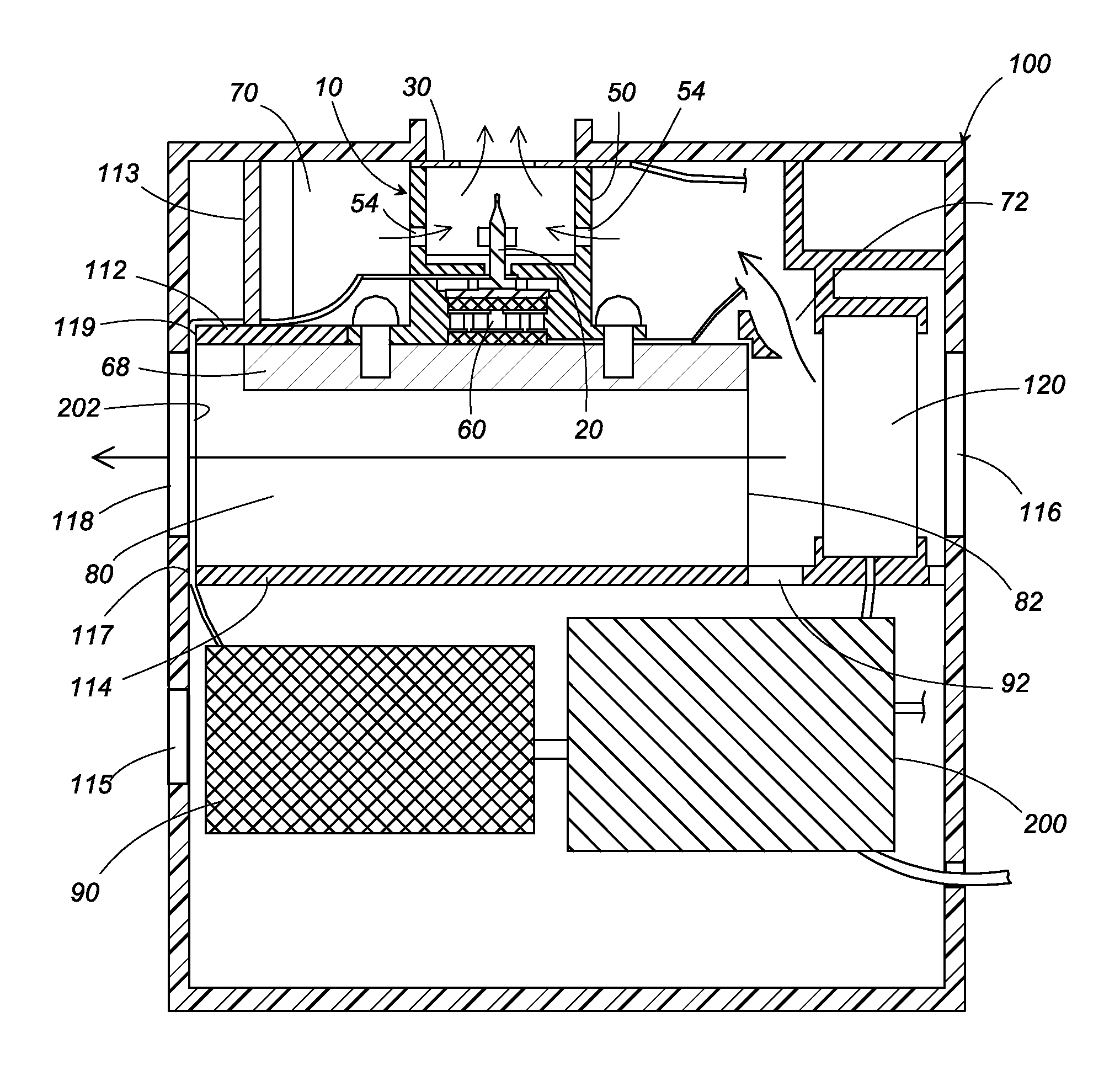

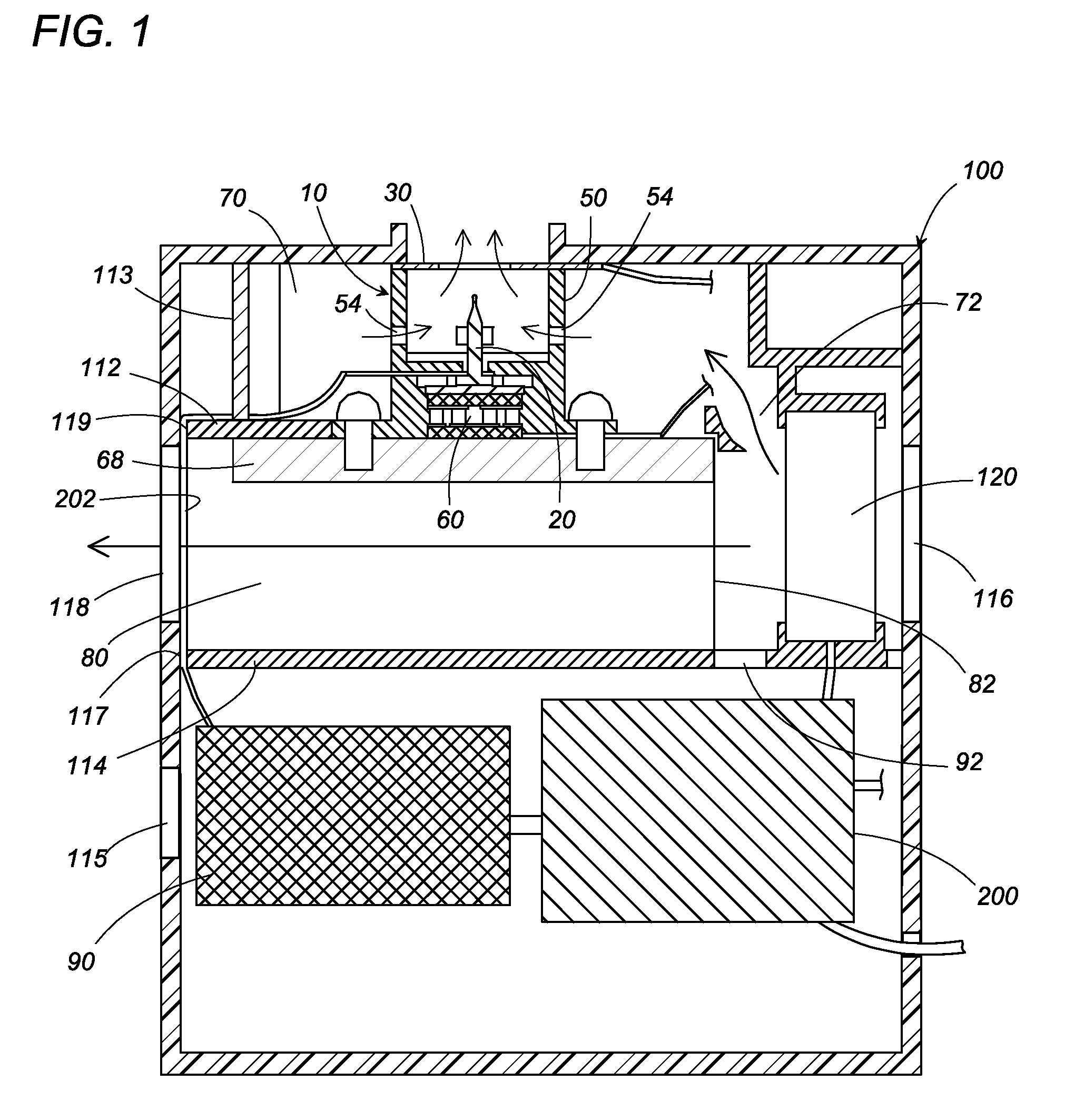

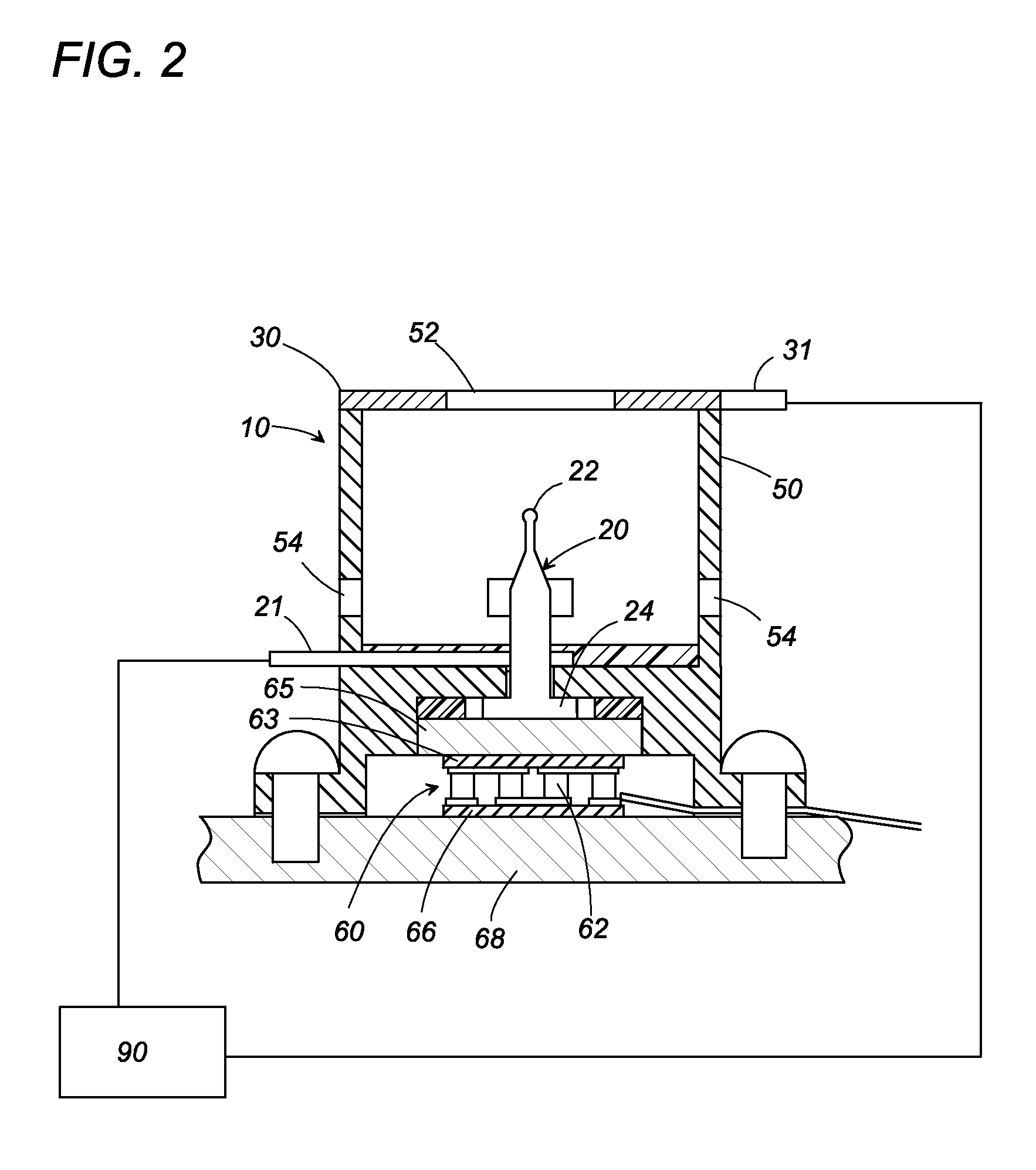

InactiveUS7854403B2Increase heat radiationGuaranteed uptimeBurnersElectrostatic heating/coolingEngineeringForced-air

An electrostatically atomizing device includes a housing and an electrostatically atomizing unit disposed within the housing. The atomizing unit includes an emitter electrode and an heat exchanger. The heat exchanger cools the emitter electrode to develop condensed water. A high voltage is applied to the emitter electrode in order to electrostatically atomizing the condensed water and generate a mist of charged minute water particles. The housing accommodates a fan generating an air flow accelerating a heat radiation of the heat exchanger, and a high voltage source generating the high voltage applied to the emitter electrode. The heat exchanger has its heat radiator section exposed to a flow passage of the air flow. The atomizing unit is formed with an air inlet for introducing the air flow which carries the mist of the charged minute water particles and release the mist. The atomizing unit and the high voltage source are arranged on opposite sides of the flow passage. A first air intake port for feeding the forced air flow from the fan and a second air intake port for feeding the air flow into the high voltage source are positioned upstream of a second air intake port which introduce the forced air flow into the flow passage.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com